Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Field Trip Report - Final

Caricato da

dmscott10Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Field Trip Report - Final

Caricato da

dmscott10Copyright:

Formati disponibili

Field Trip Report Ammonia Production at Gibson Island

University of Queensland

Field Trip Report

Ammonia Production at Incitec Pivot - Gibson Island

Declan Scott James Crook Josh Hampson

42339166 42371139 42677541

Field Trip Report Ammonia Production at Gibson Island

Table of Contents:

1. 2. 3. Introduction ...................................................................................................................................... 1 Ammonia Production Process ...................................................................................................... 1 Ammonia Synthesis Reaction ....................................................................................................... 2 3.1. 3.2. 3.3. 4. Reaction Conditions ............................................................................................................... 2 Temperature Effects ............................................................................................................... 3 Reaction Kinetics..................................................................................................................... 4

Reactor Equipment .......................................................................................................................... 5 4.1. 4.2. Reactor Type ............................................................................................................................. 5 Catalyst Type: ........................................................................................................................... 5

5. 6. 7. 8. 9.

Nitrogen Production ....................................................................................................................... 5 Safety & Environmental Concerns .............................................................................................. 6 Energy Savings & Emission Reduction ...................................................................................... 6 References .......................................................................................................................................... 7 Appendix A: Reaction Mechanism ............................................................................................... 7

List of Figures:

Figure 1: Equilibrium Constant Temperature Dependence (Eggeman, 2000) ................................. 3 Figure 2: Ammonia Synthesis Heat of Reaction Temperature Dependence (Bohnet, 2003) ........... 3 Figure 3: Temperature Dependence of Equilibrium Conversion for Ammonia Synthesis (Modak, 2002)................................................................................................................................................. 4 Figure 4: Ammonia Synthesis Reaction Rate ................................................................................... 4

Field Trip Report Ammonia Production at Gibson Island

1. Introduction

Ammonia (NH3) is a toxic, colourless gas possessing a distinct, penetrating odour. The gas exists naturally in the atmosphere, produced by certain species of nitrogen -fixing micro-organisms. However, since 1913, ammonia has been commercially produced using the Haber-Bosch process, whereby hydrogen and atmospheric nitrogen are catalytically reacted to synthesize ammonia. In todays increasingly industrialized world, ammonia forms a critical global resource. Ammonia is the second most commonly manufactured chemical with applications across a wide range of industries. Of the worlds total ammonia production, 85% is consumed in the production of fertilizers with the remainder primarily being used in explosives or as industrial solvents (Appl, 1999). Given its primary application in the fertilizer industry, production of ammonia has closely mirrored global population growth. It is believed that 40% of the worlds protein requirements can be directly attributed to ammonia production (Eggeman, 2000). Furthermore, the mining and resource sector is critically reliant on the gas for gaining access to underground deposits. Incitec Pivot is a global manufacturer of a wide range of fertilizers, explosives and industrial chemicals (Incitec Pivot, 2013). The company directly owns and operates 20 facilities around the world, with seven of these being ammonia production plants located throughout Australia. This investigation focuses on ammonia production at Incitec Pivots Gibson Island plant in South-East Queensland, which operates at an ammonia production capacity of 300,000 tonnes per annum.

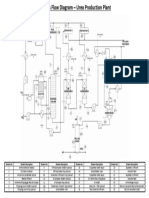

2. Ammonia Production Process

Ammonia is predominantly produced by reacting nitrogen and hydrogen over an iron catalyst (Bohnet, 2003). In order to do this, a mixture of nitrogen and hydrogen must first be obtained. Hydrogen can be produced from water through the process of steam reforming. The first step in this process is steam methane reforming in the primary reformer, which takes place according to the reaction below: CH4 +H2 O CO + 3H2 H298 =206kJ/m l

This is a highly endothermic reaction and as such is carried out at high temperatures through the application of external heating. At Gibson Island, the primary reformers operate at approximately 1400F and 400 psig (Incitec Pivot, 2013). Simultaneously to the steam reforming reaction, the water gas shift reaction shown below also takes place in the primary reformers (Eggeman, 2000). CO+H2 O CO2 +H2 H298 =-41.17kJ/m l

Product gases from the primary reforming process still contain approximately 5 to 8% unreacted methane and are therefore fed to a secondary reformer to complete the reforming process (Eggeman, 2000). The heat required to drive the endothermic reforming reaction is obtained by combusting a portion of the feed gases in an oxygen-starved environment. This combustion takes place according to the two reactions shown on the following page.

Field Trip Report Ammonia Production at Gibson Island H2 +0.5O2 H2 O CH +1.5O2 CO+2H2 O H298 =-241.83kJ/m l H298 =-519.31kJ/m l

This combustion is achieved through the addition of air and, as oxygen is consumed, nitrogen remains in the gases to be used later in the ammonia synthesis step. The remaining gases are heated by this combustion and then passed over reforming catalysts to undergo the same steam methane reforming and water gas shift reactions which take place in the primary reformer. Following this the methane content of the syngas has now been reduced to around 0.2 to 0.3%. In order to convert any remaining carbon monoxide to carbon dioxide, the syngas mixture is then fed to two shift converters, which are usually adiabatic, packed-bed reactors. This is usually done in a high and low temperature step and involves the familiar water-gas shift reaction below. CO+H2 O CO2 +H2 H298 =-41.17kJ/m l

Following shift conversion, carbon dioxide is then removed from the process gases by a packed bed absorber column using aMDEA as the chemical solvent (Incitec Pivot, 2013). The removed CO2 is then either fed to the Urea plant or the Liquid CO2 plant, which are also located on site. As the absorber does not achieve 100% CO2 removal, process gases are then fed to the methanator to reduce carbon dioxide content down to the levels required to prevent ammonia synthesis catalyst poisoning (Eggeman, 2000). These reactions are simply the reverse of the reforming reactions: CO + 3H CH4 +H2 O CO2 + H2 CO+H2 O H298 =-206kJ/m l H298 =41.17kJ/m l

Process gases, which are now predominantly a 3:1 hydrogen/nitrogen mixture, are then compressed and fed to the ammonia converter where the following synthesis reaction occurs: + 3 2 H298 =-92.44kJ/m l

Produced ammonia is then fed to either a storage tank or the Urea plant. Temperature has a significant effect on the conversion achieved for this reaction and therefore the ammonia synthesis reaction conditions are of considerable interest.

3. Ammonia Synthesis Reaction

3.1. Reaction Conditions Ammonia synthesis at Gibson Island is carried out at a pressure of 2600-2650 psig and an inlet temperature of 750F (399C). These conditions typically give a single-pass conversion of 19% (Incitec Pivot, 2013). This synthesis reaction is carried out at this elevated pressure in order to increase the equilibrium concentration of NH3.

Field Trip Report Ammonia Production at Gibson Island

3.2. Temperature Effects Temperature has a significant effect on the ammonia synthesis process. Lowering temperature increases the equilibrium constant, K, and therefore shifts the reaction towards the right. However, kinetics of the reaction limit the lowest useful temperature to around 350C (Eggeman, 2000). Figure 1 below shows how equilibrium constant varies with temperature for the ammonia synthesis reaction as well as a number of other earlier reactions discussed above.

Figure 1: Equilibrium Constant Temperature Dependence (Eggeman, 2000)

Figure 1: Equilibrium Constant Temperature Dependence (Eggeman, 2000)

As can be seen above, increasing reactor temperature significantly decreases the equilibrium constant in what appears to be a linear trend. This is due to the exothermic nature of the reaction, which make it more favourable at lower temperatures. As an exothermic reaction, the ammonia synthesis reaction will always have a negative heat of reaction however the magnitude of this is temperature dependent. Figure 2 shows the negative heat of reaction for the reaction 0.5N2 +1.5H2 NH3.

- Heat of Reaction (kJ/mol) 70 65 60 55 50 0 100 200 300 400 Temperature (C) 500 600 700

Figure 2: Ammonia Synthesis Heat of Reaction Temperature Dependence (Bohnet, 2003)

Field Trip Report Ammonia Production at Gibson Island

As shown in Figure 2 on the previous page, increasing temperature initially decreases H until a minimum is reached and H then begins increasing slowly with temperature (becoming more negative). Equilibrium conversion for the ammonia synthesis reaction decreases with increasing temperature as it is an exothermic reaction and therefore favoured by lower temperatures. Figure 3 below shows the effect of temperature on conversion at different reaction rates of 0-20 kg/m3.hr. Equilibrium conversion is indicated by the curve with a reaction rate of 0, indicating a system at equilibrium.

Figure 3: Temperature Dependence of Equilibrium Conversion for Ammonia Synthesis (Modak, 2002)

If the reaction were operated without a catalyst, very high temperatures would be required in order to overcome the activation energy to dissociate nitrogen. However, at these temperatures the equilibrium conversion would be very low and hence ammonia production would be minimal. Introducing a catalyst solves this problem by reducing the activation energy for the reaction and allowing it to take place at a much lower temperature. Although equilibrium conversion is higher at this temperature a recycle stream is still required to increase overall conversion further. 3.3. Reaction Kinetics The kinetics of ammonia production is strongly influenced by operating temperature and pressure. Increasing pressure increases the reaction rate as well as increasing the equilibrium constant, thus high pressures are preferable for ammonia synthesis. Increasing temperature increases the rate of formation of ammonia but also reduces the equilibrium ammonia concentration (Bohnet, 2003). Therefore, as shown in Figure 4, rate of formation can be seen to initially increase with temperature, reach a maximum and then decrease as the system approaches equilibrium:

Figure 4: Ammonia Synthesis Reaction Rate Temp & Pressure Dependence (Bohnet, 2003)

Field Trip Report Ammonia Production at Gibson Island

Ammonia synthesis is a heterogeneous catalytic reaction and a proposed mechanism for this reaction can be seen in Appendix A. Studies have confirmed that the nitrogen adsorption and dissociation can be regarded as the rate-controlling step for this reaction (Bohnet, 2003).

4. Reactor Equipment

4.1. Reactor Type Gibson Island utilizes a plug flow reactor for ammonia production. This is used over other reactor types as the reaction occurs in the gas phase at a very high pressure (Incitec Pivot, 2013). As it is an exothermic reaction, heat must be removed throughout the reaction in order to control the temperature and maximize the conversion. This can be done through three main reactor configurations; tube-cooled converters, quench converters or indirectly cooled multibed converters (Bohnet, 2003). Tube-cooled converters are internally cooled with the main cooling medium being the feed gas, which can flow counter or cocurrently to the reacting gas. In quench converters the catalyst volume is divided into several beds with heat being removed by injecting colder synthesis gas. Indirectly cooled multibed converters use the same configuration with boiler feed water usually providing the cooling mechanism. 4.2. Catalyst Type: In order to reduce heat requirements and achieve commercially viable reaction rates, various catalysts are used throughout the ammonia production process. In the steam reforming and methanation stages of synthesis gas production, a nickel-based catalyst is typically used (Bohnet, 2003). Regarding the shift conversion reactions, metal oxides are typically used with different specific catalysts used for the high and low temperature steps (Bohnet, 2003). Since the invention of the Haber-Bosch process, iron-based catalysts have been almost exclusively used for the ammonia synthesis reaction. The effectiveness of the iron catalyst is improved by adding reduction-resistant metal oxides such as aluminium and potassium oxides (Bohnet, 2003). IPLs Gibson Island plant employs iron-based catalysts, predominantly using Amomax-10, which is mainly composed of the iron oxide containing material wustite (Bohnet, 2003).

5. Nitrogen Production

The nitrogen used by Incitec Pivot in its ammonia production process is essentially a free input (Incitec Pivot, 2013). Nitrogen is obtained as a byproduct from the combustion of natural gas with oxygen in air and therefore has no directly attributable cost. The heat required to facilitate the secondary reforming reactions is supplied by injecting and combusting a portion of feed gas (Eggeman, 2000). Air is supplied to provide the oxygen required for this combustion. As the oxygen is consumed, the inert nitrogen content of the air remains in the product syngas. Following the methanantion and removal of carbon dioxide from the syngas (as outlined in Section 2), the resultant process gas consists of the required 3:1 ratio of nitrogen to hydrogen.

Field Trip Report Ammonia Production at Gibson Island

6. Safety & Environmental Concerns

Since its commercialization, ammonia production has demonstrated itself to be a relatively safe undertaking, however, a number of potentially hazardous factors must be considered. A report by Appl, 1999 identifies four major areas for potential harm; ignition or explosion of the process syngas or hydrocarbon feed supply, the operation of vessels at elevated temperatures and pressures, and the toxic release of ammonia during the synthesis loop. Due to their respective compositions, the natural gas feed system and the syngas (comprised of approximately 75% hydrogen) are inherently flammable. Ignition of these streams could lead to catastrophic explosions, resulting in significant damage to surrounding equipment and potential fatalities of personnel. Additionally, temperature and pressure control systems are particularly critical for the methanation reactors. These pressure vessels are prone to deviations from safe operating conditions, which can cause a dangerous runaway reaction (Eggeman, 2000). Whilst the ignition of ammonia is not a significant risk due to its high ignition temperature (6510C), it is a highly toxic compound and even a short exposure to concentrations as low as 2500ppm has caused fatalities (Appl, 1999). Under certain conditions, air-ammonia mixtures can be denser than air, meaning a toxic cloud produced by an accidental atmospheric release can flood the surrounding operating plant rather than dispersing. Effective design, fabrication, operation and inspections are critical to mitigating the above safety concerns. From an environmental perspective, ammonia production is generally regarded as a relatively clean operation. Atmospheric emissions and contamination of surrounding water systems are the major environmental concerns. Most harmful is the emission of NO2 in the flue gas of the fired primary reformer and the contamination of water, primarily by the condensation of process steam ahead of the carbon dioxide removal as well as accidental spillages (Appl, 1999). Additionally, with increasing urbanization a growing awareness has developed for mitigating noise generation and emission from ammonia plants.

7. Energy Savings & Emission Reduction

Energy consumption is a function of design, operation and maintenance of the ammonia plant (Appl, 1999). Ammonia production is a highly energy intensive operation although, regarding the Incitec Pivot plant, a number of optimisation opportunities exist. An important energy saving strategy is the conservation of process heat, primarily through the use of heat exchangers and insulation. It was observed that a number of high temperature piping and process units are exposed directly to surroundings and therefore a more thorough insulation system would be beneficial. Another significant energy sink at the Incitec Pivot plant is the pumps. It would be beneficial to reduce this workload by using gravitational forces. For example, the plug flow reactors can be orientated vertically such that the feed enters at the top of the reactors and the pressure drop is supplied by gravitational energy rather than pump work.

Field Trip Report Ammonia Production at Gibson Island

8. References

BOHNET, M. 2003. Ammonia - Production Processes. Ullmann's Encyclopedia of Industrial Chemistry. Wiley. EGGEMAN, T. 2000. Ammonia. Kirk-Othmer Encyclopedia of Chemical Technology. John Wiley & Sons, Inc. INCITEC PIVOT. 25/09/2013 2013. RE: CHEE3005 Field Trip. MODAK, J. 2002. Haber process for ammonia synthesis. Resonance, 7, 69-77.

9. Appendix A: Reaction Mechanism

Below is a proposed reaction mechanism for the heterogeneous catalytic reaction for ammonia synthesis based on experimental results.

Source: Bohnet, 2003

Potrebbero piacerti anche

- Birch ReductionDocumento5 pagineBirch ReductionShane Pike100% (1)

- CSWIP 3.1 - Question With Answer and Explanation - Part 17 - AMARINEDocumento10 pagineCSWIP 3.1 - Question With Answer and Explanation - Part 17 - AMARINEGoranNessuna valutazione finora

- Brosur Reckat 2019Documento16 pagineBrosur Reckat 2019wika mepNessuna valutazione finora

- Industrial ReportDocumento89 pagineIndustrial ReportArnab DasNessuna valutazione finora

- Research ProjectDocumento30 pagineResearch ProjectYasser AshourNessuna valutazione finora

- Mixtures Worksheet KeyDocumento1 paginaMixtures Worksheet KeyNeen Naaz0% (1)

- JMS Operating Manual Niftylift HR 21Documento46 pagineJMS Operating Manual Niftylift HR 21Ивайло ДимитровNessuna valutazione finora

- 1bottles Group Production of Bisphenol-ADocumento112 pagine1bottles Group Production of Bisphenol-AJames BelciñaNessuna valutazione finora

- Final Reports 2019 - 2 PDFDocumento178 pagineFinal Reports 2019 - 2 PDFRounak SriwastawaNessuna valutazione finora

- BY: R Reason For Change Date: Chk'D. R Drawing No.: 0Documento1 paginaBY: R Reason For Change Date: Chk'D. R Drawing No.: 0josebaldesNessuna valutazione finora

- 1 finalreportGALALshared PDFDocumento231 pagine1 finalreportGALALshared PDFTram LaiNessuna valutazione finora

- 70t MOD 70 Spreader Beam SpecsDocumento2 pagine70t MOD 70 Spreader Beam SpecsWes NowakNessuna valutazione finora

- AACE Cost EstimationDocumento26 pagineAACE Cost Estimationdmscott1093% (14)

- PB-II List of EquipmentsDocumento3 paginePB-II List of EquipmentsButchi BabuNessuna valutazione finora

- P&id NotesDocumento17 pagineP&id NotesFitriana SarifahNessuna valutazione finora

- Proceeding of The Fertilizer Industry Round TableDocumento32 pagineProceeding of The Fertilizer Industry Round TableKhánh ĐỗNessuna valutazione finora

- Plant Nutrient Dashboard (25.1.2019) - MosaicDocumento2 paginePlant Nutrient Dashboard (25.1.2019) - MosaicAhmed SalehNessuna valutazione finora

- POWER Magazine - May 2023-1Documento43 paginePOWER Magazine - May 2023-1MarcialgonzalezpNessuna valutazione finora

- Overpressure ProtectionDocumento168 pagineOverpressure Protectiondmscott10Nessuna valutazione finora

- Contact Process: Manufacture of Sulphuric AcidDocumento3 pagineContact Process: Manufacture of Sulphuric AcidfatahleeNessuna valutazione finora

- Manitou 200 AtjDocumento2 pagineManitou 200 AtjNeil Desai100% (1)

- Process Flow Diagram - Nitric AcidDocumento1 paginaProcess Flow Diagram - Nitric AcidAsma NasserNessuna valutazione finora

- Manufacture of UreaDocumento36 pagineManufacture of UreaNandadulal GhoshNessuna valutazione finora

- The Double Contact Process For Sulfuric Acid ProductionDocumento3 pagineThe Double Contact Process For Sulfuric Acid Productionshahira anuarNessuna valutazione finora

- Chapter - 3: Structure of The AtomDocumento34 pagineChapter - 3: Structure of The AtomFozia ShaikhNessuna valutazione finora

- 1996 Ifa Johannesburg WangDocumento5 pagine1996 Ifa Johannesburg WangKhánh ĐỗNessuna valutazione finora

- Prodution of Ferrous Sulfate From SteelmakingDocumento7 pagineProdution of Ferrous Sulfate From SteelmakinganaazizNessuna valutazione finora

- Odda Process Report CopyDocumento24 pagineOdda Process Report CopySB100% (1)

- LNG FSRU BOG SystemDocumento4 pagineLNG FSRU BOG Systemdmscott10Nessuna valutazione finora

- Ammonia The Next StepDocumento11 pagineAmmonia The Next StepmuralleroNessuna valutazione finora

- Heap Leach PadsDocumento72 pagineHeap Leach PadsOmar Alex Meléndez Huamán100% (1)

- Price EstimationDocumento6 paginePrice EstimationJosua Ferry ManurungNessuna valutazione finora

- MetoxidoDocumento8 pagineMetoxidocessavelinoNessuna valutazione finora

- 2002 Tech AzconaDocumento19 pagine2002 Tech AzconaOgunranti Rasaq100% (1)

- Uk Mod 24 Ui - Jul 15Documento2 pagineUk Mod 24 Ui - Jul 15yogihardNessuna valutazione finora

- 2000 Ifa Neworleans Lauchard PDFDocumento17 pagine2000 Ifa Neworleans Lauchard PDFkresimir.mikoc9765Nessuna valutazione finora

- Asco Dioxido de CarbonoDocumento176 pagineAsco Dioxido de CarbonoErnest Williams100% (1)

- Fire in Syn. Gas Line Due To Sockolet FailureDocumento9 pagineFire in Syn. Gas Line Due To Sockolet FailureNaresh SinghNessuna valutazione finora

- Producción Del Ácido SulfúricoDocumento102 pagineProducción Del Ácido SulfúricoLuis Diego Cardenas PadillaNessuna valutazione finora

- Weiland Vol 3 Issue 1Documento4 pagineWeiland Vol 3 Issue 1madeehaNessuna valutazione finora

- Saleem India BlogDocumento16 pagineSaleem India BlogSubbaReddyNessuna valutazione finora

- Output File S3 R5 Z4Documento72 pagineOutput File S3 R5 Z4Ankush JainNessuna valutazione finora

- CASE STUDY On Phosphoric Acid Plant ProcessDocumento3 pagineCASE STUDY On Phosphoric Acid Plant ProcessIsrael NarvastaNessuna valutazione finora

- Sulfuric Acid (H SO) IndustryDocumento27 pagineSulfuric Acid (H SO) IndustryAqsa chNessuna valutazione finora

- 10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraDocumento20 pagine10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraCarlosNessuna valutazione finora

- Project TGA - Flowchart PDFDocumento1 paginaProject TGA - Flowchart PDFWari Jul Yadi MalauNessuna valutazione finora

- GSFC Ambaliya Ashvin Roll No - 1 Final ApprovalDocumento128 pagineGSFC Ambaliya Ashvin Roll No - 1 Final ApprovalJames HarmonNessuna valutazione finora

- CP Pickheaters Jacketed Heating Special Report PDFDocumento25 pagineCP Pickheaters Jacketed Heating Special Report PDFnitantharaniNessuna valutazione finora

- UBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantDocumento12 pagineUBL3&4 E 0 G0 ES AA0 002P - R3 - Color Schedule For Power PlantAdvent ManurungNessuna valutazione finora

- Ammonium Sulfate (ZA)Documento8 pagineAmmonium Sulfate (ZA)Ulfa Nurul AuliaNessuna valutazione finora

- Project Profile For The Establishment of Dioctyl Phthalate (Dop) Production Plants in The Arab World (18218.en)Documento27 pagineProject Profile For The Establishment of Dioctyl Phthalate (Dop) Production Plants in The Arab World (18218.en)Manasa BanothNessuna valutazione finora

- Urea Stripper ProcedureDocumento6 pagineUrea Stripper ProcedureSoumitra GuptaNessuna valutazione finora

- Phosphoric Acid PDFDocumento24 paginePhosphoric Acid PDFabderrahimnNessuna valutazione finora

- TA29Documento5 pagineTA29abderrahimnNessuna valutazione finora

- Hemi EraDocumento24 pagineHemi ErasahjNessuna valutazione finora

- Xanthan Gum ProductionDocumento7 pagineXanthan Gum ProductionAreen Emilia Faizlukman JerryNessuna valutazione finora

- Process Flow Diagram - Urea Production PlantDocumento1 paginaProcess Flow Diagram - Urea Production PlantDasun AttanayakeNessuna valutazione finora

- Saudi Arabian Oil Company Neat Khuff Condensate Fractionation ProjectDocumento6 pagineSaudi Arabian Oil Company Neat Khuff Condensate Fractionation ProjectwalitedisonNessuna valutazione finora

- Phosphoric Acid AspenDocumento14 paginePhosphoric Acid AspenJanaina0% (1)

- AcknowledgementDocumento35 pagineAcknowledgementSaba HafeezNessuna valutazione finora

- Ud He TechnologyDocumento16 pagineUd He TechnologyBejavada Suresh100% (1)

- SiCl4 PreparationDocumento5 pagineSiCl4 PreparationAdam FlynnNessuna valutazione finora

- Alum Manufacturing ProcessDocumento13 pagineAlum Manufacturing ProcessKishor JalanNessuna valutazione finora

- Phospha Zen EsDocumento15 paginePhospha Zen EsEthan Poll100% (1)

- SSP Process DescriptionDocumento10 pagineSSP Process DescriptionChirag JaniNessuna valutazione finora

- HSFCCDocumento22 pagineHSFCCdonald55555100% (1)

- Chemical Reactor Design, Optimization, and ScaleupDa EverandChemical Reactor Design, Optimization, and ScaleupNessuna valutazione finora

- Gilbert 2010Documento9 pagineGilbert 2010Maria PaulaNessuna valutazione finora

- AMR - October 14Documento112 pagineAMR - October 14dmscott10Nessuna valutazione finora

- UQ Carpark MapDocumento2 pagineUQ Carpark Mapdmscott10Nessuna valutazione finora

- 874CCSDocumento4 pagine874CCSdmscott10Nessuna valutazione finora

- PO 50 Khalik SDocumento8 paginePO 50 Khalik Sdmscott10Nessuna valutazione finora

- TCE - GasificationDocumento4 pagineTCE - Gasificationdmscott10Nessuna valutazione finora

- Origin Energy Industry Night v2Documento1 paginaOrigin Energy Industry Night v2dmscott10Nessuna valutazione finora

- Control Loop DesignDocumento39 pagineControl Loop Designdmscott10Nessuna valutazione finora

- 850oilandgas FrackingDocumento4 pagine850oilandgas Frackingrobo.wants.boozeNessuna valutazione finora

- Pipe Schedule Segun ASME B36.1 PDFDocumento1 paginaPipe Schedule Segun ASME B36.1 PDFalberthf_1Nessuna valutazione finora

- L3 - PFDsDocumento50 pagineL3 - PFDsdmscott10Nessuna valutazione finora

- Industrial Gas Turbines en NewDocumento8 pagineIndustrial Gas Turbines en Newsujiv_sujiv1278Nessuna valutazione finora

- Finm3401 Ecp 2013Documento14 pagineFinm3401 Ecp 2013dmscott10Nessuna valutazione finora

- Finm3401 Ecp 2014Documento12 pagineFinm3401 Ecp 2014dmscott10Nessuna valutazione finora

- 11-4500 WP Solids Modeling FINALDocumento18 pagine11-4500 WP Solids Modeling FINALnay denNessuna valutazione finora

- CHEE4060 Course ProfileDocumento15 pagineCHEE4060 Course Profiledmscott10Nessuna valutazione finora

- Aspen User Guide 10Documento936 pagineAspen User Guide 10tryinghard18Nessuna valutazione finora

- T A O G R: HE Ustralian IL& AS EviewDocumento2 pagineT A O G R: HE Ustralian IL& AS Eviewdmscott10Nessuna valutazione finora

- Longford IncidentDocumento10 pagineLongford Incidentdmscott10Nessuna valutazione finora

- O&G Review - DecemberDocumento68 pagineO&G Review - Decemberdmscott10Nessuna valutazione finora

- Longford IncidentDocumento10 pagineLongford Incidentdmscott10Nessuna valutazione finora

- TextbooksDocumento1 paginaTextbooksdmscott10Nessuna valutazione finora

- Report TemplateDocumento9 pagineReport Templatedmscott10Nessuna valutazione finora

- Unit 5-Part2Documento28 pagineUnit 5-Part2Nobukhosi NdlovuNessuna valutazione finora

- Xii C Holiday HWDocumento151 pagineXii C Holiday HWArnav SaksenaNessuna valutazione finora

- The Importance of Geochemistry in The Management of Lake Environments Analysis of Parameters Composing The Water Quality Index (Wqi)Documento11 pagineThe Importance of Geochemistry in The Management of Lake Environments Analysis of Parameters Composing The Water Quality Index (Wqi)Ana Carina MatosNessuna valutazione finora

- Chapter 8 - Real GasesDocumento10 pagineChapter 8 - Real Gasescarleston thurgoodNessuna valutazione finora

- Shinko PCDocumento128 pagineShinko PCThaitadashi CalNessuna valutazione finora

- Precision Agriculture Paper PublishedDocumento9 paginePrecision Agriculture Paper PublishedSwapna RaghunathNessuna valutazione finora

- Fe 205 Labaratory Report 1Documento6 pagineFe 205 Labaratory Report 1Hüsamettin KirazNessuna valutazione finora

- Conbextra EP150 UAEDocumento4 pagineConbextra EP150 UAEjasonNessuna valutazione finora

- Instructions For Repair: BW 213 DH / PDH - 4 BW 214 DH / PDH - 4Documento838 pagineInstructions For Repair: BW 213 DH / PDH - 4 BW 214 DH / PDH - 4Hector Sacaca aliagaNessuna valutazione finora

- Me6701 Power Plant Engineering L T P CDocumento3 pagineMe6701 Power Plant Engineering L T P CNithyanandmNessuna valutazione finora

- UNIT 1 Introduction To BiopharmaceuticsDocumento208 pagineUNIT 1 Introduction To BiopharmaceuticsMamta Pant100% (5)

- As H 23b OpticsDocumento48 pagineAs H 23b OpticsHany ElGezawyNessuna valutazione finora

- STPM 2017 Sem 2uDocumento8 pagineSTPM 2017 Sem 2uAprillia ChanNessuna valutazione finora

- The Photoelectric Effect and Its Application in The Digital CameraDocumento2 pagineThe Photoelectric Effect and Its Application in The Digital Cameraallison125Nessuna valutazione finora

- Industrial Automation MOTOR CLASSDocumento18 pagineIndustrial Automation MOTOR CLASSAlamin SikderNessuna valutazione finora

- OTC-26068-MS Wettability Alteration of Heavy-Oil/Bitumen Containing Carbonates Using Solvents, High PH Solutions and Nano/Ionic LiquidsDocumento18 pagineOTC-26068-MS Wettability Alteration of Heavy-Oil/Bitumen Containing Carbonates Using Solvents, High PH Solutions and Nano/Ionic Liquidsjose floresNessuna valutazione finora

- History of Electronics: Year Person WorksDocumento2 pagineHistory of Electronics: Year Person WorksRoy AngelesNessuna valutazione finora

- Guideline For Choosing A Property MethodDocumento12 pagineGuideline For Choosing A Property MethodAtul JainNessuna valutazione finora

- General Instructions:: Section ADocumento9 pagineGeneral Instructions:: Section ASharma BhavnaNessuna valutazione finora

- Microspectroscopic Analysis of Traditional Oil Paint: Jaap Van Der WeerdDocumento193 pagineMicrospectroscopic Analysis of Traditional Oil Paint: Jaap Van Der WeerdAndra Ch123Nessuna valutazione finora

- Facilities Chemical SpareDocumento73 pagineFacilities Chemical SparesamuelNessuna valutazione finora

- Low-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionDocumento8 pagineLow-Voltage Hydrogen Peroxide Electrolyzer For Highly Efficient - Power-To-Hydrogen ConversionShangli HuangNessuna valutazione finora

- 2012-05-11 Inorganic Chemistry PART 2Documento40 pagine2012-05-11 Inorganic Chemistry PART 2Shaina OrnopiaNessuna valutazione finora

- Milling and SievingDocumento5 pagineMilling and SievingAngelina DementyevaNessuna valutazione finora

- Leakfinder Wv622nvwkitDocumento20 pagineLeakfinder Wv622nvwkitPaul ZiddyNessuna valutazione finora