Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Construction Management or Construction Project Management

Caricato da

Ar Aayush GoelCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Construction Management or Construction Project Management

Caricato da

Ar Aayush GoelCopyright:

Formati disponibili

Construction management or construction project management (CPM) is the overall planning, coordination, and control of a project from inception

to completion aimed at meeting a clients requirements in order to produce a functionally and financially viable project. CPM is project management that applies to the construction sector Construction Manager fall into the following 7 categories: Project Management Planning, Cost Management, Time Management, Quality Management, Contract Administration, Safety Management, and CM Professional Practice which includes specific activities like defining the responsibilities and management structure of the project management team, organizing and leading by implementing project controls, defining roles and responsibilities and developing communication protocols, and identifying elements of project design and construction likely to give rise to disputes and claims. The functions of construction project management typically include the following[1] : Specifying project objectives and plans including delineation of scope, budgeting, scheduling, setting performance requirements, and selecting project participants. Maximizing resource efficiency through procurement of labor, materials and equipment. Implementing various operations through proper coordination and control of planning, design, estimating, contracting and construction in the entire process. Developing effective communications and mechanisms for resolving conflicts Typically the construction industry includes three parties: an owner, a designer (architect or engineer), the builder (usually called the general contractor). Traditionally, there are two contracts between these parties as they work together to plan, design, and construct the project. [6] The first contract is the ownerdesigner contract, which involves planning, design, and construction administration. The second contract is the owner-contractor contract, which involves construction. An indirect, third-party relationship exist between the designer and the contractor due to these two contracts. An alternate contract or business model replaces the two traditional contracts with three contracts: owner-designer, owner-construction project manager, and owner-builder. The construction project management company becomes an additional party engaged in the project to act as an adviser to the owner, to which they are contractually tied. The construction manager's role is to provide construction advice to the designer, on the owner's behalf, design advice to the constructor, again on the owner's behalf, and other advice as necessary. ArchitectureEngineer Work inspection Change orders Review payments Materials and samples Shop drawings 3d image Planning and scheduling Project management methodology: Work breakdown structure Project network of activities Critical path method (CPM) Resource management Resource leveling Construction managers coordinate and schedule design and construction processes in the building of office complexes, residential homes, and industrial structures. They may be involved in the construction of highways, bridges, schools and hospitals. A construction manager approves and hires specialty contractors for operations such as plumbing, electrical wiring and framing. Construction managers

usually work on a project from conception to completion. On large projects, they may be responsible for only one segment of the operation. Architects design buildings and structures that not only look good but are safe, energy efficient and functional. An architect works with a client to set the parameters of the construction, such as construction objectives, budget and requirements of the structure. Architects often do pre-construction assessments to determine the feasibility of the project and any environmental impact the structure might have. When pre-construction assessment is complete, an architect will then develop the final construction plan, including construction details and building appearance. General Risks to Consider There are several areas of liability to watch for when providing construction management services. The degree to which you assume any of these risks depends on your role as a CM and your responsibilities as stated in your contract and demonstrated by your actions. Consider the following: Design. When CMs conduct design and constructability reviews, they may, along with the architect or engineer of record, be subject to claims involving design errors and omissions. Selection of materials. CMs may have exposure arising from the selection and timely delivery of construction materials and subsystems. Cost estimates. Project owners typically have high expectations that a CMs construction cost estimates are accurate. If costs exceed a CMs estimate, there is substantial risk of a claim Jobsite safety. CMs may assume responsibility for construction means and methods, as well as the contractors jobsite safety program and safety plans. OSHA rulings have generally concluded that a CMConstructors responsibilities for jobsite safety are akin to those of a general contractor. Scheduling and coordination. Work not performed on schedule or not well coordinated can lead to claims for project delays, increased overhead expenses and added overtime costs. Hazardous site conditions. If not careful, the CMConstructor can assume liability for existing hazardous site conditions. In addition, if toxic materials on the site must be disposed of or transported, the CM can be deemed an operator of the site or an arranger of the disposal and thus subject to severe (and sometimes criminal) sanctions in the event of an illegal dumping or accident The following provisions should be adhered to wherever practicable:(i) Vehicles and mechanical plant used for the purpose of the works shall be fitted with effective exhaust silencers, maintained in good and efficient working order and operated in such a manner as to minimise noise emissions. The contractor shall ensure that all plant complies with the relevant statutory requirements. (ii) Machines in intermittent use should be shut down or throttled down to a minimum when not in use. (iii) Compressors should be fitted with properly lined and sealed acoustic covers which should be kept closed whenever in use. Pneumatic percussive tools should be fitted with mufflers or silencers of the type recommended by the

manufacturers. (iv) Equipment which breaks concrete, brickwork or masonry by bending or bursting or nibbling shall be used in preference to percussive tools where practicable. Avoid the use of impact tools where the site is close to occupied premises. (v) Where practicable, rotary drills and bursters activated by hydraulic, chemical or electrical power shall be used for excavating hard or extrusive material. (vi) Where practicable, equipment powered by mains electricity shall be used in preference to equipment powered by internal combustion engine or locally generated electricity. (vii) Neither any part of the works nor any maintenance of plant shall be carried out in such a manner as to cause unnecessary noise or vibration except in the case of an emergency when the work is absolutely necessary for the saving of life or property or the safety of the works. (viii) Plant shall be maintained in good working order so that extraneous noise from mechanical vibration, creaking and squeaking is kept to a minimum. (ix) Noise emitting machinery which is required to run continuously shall be housed in a suitable acoustic lined enclosure wherever practicable.

Any plant used for the crushing of materials should be issued with a Permit by a Local Authority under the Pollution Prevention and Control Regulations 2000. All work should be carried out in accordance with the conditions of the Permit. Where plant is used to recycle materials, the appropriate licence from the Environment Agency shall be obtained. The process operator should notify the local authority in whose area the process is proposed prior to operation.

To ensure that our construction works do not affect residents and businesses, noise levels are continuously monitored and kept within the National Environment Agency (NEA) permissible levels.

Contractors must comply with the following noise pollution control requirements: Prior to the commencement of works, contractors are required to carry out a baseline noise survey for one week, on a 24-hour basis, to establish the background noise levels. A Noise Management Plan must be submitted before any construction work is started. The plans must include the baseline noise record, indicate the Noise Sensitive Receivers (NSRs) and proposed mitigation measures and public relation strategies to handle noise matters. Throughout the construction duration, contractors must implement all practicable measures while continuously monitoring the noise levels closely. For effective noise control, the main focus should be on control at source supplemented with control at pathway. Examples of practicable control measures to mitigate the noise impact are as follows: Use of noise reduced plants and machineries

Enclose noisy plant in an acoustic shed. Barricade noisy activities with portable noise barriers/panels. Erect noise barriers before commencement of works. 5. Establish good rapport with the community.

a) improve the planning and management of projects from the very start; (b) identify hazards early on, so they can be eliminated or reduced at the design or planning stage and the remaining risks can be properly managed; (c) target effort where it can do the most good in terms of health and safety; and (d) discourage unnecessary bureaucracy.

Clients must appoint dutyholders who are competent and adequately resourced. Clients must provide those who need it (eg, designers, contractors, CDM Co-ordinators) with preconstruction information that can reasonably be obtained. A range of surveys and reports will be needed

- for example, to check for presence of asbestos; structural stability of site and nearby structures; the location of above and below ground live services in the work area; etc. These should be done before work begins and not be left for the principal contractor to organise once the demolition work has started. CDM Co-ordinators plan effective site management that keeps people (site workers and the public) as far as possible from the risks. They should give principal contractors as much information as possible. Principal contractors co-ordinate and manage health and safety issues during the demolition project. Site managers supervise workers and ensure they are following safe working practice. Sub-contractors and site workers must understand and follow the precautions and ensure that their colleagues do too. Back to top Falls from height During demolition and dismantling, workers can be injured falling from edges, through openings, fragile surfaces and partially demolished floors. Dutyholders have a responsibility to assess, eliminate and control the risks of falls from height. Find out more about falls from height. Back to top Injury from falling materials Workers and passers-by can be injured by the premature and uncontrolled collapse of structures, and by flying debris. A safe system of work is one that keeps people as far as possible from the risks. This may include: establishing exclusion zones and hard-hat areas, clearly marked and with barriers or hoardings if necessary covered walkways using high-reach machines reinforcing machine cabs so that drivers are not injured training and supervising site workers Back to top Uncontrolled collapse The structural survey should consider: the age of the structure its previous use the type of construction nearby buildings or structures the weight of removed material or machinery on floors above ground level The method statement for the demolition should identify the sequence required to prevent accidental collapse of the structure. Back to top Risks from connected services Gas, electricity, water and telecommunications services need to be isolated or disconnected before demolition work begins. If this is not possible, pipes and cables must be labelled clearly, to make sure they are not disturbed. Back to top Traffic management Effective traffic management systems are essential on site, to avoid putting workers at risk of being hit by vehicles turning, slewing, or reversing. Where possible, vision aids and zero tail swing machines should be used. Find out more about traffic management Back to top

Hazardous materials Hazardous materials that need to be considered include dust, asbestos and respirable crystalline silica (RCS).There may also be material or contamination on site that has not been cleared, for example: acids from industrial processes paints flammable liquids unidentified drums microbiological hazards (especially in old hospital buildings). Find out more about the control of substances hazardous to health (COSHH) Back to top Noise and vibration Frequent exposure to loud noise can permanently damage a persons hearing. Noise can also create a safety risk if it makes it difficult for workers to communicate effectively or stops them hearing warning signals. More information on noise at work Vibrating hand tools used in demolition can cause hand-arm vibration syndrome (HAVS).Workers exposure to vibration needs to be managed and reduced as far as possible. Find out more about managing the risks caused by use of vibrating tools Back to top Fire Fire is a risk where hot work (using any tools that generate spark, flame or heat) is being done. During structural alteration, the fire plan must be kept up to date as the escape routes and fire points may alter. There must be an effective way to raise the alarm.

Potrebbero piacerti anche

- Construction Management Plan for Myatts Field North ProjectDocumento49 pagineConstruction Management Plan for Myatts Field North ProjectHans Hans SadzNessuna valutazione finora

- Kamal 2015Documento11 pagineKamal 2015Mohammed AbduramanNessuna valutazione finora

- Preparing for Construction StageDocumento2 paginePreparing for Construction Stagerobert alcantaraNessuna valutazione finora

- Hse-Site Procedure ManualDocumento21 pagineHse-Site Procedure ManualAbrar AhmedNessuna valutazione finora

- Civil Work ProcedureDocumento21 pagineCivil Work ProcedureSunday JamesNessuna valutazione finora

- c14 BSDDocumento17 paginec14 BSDCristian BlanaruNessuna valutazione finora

- Concept & Feasibilit y Design Commissi On& HandoverDocumento11 pagineConcept & Feasibilit y Design Commissi On& HandoverAsrul AfiqNessuna valutazione finora

- Construction Management OverviewDocumento3 pagineConstruction Management OverviewT N Roland BourgeNessuna valutazione finora

- Construction Management Framework OutlineDocumento11 pagineConstruction Management Framework OutlineZhi HaoNessuna valutazione finora

- Post Construction ServicesDocumento26 paginePost Construction ServicesJayRapRapTizonNessuna valutazione finora

- Mobilization Plan PreparationDocumento5 pagineMobilization Plan PreparationAhmed AdelNessuna valutazione finora

- Construction Methods and Project Management GuideDocumento30 pagineConstruction Methods and Project Management GuideJay LoyaoNessuna valutazione finora

- Parties of A Construction ProjectDocumento8 pagineParties of A Construction ProjectT N Roland BourgeNessuna valutazione finora

- Safety Health & Environment MethodologyDocumento14 pagineSafety Health & Environment MethodologymusengemNessuna valutazione finora

- Module 1 - General Introduction To Construction IndustryDocumento9 pagineModule 1 - General Introduction To Construction IndustryAARONLEMUEL CLIDORONessuna valutazione finora

- Section 1 Construction Management SafetyDocumento42 pagineSection 1 Construction Management SafetyAmarendra KeerthiNessuna valutazione finora

- REVIEWERDocumento14 pagineREVIEWERJana MinNessuna valutazione finora

- Civil Engineering FunctionsDocumento5 pagineCivil Engineering FunctionsWilhelm GabaonNessuna valutazione finora

- Comprehensive Services of An Architect 2.0Documento16 pagineComprehensive Services of An Architect 2.0Mariel Paz MartinoNessuna valutazione finora

- Construction Management Construction Management Construction ManagementDocumento13 pagineConstruction Management Construction Management Construction Management1234anscribdNessuna valutazione finora

- Construction Guidelines for Occupied BuildingsDocumento7 pagineConstruction Guidelines for Occupied BuildingsAthirahNessuna valutazione finora

- Building ConstructionDocumento7 pagineBuilding ConstructionRaheel AhmedNessuna valutazione finora

- Construction Process ManagementDocumento9 pagineConstruction Process ManagementAsrul AfiqNessuna valutazione finora

- ASSIGNMENT PGPM 14 (Contracts Management)Documento10 pagineASSIGNMENT PGPM 14 (Contracts Management)Rammohan Vysyaraju0% (1)

- 309 Weeks 1-5 NoteDocumento10 pagine309 Weeks 1-5 NoteArazim OfYabatechNessuna valutazione finora

- Safety Rules in ConstructionDocumento4 pagineSafety Rules in ConstructionMariya MariyaNessuna valutazione finora

- 15.1 Safety Management: Contractor Management System: 15.1.1 PurposeDocumento13 pagine15.1 Safety Management: Contractor Management System: 15.1.1 Purposesyedahmad39Nessuna valutazione finora

- Clients ResponsibilityDocumento3 pagineClients ResponsibilityRonald BadzaNessuna valutazione finora

- Is CDMDocumento5 pagineIs CDMChimaovu EhoroNessuna valutazione finora

- Construction - Demolition - HSEDocumento6 pagineConstruction - Demolition - HSEmjdscribeNessuna valutazione finora

- Demolition of Derelict Victorian BuildingDocumento23 pagineDemolition of Derelict Victorian Buildingmags bpclNessuna valutazione finora

- SPP 205Documento2 pagineSPP 205Jadine ParambitaNessuna valutazione finora

- KNS 1472Documento15 pagineKNS 1472Anonymous 7oXNA46xiN100% (1)

- General Approach and Methodology 01 BY JUNAIDDocumento9 pagineGeneral Approach and Methodology 01 BY JUNAIDtopocon_707301799100% (6)

- Role of ContractorDocumento5 pagineRole of ContractorMuhammad Adji PradanaNessuna valutazione finora

- Construction ManagementDocumento3 pagineConstruction ManagementViktoria YumangNessuna valutazione finora

- ARC224 Archl PROGM NDocumento20 pagineARC224 Archl PROGM NMuhammad AminuNessuna valutazione finora

- Construction Method Revisi 1Documento15 pagineConstruction Method Revisi 1candra_zakaria4416100% (1)

- Assignment-7BU504-100601249 - 1Documento14 pagineAssignment-7BU504-100601249 - 1Jayeola Aborode100% (1)

- ESHS Code of Conduct for Road WorksDocumento11 pagineESHS Code of Conduct for Road Workssimon maaakla0% (1)

- CooooDocumento8 pagineCooooMohammed AbduNessuna valutazione finora

- Guide Safety BuildingsDocumento46 pagineGuide Safety BuildingsFrank StephensNessuna valutazione finora

- Construction Safety Guideline For Indonesia PDFDocumento21 pagineConstruction Safety Guideline For Indonesia PDFsatriaNessuna valutazione finora

- CONSTRUCTION Engineering and PlanningDocumento14 pagineCONSTRUCTION Engineering and PlanningFaheem MushtaqNessuna valutazione finora

- PGPM 31Documento16 paginePGPM 31Rutuja GameyNessuna valutazione finora

- Construction Economics AND LAWDocumento21 pagineConstruction Economics AND LAWCalin SimionNessuna valutazione finora

- The Modern Building ConstructionDocumento8 pagineThe Modern Building ConstructionPinky Dwi PrasetyoNessuna valutazione finora

- Rich Text Editor File: Construction TypesDocumento6 pagineRich Text Editor File: Construction TypesMuhannad AbdulRaoufNessuna valutazione finora

- The Factors Affecting The Trenchless ProjectsDocumento5 pagineThe Factors Affecting The Trenchless ProjectsKOKKONDA VENKATESHWARNessuna valutazione finora

- Safety Measures for High-Rise ConstructionDocumento9 pagineSafety Measures for High-Rise Constructionarnel sungkipNessuna valutazione finora

- Construction ManagementDocumento12 pagineConstruction ManagementSara RojasNessuna valutazione finora

- Lo TSZ Lung, CEG98/6 (CED Intake) 6 September, 1999Documento3 pagineLo TSZ Lung, CEG98/6 (CED Intake) 6 September, 1999Louis LaiNessuna valutazione finora

- Company Policies Project Planning and Quality ControlDocumento5 pagineCompany Policies Project Planning and Quality Controldavid karasilaNessuna valutazione finora

- 3327-Preconstruction InformationDocumento12 pagine3327-Preconstruction InformationKURONessuna valutazione finora

- COP Facade RetentionDocumento9 pagineCOP Facade RetentionAndre MarsNessuna valutazione finora

- CEMDocumento9 pagineCEMChristineNessuna valutazione finora

- JD For Construction Safety HiringDocumento3 pagineJD For Construction Safety HiringravindraNessuna valutazione finora

- Idm 31Documento41 pagineIdm 31NIKHIL MATHURNessuna valutazione finora

- Design & Construction of the Contract Package ConceptDa EverandDesign & Construction of the Contract Package ConceptNessuna valutazione finora

- Project Management For Procurement Management ModuleDa EverandProject Management For Procurement Management ModuleNessuna valutazione finora

- Decoding Finn Juhl's Egyptian Chair - Workshop - BriefDocumento5 pagineDecoding Finn Juhl's Egyptian Chair - Workshop - BriefAr Aayush GoelNessuna valutazione finora

- Industrial Tourism When The Industry Becomes A Chance For TourismDocumento9 pagineIndustrial Tourism When The Industry Becomes A Chance For TourismAr Aayush GoelNessuna valutazione finora

- Conferenceobject 93516Documento10 pagineConferenceobject 93516Ar Aayush GoelNessuna valutazione finora

- Light Industrial Area Design GuidelinesDocumento12 pagineLight Industrial Area Design GuidelinesAr Aayush GoelNessuna valutazione finora

- WHI Brochure 2022 - Classic Resort CollectionDocumento23 pagineWHI Brochure 2022 - Classic Resort CollectionAr Aayush GoelNessuna valutazione finora

- An Introduction To 00 Hubb RichDocumento596 pagineAn Introduction To 00 Hubb RichSerban CalinNessuna valutazione finora

- 169 172, Tesma407, IJEASTDocumento4 pagine169 172, Tesma407, IJEASTAr Aayush GoelNessuna valutazione finora

- Japan International Cooperation Agency: NewsletterDocumento16 pagineJapan International Cooperation Agency: NewsletterAr Aayush GoelNessuna valutazione finora

- General ReqDocumento19 pagineGeneral ReqVincent VivekNessuna valutazione finora

- History of Architecture - Gate Architecture - Study MaterialDocumento12 pagineHistory of Architecture - Gate Architecture - Study MaterialAr Aayush GoelNessuna valutazione finora

- To Download and Install Kaltura CaptureDocumento4 pagineTo Download and Install Kaltura CaptureAr Aayush GoelNessuna valutazione finora

- Guided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilDocumento30 pagineGuided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilAr Aayush GoelNessuna valutazione finora

- Hvac Systems ComponentsDocumento28 pagineHvac Systems ComponentsArvind RNessuna valutazione finora

- Industrial & Business Park Design GuidelinesDocumento22 pagineIndustrial & Business Park Design GuidelinesAr Aayush GoelNessuna valutazione finora

- UPSC CPWD Architecture 2016Documento38 pagineUPSC CPWD Architecture 2016Sweety KumariNessuna valutazione finora

- Lec 1Documento33 pagineLec 1Ar Aayush GoelNessuna valutazione finora

- URR - Ved Mittal PDFDocumento41 pagineURR - Ved Mittal PDFAr Aayush GoelNessuna valutazione finora

- Town Planning and Development LawsDocumento24 pagineTown Planning and Development LawsDevika Hemalatha DeviNessuna valutazione finora

- Quantitative Aptitude Tricks - PDF Download: ImplificationDocumento12 pagineQuantitative Aptitude Tricks - PDF Download: ImplificationSwapnarani JadavNessuna valutazione finora

- Reasoning Tricks PDFDocumento53 pagineReasoning Tricks PDFrupaliNessuna valutazione finora

- Hindu Temple Architecture HistoryDocumento100 pagineHindu Temple Architecture HistoryHarshi Garg60% (5)

- Town Planning in India - Ancient Age - Med PDFDocumento22 pagineTown Planning in India - Ancient Age - Med PDFAr Aayush GoelNessuna valutazione finora

- 12-A Review of Urban (Lalit Batra)Documento8 pagine12-A Review of Urban (Lalit Batra)Ar Aayush GoelNessuna valutazione finora

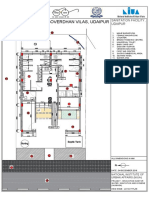

- Public Toilets at Goverdhan Vilas, UdaipurDocumento1 paginaPublic Toilets at Goverdhan Vilas, UdaipurAr Aayush GoelNessuna valutazione finora

- Puzzles WorkbookDocumento31 paginePuzzles WorkbookAr Aayush GoelNessuna valutazione finora

- URR Ved MittalDocumento6 pagineURR Ved MittalAr Aayush GoelNessuna valutazione finora

- Buildings: DefinitionsDocumento31 pagineBuildings: DefinitionsAr Aayush GoelNessuna valutazione finora

- Notification 201921122018Documento5 pagineNotification 201921122018Ar Aayush GoelNessuna valutazione finora

- 12-A Review of Urban (Lalit Batra) PDFDocumento51 pagine12-A Review of Urban (Lalit Batra) PDFKevin HansenNessuna valutazione finora

- Housing Projects in SCP - 60 CitiesDocumento3 pagineHousing Projects in SCP - 60 CitiesAr Aayush GoelNessuna valutazione finora

- Lesson 1 - PMP Auth Exam PrepDocumento64 pagineLesson 1 - PMP Auth Exam PrepDiego Pérez Ortega100% (1)

- Construction Extension To The PMBOK: GuideDocumento10 pagineConstruction Extension To The PMBOK: GuideGaby Vilchez RojasNessuna valutazione finora

- Project Life Cycle Iterative and Adaptive - Ultimate GuideDocumento14 pagineProject Life Cycle Iterative and Adaptive - Ultimate GuideAamirMalikNessuna valutazione finora

- PMBOK Project Management ProcessesDocumento19 paginePMBOK Project Management ProcessesRidhoVerianNessuna valutazione finora

- SAP Certified HCM Consultant: Samantha-Robinson-2a90286Documento15 pagineSAP Certified HCM Consultant: Samantha-Robinson-2a90286Nandini maskeNessuna valutazione finora

- P3ODocumento38 pagineP3Oapmegremis100% (1)

- Master Test PlanDocumento18 pagineMaster Test PlanMLastTryNessuna valutazione finora

- COE SetupDocumento28 pagineCOE SetuphkodaliNessuna valutazione finora

- Personal Interaction and Customer Relationship Management in Project BusinessDocumento8 paginePersonal Interaction and Customer Relationship Management in Project BusinessToilaKhoaNguyenNessuna valutazione finora

- Construction Project ManagementDocumento51 pagineConstruction Project Managementocduran42004100% (5)

- Department of Business Administration, Faculty of Arts, Brandon University, Manitoba, CanadaDocumento8 pagineDepartment of Business Administration, Faculty of Arts, Brandon University, Manitoba, CanadavithuNessuna valutazione finora

- Construction ManagementDocumento30 pagineConstruction ManagementaNessuna valutazione finora

- Positive Intelligence Webinar (Handout)Documento26 paginePositive Intelligence Webinar (Handout)Spil_vv_IJmuiden100% (3)

- Presentation - How A Traditional Project Manager Transforms To Scrum - FINAL PDFDocumento26 paginePresentation - How A Traditional Project Manager Transforms To Scrum - FINAL PDFRaghuRamNessuna valutazione finora

- MSF Agile EssentialsDocumento54 pagineMSF Agile EssentialsJuan MolinaNessuna valutazione finora

- IT PM Kathy Schwalbe Chapter 1 ACC HariDocumento49 pagineIT PM Kathy Schwalbe Chapter 1 ACC Haritsaaga4Nessuna valutazione finora

- Skills For Success Competency FrameworkDocumento7 pagineSkills For Success Competency FrameworkSandra BerwickNessuna valutazione finora

- University Institute of Information Technology (UIIT), PMAS-Arid Agriculture University (AAUR), RawalpindiDocumento41 pagineUniversity Institute of Information Technology (UIIT), PMAS-Arid Agriculture University (AAUR), RawalpindiShopify SEONessuna valutazione finora

- Check Engineering DocumentsDocumento50 pagineCheck Engineering DocumentsAleksandar Spasojevic100% (1)

- Project Manager PMP Scrum Master in Boston MA Resume Suzanne AttwoodDocumento2 pagineProject Manager PMP Scrum Master in Boston MA Resume Suzanne AttwoodSuzanneAttwoodNessuna valutazione finora

- Computer Science (Project File)Documento38 pagineComputer Science (Project File)sanchitNessuna valutazione finora

- 04 Digital Transformation of Capital Execution With EPC 4.0 Strategy Julien de BeerDocumento39 pagine04 Digital Transformation of Capital Execution With EPC 4.0 Strategy Julien de BeerMuhammad Saeed100% (2)

- CH 4 - PPLDocumento55 pagineCH 4 - PPLgashaw yematawNessuna valutazione finora

- Project Management LinkedinDocumento13 pagineProject Management LinkedinYesi YuliantikaNessuna valutazione finora

- S.No Questions Please Use The Answers Marked in GreenDocumento3 pagineS.No Questions Please Use The Answers Marked in GreenShilpaJ100% (1)

- MS EpmDocumento2 pagineMS EpmZardozofozNessuna valutazione finora

- University of Zimbabwe: Mba528: Project ManagementDocumento6 pagineUniversity of Zimbabwe: Mba528: Project ManagementjrmutengeraNessuna valutazione finora

- PooDocumento8 paginePoowalabuNessuna valutazione finora

- Drilling Project, WP&B and AFE in The E & P Industry (Tatacara Pengisian Budget Schedule) PDFDocumento2 pagineDrilling Project, WP&B and AFE in The E & P Industry (Tatacara Pengisian Budget Schedule) PDFFauzan Rahman HaqNessuna valutazione finora

- Linear Project Management Framework: Dr. Rupali KalekarDocumento59 pagineLinear Project Management Framework: Dr. Rupali Kalekargopi patilNessuna valutazione finora