Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

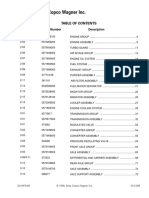

Flow Chart Details

Caricato da

sujaraghupsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Flow Chart Details

Caricato da

sujaraghupsCopyright:

Formati disponibili

FLOW CHART DETAILS FOR BG AC EMU MOTOR COACH OVERHAULING

STOP 01MP 02MP 03MP 04MP 05MP 0 MP 0!MP 0"MP RECEIPT OF MOTOR COACH FOR POH FROM RUNNING DEPOT AS PER PLAN AND COACH BLOWING WITH COMPRESSOR AIR WASHING OF COACH IN WASHING PLANT TURNING OF WHEEL SET IN WHEEL LATHE PLACE THE COACH ON SUITABLE ROAD IN SHOP FLOOR AFTER GIVING CLEAR INSTRUCTIONS TO ALL SECTIONS OF WORKSHOP. DISCONNECT THE REQUIRED COMPONENTS FOR LIFTING OF COACH. PROVIDE SUITABLE LIFTING HOOKS ON COACH BODY FOR LIFTING. LIFT THE COACH BODY WITH SUITABLE CRANES AND PLACE THE COACH BODY ON SUITABLE TRUSSELS AT APPROPRIATE PLACE. UNLOAD ALL ELECTRICAL AND MECHANICAL EQUIPMENTS FROM COACH WITH SUITABLE TOOLS. TRANSPORT THE UNLOADED EQUIPMENTS BY SUITABLE HANDLING EQUIPMENTS TO CONCERNED SECTION FOR OVERHAULING WITH SUITABLE IDENTIFICATION. IDENTIFY EQUIPMENTS BEFORE COMMENCEMENT OF OVERHAULING. DISMANTLE THECOMPONENTS FROM EQUIPMENTS WITHSUITABLE TOOLS REPLACE$REWORK THE DEFECTIVE COMPONENTS IF REQUIRED. ASSEMBLE THE COMPONENTS TRANSPORT THE OVERHAULED EQUIPMENTS FROM SECTIONS FOR LOADING INTO COACH WITH SUITABLE HANDLING EQUIPMENTS AFTER IDENTIFICATION OF RESPECTIVE EQUIPMENTS. LOAD THE OVERHAULED EQUIPMENTS INTO THE COACH. ENSURE TIGHTNESS OF ALL TERMINALS% BED BOLTS WITH SUITABLE TOOLS. ENSURE COACH IS READY IN ALL RESPECTS FOR LIFTING AND CONNECT SUITABLE LIFTING HOOKS ON COACH BODY FOR LIFTING. LIFT THE COACH BODY WITH SUITABLE CRANES AND LOWER ONTO THE NOMINATED BOGIES. CONNECT THE REQUIRED COMPONENTS AFTER LOWERING OF COACH BODY ON BOGIES. PUSHOUT THE COACH FROM SHOP FLOOR FOR FINAL TESTING & STAGE'III AFTER OVERHAUL. CARRYOUT TRAIL RUN. APPLY PUTTY OVER COACH BODY IF REQUIRED. PAINT AS PER RECOMMENDED COLOUR SCHEME INTERIOR AND E(TERIOR PORTION OF THE COACH. CARRY OUT STENCILING% LETTRING WORKS ON INTERIOR AND E(TERIOR PORTION OF COACH. MFT3 MFT4 MC1 & MC MR1 & MR5 FIT 01MIP 02MIP 03MIP 01MFT 02MFT 03MFT 04MFT MIP1' MIP3 MFT1 MFT2 INSPECT THE CONDITION OF ALL COMPONENTS. INSPECT ALL DOORS% SEATS% FLOORING% WINDOWS% UNDER FRAME FOR ANY DAMAGE. CARRY OUT IN'PROCESS INSPECTION FOR PAINTING. CARRY OUT FINAL TESTING & STAGE'I )BENCH TEST* CARRYOUT FINAL TESTING & STAGE & II )LT TEST* CARRYOUT FINAL TESTING & STAGE & III )POWER TESTING* CARRYOUT FINAL TESTING & STAGE & IV )+OINT INSPECTION* DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER INSPECTION. DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER FINAL TESTING )BENCH TEST* DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER FINAL TESTING )LT TEST* DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER FINAL TESTING )POWER TEST* DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER FINAL TESTING )+OINT INSPECTION* IMPLEMENT THE CORRECTIVE ACTION AFTER INSPECTION$TESTING RECORD DATAS AFTER INSPECTION$TESTING. HAND OVER THE OVERHAULED COACH TO RUNNING DEPOT.

0#MP 10MP 11MP 12MP 13MP

14MP 15MP 1 MP 1!MP 1"MP 1#MP 20MP 21MP 22MP 23MP

FLOW CHART DETAILS FOR BG AC EMU TRAILER COACH OVERHAULING

STOP 01TP 02TP 03TP 04TP 05TP 0 TP 0!TP 0"TP 0#TP 10TP 11TP 12TP 13TP 14TP 15TP 1 TP 1!TP 1"TP 1#TP RECEIPT OF COACH FOR POH FROM RUNNING DEPOT AS PER PLAN )A & C & D FORMATION* WASHING OF COACH IN WASHING PLANT TURNING OF WHEEL SET IN WHEEL LATHE. PLACE THE COACH ON SUITABLE ROAD TO PAINT SHOP AFTER GIVING CLEAR INSTRUCTIONS TO ALL SECTIONS OF WORKSHOP. APPLY PUTTY OVER COACH BODY IF REQUIRED. REMOVAL OF FANS , LIGHTS FROM COACH. PAINT AS PER RECOMMENDED COLOUR SCHEME ON INTERIOR AND E(TERIOR PORTION OF COACH. CARRYOUT STENCILING% LETTERING WORKS ON INTERIOR AND E(TERIOR PORTION OF COACH. PUSH OUT THE COACHES FROM PAINT SHOP 03TFT PLACE THE COACHES ON SUITABLE ROAD TO SHOP FLOOR. TIP1 & TIP3 DISCONNECT THE REQUIRED COMPONENTS FOR LIFTING OF COACH. PROVIDE SUITABLE LIFTING HOOKS ON COACH BODY FOR LIFTING. LIFT THE COACH BODY WITH SUITABLE CRANES AND PLACE THE COACH BODY ON SUITABLE TRUSSELS AT APPROPRIATE PLACE. UNLOAD ALL ELECTRICAL AND MECAHNICAL EQUIPMENTS FROM COACH WITH SUITABLE TOOLS. TRANSPORT THE UNLOADED EQUIPMENTS BY SUITABLE HANDLING EQUIPMENTS TO CONCERNED SECTION FOR OVERHAULING. IDENTIFY EQUIPMENTS BEFORE COMMENCEMENT OF OVERHAULING. DISMANTLE THE COMPONENTS FROM EQUIPMENTS WITH SUITABLE TOOLS. REPLACE$REWORK THE DEFECTIVE COMPONENTS. ASSEMBLE THE COMPONENTS. TRANSPORT THE OVERHAULED EQUIPMENTS FROM SECTIONS FOR LOADING INTO COACH WITH SUITABLE HANDLING EQUIPMENTS AFTER IDENTIFICATION OF RESPECTIVE EQUIPMENTS. LOAD THE OVERHAULED EQUIPMENTS INTO THE COACH. ENSURE TIGHTNESS OF ALL TERMINALS% BED BOLTS WITH SUITABLE TOOLS. ENSURE COACH IS READY IN ALL RESPECTS FOR LIFTING AND CONNECT SUITABLE LIFTING HOOKS ON COAVH BODY FOR LIFTING. LIFT THE COACH BODY WITH SUITABLE CRANES AND LOWER ONTO THE NOMINATED BOGIES. CONNECT THE REQUIRED COMPONENTS AFTER LOWERING OF COACH BODY ON BOGIES. TFT'1 TFT'2 TFT'3 TC1 & TC5 TR1 & TR4 FIT DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER INSPECTION. DECIDE WHETHER ANY CORRECTIVE ACTION IS REQUIRED AFTER FINAL TESTING )BENCH TEST* DECIDE WHETHER ANY CORRECTIVE ACTION IF REQUIRED AFTER FINAL TESTING )BRAKE TEST* DECIDE WHETHER ANY CORRECTIVE ACTION IF REQUIRED AFTER FINAL TESTING )+OINT INSPECTION* IMPLEMENT THE CORRECTIVE ACTION AFTER INSPECTION. RECORD DATAS AFTER INSPECTION. HAND OVER THE OVERHAULED COACH TO RUNNING DEPOT. CARRYOUT FINAL TESTING STAGE & III )+OINT INSPECTION* 2 .TP 01TIP 02TIP 03TIP 01TFT 02TFT 25TP TESTING PUSHOUT THE COACH FROM SHOP FLOOR FOR FINAL STAGE & II AFTER OVERHAUL. CARRY OUT TRIAL RUN. INSPECT THE CONDITION OF ALL COMPONENTS. CARRYOUT IN'PROCESS INSPECTION FOR PAINTING. INSPECT ALL DOORS% SEATS% FLOORING% WINDOWS% UNDER FRAME FOR ANY DAMAGE. CARRYOUT FINAL TESTING STAGE & I )BENCH TEST* CARRYOUT FINAL TESTING STAGE & II )BRAKE TEST*

20TP 21TP 22TP 23TP 24TP

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Car Wash Equipment and Investment RequirementsDocumento2 pagineCar Wash Equipment and Investment RequirementsyeshaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ce1Documento1 paginace1sujaraghupsNessuna valutazione finora

- 5_6057415857582114918Documento15 pagine5_6057415857582114918sujaraghupsNessuna valutazione finora

- LUG PO LGDDocumento3 pagineLUG PO LGDsujaraghupsNessuna valutazione finora

- CONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualDocumento153 pagineCONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualFaraz MirzaNessuna valutazione finora

- Ba Cap MeterDocumento3 pagineBa Cap MetersujaraghupsNessuna valutazione finora

- SPECIFICATION FOR 6531 KVA TFP Steel TankDocumento17 pagineSPECIFICATION FOR 6531 KVA TFP Steel TanksujaraghupsNessuna valutazione finora

- 4065936Documento2 pagine4065936sujaraghupsNessuna valutazione finora

- Metallurgical ChemicalDocumento10 pagineMetallurgical ChemicalsujaraghupsNessuna valutazione finora

- Risk Reduction Guide0.2Documento1 paginaRisk Reduction Guide0.2sujaraghupsNessuna valutazione finora

- DewaltDocumento2 pagineDewaltsujaraghupsNessuna valutazione finora

- New SpecDocumento18 pagineNew SpecsujaraghupsNessuna valutazione finora

- cell 1 5 vDocumento2 paginecell 1 5 vsujaraghupsNessuna valutazione finora

- BRFACH16GB 11 2017 I GB Klauke Technical ArticleDocumento44 pagineBRFACH16GB 11 2017 I GB Klauke Technical ArticlesujaraghupsNessuna valutazione finora

- CONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualDocumento153 pagineCONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualFaraz MirzaNessuna valutazione finora

- 5 219677166189674788Documento10 pagine5 219677166189674788sujaraghupsNessuna valutazione finora

- Handheld Thermal Imaging Camera Model - TE-02Documento9 pagineHandheld Thermal Imaging Camera Model - TE-02sujaraghupsNessuna valutazione finora

- Upgrading Railway Bridge DesignDocumento25 pagineUpgrading Railway Bridge DesignsujaraghupsNessuna valutazione finora

- Brbestofr17gb 03 2017 I GBDocumento2 pagineBrbestofr17gb 03 2017 I GBsujaraghupsNessuna valutazione finora

- Rajbhasha ActDocumento3 pagineRajbhasha Actsahilsinha68100% (1)

- Act With AmendmentDocumento134 pagineAct With AmendmentSowjanya BondaNessuna valutazione finora

- MS - 304 - Dated 09.02.2001Documento5 pagineMS - 304 - Dated 09.02.2001sujaraghupsNessuna valutazione finora

- GreenCo Book Abridged Version 2017Documento28 pagineGreenCo Book Abridged Version 2017sujaraghupsNessuna valutazione finora

- DC DCDocumento1 paginaDC DCsujaraghupsNessuna valutazione finora

- Duties CEEDocumento1 paginaDuties CEEsujaraghupsNessuna valutazione finora

- Limits Fits VIIISeDocumento18 pagineLimits Fits VIIISecprabhakaranNessuna valutazione finora

- OISD-STD-105 Revision - I September 2004 FOR RESTRICTED CIRCULATIONDocumento23 pagineOISD-STD-105 Revision - I September 2004 FOR RESTRICTED CIRCULATIONPraveen Kumar88% (8)

- General FAQDocumento2 pagineGeneral FAQsujaraghupsNessuna valutazione finora

- Tolerances, Limits, Fits and Surface FinishDocumento6 pagineTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Tolerances, Limits, Fits and Surface FinishDocumento6 pagineTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Roller Bearing Lubrication PDFDocumento70 pagineRoller Bearing Lubrication PDFsujaraghupsNessuna valutazione finora

- AMO certificate holder record keeping requirementsDocumento6 pagineAMO certificate holder record keeping requirementsMunir DirgantaraNessuna valutazione finora

- General Motor Relearn ProceduresDocumento8 pagineGeneral Motor Relearn Procedurescherokewag86% (7)

- Drill Jumbo Product GuideDocumento6 pagineDrill Jumbo Product GuidejiaozhongxingNessuna valutazione finora

- Pro Forma Invoice: To Invoice Number VAT Number Issued Due FromDocumento2 paginePro Forma Invoice: To Invoice Number VAT Number Issued Due FromPaulNessuna valutazione finora

- ST6C740Documento238 pagineST6C740Ermilo LopezNessuna valutazione finora

- 2.5 Ton Diesel Forklift SpecificationDocumento2 pagine2.5 Ton Diesel Forklift SpecificationFrank HigueraNessuna valutazione finora

- VW Tiguan 2 Propshaft Rear Final Drive EngDocumento87 pagineVW Tiguan 2 Propshaft Rear Final Drive Engjose reirizNessuna valutazione finora

- Prueba y Ajuste de Valvula de PrioridadDocumento6 paginePrueba y Ajuste de Valvula de PrioridadHenry MonteagudoNessuna valutazione finora

- Ta RulesDocumento25 pagineTa RulesMohit JoonNessuna valutazione finora

- Maruti Suzuki India LTD (MSIL) : Presented byDocumento22 pagineMaruti Suzuki India LTD (MSIL) : Presented byAvnit kumarNessuna valutazione finora

- VSP Glow Plug CatalogueDocumento60 pagineVSP Glow Plug CatalogueMMM-MMM100% (1)

- Toyota New Pricelist (9 Nov 2023) - UpdatedDocumento2 pagineToyota New Pricelist (9 Nov 2023) - Updatedmingwei72Nessuna valutazione finora

- Sc18 Brochure en DataDocumento4 pagineSc18 Brochure en DataMarketing ChiarottotalNessuna valutazione finora

- Features of your vehicle controlsDocumento1 paginaFeatures of your vehicle controlsIlyas DZNessuna valutazione finora

- DoppelmayrDocumento21 pagineDoppelmayrGretchen BurnsNessuna valutazione finora

- Accessory DrivesDocumento2 pagineAccessory Drivesbassumudhol100% (1)

- 2.0 Engine Mechanical System - General InformationDocumento16 pagine2.0 Engine Mechanical System - General InformationstevoxNessuna valutazione finora

- Alluxindo Pratama Sukses Mining Equipment ListDocumento1 paginaAlluxindo Pratama Sukses Mining Equipment ListArdi dutaNessuna valutazione finora

- Brake System Uniform Inspection GuidelinesDocumento33 pagineBrake System Uniform Inspection GuidelinesAlmaNessuna valutazione finora

- Bobcat E45 Spec Sheet 1Documento2 pagineBobcat E45 Spec Sheet 1Ainur Bamol NamsembilanNessuna valutazione finora

- Engine faults, causes and remedies chartDocumento1 paginaEngine faults, causes and remedies chartPabsepulvNessuna valutazione finora

- Automatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElDocumento186 pagineAutomatic Transaxle and Transfer Workshop Manual Aw6A-El Aw6Ax-ElVIDAL ALEJANDRO GARCIAVARGAS100% (1)

- YTE Suspension Installation MaintenanceDocumento16 pagineYTE Suspension Installation MaintenanceRam OscNessuna valutazione finora

- I20 Key Features Technical Specifications: DimensionsDocumento4 pagineI20 Key Features Technical Specifications: Dimensionsvaibhavsaini88Nessuna valutazione finora

- 113 Ijmperdjun2019113Documento12 pagine113 Ijmperdjun2019113TJPRC PublicationsNessuna valutazione finora

- Honda Civic PDFDocumento643 pagineHonda Civic PDFYckah YckahNessuna valutazione finora

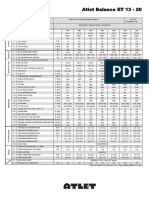

- Atlet Balance ET 13 - 20: OthersDocumento2 pagineAtlet Balance ET 13 - 20: OthersXb ZNessuna valutazione finora

- Fuel System DiagnosisDocumento34 pagineFuel System DiagnosisAhmed AbazaNessuna valutazione finora

- Transport Listening AnswersDocumento4 pagineTransport Listening Answersapi-114502624Nessuna valutazione finora