Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Internal Audit Report Format For Health & Safety

Caricato da

ansariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Internal Audit Report Format For Health & Safety

Caricato da

ansariCopyright:

Formati disponibili

INTERNAL AUDIT REPORT

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

10/31/2013 [Type the company name] pc

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

TABLE OF CONTENTS

1.0. 2.0. 3.0. 4.0. 5.0. 6.0. 7.0.

INTRODUCTION OF COMPANY EXECUTIVE SUMMARY SCOPE, FOCUS AND OBJECTIVES INTRODUCTION OF ASSESSMENT HAZARD IDENTIFICATION LIST OF IDENTIFIED HIGH RISK AREAS DETERMINING CONTROLS & RECOMMENDATIONS

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

1.0. INTRODUCTION OF COMPANY:

Name and Address of Company Telephone E-mail Year of Establishment Sole Proprietor Joint Venture Multinational Limited Liability Company Other (Please Specify) Fax Website

Ownership

Physical Location Type of Activity Sector Size of the Facility Industrial Process Used Production / Service Capacity Market Total No. of Employees Company Highlights Contact Person (Name & Designation) Name H&S Team members Leader: Designation Section Current Full Capacity Export % Local % Outsourced Others Small Medium Large Manufacturing Service Other (Please Specify)

Export Direct (Permanent)

Local Direct (Casual) Direct (Contract)

Mix

2.0. EXECUTIVE SUMMARY:

Company: Service Provided: OHS Assessment / OHS Management System Consultant: Assessment Dates: Region: North / South Report Submission Date:

Identified Measures of OHS Assessment

Identified / Suggested Measures (Control Measures) Identified Hazard and Associated Risk Likelihood Severity of 1-5 Occurrence 1-5 Total Impact (Severity x Likelihood) Identified Associated Cost Savings (Million PKR per annum) Responsibe Investment Implementation Pay Back Person Required Timelines Period from (Million (Target Dates) (Months) Company PKR) Linked Key Performance Category Indicator * (Mention title only)

Sr. #

1 2 3 4 5

Total

3.0. SCOPE, FOCUS AND OBJECTIVES

3.1.

Scope:

Complete supply Chain with in the boundary of company (includes Production, quality / inspection lab, raw material store, finish goods store, etc.)

3.2.

Focus:

The focus of one day assessment based on the standard OHSAS 18001:2007 clause 4.3.1 (Hazard identification, risk assessment and determining controls) to ensure better understanding on available hazards at the company, its associated risk and to determine control of No/Low cost for the betterment of Health & Safety Management of the company.

3.3.

Objectives:

The assessment has following objectives; Continuation of learning & training on OHSAS 18001:2007 standard Initiation of Health & Safety Management System at company Identification of hazards & Risk assessment Identify immediate and permanent Control measures against identified high risk hazards Improve overall Health & Safety Management system of company

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

4.0. INTRODUCTION OF ASSESSMENT:

This Hazard identification & Risk assessment program is designed to review the practical implementation of health and safety arrangements in the manufacturing companies. Using the severity and probability criteria defined below, the risk factors has been introduced onto a Risk Matrix based on RISK = PROBABILITY X SEVERITY. The same formula will follow for calculating the risk of all identified observations / hazards against the listed questionnaire of hazards which corresponded answer is No. Remedial actions are necessary on high risk observations for the improvement of Health & Safety Management of company. S = Criteria for evaluating the Severity Category / Personnel Illness/ Injury Descriptive Word 5 CATASTROPHIC 4 CRITICAL 3 SIGNIFICANT Death

Severe injury or severe occupational illness >2 Week hospitalization Major injury or major occupational illness <2 Week hospitalization Minor injury or minor occupational illness No hospitalization Day case First Aid No injury or illness

2 MARGINAL

1 NEGLIGIBLE

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

P = Criteria for evaluating the Probability PROBABILITY Level 5 4 3 2 1 Descriptive word FREQUENT PROBABLE OCCASIONAL REMOTE IMPROBABLE Definition Likely to occur repeatedly in system life cycle Likely to occur several times in system life cycle Likely to occur sometime in system life cycle Remote occurrence during system life cycle. It can be assumed physically impossible to occur

R = Risk Matrix

5

5 4 3 2 1 10 8 6 4 2 15 12 9 6 2 20 16 12 8 4 25 20 15 10 5

Probability

4 3 2 1 1

2 3 Severity

Legend 20 >10& 20 >5 & 10 >5 E: Extreme risk - immediate action required H: High risk - urgent management attention needed M: Medium risk - management attention as soon as possible L: Low risk - longer term action may be required

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.0. HAZARD IDENTIFICATION:

5.1.

5.1.1. 5.1.2.

GENERAL WORK ENVIRONMENT

Are all worksites clean and orderly? (No, 9 = 3 X 3 ) Are work surfaces kept dry or appropriate means taken to assure the surfaces are slip-resistant? Are all spilled materials or liquids cleaned up immediately? (Yes) 5.1.3. Is combustible scrap, debris and waste stored safely and removed from the worksite promptly? 5.1.4. Is combustible dust cleaned up with a vacuum system to prevent the dust going into suspension? 5.1.5. Are pits and floor openings covered or otherwise guarded?

5.2.

5.2.1.

PERSONAL PROTECTIVE EQUIPMENT

Are protective goggles or face shields provided and worn where there is any danger of flying particles or corrosive materials? 5.2.2. Are approved safety glasses required to be worn at all times in areas where there is a risk of eye injuries such as punctures, abrasions, contusions or burns? 5.2.3. Is appropriate foot protection required where there is the risk of foot injuries from hot, corrosive, poisonous substances, falling objects, crushing or penetrating actions? 5.2.4. Are approved respirators provided for regular or emergency use where needed? Is all protective equipment maintained in a sanitary condition and ready for use? 5.2.5. Where special equipment is needed for electrical workers, is it available?

5.3.

5.3.1. 5.3.2.

WALKWAYS

Are aisles and passageways kept clear? Are aisles and walkways marked as appropriate? Are wet surfaces covered with non-slip materials?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.3.3.

Are holes in the floor, sidewalk or other walking surface repaired properly, covered or otherwise made safe? Is there safe clearance for walking in aisles where motorized or mechanical handling equipment is operating. Are spilled materials cleaned up immediately?

5.3.4.

Are materials or equipment stored in such a way that sharp projectiles will not interfere with the walkway? Are changes of direction or elevations readily identifiable?

5.3.5.

Are aisles or walkways that pass near moving or operating machinery, welding operations or similar operations arranged so employees will not be subjected to potential hazards?

5.4.

5.4.1.

FLOOR AND WALL STAIRWAYS

Are floor openings guarded by a cover, guardrail, or equivalent on all sides (except at entrance to stairways or ladders)? 5.4.2. 5.4.3. withstand a load of at least 200 pounds? Is the glass in windows, doors, glass walls that are subject to human impact, of sufficient thickness and type for the condition of use? 5.4.4. Are grates or similar type covers over floor openings such as floor drains, of such design that foot traffic or rolling equipment will not be affected by the grate spacing? 5.4.5. Are floor or wall openings in fire resistive construction provided with doors or covers compatible with the fire rating of the structure and provided with self-closing feature when appropriate?

5.5.

5.5.1.

STAIRS & STAIRWAYS

Are standard stair rails or handrails on all stairways having four or more risers? Are all stairways at least 22 inches wide? 5.5.2. 5.5.3. 5.5.4. Do stairs have at least a 6'6" overhead clearance? Do stairs angle no more than 50 and no less than 30 degrees? Do stairway handrails have a least 1-1/2 inches of clearance between the handrails and the wall or surface they are mounted on? 5.5.5. Are stairway handrails capable of withstanding a load of 200 pounds, applied in any direction?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.6.

5.6.1.

ELEVATED SURFACES

Are signs posted, when appropriate, showing the elevated surface load capacity? 5.6.2. Are surfaces elevated more than 30 inches above the floor or ground provided with standard guardrails? 5.6.3. Are all elevated surfaces (beneath which people or machinery could be exposed to falling objects) provided with standard 4-inch toeboards? 5.6.4. Is a permanent means of access and egress provided to elevated storage and work surfaces? Is required headroom provided where necessary? 5.6.5. Is material on elevated surfaces piled, stacked or racked in a manner to prevent it from tipping, falling, collapsing, rolling or spreading?

5.7.

5.7.1.

EXITING OR EGRESS

Are all exits marked with an exit sign and illuminated by a reliable light source? 5.7.2. Are the directions to exits, when not immediately apparent, marked with visible signs? 5.7.3. Are doors, passageways or stairways, that are neither exits nor access to exits and which could be mistaken for exits, appropriately marked "NOT AN EXIT", "TO BASEMENT", "STOREROOM", and the like? 5.7.4. 5.7.5. Are all exits kept free of obstructions? Is the number of exits from each floor of a building, and the number of exits from the building itself, appropriate for the building occupancy load?

5.8.

5.8.1.

HAND TOOLS & EQUIPMENT

Are all tools and equipment (both, company and employee-owned) used by employees at their workplace in good condition? 5.8.2. Are hand tools such as chisels, punches, which develop mushroomed heads during use, reconditioned or replaced as necessary? 5.8.3. Are broken or fractured handles on hammers, axes and similar equipment replaced promptly? Are worn or bent wrenches replaced regularly?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.8.4.

Are appropriate safety glasses, face shields, and similar equipment used while using hand tools or equipment that might produce flying materials or be subject to breakage?

5.8.5.

Is eye and face protection used when driving hardened or tempered spuds or nails?

5.9.

5.9.1.

MACHINE GUARDING

Is there a training program to instruct employees on safe methods of machine operation? 5.9.2. Is there adequate supervision to ensure that employees are following safe machine operating procedures? Is there a regular program of safety inspection of machinery and equipment? 5.9.3. 5.9.4. Is all machinery and equipment kept clean and properly maintained? Is sufficient clearance provided around and between machines to allow for safe operations, set up and servicing, material handling and waste removal? 5.9.5. Are machinery guards secure and so arranged that they do not offer a hazard in their use? 5.9.6. If special hand tools are used for placing and removing material, do they protect the operator's hands? 5.9.7. Are revolving drums, barrels, and containers required to be guarded by an enclosure that is interlocked with the drive mechanism, so that revolution cannot occur unless the guard enclosure is in place, so guarded?

5.10.

5.10.1.

COMPRESSORS & COMPRESSED AIR

Are compressors equipped with pressure relief valves, and pressure gauges?

5.10.2.

Are compressor air intakes installed and equipped to ensure that only clean uncontaminated air enters the compressor?

5.10.3. 5.10.4.

Are air filters installed on the compressor intake? Is the belt drive system totally enclosed to provide protection for the front, back, top, and sides? Is it strictly prohibited to direct compressed air towards a person?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.10.5.

Are employees prohibited from using highly compressed air for cleaning purposes?

5.10.6.

Is it prohibited to use compressed air to clean up or move combustible dust if such action could cause the dust to be suspended in the air and cause a fire or explosion hazard?

5.11.

5.11.1.

HOIST & AUXILIARY EQUIPMENT

Is each overhead electric hoist equipped with a limit device to stop the hook travel at its highest and lowest point of safe travel?

5.11.2.

Will each hoist automatically stop and hold any load up to 125 percent of its rated load, if its actuating force is removed?

5.11.3.

Are close-fitting guards or other suitable devices installed on hoist to assure hoist ropes will be maintained in the sheave groves?

5.11.4.

Are all hoist chains or ropes of sufficient length to handle the full range of movement for the application while still maintaining two full wraps on the drum at all times?

5.11.5.

Are only employees who have been trained in the proper use of hoists allowed to operate them?

5.12.

5.12.1. 5.12.2.

SPRAYING OPERATIONS

Is adequate ventilation assured before spray operations are started? Is mechanical ventilation provided when spraying operation is done in enclosed areas?

5.12.3. 5.12.4.

Is the electric drying apparatus properly grounded? Are lighting fixtures for spray booths located outside of the booth and the interior lighted through sealed clear panels?

5.12.5.

Are the electric motors for exhaust fans placed outside booths or ducts? Are belts and pulleys inside the booth fully enclosed?

5.12.6.

Do ducts have access doors to allow cleaning? Do all drying spaces have adequate ventilation?

5.13.

ENTERING CONFINED SPACES

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.13.1.

Are confined spaces thoroughly emptied of any corrosive or hazardous substances, such as acids or caustics, before entry?

5.13.2.

Before entry, are all lines to a confined space, containing inert, toxic, flammable, or corrosive materials valved off and blanked or disconnected and separated?

5.13.3.

Is the atmosphere inside the confined space frequently tested or continuously monitor during conduct of work?

5.13.4.

Is there an assigned safety standby employee outside of the confined space, whose sole responsibility is to watch the work in progress, sound an alarm if necessary, and render assistance?

5.13.5.

Is there an effective communication system in place whenever respiratory equipment is used and the employee in the confined space is out of sight of the standby person?

5.13.6.

Is approved respiratory equipment required if the atmosphere inside the confined space cannot be made acceptable?

5.13.7.

If employees will be using oxygen-consuming equipment such as salamanders, torches, furnaces, in a confined space, is sufficient air provided to assure combustion without reducing the oxygen concentration of the atmosphere below 19.5 percent by volume?

5.14.

5.14.1. 5.14.2.

ENVIRONMENTAL CONTROLS

Are all work areas properly illuminated? Are employees instructed in proper first aid and other emergency procedures?

5.14.3.

Are hazardous substances identified which may cause harm by inhalation, ingestion, skin absorption or contact?

5.14.4.

Is personal protective equipment provided, used and maintained wherever required?

5.14.5.

Are there written standard operating procedures for the selection and use of respirators where needed? Are restrooms and washrooms kept clean and sanitary?

5.14.6.

Is all water provided for drinking, washing, and cooking potable? Are all outlets for water not suitable for drinking clearly identified?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.14.7.

Are employees working on streets and roadways where they are exposed to the hazards of traffic, required to wear bright colored (traffic orange) warning vest?

5.15.

5.15.1.

FLAMMABLE & COMBUSTIBLE MATERIALS

Are combustible scrap, debris and waste materials (i.e. oily rags) stored in covered metal receptacles and removed from the worksite promptly?

5.15.2.

Is proper storage practiced to minimize the risk of fire including spontaneous combustion?

5.15.3.

Are approved containers and tanks used for the storage and handling of flammable and combustible liquids?

5.15.4.

Do storage rooms for flammable and combustible liquids have mechanical or gravity ventilation?

5.15.5.

Is liquefied petroleum gas stored, handled, and used in accordance with safe practices and standards? Are liquefied petroleum storage tanks guarded to prevent damage from vehicles?

5.15.6.

Are all solvent wastes and flammable liquids kept in fire-resistant covered containers until they are removed from the worksite?

5.15.7.

Are fuel gas cylinders and oxygen cylinders separated by distance, fire resistant barriers or other means while in storage?

5.15.8.

Are appropriate fire extinguishers mounted within 75 feet of outside areas containing flammable liquids, and within 10 feet of any inside storage area for such materials?

5.15.9.

Is the transfer/withdrawal of flammable or combustible liquids performed by trained personnel?

5.15.10. Are spare portable or butane tanks, which are sued by industrial trucks stored in accord with regulations?

5.16.

5.16.1. 5.16.2.

FIRE PROTECTION

Do you have a fire prevention plan? Does your plan describe the type of fire protection equipment and/or systems?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.16.3.

Have you established practices and procedures to control potential fire hazards and ignition sources? Are employees aware of the fire hazards of the material and processes to which they are exposed? Is your local fire department well acquainted with your facilities, location and specific hazards?

5.16.4. 5.16.5. 5.16.6.

If you have a fire alarm system, is it tested at least annually? Are fire extinguishers recharged regularly and noted on the inspection tag? Are employees periodically instructed in the use of extinguishers and fire protection procedures?

5.17.

5.17.1.

HAZARDOUS CHEMICAL EXPOSURES

Are employees trained in the safe handling practices of hazardous chemicals such as acids, caustics, and the like?

5.17.2.

Are employees aware of the potential hazards involving various chemicals stored or used in the workplace-- such as acids, bases, caustics, epoxies, and phenols?

5.17.3.

Have standard operating procedures been established and are they being followed when cleaning up chemical spills?

5.17.4.

Where needed for emergency use, are respirators stored in a convenient, clean and sanitary location?

5.17.5.

Are respirators intended for emergency use adequate for the various uses for which they may be needed? Are employees prohibited from eating in areas where hazardous chemicals are present?

5.17.6.

Is personal protective equipment provided, used and maintained whenever necessary?

5.17.7.

Are there written standard operating procedures for the selection and use of respirators where needed? If you have a respirator protection program, are your employees instructed on the correct usage and limitations of the respirators?

5.17.8.

Are materials, which give off toxic asphyxiant, suffocating or anesthetic fumes, stored in remote or isolated locations when not in use?

5.18.

HAZARDOUS SUBSTANCES COMMUNICATION

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.18.1. 5.18.2.

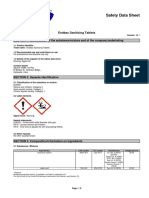

Is there a list of hazardous substances used in your workplace? Is there a written hazard communication program dealing with Material Safety Data Sheets (MSDS) labeling, and employee training?

5.18.3. 5.18.4.

Who is responsible for MSDSs, container labeling, employee training? Is each container for a hazardous substance (i.e. vats, bottles, storage tanks,) labeled with product identity and a hazard warning (communication of the specific health hazards and physical hazards)?

5.18.5.

Is there a Material Safety Data Sheet readily available for each hazardous substance used?

5.19.

5.19.1.

ELECTRICAL

Are your workplace electricians familiar with the Cal/OSHA Electrical Safety Orders? Do you specify compliance with Cal/OSHA for all contract electrical work?

5.19.2.

Are all employees required to report as soon as practicable any obvious hazard to life or property observed in connection with electrical equipment or lines?

5.19.3.

Are employees instructed to make preliminary inspections and/or appropriate tests to determine what conditions exist before starting work on electrical equipment or lines?

5.19.4.

When electrical equipment or lines are to be serviced, maintained or adjusted, are necessary switches opened, locked-out and tagged whenever possible?

5.19.5.

Is the use of metal ladders prohibited in area where the ladder or the person using the ladder could come in contact with energized parts of equipment, fixtures or circuit conductors?

5.19.6.

Are all disconnecting switches and circuit breakers labeled to indicate their use or equipment served? Are disconnecting means always opened before fuses are replaced?

5.19.7.

Do all interior wiring systems include provisions for grounding metal parts of electrical raceways, equipment and enclosures?

5.19.8.

Is each motor disconnecting switch or circuit breaker located within sight of the motor control device?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.20.

5.20.1.

NOISE

Are there areas in the workplace where continuous noise levels exceed 85 dBA? (To determine maximum allowable levels for intermittent or impact noise, see Title 8, Section 5097.)

5.20.2.

Is there an ongoing preventive health program to educate employees in safe levels of noise and exposure, effects of noise on their health, and use of personal protection?

5.20.3.

Is the training repeated annually for employees exposed to continuous noise above 85 dBA?

5.20.4.

Have work areas where noise levels make voice communication between employees difficult been identified and posted?

5.20.5.

Is approved hearing protective equipment (noise attenuating devices) available to every employee working in areas where continuous noise levels exceed 85 dBA?

5.21.

5.21.1.

IDENTIFICATION OF PIPING SYSTEMS

When non-portable water is piped through a facility, are outlets or taps posted to alert employees that it is unsafe and not to be used for drinking, washing or other personal use?

5.21.2.

When hazardous substances are transported through above ground piping, is each pipeline identified at points where confusion could introduce hazards to employees?

5.21.3.

When pipelines carrying hazardous substances are identified by tags, are the tags constructed of durable materials, the message carried clearly ad permanently distinguishable and are tags installed at each valve or outlet?

5.22.

5.22.1. 5.22.2.

MATERIAL HANDLING

Is there safe clearance for equipment through aisles and doorways? Are aisle ways designated, permanently marked, and kept clear to allow unhindered passage? Are motorized vehicles and mechanized equipment inspected daily or prior to use?

5.22.3.

Are vehicles shut off and brakes set prior to loading or unloading?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.22.4.

When hoisting material or equipment, are provisions made to assure no one will be passing under the suspended loads?

5.22.5.

Are Material Safety Data Sheets available to employees handling hazardous substances?

5.23.

CONTROL

OF

HARMFUL

SUBSTANCES

BY

VENTILATION

5.23.1. Is the volume and velocity of air in each exhaust system sufficient to gather the dusts, fumes, mists, vapors or gases to be controlled, and to convey them to a suitable point of disposal? 5.23.2. Are exhaust inlets, ducts and plenums designed, constructed, and supported to prevent collapse or failure of any part of the system? 5.23.3. Are clean-out ports or doors provided at intervals not to exceed 12 feet in all horizontal runs of exhaust ducts? 5.23.4. Where two or more different type of operations are being controlled through the same exhaust system, will the combination of substances being controlled, constitute a fire, explosion or chemical reaction hazard in the duct? 5.23.5. Where two or more ventilation systems are serving a work area, is their operation such that one will not offset the functions of the other?

5.24.

5.24.1.

SANITIZING EQUIPMENT & CLOTHING

Is personal protective clothing or equipment, that employees are required to wear or use, of a type capable of being easily cleaned and disinfected?

5.24.2.

Are employees prohibited from interchanging personal protective clothing or equipment, unless it has been properly cleaned?

5.24.3.

Are machines and equipment, which processes, handle or apply materials that could be injurious to employees, cleaned and/or decontaminated before being overhauled or placed in storage?

5.24.4.

Are employees prohibited from smoking or eating in any area where contaminates are present that could be injurious if ingested?

5.25.

EMERGENCY ACTION PLAN

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.25.1. 5.25.2. 5.25.3.

Are you required to have an emergency action plan? Does the emergency action plan comply with requirements of standard? Have emergency escape procedures and routes been developed and communicated to all employers? Do employees, who remain to operate critical plant operations before they evacuate, know the proper procedures?

5.25.4.

Is the employee alarm system that provides a warning for emergency action recognizable and perceptible above ambient conditions?

5.25.5.

For conducting rescue and medical duties?

5.26.

5.26.1.

VENTILATION FOR INDOOR AIR QUALITY

Does your HVAC system provide at least the quantity of outdoor air required by the State Building Standards Code, Title 24, Part 2 at the time the building was constructed?

5.26.2.

Is the HVAC system inspected at least annually, and problems corrected? Are inspection records retained for at least 5 years?

5.27.

5.27.1. 5.27.2.

HAZARD COMMUNICATION

Is there a list of hazardous substances used in your workplace? Is there a written hazard communication program dealing with Material Safety Data Sheets (MSDS), labeling, and employee training?

5.27.3.

Is each container for a hazardous substance (i.e., vats, bottles, storage tanks, etc.) labeled with product identity and a hazard warning (communication of the specific health hazards and physical hazards)?

5.27.4.

Is there a Material Safety Data Sheet readily available for each hazardous substance used?

5.27.5. 5.27.6. 5.27.7. 5.27.8. 5.27.9.

Is there an employee training program for hazardous substances? Does this program include? Are employees trained in the following: How to recognize tasks that might result in occupational exposure? How to use work practice and engineering controls and personal protective equipment and to know their limitations?

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

5.27.10. How to obtain information on the types selection, proper use, location, removal handling, decontamination, and disposal of personal protective equipment? 5.27.11. Who to contact and what to do in an emergency?

5.0. LIST OF IDENTIFIED HIGH RISK AREAS:

S# 1 2 3 4 5 6 7 8 9 10 Observations Risk Factor

6.0. DETERMINING CONTROLS & RECOMMENDATIONS:

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

1) High Risk Activity / point Type Immediate Solution Permanent solution

Elimination

Substitution

Engineering Controls

Signage, Administrative Controls

PPEs

2) High Risk Activity / point Type Immediate Solution Permanent solution

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

Elimination

Substitution

Engineering Controls

Signage, Administrative Controls

PPEs

3) High Risk Activity / point Type Immediate Solution Permanent solution

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

Elimination

Substitution

Engineering Controls

Signage, Administrative Controls

PPEs

4) High Risk Activity / point

Internal Audit Report of __________________________________

Hazard Identification, Risk Assessment and Control Measures for Health & Safety Management

Type

Immediate Solution

Permanent solution

Elimination

Substitution

Engineering Controls

Signage, Administrative Controls

PPEs

Potrebbero piacerti anche

- Health and Safety ReportDocumento8 pagineHealth and Safety ReportGregMckenzie100% (1)

- 2010 Safety ManualDocumento290 pagine2010 Safety ManualPaul Januario G. RostrataNessuna valutazione finora

- OHSMS Manual DartDocumento29 pagineOHSMS Manual DartSyed Qaisar ImamNessuna valutazione finora

- A-ONE TECHNIQUES Safety Calendar 2012Documento1 paginaA-ONE TECHNIQUES Safety Calendar 2012Anonymous 5F2C52vNessuna valutazione finora

- Induction For VisitorsDocumento15 pagineInduction For VisitorsHSE UPANessuna valutazione finora

- Workplace InspectionDocumento11 pagineWorkplace Inspection123alNessuna valutazione finora

- HRM Job Discription of A CompanyDocumento4 pagineHRM Job Discription of A Companyaddy52Nessuna valutazione finora

- CONTROL SHEETS & FORMS permit guideDocumento3 pagineCONTROL SHEETS & FORMS permit guideHenry WoartNessuna valutazione finora

- Director Environmental Health Safety EHS in Philadelphia PA Resume Akhil BuchDocumento3 pagineDirector Environmental Health Safety EHS in Philadelphia PA Resume Akhil BuchAkhilBuchNessuna valutazione finora

- Hsebooks CatalogueDocumento32 pagineHsebooks CatalogueVikas YamagarNessuna valutazione finora

- Behavioral Based Safety & Safety LeadershipDocumento3 pagineBehavioral Based Safety & Safety Leadership360 International Limited50% (2)

- Health and Safety Improvement ProgramDocumento11 pagineHealth and Safety Improvement ProgramEng Muhammad MarzoukNessuna valutazione finora

- 9+ Year HSE Advisor Seeking New OpportunityDocumento4 pagine9+ Year HSE Advisor Seeking New OpportunityKhan SaabNessuna valutazione finora

- HealthSafety Booklet PDFDocumento29 pagineHealthSafety Booklet PDFAnonymous VQaagfrQINessuna valutazione finora

- Riddor: Health and Safety Advice For StonemasonsDocumento12 pagineRiddor: Health and Safety Advice For StonemasonsMohammed IlliasuddinNessuna valutazione finora

- July SMR RevDocumento2 pagineJuly SMR RevShyam SadanandanNessuna valutazione finora

- Training Needs AssessmentDocumento5 pagineTraining Needs AssessmentahmadNessuna valutazione finora

- KBR It It Sti InstructionsDocumento2 pagineKBR It It Sti InstructionsbotahraNessuna valutazione finora

- Safety Leadership Survey key factorsDocumento4 pagineSafety Leadership Survey key factorslooking99Nessuna valutazione finora

- 01 - Aramco Exam & Interview QuestionsDocumento4 pagine01 - Aramco Exam & Interview QuestionsChen XinNessuna valutazione finora

- HSEQ Questionaire For Contractor EvaluationDocumento6 pagineHSEQ Questionaire For Contractor EvaluationNasih Tr100% (1)

- On-Site Emergency Plan and Reporting FlowchartDocumento4 pagineOn-Site Emergency Plan and Reporting FlowchartMd Nurul IslamNessuna valutazione finora

- Health and Safety Rules and Regulations 2012 PDFDocumento54 pagineHealth and Safety Rules and Regulations 2012 PDFBranislavVorgic100% (1)

- Behavior Based SafetyDocumento6 pagineBehavior Based Safetyapi-313899066Nessuna valutazione finora

- Safety Results LTD CRSP Practice Questions Series Two Dec 2015Documento22 pagineSafety Results LTD CRSP Practice Questions Series Two Dec 2015NeeleshSoganiNessuna valutazione finora

- Safety Observation FormDocumento1 paginaSafety Observation FormMahmoud MahdyNessuna valutazione finora

- RDOS Safety Audit Executive SummaryDocumento4 pagineRDOS Safety Audit Executive SummaryJoe FriesNessuna valutazione finora

- Power Tools - Montly HSE Inspection ChecklistDocumento3 paginePower Tools - Montly HSE Inspection ChecklistphitoNessuna valutazione finora

- HSE Management System ArenscoDocumento22 pagineHSE Management System ArenscoJaber AmariNessuna valutazione finora

- Safety TrainingDocumento6 pagineSafety Trainingsvpriya233282Nessuna valutazione finora

- 9.0 - Workplace Wellness v3.0 EnglishDocumento10 pagine9.0 - Workplace Wellness v3.0 EnglishVi VekNessuna valutazione finora

- EHS Audit ChecklistDocumento6 pagineEHS Audit ChecklistVIJAY BHARATENessuna valutazione finora

- Toolbox TalksDocumento1 paginaToolbox TalksMohammad Abubakar SiddiqNessuna valutazione finora

- Incident-sharing-and-Statistics-Standard-10.2018 OPALDocumento28 pagineIncident-sharing-and-Statistics-Standard-10.2018 OPALSHRISH SHUKLA100% (1)

- Hse Severe Weather Checklist and Guidance DocumentDocumento46 pagineHse Severe Weather Checklist and Guidance DocumentSaddem Hadfi100% (1)

- SC Workers' Welfare Standards (Edition 1)Documento50 pagineSC Workers' Welfare Standards (Edition 1)shabina921Nessuna valutazione finora

- Safe System Of Work A Complete Guide - 2020 EditionDa EverandSafe System Of Work A Complete Guide - 2020 EditionNessuna valutazione finora

- Health Requirements for Labour AccommodationsDocumento7 pagineHealth Requirements for Labour Accommodationsdemie figueroaNessuna valutazione finora

- Benzoxe N - Ghs Msds Template Safety Data SheetDocumento5 pagineBenzoxe N - Ghs Msds Template Safety Data Sheetelpangjaya jayNessuna valutazione finora

- Consulting Workers On Health and SafetyDocumento77 pagineConsulting Workers On Health and SafetyMurat AnlıNessuna valutazione finora

- Workers' Participation in ManagementDocumento37 pagineWorkers' Participation in ManagementPiyush ParmarNessuna valutazione finora

- Ergonomics Manual ToolsDocumento4 pagineErgonomics Manual ToolsZeeshan Bajwa100% (1)

- F-025-Power Tool Inspection ChecklistDocumento2 pagineF-025-Power Tool Inspection ChecklistAbdus SamadNessuna valutazione finora

- Final - PSM - Incident InvestigationDocumento29 pagineFinal - PSM - Incident InvestigationSimon TounsiNessuna valutazione finora

- Nebosh Diploma FlyerDocumento5 pagineNebosh Diploma Flyerhsecouncil100% (1)

- International Diploma Unit 3 Supplementary Guidance Sept 2017Documento6 pagineInternational Diploma Unit 3 Supplementary Guidance Sept 2017raj KumarNessuna valutazione finora

- Bloodborn Pathogen ProgramDocumento22 pagineBloodborn Pathogen Programsitimaezyaroh100% (1)

- Guide To Accident/Incident Investigations: (Including A Sample Investigation Form)Documento6 pagineGuide To Accident/Incident Investigations: (Including A Sample Investigation Form)forosapoNessuna valutazione finora

- Fire Safety ChecklistDocumento13 pagineFire Safety ChecklistPampa DasNessuna valutazione finora

- Form O - CPD Record - WF - V3.0 EnglishDocumento5 pagineForm O - CPD Record - WF - V3.0 EnglishsasaNessuna valutazione finora

- Weekly HSE Performance ReportDocumento2 pagineWeekly HSE Performance ReportBorislav VulićNessuna valutazione finora

- Ladder Safety Tips <40Documento2 pagineLadder Safety Tips <40Ange JuanNessuna valutazione finora

- Hardrock Mining and Beneficiation Environmental Management System GuideDocumento51 pagineHardrock Mining and Beneficiation Environmental Management System GuidenationalminingNessuna valutazione finora

- IS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements SummaryDocumento9 pagineIS0 9001 - 2008 OHSAS 18001 and ISO 14001 Requirements Summaryジェイ センニュリンNessuna valutazione finora

- Workplace Inspection ChecklistDocumento5 pagineWorkplace Inspection ChecklistVepxvia NadiradzeNessuna valutazione finora

- Toolbox Talks Pneumatic Tools EnglishDocumento1 paginaToolbox Talks Pneumatic Tools EnglishebbasinghNessuna valutazione finora

- Safety Induction TrainingDocumento62 pagineSafety Induction TrainingshoaibNessuna valutazione finora

- LRQA Safety Leadership Programme BrochureDocumento12 pagineLRQA Safety Leadership Programme BrochureVishal B. ChavanNessuna valutazione finora

- Step-By-Step Risk ManagementDocumento25 pagineStep-By-Step Risk ManagementansariNessuna valutazione finora

- The Complete Guide to Simple OEE MeasurementDocumento26 pagineThe Complete Guide to Simple OEE MeasurementWan Sek Choon100% (2)

- UntitledDocumento2 pagineUntitledansariNessuna valutazione finora

- How To Design A Best Plant LayoutDocumento3 pagineHow To Design A Best Plant LayoutansariNessuna valutazione finora

- H12G-01 Polypropylene Homopolymer: Typical PropertiesDocumento2 pagineH12G-01 Polypropylene Homopolymer: Typical PropertiesortizmauricioNessuna valutazione finora

- Safety Data Sheet: 1. IdentificationDocumento8 pagineSafety Data Sheet: 1. IdentificationWork ForceNessuna valutazione finora

- Blue Shield 4-5 MSDSDocumento7 pagineBlue Shield 4-5 MSDSsalcabesNessuna valutazione finora

- WCC - Colmonoy 88, 88M, 88HV, 88DJ, 88PTA SDS 9-2019Documento5 pagineWCC - Colmonoy 88, 88M, 88HV, 88DJ, 88PTA SDS 9-2019Himansu MohapatraNessuna valutazione finora

- Super Stainless Polish SDSDocumento6 pagineSuper Stainless Polish SDSjummakhan jummakhanNessuna valutazione finora

- Lesson 1: Pest Management Basics: What Are Pesticides?Documento16 pagineLesson 1: Pest Management Basics: What Are Pesticides?Juday CautiverNessuna valutazione finora

- Oxivir Plus SDS SheetsDocumento5 pagineOxivir Plus SDS SheetsSteven LeeNessuna valutazione finora

- SDS Kalmatron KF-ADocumento5 pagineSDS Kalmatron KF-AHelen A. RusinoffNessuna valutazione finora

- SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocumento16 pagineSECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingSehry SyedNessuna valutazione finora

- Sustainability at Jubilant Life Sciences LimitedDocumento13 pagineSustainability at Jubilant Life Sciences Limitedsourav84Nessuna valutazione finora

- MSDS Carbon Fiber Sheet PDFDocumento6 pagineMSDS Carbon Fiber Sheet PDFiran1362Nessuna valutazione finora

- Work Place Safety Pocket GuideDocumento50 pagineWork Place Safety Pocket GuideGajanan R Ghatage100% (1)

- Interspeed 640Documento4 pagineInterspeed 640Stefano CostaNessuna valutazione finora

- Hydrex 7111Documento7 pagineHydrex 7111Abdulrzzak AlturkmaniNessuna valutazione finora

- SDS - Carbon Dioxide, Dry IceDocumento10 pagineSDS - Carbon Dioxide, Dry IceSangamesh MNessuna valutazione finora

- MSDS JNL-1241Documento5 pagineMSDS JNL-1241Sagu Lempeng100% (1)

- 763 Rust Transformer PDFDocumento7 pagine763 Rust Transformer PDFricardoamarillaNessuna valutazione finora

- MsdsDocumento5 pagineMsdsLukman Nul HakimNessuna valutazione finora

- MSDS TDS PDFDocumento3 pagineMSDS TDS PDFArdhy LazuardyNessuna valutazione finora

- FDS Tecnoflon® For 7353Documento14 pagineFDS Tecnoflon® For 7353ALEXANDRENessuna valutazione finora

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocumento8 pagineSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingJainil PanchalNessuna valutazione finora

- MSDS 43310Documento2 pagineMSDS 43310Elias100% (1)

- Isomol 500 Exp V01Documento9 pagineIsomol 500 Exp V01Marco OlivoNessuna valutazione finora

- 1-Butanol Anhyd PDFDocumento8 pagine1-Butanol Anhyd PDFDiana AmpulembangNessuna valutazione finora

- Jotun Resist 86Documento5 pagineJotun Resist 86Ansar AliNessuna valutazione finora

- Safety Data Sheet for PolystyreneDocumento3 pagineSafety Data Sheet for PolystyreneMatt AngNessuna valutazione finora

- Xylene GB PDFDocumento69 pagineXylene GB PDFbacabacabacaNessuna valutazione finora

- Off The JobDocumento17 pagineOff The Jobjonesa asisNessuna valutazione finora

- Material Safety Data Sheet Surfa Activator D (Long)Documento3 pagineMaterial Safety Data Sheet Surfa Activator D (Long)Fabrication PMCNessuna valutazione finora

- Identification of Preparation: Mixture of Polymers, Fillers, Cement and Additives. BlendDocumento4 pagineIdentification of Preparation: Mixture of Polymers, Fillers, Cement and Additives. Blendsoliman fathyNessuna valutazione finora