Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SWP-10 Loading & Unloading Using Lorry & Mobile Crane Daiman

Caricato da

Hassan AbdullahCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SWP-10 Loading & Unloading Using Lorry & Mobile Crane Daiman

Caricato da

Hassan AbdullahCopyright:

Formati disponibili

Ryobi Kiso (S) Pte Ltd

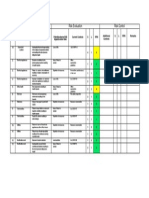

Safe Work Practices (SWP) Loading/Unloading/Stacking Material by Lorry or Mobile Crane Procedures check for minimum requirements (Please tick):

SWP-10

Permit-to-Work Procedure in place where applicable Logout/ Tag out !stem where applicable PP" requirements "mergenc! #esponse Plan("#P)

$efore materials are being stacked% first ensure that the ground where the materials will be placed is le&el and firm% strong enough to withstand the load of both stacks and machiner!% be well consolidated and its stabilit! should not be affected b! weather conditions such as hea&! rain' (ood drainage should be pro&ided' )lear an! obstacles or unused materials from the stacking area as the! ma! make stacks unstable' *n an indoor en&ironment% the ma+imum height of the stack should not be more than four times the shortest width of the materials ( i'e' a ratio of ,:-) .or outside en&ironment% the ration should be reduced to /:-' $efore un stacking% e+amine the stack for signs of instabilit! or faults tack should not lean against or be supported b! other stacks Take steps to e+clude people from all areas at risk from falling material 0rrange storage areas to gi&e good &isibilit! for pedestrians and &ehicles' tacks of materials should not be placed too close to each other' 0llow a distance between them for safe retrie&al' Pedestrians should use designated walkwa!s% segregated from &ehicles where possible% and be e+cluded from acti&e stacking areas' tacking areas should ha&e adequate lighting 1ri&e !our truck at a safe and reasonable speed (-2kph)' Take special care dri&ing on wet or oil! surfaces and/or in congested areas' #oadwa!s or aisles should be clearl! defined and strong enough to withstand the weight of loaded &ehicles' tack condition should be regularl! monitored b! adequatel! trained staff who can identif! stack faults 3elmets% glo&es and safet! footwear will normall! be required to protect emplo!ees% as well as appreciate clothing for outside working' 3igh &isibilit! clothing is required where there are frequent &ehicle mo&ements 1uring transportation or mo&ement of materials% etc' it is essential that the o&erall height should not e+ceed -'4m (or abo&e the e!e le&el of the one pushing the materials% whiche&er is more applicable for a clear &iew of the direction of tra&el' 0lwa!s gi&e wa! to others and do not sound the horn unnecessaril! e+cept to warn others of the approaching traffic% and at e+its and turning corners' "nsure that !our path of tra&el is kept clear' low down and stop when approaching blind corners or doorwa!s' (o head onl! when the wa! is clear' "nsure that the o&erhead or height clearances are sufficient'

Page 1 of 2

Ryobi Kiso (S) Pte Ltd

SWP-10

When dri&ing% keep the forks at about 5 inches abo&e the ground' 6e&er o&erload a material handling equipment 7 know its safe working load' 6e&er use a material handling equipment as a &ertical access for personnel' *t should not be used to carr! passengers either' 8aterial-handling equipment should not be parked along passagewa!s or near e+its' The! should not be left unattended without neutralising the controls% setting the brakes% shutting off the power% remo&ing the ignition ke!% and lowering the forks to its lowest possible position' 9nl! authorised personnel are allowed to operate material-handling equipment' $efore operating an! material-handling equipment% check: 9&erhead guard is in-place to protect operator from falling ob:ects .orks are properl! secured and aligned T!res ha&e correct pressure% threaded% and in good ser&iceable condition teering wheel has correct control o&er the direction of tra&el "nsure batter! water is at the correct le&el "ffecti&e brake and lift controls "ffecti&e horn and flashing (warning) beacon #eport an! defects to !our super&isor immediatel!' 1o not use the equipment until the defects ha&e been rectified'

Lifting uper&isor to inspect all lifting gear prior to slinging on to the lifting blocks and hooks' $riefing b! safet! super&isor to all personnel in&ol&ed on the sequence of acti&it!' Loading and unloading equipment b! lorr! crane or mobile crane' #emo&e all loose items on top the machiner! before hoisting 0ttached tag line to loads before commence of lifting' Lifting operations are not to be carried out during ad&erse weather' Position% fasten and install all lifting gear at designated positions b! riggers' 0ll personnel must be cleared from the top of the load prior to lifting' 6o personnel must be under the suspended load or within the &icinit! during hoisting' $arricaded area of operation with warning sign' Lorr! crane or mobile crane to minimi;e lifting eccentricit! and coordinate mo&ement of rigger and maintain signaller &isual path with lorr! crane operator' 0&oid hast! mo&ement to minimi;e accident' Position load o&er the designated position and lowered it'

Prepared $!: 8r 1aiman 1esignation: W 39 1ate: -, <une 42-2

#e&iewed $!: 8r 6g )hoon 3uat 1esignation: enior Pro:ect 8anager 1ate: -, <une 42-2

Page 2 of 2

Potrebbero piacerti anche

- SOPDocumento8 pagineSOPAilyn MercadoNessuna valutazione finora

- Sop LiftingDocumento5 pagineSop LiftingShaiful AnnuarNessuna valutazione finora

- Jha Crane OperationsDocumento2 pagineJha Crane OperationsJaycee Bareng Pagador100% (1)

- Appendix A-Job Safety Analysis FormDocumento3 pagineAppendix A-Job Safety Analysis Formjiks_i4uNessuna valutazione finora

- JSA DrillingDocumento4 pagineJSA DrillingAmalNessuna valutazione finora

- Asian Paints - Prem Gloss EnamelDocumento1 paginaAsian Paints - Prem Gloss EnamelwilliumstNessuna valutazione finora

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Documento6 pagineJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNessuna valutazione finora

- Boom Lift PDFDocumento2 pagineBoom Lift PDFcityofdarwingisNessuna valutazione finora

- SWP-03 Electrical Safety DaimanDocumento4 pagineSWP-03 Electrical Safety DaimanHassan AbdullahNessuna valutazione finora

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocumento13 pagineJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezNessuna valutazione finora

- Sop of ScaffoldingDocumento3 pagineSop of ScaffoldingSanjeet Singh100% (1)

- JSA of Charging UnitDocumento3 pagineJSA of Charging UnitMuhammad AliNessuna valutazione finora

- Job Safety & Environment Analysis: Revision NoDocumento3 pagineJob Safety & Environment Analysis: Revision NonishanthNessuna valutazione finora

- JSA PRE-TEST UploadDocumento2 pagineJSA PRE-TEST UploadDenny Kurniawan PrawiraNessuna valutazione finora

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocumento2 pagineNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNessuna valutazione finora

- Building De-Dusting JSADocumento3 pagineBuilding De-Dusting JSAJayesh J PillaiNessuna valutazione finora

- Mig Welding JSADocumento2 pagineMig Welding JSANoval Febri100% (1)

- Lifting Plan V - 409 18ins Con ValDocumento9 pagineLifting Plan V - 409 18ins Con ValAhmed Butt100% (1)

- Job Safety Analysis: How To Use This FormDocumento4 pagineJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Jsa n2 Purging PDF FreeDocumento1 paginaJsa n2 Purging PDF FreeSKH CultureNessuna valutazione finora

- Job Safety Analysis WorksheetDocumento7 pagineJob Safety Analysis WorksheetMohamedSaidNessuna valutazione finora

- Lock Out Tag Out SafetyDocumento2 pagineLock Out Tag Out SafetyAhmed IbrahimNessuna valutazione finora

- 024 - Mobile Scaffold Inspection ChecklistDocumento1 pagina024 - Mobile Scaffold Inspection ChecklistFaiez AripiNessuna valutazione finora

- HSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesDocumento1 paginaHSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesKyaw MinNessuna valutazione finora

- Work at Height Safety AnalysisDocumento2 pagineWork at Height Safety AnalysiszebmechNessuna valutazione finora

- SWP-20 Usage of Ladder DaimanDocumento1 paginaSWP-20 Usage of Ladder DaimanHassan AbdullahNessuna valutazione finora

- Jsa For The Installation of I EamDocumento5 pagineJsa For The Installation of I EamMohammed MinhajNessuna valutazione finora

- Job Safety Analysis (JSA) - Night Work DateDocumento2 pagineJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- Concrete Mixer Safety ChecklistDocumento1 paginaConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- Breaker Machine Safety ChecklistDocumento1 paginaBreaker Machine Safety ChecklistNair R RakeshNessuna valutazione finora

- Lifting Hoisting Hazard HuntDocumento1 paginaLifting Hoisting Hazard Hunt曹庆园100% (1)

- Tower Cranes CommisioningDocumento15 pagineTower Cranes Commisioningpammu18Nessuna valutazione finora

- JHA Jack Hydraulic PalletDocumento1 paginaJHA Jack Hydraulic PalletIndranil Mitra100% (1)

- JSA - Crane Setuppdf PDFDocumento12 pagineJSA - Crane Setuppdf PDFChoko ChokriNessuna valutazione finora

- JSA For New EmployeesDocumento20 pagineJSA For New EmployeesNilayNessuna valutazione finora

- JSA Lifting With Equipment+Load ChartDocumento13 pagineJSA Lifting With Equipment+Load ChartBoas BoetarzNessuna valutazione finora

- Updated JSA For SAPMTofficeDocumento30 pagineUpdated JSA For SAPMTofficeShaikh Abu bakarNessuna valutazione finora

- 28.1.1 Mobile Equipment Inspection ChecklistDocumento1 pagina28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNessuna valutazione finora

- Jsa Bearing Replacement-OverhaulingDocumento2 pagineJsa Bearing Replacement-Overhaulingashish engineeringNessuna valutazione finora

- Rigging JSA RiggerDocumento12 pagineRigging JSA RiggeraQiLGunawanNessuna valutazione finora

- JSA NO 3-Pile CapDocumento8 pagineJSA NO 3-Pile Capknabpsho50% (2)

- Genie E Series Slab Scissor Lift Operation PDFDocumento11 pagineGenie E Series Slab Scissor Lift Operation PDFRajesh gpNessuna valutazione finora

- Standard Operating ProcedureDocumento55 pagineStandard Operating Procedureboy tryadi100% (1)

- Schedule For Inspection Nov 19Documento1 paginaSchedule For Inspection Nov 19Siddharth RanaNessuna valutazione finora

- OH&S Monthly Activity PlanDocumento1 paginaOH&S Monthly Activity PlanBhagat Deepak100% (1)

- JHA For Work PermitDocumento1 paginaJHA For Work PermitShahid RazaNessuna valutazione finora

- PTW JHA Prayer Garment Hanging Rack InstallationDocumento2 paginePTW JHA Prayer Garment Hanging Rack InstallationPHH9834Nessuna valutazione finora

- Working at Height Rescue Plan: WHS-FM-008Documento2 pagineWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoNessuna valutazione finora

- Part 3 ObservationsDocumento7 paginePart 3 ObservationsAmjadNessuna valutazione finora

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Documento3 pagineJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNessuna valutazione finora

- ISC-JSA Grouting Works For Shared FenceDocumento4 pagineISC-JSA Grouting Works For Shared FenceSameer AlmahboubNessuna valutazione finora

- F - SAF - 25 - Fall Protection Plan - Review - 23Documento7 pagineF - SAF - 25 - Fall Protection Plan - Review - 23Annie BosmanNessuna valutazione finora

- Suspended From Man-Rider (Vertical Rescue Plan)Documento1 paginaSuspended From Man-Rider (Vertical Rescue Plan)Paul100% (1)

- Job Hazard AnalysisDocumento3 pagineJob Hazard AnalysisBrain Dee Tech LtdNessuna valutazione finora

- 10 Questions For Line of FireDocumento2 pagine10 Questions For Line of FireGary Moses100% (1)

- Radiography JSADocumento2 pagineRadiography JSAVipul ShankarNessuna valutazione finora

- JOB SAFETY ANALYSIS FOR HOT SPLICING BELT REPLACEMENTDocumento8 pagineJOB SAFETY ANALYSIS FOR HOT SPLICING BELT REPLACEMENTPed KapedNessuna valutazione finora

- HSE guidance on safety devices for rapid roller doorsDocumento11 pagineHSE guidance on safety devices for rapid roller doorsmsc920138Nessuna valutazione finora

- Appointment of Lifting RiggermanDocumento2 pagineAppointment of Lifting RiggermanHassan AbdullahNessuna valutazione finora

- Appointment of Contractor WelderDocumento1 paginaAppointment of Contractor WelderHassan Abdullah0% (1)

- Ryobi Kiso appointment letterDocumento1 paginaRyobi Kiso appointment letterHassan AbdullahNessuna valutazione finora

- Environmental Risk Assessment MatrixDocumento1 paginaEnvironmental Risk Assessment MatrixHassan Abdullah100% (1)

- EOHSMS-02-C27 LOA Explosive Power Tool UserDocumento1 paginaEOHSMS-02-C27 LOA Explosive Power Tool UserHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C22 LOA Lifting SupervisorDocumento3 pagineEOHSMS-02-C22 LOA Lifting SupervisorHassan Abdullah100% (1)

- Appointment Letter SignalmanDocumento1 paginaAppointment Letter SignalmanHassan AbdullahNessuna valutazione finora

- Appointment Of Contractor Confined Space AssessorDocumento2 pagineAppointment Of Contractor Confined Space AssessorHassan Abdullah100% (1)

- Eohsms-02-C25 Loa First AiderDocumento1 paginaEohsms-02-C25 Loa First AiderHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C14 - RV 0 Air Receiver & Compressor ChecklistDocumento1 paginaEOHSMS-02-C14 - RV 0 Air Receiver & Compressor ChecklistHassan AbdullahNessuna valutazione finora

- Eohsms-02-C21 Loa Crane OperatorDocumento2 pagineEohsms-02-C21 Loa Crane OperatorHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C20 LOA Scaffold SupervisorDocumento1 paginaEOHSMS-02-C20 LOA Scaffold SupervisorHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C19 LOA Scaffold ErectorDocumento1 paginaEOHSMS-02-C19 LOA Scaffold ErectorHassan AbdullahNessuna valutazione finora

- Ryobi Kiso appointment letter WSH coordinatorDocumento2 pagineRyobi Kiso appointment letter WSH coordinatorHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C16 - RV 0 Monthly Concrete Breaker Inspection FormDocumento1 paginaEOHSMS-02-C16 - RV 0 Monthly Concrete Breaker Inspection FormHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C17 - RV 0 Ladder Inspection FormDocumento1 paginaEOHSMS-02-C17 - RV 0 Ladder Inspection FormHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C15 - RV 0 Monthly Electrical Equipment Tools Inspection ChecklistDocumento1 paginaEOHSMS-02-C15 - RV 0 Monthly Electrical Equipment Tools Inspection ChecklistHassan AbdullahNessuna valutazione finora

- Crane Pre-Inspection FormDocumento2 pagineCrane Pre-Inspection FormHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C13 - RV 0 Air Receiver Compressor Pre InspectionDocumento1 paginaEOHSMS-02-C13 - RV 0 Air Receiver Compressor Pre InspectionHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C10 - RV 0 Electric Welding Inspection ChecklistDocumento1 paginaEOHSMS-02-C10 - RV 0 Electric Welding Inspection ChecklistHassan AbdullahNessuna valutazione finora

- Ryobi Gas Cutting Tool ChecklistDocumento1 paginaRyobi Gas Cutting Tool ChecklistHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C12 - RV 0 Monthly Fire Extinguisher ChecklistDocumento1 paginaEOHSMS-02-C12 - RV 0 Monthly Fire Extinguisher ChecklistHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C07 - RV 0 Monthly Lifting Gear Inspection FormDocumento1 paginaEOHSMS-02-C07 - RV 0 Monthly Lifting Gear Inspection FormHassan Abdullah100% (2)

- EOHSMS-02-C09 - RV 0 Pre Inspection Generator - Welding ChecklistDocumento2 pagineEOHSMS-02-C09 - RV 0 Pre Inspection Generator - Welding ChecklistHassan AbdullahNessuna valutazione finora

- Mobile & Lorry Crane Checklist Form: Ryobi Kiso (S) Pte LTDDocumento1 paginaMobile & Lorry Crane Checklist Form: Ryobi Kiso (S) Pte LTDHassan AbdullahNessuna valutazione finora

- Static pile load test using kentledge stackDocumento2 pagineStatic pile load test using kentledge stackHassan Abdullah100% (1)

- EOHSMS-02-C08 - RV 0 Lifting Supervisor ChecklistDocumento2 pagineEOHSMS-02-C08 - RV 0 Lifting Supervisor ChecklistHassan Abdullah100% (1)

- EOHSMS-02-C04 - RV 0 Test Pile Operation ChecklistDocumento1 paginaEOHSMS-02-C04 - RV 0 Test Pile Operation ChecklistHassan AbdullahNessuna valutazione finora

- EOHSMS-02-C02 - RV 0 Excavator ChecklistDocumento3 pagineEOHSMS-02-C02 - RV 0 Excavator ChecklistHassan AbdullahNessuna valutazione finora

- Ryobi Piling Rig Checklist EOHSMS-02-C03Documento1 paginaRyobi Piling Rig Checklist EOHSMS-02-C03Hassan AbdullahNessuna valutazione finora

- Vehicle Dynamics of A Solar Racing CarDocumento20 pagineVehicle Dynamics of A Solar Racing CarVikas KumarNessuna valutazione finora

- Speed Hump Request ProcedureDocumento19 pagineSpeed Hump Request ProcedureEnis Eryılmaz100% (1)

- 15 Causes of Delays During Construction Phase of Road ProjectsDocumento11 pagine15 Causes of Delays During Construction Phase of Road Projectsemer_quezon100% (1)

- Arch. Specs PDFDocumento342 pagineArch. Specs PDFRania SaiedNessuna valutazione finora

- F3000 CFDDocumento2 pagineF3000 CFDPao SantanaNessuna valutazione finora

- JB Larkin Bus Terminal, Johor Bahru Terminal 1 Seremban, SerembanDocumento2 pagineJB Larkin Bus Terminal, Johor Bahru Terminal 1 Seremban, SerembanSugedan SanthiranNessuna valutazione finora

- Course Outline: CIV216 Highway EngineeringDocumento8 pagineCourse Outline: CIV216 Highway EngineeringMital DamaniNessuna valutazione finora

- Considerations For Highway Planning and Design Highway Geometric DesignDocumento13 pagineConsiderations For Highway Planning and Design Highway Geometric DesignJosh TuraiNessuna valutazione finora

- The Obituaries - : Wake Keeping & Poetry NightsDocumento9 pagineThe Obituaries - : Wake Keeping & Poetry NightsAmma BiragoNessuna valutazione finora

- Corporate Properties Study Benton Harbor/St. Joseph Part IIDocumento112 pagineCorporate Properties Study Benton Harbor/St. Joseph Part IIProtectJKPNessuna valutazione finora

- Ili Department of Public Works and Highways: - 097 13'Dpwh 10 20 202Fj.Documento2 pagineIli Department of Public Works and Highways: - 097 13'Dpwh 10 20 202Fj.Dyeri FloresNessuna valutazione finora

- Bus Rapid Transit SystemDocumento118 pagineBus Rapid Transit SystemHareesh ManchikantiNessuna valutazione finora

- TGA 33 480 6x4 BBSDocumento4 pagineTGA 33 480 6x4 BBSricardo_santos_280Nessuna valutazione finora

- Ankadeli Top To Ankadeli DownDocumento651 pagineAnkadeli Top To Ankadeli DownArabinda sahuNessuna valutazione finora

- Azzurro Aug PetroserveDocumento1 paginaAzzurro Aug PetroserveKalpesh MistryNessuna valutazione finora

- Gate Booking TokenDocumento1 paginaGate Booking Tokenlea anggitaNessuna valutazione finora

- ColregDocumento6 pagineColregCarl Joshua BallesterosNessuna valutazione finora

- TVS Motor Company Introduces 2 New, Exciting Colours For TVS WEGO (Company Update)Documento5 pagineTVS Motor Company Introduces 2 New, Exciting Colours For TVS WEGO (Company Update)Shyam SunderNessuna valutazione finora

- Furnishing of aggregates for access road projectDocumento192 pagineFurnishing of aggregates for access road projectArnold LundayNessuna valutazione finora

- HONDA PCX125-21-OWNERS ManualDocumento171 pagineHONDA PCX125-21-OWNERS Manualmitros_karamitrosNessuna valutazione finora

- Site Inventory ChecklistDocumento5 pagineSite Inventory ChecklistZianne CalubNessuna valutazione finora

- Harris v. City of St. Louis PetitionDocumento14 pagineHarris v. City of St. Louis PetitionMarianne MartinezNessuna valutazione finora

- Jaipur TTDocumento6 pagineJaipur TTDevansh Pratap SinghNessuna valutazione finora

- Truck Suspension Past Generation Products: AR 34K AR 38K HN 40K - 46K HN /HNT 40K - 46KDocumento26 pagineTruck Suspension Past Generation Products: AR 34K AR 38K HN 40K - 46K HN /HNT 40K - 46Kgustavoemosquera5093Nessuna valutazione finora

- Mash Manual 2016Documento283 pagineMash Manual 2016paiboontNessuna valutazione finora

- Az Tourist News - May 2009Documento32 pagineAz Tourist News - May 2009Tony Venuti100% (1)

- Location of Chassis and Engine NumbersDocumento9 pagineLocation of Chassis and Engine NumbersWilliam Cj LyngdohNessuna valutazione finora

- Reduce London Commute Times Through Public TransportDocumento10 pagineReduce London Commute Times Through Public TransportLana BawanehNessuna valutazione finora

- Biomechanics of Side Impact: Injury Criteria, Aging Occupants, and Airbag TechnologyDocumento17 pagineBiomechanics of Side Impact: Injury Criteria, Aging Occupants, and Airbag TechnologyStefanita CiunelNessuna valutazione finora

- Slewing Gearboxes-Dinamic OilDocumento12 pagineSlewing Gearboxes-Dinamic OiltonyNessuna valutazione finora

- The Inimitable Jeeves [Classic Tales Edition]Da EverandThe Inimitable Jeeves [Classic Tales Edition]Valutazione: 5 su 5 stelle5/5 (3)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherDa EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherNessuna valutazione finora

- Other People's Dirt: A Housecleaner's Curious AdventuresDa EverandOther People's Dirt: A Housecleaner's Curious AdventuresValutazione: 3.5 su 5 stelle3.5/5 (104)

- The Importance of Being Earnest: Classic Tales EditionDa EverandThe Importance of Being Earnest: Classic Tales EditionValutazione: 4.5 su 5 stelle4.5/5 (43)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedDa EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedValutazione: 4.5 su 5 stelle4.5/5 (5)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticDa EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticValutazione: 3.5 su 5 stelle3.5/5 (10)

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtDa EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtValutazione: 4 su 5 stelle4/5 (60)

- Lessons from Tara: Life Advice from the World's Most Brilliant DogDa EverandLessons from Tara: Life Advice from the World's Most Brilliant DogValutazione: 4.5 su 5 stelle4.5/5 (42)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesDa EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesValutazione: 3.5 su 5 stelle3.5/5 (7)

- The Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverDa EverandThe Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverValutazione: 3.5 su 5 stelle3.5/5 (4)

- 100 Bible Verses Everyone Should Know by HeartDa Everand100 Bible Verses Everyone Should Know by HeartValutazione: 4.5 su 5 stelle4.5/5 (20)

- Humorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreDa EverandHumorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreNessuna valutazione finora

- Tidy the F*ck Up: The American Art of Organizing Your Sh*tDa EverandTidy the F*ck Up: The American Art of Organizing Your Sh*tValutazione: 4.5 su 5 stelle4.5/5 (99)

- The Comedians in Cars Getting Coffee BookDa EverandThe Comedians in Cars Getting Coffee BookValutazione: 4.5 su 5 stelle4.5/5 (8)

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)