Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Program Name: CE's APQP and Product Launch System (APLS)

Caricato da

Janaka MangalaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Program Name: CE's APQP and Product Launch System (APLS)

Caricato da

Janaka MangalaCopyright:

Formati disponibili

2008.09.

11 11:14

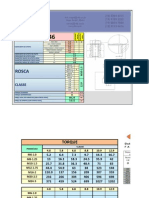

PHASE 3 - TOOL BUILD RFQ

Document Type: Document No: APLS CE-1201027-FM Rev. Date: 05.aug.04 Rev. Level: 9

CE's APQP and Product Launch System (APLS)

Program Name

Product & Machine Information

Part Name

Faceplate

Texture Type

see below

Machine Tonnage Mach. Manufacturer Machine Type

Customer No. of Cavities

1-cav

Texture Supplier Plastic Resin Type

PC-ABS

MOLD TYPE

Prototype

MOLD CONSTRUCTION

X

Standard Three Plate Reverse Ejection Modular Stack Cavities Inserted In Solid Cores A Plate B Plate

STEEL TYPE

P-20 P-20

X Production X Injection Mold

Blow Mold Rotational Mold Other Est. Mold Base: Length: Width: Height:

Cavities Cores Side Actions Other

e.g. P-20, P-20 HH, 4140, stainless steel H-13, S-7, Aluminum, BeCu, Ampco

EJECTION

SH

COOLING

MH Blocks

SIDE ACTIONS

Qty

Mechanical Slides Hydraulic Slides Hydraulic Cylinders Cam Pins Air Cylinder Spring Loaded Hand Load

X Standard

Reverse Hydraulic Mechanical Ejector Pins Ejector Blades Ejector Sleeves Lifters Strippers 2 Stage Ejection Air Poppets Guided Ejection Spring Loaded Cover Assist Ejection Accelerated Ejection Early Returns Other Notes: Notes:

Mold Base Slides Inserts Lifters Core Pins Clamp Plates Stripper Plates Thermal Pins Baffles Bubblers Rotating Water Junction Other

Lifters Other

Notes: Faceplate-assume 3 lifters

2008.09.11 11:14

Program Name

GATING

SH

PLATING

MH Nitriding Electrodes Ni Chrome Polyond Armoloy XADC Other Specify Plated Area(s) In Cavity:

SPECIAL FEATURES

Qty:

Cold Sprue Center Cold Sprue Offset Hot Drop Manifold Valve Gate

X X

Date Codes Shift Codes Material ID Floating Plates Transducers PL Locks Switches Engraving

Subgate Edge Gate Cashew Gate Direct Gated Other

X X X

QMC Plates Cycle Counter Mold Samples Gate Inserts Cavity Shut-Off

Number of Gates (Drops): Manifold Manufacturer: Manifold Series: Color Changes:

X

X

Water Manifolds Lift Lug

FINISHES

SH A1 - Grade #3 Diamond Buff A2 - Grade #6 Diamond Buff A3 - Grade #15 Diamond Buff B1 - 600 Grit Paper B2 - 400 Grit Paper B3 - 320 Grit Paper C1 - 600 Stone C2 - 400 Stone C3 - 320 Stone D1 - Dry Blast Glass bead #11 D2 - Dry Blast #240 Oxide D3 - Dry Blast #24 Oxide Other Special Instructions and Comments: MH

THREADS

Auto-Unscrewing (Rack) Auto-Unscrewing (Motor) Hand Loads extra sets Line of Draw Out of Draw Expanding Hasco Other

PROCESS FEATURES

Gas Assist In-Mold Decorating Insert Molding Two-Shot

GENERAL INFO

No. of Samples: Build Timing (wks): Data Release Date: Tool Certification: Quote Number: Job Number: yes 1

Quote cold sprue/runner to subgate into tab (1 per cav) Quote optional 1 drop (1 per cav) pneumatic valve gate hot-half from Incoe (include installation) Quote seperately #3 Ford Stipple Quote line item for QMC Plates, Lift Lug and Water manifolds

Notes: 1) All quotes submitted must be based off of Cascade Engineering's Tool Build Standards. Any deviation from our Tool Build Standards must be authorized and documented by the Project Tool Engineer. 2) All 2-D and 3-D Tool Data Is Property of Cascad

Send quotes to: Phone No.: FAX No.: E-Mail:

Kevin Bull 616-254-4214 616-975-4717 bullk@cascadeng.com

Date Sent: Submit Quotes By:

2005.07.19 2005.07.22

Potrebbero piacerti anche

- Form Tooling List Approval Tooling (002) Rev 4Documento3 pagineForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNessuna valutazione finora

- Tool Steel - Material Selection Guide: High Speed SteelsDocumento1 paginaTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNessuna valutazione finora

- Injection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedDocumento4 pagineInjection Molded Plastic Part Cost Estimator: Design Organizatio Date Part EvaluatedTiago CerqueiraNessuna valutazione finora

- SMALL CHANGE FORMDocumento2 pagineSMALL CHANGE FORMchibugirlNessuna valutazione finora

- Autocar Ppap Requirements Rev 5Documento17 pagineAutocar Ppap Requirements Rev 5man hoNessuna valutazione finora

- DPMTDocumento41 pagineDPMTNirmal HaardNessuna valutazione finora

- CTM Mold Design Standards PDFDocumento43 pagineCTM Mold Design Standards PDFDini ViruNessuna valutazione finora

- 03 - SIPOC Diagram - 2009-06-11Documento1 pagina03 - SIPOC Diagram - 2009-06-11Anand RajaNessuna valutazione finora

- TL 211 enDocumento19 pagineTL 211 enCarlos AraujoNessuna valutazione finora

- Mold Spec Guidelines Jun 08revisedDocumento27 pagineMold Spec Guidelines Jun 08revisedDirk HenningNessuna valutazione finora

- Injection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Documento1 paginaInjection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Jake Floyd G. FabianNessuna valutazione finora

- IATF16949+Chapter+21 +Automotive+Core+ToolsDocumento18 pagineIATF16949+Chapter+21 +Automotive+Core+ToolsNhựt Nguyễn HữuNessuna valutazione finora

- Process FMEA for Farm Equipment SectorDocumento1 paginaProcess FMEA for Farm Equipment SectorBALACHANDAR SNessuna valutazione finora

- Fulfill Instructions Quotation Analysis FormDocumento5 pagineFulfill Instructions Quotation Analysis FormAnonymous VRspXsmNessuna valutazione finora

- Development Procedure 16-08-2021Documento6 pagineDevelopment Procedure 16-08-2021CompdevpNessuna valutazione finora

- Sptech Tooling GuideDocumento25 pagineSptech Tooling GuideKa Wing LeeNessuna valutazione finora

- PPAP Process Checklist / Sign Off Sheet InstructionsDocumento7 paginePPAP Process Checklist / Sign Off Sheet InstructionsSharmad TamhaneNessuna valutazione finora

- Product Design and DevelopmentDocumento13 pagineProduct Design and DevelopmentGeorgiana BusuiocNessuna valutazione finora

- Mold Bases & Plates Catalog 2020 DECDocumento292 pagineMold Bases & Plates Catalog 2020 DECShinichi SuzukiNessuna valutazione finora

- Introduction to Product Planning and DevelopmentDocumento20 pagineIntroduction to Product Planning and DevelopmentSu-ho HanNessuna valutazione finora

- Injctmld F03Documento2 pagineInjctmld F03prasad_kcpNessuna valutazione finora

- Inj Mold CalculateDocumento9 pagineInj Mold CalculateGiap NguyenNessuna valutazione finora

- Tata Motors Ltd.Documento44 pagineTata Motors Ltd.Arjun BhardwajNessuna valutazione finora

- Mammut Industries Trailer Design ProcessDocumento9 pagineMammut Industries Trailer Design ProcessvinothNessuna valutazione finora

- Development Processes and Organizational StructuresDocumento51 pagineDevelopment Processes and Organizational StructuresCHANDHRIKKA RNessuna valutazione finora

- MB 219-229 PDFDocumento11 pagineMB 219-229 PDFAmitava DattaNessuna valutazione finora

- Performance Appraisal Form AnalysisDocumento5 paginePerformance Appraisal Form AnalysisShami KantNessuna valutazione finora

- D10369520ADocumento4 pagineD10369520AQUALITY ControlNessuna valutazione finora

- Scorpio - N - Accessories Catalogue - Rev - 1.9Documento70 pagineScorpio - N - Accessories Catalogue - Rev - 1.9Kunal GuptaNessuna valutazione finora

- PT Vs SOP 17 Tooling RepairDocumento7 paginePT Vs SOP 17 Tooling RepairRidwanNessuna valutazione finora

- Injection Mould Component Cost EstimationDocumento7 pagineInjection Mould Component Cost EstimationVenkateswaran venkateswaranNessuna valutazione finora

- MOULD MAINTENANCE GUIDEDocumento40 pagineMOULD MAINTENANCE GUIDEprashanthNessuna valutazione finora

- Moulding TroubleshootingDocumento22 pagineMoulding TroubleshootingPiousPatialaNessuna valutazione finora

- Lifter SliderDocumento119 pagineLifter SliderTejas MahadikNessuna valutazione finora

- CAR 5 User GuideDocumento34 pagineCAR 5 User GuideChandrajeet ShelkeNessuna valutazione finora

- Mold SpecificationDocumento1 paginaMold SpecificationVictor Villouta LunaNessuna valutazione finora

- Trouble Shooting Injection Molding ProcessDocumento16 pagineTrouble Shooting Injection Molding ProcessKaya Eralp AsanNessuna valutazione finora

- 007 Oper. Control - Injection Molding MachineDocumento6 pagine007 Oper. Control - Injection Molding MachineRobert UlatanNessuna valutazione finora

- Developing A Project Scope For An Injection MoldDocumento3 pagineDeveloping A Project Scope For An Injection MoldnadoNessuna valutazione finora

- Mold ChecklistDocumento5 pagineMold ChecklistSelvaraj BalasundramNessuna valutazione finora

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocumento2 pagineNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNessuna valutazione finora

- GM 1927-16b Injection Molding Process AuditDocumento6 pagineGM 1927-16b Injection Molding Process AuditfernandoNessuna valutazione finora

- Rev 12Documento2 pagineRev 12api-273257329Nessuna valutazione finora

- Ampco Mold Design GuidelinesDocumento39 pagineAmpco Mold Design GuidelinesNaukowyDrpNessuna valutazione finora

- Minsa Trial Report Molde SC194Documento2 pagineMinsa Trial Report Molde SC194daniel ortiz fuentesNessuna valutazione finora

- APQP FormDocumento103 pagineAPQP FormJERFSON AUGUSTONessuna valutazione finora

- Design Guide For RIM Reaction Injection Molded Plastic PartsDocumento28 pagineDesign Guide For RIM Reaction Injection Molded Plastic Partsl_gasztoNessuna valutazione finora

- Basic Gating and Runner DesignDocumento66 pagineBasic Gating and Runner DesignRockfort HarshaNessuna valutazione finora

- Technical Specification MatrixDocumento1 paginaTechnical Specification MatrixPriyaprasad PandaNessuna valutazione finora

- Injection Molding LabDocumento2 pagineInjection Molding LabZulhusni Abdul JamanNessuna valutazione finora

- Injection Molding Cost CalculatorDocumento111 pagineInjection Molding Cost CalculatorvenkithankamNessuna valutazione finora

- Rust and Paint Peel Off Issue 8D ReportDocumento1 paginaRust and Paint Peel Off Issue 8D ReportLorenzo CarmeniNessuna valutazione finora

- TL 52622 en 07-2012Documento12 pagineTL 52622 en 07-2012Juan Carlos Jaramillo LariosNessuna valutazione finora

- FLC ProcessDocumento20 pagineFLC ProcesswtwilightwNessuna valutazione finora

- Mold Cost EstimationDocumento5 pagineMold Cost EstimationPenjahit TedyNessuna valutazione finora

- Supplier Cost Increase1Documento3 pagineSupplier Cost Increase1prasad_kcpNessuna valutazione finora

- Part Approval File Checklist Mandatory Documents For All PartsDocumento2 paginePart Approval File Checklist Mandatory Documents For All Partssumit_saraf_5Nessuna valutazione finora

- DFX Design For X A Complete Guide - 2020 EditionDa EverandDFX Design For X A Complete Guide - 2020 EditionNessuna valutazione finora

- Assembly Process A Complete Guide - 2020 EditionDa EverandAssembly Process A Complete Guide - 2020 EditionNessuna valutazione finora

- Summary, Conclusions and RecommendationsDocumento3 pagineSummary, Conclusions and RecommendationsJanaka MangalaNessuna valutazione finora

- SPI Tooling SpecificationsDocumento3 pagineSPI Tooling SpecificationsJanaka MangalaNessuna valutazione finora

- Aiac 11Documento55 pagineAiac 11Janaka MangalaNessuna valutazione finora

- Dupont Design GuideDocumento136 pagineDupont Design Guidemarcelo_atomoNessuna valutazione finora

- Drilling and Tapping ABSDocumento1 paginaDrilling and Tapping ABSJanaka MangalaNessuna valutazione finora

- Endo Morphology ChartDocumento1 paginaEndo Morphology ChartJanaka MangalaNessuna valutazione finora

- Insight and Synerg Readme FirstDocumento2 pagineInsight and Synerg Readme FirstJanaka MangalaNessuna valutazione finora

- Ban Ki-moon Welcome Speech Promotes Good GovernanceDocumento5 pagineBan Ki-moon Welcome Speech Promotes Good GovernanceChirasree DasguptaNessuna valutazione finora

- Dos&DontsDocumento1 paginaDos&DontsJanaka MangalaNessuna valutazione finora

- Class Demo GCode EditedDocumento5 pagineClass Demo GCode EditedJanaka MangalaNessuna valutazione finora

- DCP Leaflet 2011Documento2 pagineDCP Leaflet 2011Janaka MangalaNessuna valutazione finora

- DCP Leaflet 2011Documento2 pagineDCP Leaflet 2011Janaka MangalaNessuna valutazione finora

- Design and Manufacturing of Injection MoldDocumento30 pagineDesign and Manufacturing of Injection Moldandresromero80Nessuna valutazione finora

- 11Documento10 pagine11Janaka MangalaNessuna valutazione finora

- Nymax 1200 Processing GuideDocumento4 pagineNymax 1200 Processing GuideJanaka MangalaNessuna valutazione finora

- Steel ChartDocumento5 pagineSteel ChartTommie PrinslooNessuna valutazione finora

- Tsxgmp330pwk English v2.2Documento40 pagineTsxgmp330pwk English v2.2Janaka MangalaNessuna valutazione finora

- 7962 CAD Assignments 1Documento1 pagina7962 CAD Assignments 1Janaka MangalaNessuna valutazione finora

- Software ManualDocumento0 pagineSoftware ManualJanaka MangalaNessuna valutazione finora

- LC Technology TG Nov2006Documento29 pagineLC Technology TG Nov2006Janaka MangalaNessuna valutazione finora

- Instructions How To Use A Milling MachineDocumento58 pagineInstructions How To Use A Milling MachineEng-Ramy El-MorsyNessuna valutazione finora

- New Text DocumentDocumento3 pagineNew Text DocumentJanaka MangalaNessuna valutazione finora

- Injection MoldingDocumento8 pagineInjection MoldingDebasmiti MishraNessuna valutazione finora

- Fit and TolerancesDocumento15 pagineFit and TolerancesRajasekaran Vt100% (1)

- Ami Molding WindowDocumento14 pagineAmi Molding WindowJanaka Mangala100% (1)

- Expert PET Processing Guidance & TestingDocumento1 paginaExpert PET Processing Guidance & TestingJanaka MangalaNessuna valutazione finora

- Copper AlloysDocumento1 paginaCopper AlloysJanaka MangalaNessuna valutazione finora

- Basic Injection Molding Conversions and CalculationsDocumento1 paginaBasic Injection Molding Conversions and CalculationsJanaka MangalaNessuna valutazione finora

- Summary, Conclusions and RecommendationsDocumento3 pagineSummary, Conclusions and RecommendationsJanaka MangalaNessuna valutazione finora

- Goodreach Wilcox Weld 9781631263286 - ch11Documento30 pagineGoodreach Wilcox Weld 9781631263286 - ch11Anonymous nw5AXJqjdNessuna valutazione finora

- A Study of Low Young's Modulus Ti-Nb-Zr Alloys Using D ElectronsDocumento4 pagineA Study of Low Young's Modulus Ti-Nb-Zr Alloys Using D ElectronsCrescencio RodríguezNessuna valutazione finora

- Din 3357Documento7 pagineDin 3357sheik MohammedNessuna valutazione finora

- Arcelormittal A514 and T-1Documento6 pagineArcelormittal A514 and T-1Hugo RodriguezNessuna valutazione finora

- AntiSegregation HopperDocumento5 pagineAntiSegregation Hoppermecaunidos7771Nessuna valutazione finora

- Copper RecyclingDocumento47 pagineCopper Recyclingalberto_barrosoNessuna valutazione finora

- CameronDocumento4 pagineCameronhermon_agustio0% (1)

- Catalog VaneDocumento16 pagineCatalog VanehbcbmwtuningNessuna valutazione finora

- Bending (Metalworking)Documento7 pagineBending (Metalworking)semizxxxNessuna valutazione finora

- Pengenalan Material Dan MetalurgiDocumento3 paginePengenalan Material Dan MetalurgiMugi MaulaNessuna valutazione finora

- Chemistry AssignmentDocumento10 pagineChemistry AssignmentGurupungav NarayananNessuna valutazione finora

- Materials Guideline Update: Preliminary Survey ResultsDocumento44 pagineMaterials Guideline Update: Preliminary Survey ResultsmrinalkantibhaduriNessuna valutazione finora

- 6 Different Types of Electrical ConduitsDocumento2 pagine6 Different Types of Electrical Conduitskash30Nessuna valutazione finora

- Vanessa Basic Datasheet-Valves PDFDocumento10 pagineVanessa Basic Datasheet-Valves PDFGogyNessuna valutazione finora

- Civil - Ele SpecificationDocumento283 pagineCivil - Ele SpecificationTATATAHERNessuna valutazione finora

- Symbol Equations You Need To Be Familiar WithDocumento3 pagineSymbol Equations You Need To Be Familiar WithKamrul Alam MasumNessuna valutazione finora

- Arc Welding Electrodes (Product Catalogue)Documento28 pagineArc Welding Electrodes (Product Catalogue)ddprt123Nessuna valutazione finora

- PEM Economy Gauge 1Documento5 paginePEM Economy Gauge 1kprasannanNessuna valutazione finora

- b51 Gabions 403Documento6 pagineb51 Gabions 403Bachtiar Ali AfandiNessuna valutazione finora

- Torque and clamp load calculation for M10 boltsDocumento4 pagineTorque and clamp load calculation for M10 boltsmajonas77Nessuna valutazione finora

- Mechanical Properties and Seawater Behavior of Nitronic 50Documento38 pagineMechanical Properties and Seawater Behavior of Nitronic 50wrowletNessuna valutazione finora

- Why Solder Bumps WrinkleDocumento3 pagineWhy Solder Bumps WrinklepeleniusNessuna valutazione finora

- PEB Steel Alliance Ltd. Offers State-of-the-Art Steel Building SolutionsDocumento26 paginePEB Steel Alliance Ltd. Offers State-of-the-Art Steel Building SolutionsAbdul MaminNessuna valutazione finora

- Corrosion Solved ProblemsDocumento39 pagineCorrosion Solved Problemshanna1100% (4)

- D5-2 Prepainted Galvanized Galvalume Steel Coils With Protective Plastic FilmDocumento2 pagineD5-2 Prepainted Galvanized Galvalume Steel Coils With Protective Plastic FilmFernandoCrespoMonNessuna valutazione finora

- Experimental Analysis and Mechanical Characterisation of A356 Alloy Metal Matrix With Alumina Oxide&GraphiteDocumento20 pagineExperimental Analysis and Mechanical Characterisation of A356 Alloy Metal Matrix With Alumina Oxide&Graphitesathishvoc92Nessuna valutazione finora

- Floor Deck Profile TS 47/180: Product Data SheetDocumento3 pagineFloor Deck Profile TS 47/180: Product Data SheetMohamed KareemNessuna valutazione finora

- Astm G192.17156Documento10 pagineAstm G192.17156Christian Olave100% (3)

- Valve Body Bolt Temp Rating For ValvesDocumento4 pagineValve Body Bolt Temp Rating For ValvesVinothkumarNessuna valutazione finora

- EdDocumento1 paginaEdpandirajaNessuna valutazione finora