Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pile Design 2 Pilegroup

Caricato da

Varad SonawadekarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pile Design 2 Pilegroup

Caricato da

Varad SonawadekarCopyright:

Formati disponibili

DESIGN OF PILE POUNDATION 2 PILE GROUP PARAMETERS: DIAMETER OF PILE (D) = DEPTH OF PILE (D1) = NUMBER OF PILE (N)

= GRADE OF CONCRETE (Fck) = GRADE OF STEEL (Fy) = DEPTH OF PILE CAP (D2) = PILE SPACING FACTOR (K) = SPACING OF PILE (K*D] =SP. EDGE DISTANCE TO THE PILE (ED) = TOTAL LENGTH OF PILE CAP [(K+1)*D+300] = TOTAL WIDTH OF PILE CAP (B) = AREA OF EACH PILE (A) = SELF WEIGHT OF PILE CAP = SOCKETING DEPTH OF PILE (D3) = SELF WEIGHT OF PILE = STRUCTURAL CAPACITY : PERCENTAGE OF STEEL = ULTIMATE CAPACITY (0.4*Fck*Ac+0.67*Fy*Asc) = PARTIAL SAFTY FACTOR ( f ) = SERVICE LOAD = ANALYSIS RESULTS : DEAD LOAD+LIVE LOAD MAXIMUM AXIAL LOAD ON PILE (DL+LL) = Fy/2+(Mx+Fx*D2)/SP. MINIMUM AXIAL LOAD ON PILE (DL+LL) = Fy/2-(Mx+Fx*D2)/SP 1 103.72 1.5 69.15 % MT 350 10 2 20 415 700 2.5 875 150 1525 650 96211.5 1.73 525 2.41 mm Mtrs No's N/mm2 mm2 mm mm mm mm mm mm2 MT mm MT X ##

Z 1525 X

UNITS : METER, MTON Fx Fy 5 150

Fz 5 84.71 65.29

Mx 5 MT MT

My 10

Mz 15

DESIGN FORCES & MOMENTS @ TOP OF PILE DEPTH OF FIXITY: IS 2911(PART 1/SEC2) 1987 UNDER TABLE-1 APPENDIX "C"

Fx 2.5

Fy 85.58

Fz 2.5

TYPE OF SOIL

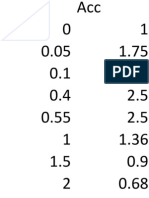

TABLE-1 TYPICAL VALUES OF "K1" (kg/cm2) DRY 0.26 0.775 2.076 -

SUBMERGED 0.146 0.526 1.245 0.041 200 kg/cm^2 254558.44 kg/cm^2 73671.309 cm^4 kg/cm^2

LOOSE SAND MEDIUM SAND DENSE SAND VERY LOOSE SAND UNDER REPEATED LOADING GREDE OF CONCRETE (Fck) = ELASTIC MOULUS OF CONCRETE (Ec) = MOMENT OF INERTIA OF PILE(I) =

VALUE OF K1 (DENSE SAND IN SUBMERGED CONDITION) = 2.076 (REF: IS : 2911 (Part I/Sec 2) - 1979 T= 97.98773 cm 4T = 391.9509 < (Le) 10 HENCE THE FIG - 2 GIVEN IN THE APPENDIX "C" IS VALID L1 = 0 SINCE THE SOIL UP TO BOTTM OF PILE CAP IS DENSE SAND L1/T = 0 FROM FIG - 2 OF APPENDIX "C" FOR L1/T = 0 FOR FIXED HEAD PILE Lf/T = 2.17 THEREFORE, Lf = 2.126 Mtrs MAXIMUM MOMENT IN THE PILE = Q(L1+Lf)/2 REDUCTION FACTOR (m) = 0.83 THEREFORE DESIGN FORCES, Pu = Muz = 85.58 2.21 MT t-m

Muy = 2.206 t-m The section is to be checked for biaxial bending. Pu/fckD^2 = 0.349312773 p/fck = 0.05 z-z axis, d'/b = 0.1 Mu/fckD3= 0.05 [Ref. SP:16, Chart 56] Muz1 = 4.2875 Muz1 = (Mu/fckD3)*fck*D^3 t-m y-y axis, d'/D= 0.1 Muy1 = 4.2875 t-m Muz/Muz1= 0.514536 Muy/Muy1= 0.514536 Puz = 116.5362 Pu/Puz = 0.734378 The maximum allowable value Muy/Muy1, corresponding to the above values of Muz/Muz1 & Pu/Puz is which is higher than the actual value 0.514536 [Ref.SP:16, Chart 64] The assumed reinforcement of 1 % is therefore satisfactory. a = 1.8906303 1.89063 2 As = 962.115 mm (Muz/Muz1)a+(Muy/Muy1)a = 0.5694076 which is <= 1 DIAMETER OF BAR USED = 16 mm NUMBER BAR REQUIRED = 4.785156 PROVIDE 8 No'S OF 16 mm DIA BARS DESIGN OF PILE CAP : LENGTH OF PILE CAP (L) = WIDTH OF PILE CAP (B) = DEPTH OF THE PILE CAP (D2) MAXIMUM LOAD ON EACH PILE = TOTAL LOAD ON EACH PILE INCLUDING SELF WEIGHT = MAXIMUM BENDING MOMENT (M) = REF: IS : 456 -2000, ANNEX "G", PAGE-96) THEREFORE, Xu.max/d = THEREFORE, Q =0.36*(Xu.max/d)*(1-0.42*Xu.max/d) 1525 650 700 85.58 86.44897 37.82143 0.48 2.759 mm mm mm MT MT T-M

0.9

DEPTH REQUIRED =SQRT(M/Q*B) 459.214 mm ADDING 60mm COVER AND ASSUMING 20 DIA BARS EFFECTIVE DEPTH PROVIDED = 630 mm AREA OF STEEL REQUIRED (Ast) = 1833.015 mm^2 DIAMETER OF BAR USED = 20 mm NUMBER BAR REQUIRED = 5.834655 PROVIDE 11 No'S OF 20 mm DIA BARS PROVIDE % OF STEEL = 0.843897 CHECK FOR SHEAR: MAXIMUM SHEAR FORCE = 85.58 MT PERMISSIBLE SHEAR STRESS = 0.58 N/mm^2 (REF: IS : 456-2000, TABLE-19) SHEAR RESISTED BY CONCRETE (Vs) = 23.751 MT THERE FORE (Vus) = 61.83 MT SPACING SHEAR RRINFORCEMENT(4L-10 DIA) (Sv) = 115.5727 PROVIDE SHERA REINFORCEMENT OF 4L-10mm DIA @ 140 mmC/C

TO CALCULATE AREA OF STEEL USING EQUATION (REF: IS 456-2000, ANNEX "G" ) Mu = 0.87*Fy*Ast*d(1-Ast*Fy/(b*d*Fck) Mu = [(0.87*Fy*d)]*Ast - [0.87*(Fy)^2*(Ast)^2/(b*Fck)] [(0.87*(Fy)^2)/(b*Fck)]*Ast^2 - 0.87*Fy*d + Mu = 0 Ax^2+BX+C =0 A = 0.87*(Fy)^2/(b*Fck)11.5258269 = B = (0.87*Fy*d) = -227461.5 C = Mu = 378214258

Potrebbero piacerti anche

- GLSR Design 11 06 04 1Documento7 pagineGLSR Design 11 06 04 1Varad SonawadekarNessuna valutazione finora

- RCC Oht AlternateDocumento50 pagineRCC Oht AlternateVarad Sonawadekar100% (1)

- Pile Design 2 PilegroupDocumento7 paginePile Design 2 PilegroupVarad SonawadekarNessuna valutazione finora

- Pure Water SumpDocumento8 paginePure Water SumpVarad Sonawadekar100% (1)

- Retaining WallDocumento8 pagineRetaining WallVarad SonawadekarNessuna valutazione finora

- Design of Canal DropsDocumento10 pagineDesign of Canal DropsVarad Sonawadekar100% (1)

- Combined FootingDocumento96 pagineCombined FootingVarad Sonawadekar100% (1)

- Column Base 2Documento2 pagineColumn Base 2Varad SonawadekarNessuna valutazione finora

- Pipe CulvertDocumento4 paginePipe CulvertVarad Sonawadekar0% (1)

- Weir DesignDocumento2 pagineWeir Designanbukgi67% (6)

- Concrete Mix DesignDocumento9 pagineConcrete Mix DesignVarad SonawadekarNessuna valutazione finora

- Slab Design 1Documento19 pagineSlab Design 1Varad SonawadekarNessuna valutazione finora

- Ring FoundationDocumento22 pagineRing FoundationVarad Sonawadekar100% (1)

- Column DesignDocumento39 pagineColumn DesignVarad Sonawadekar100% (9)

- Asian Journal of Civil Engineering (Building and Housing) Vol. 8Documento16 pagineAsian Journal of Civil Engineering (Building and Housing) Vol. 8muhammadyf100% (2)

- Footing Design CirclrcolumnDocumento3 pagineFooting Design CirclrcolumnVarad SonawadekarNessuna valutazione finora

- Shear Walls With OpeningsDocumento29 pagineShear Walls With OpeningsVarad SonawadekarNessuna valutazione finora

- Lecture 1Documento85 pagineLecture 1phuong2311Nessuna valutazione finora

- For More & More Placement Papers& Interview QUESTIONS, Join Our GroupDocumento74 pagineFor More & More Placement Papers& Interview QUESTIONS, Join Our GroupVarad SonawadekarNessuna valutazione finora

- Basics of ExcelDocumento17 pagineBasics of Exceltibinaugustine2456Nessuna valutazione finora

- Roof Systems: Eaves BeamsDocumento75 pagineRoof Systems: Eaves BeamsatiattiNessuna valutazione finora

- Hollow Sections Book WardenierDocumento199 pagineHollow Sections Book WardenierANUSSBAUMER100% (3)

- DR CVR Murty - SefiDocumento4 pagineDR CVR Murty - SefiVarad Sonawadekar0% (1)

- GP Mains 2008 Mech Engg (2008)Documento11 pagineGP Mains 2008 Mech Engg (2008)Varad SonawadekarNessuna valutazione finora

- Spectra Medium SoilDocumento1 paginaSpectra Medium SoilVarad SonawadekarNessuna valutazione finora

- Dynamic Foundation DesignDocumento2 pagineDynamic Foundation DesignyhproNessuna valutazione finora

- Syllabus of KAS GP Main ExamDocumento95 pagineSyllabus of KAS GP Main ExamRoopa ShreeNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- John Deere 4044M, 4044R, 4049M, 4049R, 4052M, 4052R, 4066M, 4066R Tractor Manual TM131019 PDFDocumento31 pagineJohn Deere 4044M, 4044R, 4049M, 4049R, 4052M, 4052R, 4066M, 4066R Tractor Manual TM131019 PDFEquipment Manuals0% (3)

- Abu Dhabi Parking Standards PDFDocumento40 pagineAbu Dhabi Parking Standards PDFyvette100% (3)

- 1434 20 Bal 88-10-2771-11-2010 enDocumento186 pagine1434 20 Bal 88-10-2771-11-2010 enmisternyckNessuna valutazione finora

- Faculty Profile PnuDocumento5 pagineFaculty Profile Pnunavneetkpatil8409Nessuna valutazione finora

- Wick DrainsDocumento1 paginaWick Drainsaecom2009Nessuna valutazione finora

- Trip Coil Supervision RelayDocumento8 pagineTrip Coil Supervision RelaybxteoNessuna valutazione finora

- CEMS Overview PDFDocumento42 pagineCEMS Overview PDFqaedmahmoodNessuna valutazione finora

- Analysis of The Filament-Wound Glass Reinforced Rectangular Cross Section Composite Pipes in AnsysDocumento1 paginaAnalysis of The Filament-Wound Glass Reinforced Rectangular Cross Section Composite Pipes in AnsysIJIERT-International Journal of Innovations in Engineering Research and TechnologyNessuna valutazione finora

- Upright TL49 PDFDocumento2 pagineUpright TL49 PDFCALUGAR TEODOR0% (1)

- Fukada TreeDocumento4 pagineFukada Treeiuridicaprima4Nessuna valutazione finora

- Sproket Ratio CalculatorDocumento2 pagineSproket Ratio CalculatorH3liax100% (6)

- ASTM / JIS /DIN之儀控常用材質對照表: A126 Class BDocumento2 pagineASTM / JIS /DIN之儀控常用材質對照表: A126 Class BKetan DesaiNessuna valutazione finora

- Naveed MD CVDocumento2 pagineNaveed MD CVSajid Iqbal100% (1)

- 3BDD010421R0401 A en S900 I O S - and N-System With SA920 InstallationDocumento110 pagine3BDD010421R0401 A en S900 I O S - and N-System With SA920 Installationilke HANNessuna valutazione finora

- EME E-Note 02032016 091807AMDocumento207 pagineEME E-Note 02032016 091807AMDHAVAL PANCHALNessuna valutazione finora

- Communication Satellites Computer Networks PDFDocumento2 pagineCommunication Satellites Computer Networks PDFRichardNessuna valutazione finora

- Cost of Table Water ProductionDocumento4 pagineCost of Table Water ProductionNasiru029Nessuna valutazione finora

- Babbitted Bearing Health Assessment PDFDocumento15 pagineBabbitted Bearing Health Assessment PDFdavih007Nessuna valutazione finora

- 6EP13332BA01 Datasheet en PDFDocumento4 pagine6EP13332BA01 Datasheet en PDFCristian Osses PaniselloNessuna valutazione finora

- Typical Design For Type b1Documento4 pagineTypical Design For Type b1Ganesh PrabuNessuna valutazione finora

- PLTGDocumento20 paginePLTGbeacon-docs100% (1)

- Iso11922 1 1997Documento17 pagineIso11922 1 1997Ayman S. Ashour0% (1)

- PresentationDocumento22 paginePresentationEstiakNessuna valutazione finora

- AISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFDocumento24 pagineAISC Design Fabrication and Erection of Steel Building Edge Form - 2002 PDFhoustonhimselfNessuna valutazione finora

- SOURSERVICE Brochure PDFDocumento8 pagineSOURSERVICE Brochure PDFshank100Nessuna valutazione finora

- Fire Code 2013 PDFDocumento1.033 pagineFire Code 2013 PDFKo PaukNessuna valutazione finora

- Gas and Steam Turbine For BoatsDocumento49 pagineGas and Steam Turbine For BoatsAlisandro AfataNessuna valutazione finora

- Onboard Maintenance Paint Guide - tcm40 67407 PDFDocumento9 pagineOnboard Maintenance Paint Guide - tcm40 67407 PDFPrince SadhotraNessuna valutazione finora

- Rel 003Documento0 pagineRel 003Bence M ZoltanNessuna valutazione finora

- Metro Standard StructDwgs 080613Documento41 pagineMetro Standard StructDwgs 080613rpazbNessuna valutazione finora