Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Martin Hanger Bearing Brochure

Caricato da

Anonymous jW9BkgbQmEDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Martin Hanger Bearing Brochure

Caricato da

Anonymous jW9BkgbQmECopyright:

Formati disponibili

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page a

S C R E W

C O N V E Y O R

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page b

Screw Conveyor Hanger

Bearing Selection Application

BEARING MATERIAL

MAXIMUM

OPERATING

TEMP. (F)

STYLES AVAILABLE

MATERIAL

FDA

COMPLIANT

Martin MSB

300

220, 216

Yes

Food

Engineered PTFE

Ertalyte

200

220, 216

Yes

Food

Registered Trademark of Quadrant

Engineering Products

Gatke

400

220, 216

Martin HARD IRON

500

220

CAST HARD IRON

500

220, 216, 19B

WOOD

160

220, 216, 19B

Yes

Grain, Feed, Fertilizer

Martin BRONZE

850

220

Yes

Grain, Feed,

Processing

NYLON 101

250

220

Yes

Food and Grain

NYLATRON GS

250

220, 19B

Yes

Chemical, Handling,

Grain, Feed

UHMW

225

220, 216

Yes

Food

STELLITE

1000

220, 216

INDUSTRIAL GRADE

ENGINEERED NYLON

160

220

WHITE MELAMINE

190

220

Yes

FOOD GRADE ENGINEERED NYLON

300

220

Yes

BALL BEARING

180

60, 70

Martin HDPE

200

220

Yes

CERAMIC 1

1,000

220, 216

Yes

Martin URETHANE

200

220

YES

TIVAR 1000

275

220, 216

YES

1 Higher temperature ceramics are available.

SELF

LUBE

SOME SUGGESTED USES

Chemical

Yes

Yes

Yes

Requires Hardened Shaft

Liime, Cement, Salt,

Gypsum

Requires hardened shaft.

Can be noisy. Lubrication

required in some applications.

Grain, Feed, Fertilizer

Food

Yes

Fiberglass fabric. Good for higher

speeds.

Chemical, Cement,

Aggregate

Chemical, Cement,

Aggregate

Yes

COMMENTS

Food, Grain, Fertilizer

Good general purpose.

High quality bearings. High load

capacity.

For dry applications.

Very low load capacity.

Material USDA approved. Does not

swell in water.

Requires Stellite insert in shaft.

Economical replacement for wood.

Suitable for repeat use in food contact

applications at temps not exceeding

190F.

For dry application.

Non-abrasive applications General purpose use.

Yes

Grain, Feed, Chemical

Handling

Recommended for non-abrasive applications

Chemical, Cement, Food Requires hardened shafts.

Grain, Chemical, Fertilizer Good general purpose.

Grain, Chemical

Good general purpose.

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 1

Hangers

Style 226

Style 216

Style 220

Style 230

Style 316

Style 326

No. 226 hangers are designed for flush mounting inside the

trough permitting dust-tight or weather-proof operation. This

type hanger allows for minimum obstruction of material flow in

high capacity conveyors. Available with friction type bearing.

No. 216 hangers are designed for heavy duty applications. This

hanger is flush mounted inside the trough permitting dust tight

or weather proof operation. Hard iron or bronze bearings are

normally furnished; however, the hanger can be furnished with

other bearings.

No. 220 hangers are designed for mount on top of the trough

flanges and may be used where dust-tight or weather proof

operation is not required. This type hanger allows for minimum

obstruction of material flow in high capacity conveyors.

Available with friction type bearing.

No. 230 hangers are designed for heavy duty applications where

mounting on top of the trough flanges is required. Hard iron or

bronze bearings are normally furnished; however, other bearings are available.

No. 316 hangers are designed for heavy duty use in conveyors

where abnormal heat requires unequal expansion between the

screw and conveyor trough. Hard iron or bronze bearings are

normally furnished; however, this hanger can be furnished with

other bearings.

No. 326 hangers are designed to permit minimum obstruction of

material flow and are used in conveyors where abnormal heat

requires unequal expansion between the screw and the conveyor

trough. Hard iron or bronze bearings are normally furnished, but

other type bearings are available.

1

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 2

Hangers

Style 60

Style 70

Style 30

No. 60 hangers are furnished with a heavy duty, permanently lubricated and sealed, self aligning ball bearing which permits temperatures

up to 245 F. and will allow for up to 4 shaft misalignment. This hanger is mounted on top of the trough flanges. Grease fitting can be furnished if specified.

No. 70 hangers are furnished with a heavy duty, permanently lubricated and sealed, self aligning ball bearing which permit temperatures up

to 245 F. and will allow for up to 4 shaft misalignment. This hanger is

mounted inside the trough. Grease fittings can be furnished if specified.

No. 30 hangers are designed for side mounting within the conveyor

trough on the noncarrying side and permit a minimum of obstruction

of material flow. Available with friction type bearing.

Style 216F

No. 216F hangers are designed for heavy duty applications and are

mounted inside of flared trough. Hard iron or bronze bearings are

normally furnished; however, other bearings are available.

Style 19B

The No. 19B hanger is similar in construction to the No. 18B except

they are mounted on top of the trough angles. Built-in ledges provide

supports for the ends of the cover. They are streamline in design and

permit free passage of the material. They are regularly furnished with

Arguto oil impregnated wood, hard iron, bronze, or other special caps

can be furnished.

Air Purged

Hanger

Air purged hangers are recommended when handling dusty and abrasive materials which contribute to shutdowns and hanger bearing failures. Air-swept hangers are available for 9-24 conveyors. They

should not be used when handling hot materials (over 250 F) or wet

sticky materials or when handling non abrasive materials when an

inexpensive hanger will do the job satisfactorily. In service, air-purged

hangers deliver relatively trouble-free operation. They help solve noise

nuisance problems, and they help reduce power requirement because

of the low coefficient of fraction. Maximum trough loading should not

exceed 15%. The air, at approximately 1-1/4 PSI enters the housing at

the top, passes over and around the bearing, and is dissipated around

the coupling shaft on both sides of the housing. Thus the bearing is

protected from dust and the material in the trough at all times. Only 3

to 7 cu. ft. of air per minute is required to keep each hanger bearing clean.

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 3

Hangers

Style 220

Pipe Tap 18

No. 220 hangers are designed for mounting on top of

the trough flanges and may be used where dust-tight

or weather proof operation is not required. This type

hanger allows for minimum obstruction of material

flow in high capacity conveyors. Available with friction

type bearing.

Conveyor

Diameter

Coupling

Size

Part

Number*

Bolts E

M SLOT

M

Slot

612

112

714

8 4

2 2

9 4

8

3

8

1214

1214

212

212

2

2

1312

1312

8

8

1314

1314

212

212

2

2

1412

1412

2

2

1

2

1534

1534

1534

212

212

212

2

3

3

1712

1712

1712

2

2

1734

1734

212

212

3

3

1912

1912

4CH2202

31316

312

16

1 2

6CH2203

4 2

4 2

16

112

2

9CH2203

9CH2204

618

618

412

412

4

1

4

10

112

2

10CH2203

10CH2204

638

638

412

412

4

4

2

2716

3

12CH2204

12CH2205

12CH2206

734

734

734

5

5

5

8

8

3

8

2716

3

14CH2205

14CH2206

914

914

5

5

2

2

16

16CH2206

1058

1934

212

2112

18

3

3716

18CH2206

18CH2207

1218

1218

6

6

2

1

2

8

5

8

2214

2214

312

312

3

4

2412

2412

11

20

3

3716

20CH2206

20CH2207

1312

1312

6

6

2

2

8

8

2414

2414

312

312

3

4

2612

2612

11

3716

24CH2207

1612

2814

312

3012

11

12

14

24

16 3 4

16 1116

16 1116

9

11

16 1116

10

12

16 1516

16

21

28

16 1516

26

33

Weight

Each

16 1516

39

16 11116

41

49

16 11116

43

51

16 11116

57

*Refer to Page 10 for bearings

NOTE: For hangers with oil pipe add 0 to part number

Pipe Tap 18

Style 226

M SLOT

Bolts E

No. 226 hangers are designed for flush mounting

inside the trough permitting dust-tight or weatherproof operation. This type hanger allows for minimum

obstruction of material flow in high capacity conveyors. Also available with friction type bearing.

Conveyor

Diameter

Coupling

Size

Part

Number*

M

Slot

Weight

Each

16 34

16 1116

16 1116

9

11

16 1116

10

12

16 1516

16

21

28

16 1516

26

33

4CH2262

358

312

16

11

16

112

1 2

6CH2263

4 2

4 2

16

2 2

112

2

9CH2263

9CH2264

10

10

618

618

412

412

4

1

4

8

3

8

1

1

212

212

2

2

10

112

2

10CH2263

10CH2264

11

11

638

638

412

412

4

4

8

8

1

1

212

212

2

2

2

2716

3

12CH2264

12CH2265

12CH2266

13

13

13

734

734

734

5

5

5

8

8

3

8

2

2

1

2

1

114

114

114

212

212

212

2

3

3

2716

3

14CH2265

14CH2266

15

15

914

914

5

5

2

2

2

2

138

138

212

212

3

3

16

16CH2266

17

1058

138

212

18

3

3716

18CH2266

18CH2267

19

19

1218

1218

6

6

2

1

2

8

5

8

112

112

312

312

3

4

11

20

3

3716

20CH2266

20CH2267

21

21

1312

1312

6

6

2

2

8

8

112

112

312

312

3

4

11

3716

24CH2267

25

1612

158

312

11

12

14

24

*Refer to Page 10 for bearings

*For hangers with oil pipe add 0 to part number

16 1516

39

16 11116

41

49

16 11116

43

51

16 11116

57

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 4

Hangers

Style 216

Pipe Tap 18

M SLOT

No. 216 hangers are designed for heavy duty applications. This hanger is flush mounted inside the trough

permitting dust tight or weather proof operation. Hard

iron or bronze bearings are normally furnished; however, the hanger can be furnished with other bearings.

Conveyor

Diameter

Coupling

Size

Part

Number*

Bolts E

M

Slot

112

6CH2163

412

412

16

212

1 2

2

9CH2163

9CH2164

10

10

6 8

618

4 2

412

4

1

4

8

3

8

1

1

2 2

212

2

2

10

112

2

10CH2163

10CH2164

11

11

638

638

412

412

4

4

8

8

1

1

212

212

2

2

2

2716

3

12CH2164

12CH2165

12CH2166

13

13

13

734

734

734

5

5

5

8

8

3

8

2

2

1

2

1

114

114

114

212

212

212

2

3

3

2716

3

14CH2165

14CH2166

15

15

914

914

5

5

2

2

2

2

138

138

212

212

3

3

16

16CH2166

17

1058

138

212

18

3

3716

18CH2166

18CH2167

19

19

12 8

1218

6

6

2

2

3 2

312

3

4

11

1 2

112

8

8

3

3716

20CH2166

20CH2167

21

21

1312

1312

6

6

2

2

8

8

112

112

312

312

3

4

11

3716

24CH2167

25

1612

158

312

11

12

14

20

24

*Refer to Page 10 for bearings

Weight

Each

16 1116

16 1116

7

9

16 1116

8

10

16 1516

14

18

21

16 1516

23

25

16 1516

28

16 1 16

34

44

16 11116

36

47

16 11116

53

11

*For hangers with oil pipe add 0 to part number

Style 230

No. 230 hangers are designed for heavy duty applications where mounting on top of the trough flange is

required. Hard iron or bronze bearings are normally

furnished; however, other bearings are available.

Conveyor

Diameter

Coupling

Size

Part

Number*

112

6CH2303

1 2

2

10

412

412

9CH2303

9CH2304

6 8

618

4 2

412

4

1

4

112

2

10CH2303

10CH2304

638

638

412

412

4

4

2

2716

3

12CH2304

12CH2305

12CH2306

734

734

734

5

5

5

8

8

3

8

2716

3

14CH2305

14CH2306

914

914

5

5

8

8

16

16CH2306

1058

18

3

3716

18CH2306

18CH2307

12 8

1218

6

6

2

2

3

3716

20CH2306

20CH2307

1312

1312

6

6

2

2

3716

24CH2307

1612

12

14

20

24

*Refer to Page 10 for bearings

M

Slot

834

212

934

8

3

8

12 4

1214

2 2

212

2

2

13 2

1312

8

8

1314

1314

212

212

2

2

1412

1412

2

2

1

2

1534

1534

1534

212

212

212

2

3

3

1712

1712

1712

2

2

1734

1734

212

212

3

3

1912

1912

1934

212

2112

8

8

22 4

2214

3 2

312

3

4

24 2

2412

11

8

8

2414

2414

312

312

3

4

2612

2612

11

2814

334

3012

11

*For hangers with oil pipe add 0 to part number

Weight

Each

16 1116

16 1116

8

10

16 1116

9

11

16 1516

15

20

25

16 1516

24

29

16 1516

35

16 1 16

34

47

16 11116

40

49

16 11116

55

11

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 5

Hangers

Style 316

Pipe Tap 18

No. 316 hangers are designed for heavy duty

use in conveyors where abnormal heat

requires unequal expansion between the

screw and conveyor trough. Hard iron or

bronze bearings are normally used; however,

this hanger can be furnished with other bearings.

Bolts E

Style 326

Pipe Tap 18

No. 326 hangers are designed to permit minimum obstruction of material flow and are used

in conveyors where abnormal heat requires

unequal expansion between the screw and the

conveyor trough. Hard iron or bronze bearings

are normally used, but other type bearings are

available.

Bolts E

Part Number

Conveyor

Diameter

6

9

10

12

14

16

18

20

24

Coupling

Size

112

112

2

112

2

2

2716

3

2716

3

3

3

3716

3

3716

3716

Style

316*

Style

326*

6CH3163

9CH3163

9CH3164

10CH3163

10CH3164

12CH3164

12CH3165

12CH3166

14CH3165

14CH3166

16CH3166

18CH3166

18CH3167

20CH3166

20CH3167

24CH3167

6CH3263

9CH3263

9CH3264

10CH3263

10CH3264

12CH3264

12CH3265

12CH3266

14CH3265

14CH3266

16CH3266

18CH3266

18CH3267

20CH3266

20CH3267

24CH3267

7

10

10

11

11

13

13

13

15

15

17

19

19

21

21

25

*Refer to Page 10 for bearings

412

618

618

638

638

734

734

734

914

914

1058

1218

1218

1312

1312

1612

6

6

6

6

6

612

612

612

612

612

612

612

7

7

7

7

16

16

3

16

3

16

3

16

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

1

4

8

8

3

8

3

8

3

8

1

2

1

2

1

2

1

2

1

2

1

2

5

8

5

8

5

8

5

8

5

8

4

1

1

1

1

114

114

114

138

138

138

158

158

158

158

134

412

412

412

412

412

5

5

5

5

5

5

514

514

514

514

514

2

2

2

2

2

2

3

3

3

3

3

3

4

3

4

4

*For hangers with oil pipe add 0 to part number

B - Bolt

Size

Standard

Coupling

Drilling

Air Purged Hanger

Screw

Diameter

Air purged hangers are recommended

when handling dusty and abrasive materials which contribute to shut-downs and

hanger bearing failures. They should not

be used when handling hot materials (over

250F) or wet sticky materials or when

handling nonabrasive materials when an

inexpensive hanger will do the job satisfactorily. Maximum trough loading should not

exceed 15%. The air, at approximately 114

PSI, enters the housing at the top, passes

over and around the bearing, and is dissipated around the coupling shaft on both

sides of the housing. Only 3 to 7 cu. ft. of

air per minute is required to keep each

hanger bearing clean.

Part

Number

9

12

14

16

18

20

24

Shaft

Dia.

Weight

Each

9CHAPH3

9CHAPH4

12CHAPH4

12CHAPH5

12CHAPH6

14CHAPH5

14CHAPH6

16CHAPH6

18CHAPH6

20CHAPH6

20CHAPH7

24CHAPH7

112

2

2

2716

3

2716

3

3

3

3

3716

3716

15

20

30

52

68

60

74

77

91

105

140

155

Space required on coupling for hanger.

Air supply should be clean and dry.

10

8

8

1

2

412

618

114

714

114

114

2

3

3

3

3

3

3

4

4

13

15

914

114

138

17

19

21

2

8

5

8

5

6

6

1058

1218

1312

114

134

134

138

158

138

25

1612

134

158

Dimensions in inches.

Weight in pounds.

8

2

1

2

1

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 6

Hangers

C

Bolts E

Style 30

No. 30 hangers are designed for side mounting

within the conveyor trough on the non-carrying

side and permit a minimum of obstruction of material flow. Available with friction type bearing.

Conveyor

Diameter

Coupling

Diameter

Part

Number*

Weight

Each

112

6CH303

312

414

112

16

318

1 2

2

9CH303

9CH304

5

5

5 8

578

1 2

112

8

1

2

8

3

8

4 4

414

2

1

2

2

2

6

8

10

112

2

10CH303

10CH304

512

512

638

638

112

112

8

2

2

2

438

438

4

4

2

2

8

9

2

2716

3

12CH304

12CH305

12CH306

612

612

612

712

712

712

112

2

2

2

2

1

2

2

2

1

2

1

512

512

512

4

4

3

4

2

3

3

12

18

20

2716

3

14CH305

14CH306

712

712

9

9

2

2

2

2

8

8

678

678

8

8

3

3

20

22

16

16CH306

812

1038

32

18

3

3716

18CH306

18CH307

9 2

912

11 8

1178

2

3

4

4

8

8

9

9

1 4

114

3

4

30

33

3

3716

20CH306

20CH307

1012

1012

1314

1314

2

3

4

4

8

8

1014

1014

114

114

3

4

32

38

3716

24CH307

1212

1614

1234

112

46

12

14

20

24

*Refer to Page 10 for bearings

NOTE: For hangers with oil pipe add 0 to part number

8 Pipe Tap

Bolts E

M Slot

Style 216F

No. 216F hangers are designed for

heavy duty applications and are

mounted inside of flared trough.

Hard iron or bronze bearings are

normally furnished; however, other

bearings are available.

Conveyor

Diameter

Coupling

Diameter

Part

Number*

D

3

112

6CH216F3

14

1 2

2

9CH216F3

9CH216F4

18

12

2

2716

3

12CH216F4

12CH216F5

12CH216F6

22

10

14

2716

3

14CH216F5

14CH216F6

24

11

16

16CH216F6

28

1112

18

3

3716

18CH216F6

18CH216F7

31

12 8

20

3

3716

20CH216F6

20CH216F7

34

1312

24

3716

24CH216F7

40

1612

*Refer to Page 10 for bearings

NOTE: For hangers with oil pipe add 0 to part number

16

Weight

Each

M

Slot

212

2 2

14

17

118

212

2

3

24

28

32

118

212

31

34

118

212

38

1 2

3 2

3

4

52

61

11

112

312

3

4

55

64

11

112

312

71

11

16

16 34

16 34

16 34

16 34

16 34

16 78

16 78

16 78

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 7

Hangers

Style 60

M Slot

Bolts E

No. 60 hangers are furnished with a heavy

duty, permanently lubricated and sealed,

self-aligning ball bearing which permits temperatures up to 245 F. and will allow for up

to 4 shaft misalignment. This hanger is

mounted on top of the trough flanges.

Grease fitting can be furnished if specified.

Conveyor

Diameter

Coupling

Size

Part

Number*

834

11116

8

8

12 4

1214

1 16

134

2

2

8

9

8

8

1314

1314

11116

134

2

2

9

10

2

2

1

2

1534

1534

1534

134

16364

21116

212

212

212

12

20

30

2

2

1734

1734

16364

21132

212

212

21

32

1934

21132

212

35

2214

21132

312

40

11

2414

21132

312

45

11

2814

23164

33/4

58

11

112

6CH603

934

412

16

1 2

2

9CH603

9CH604

13 2

1312

6 8

618

4

4

4

4

112

2

10CH603

10CH604

1412

1412

638

638

4

4

2

2716

3

12CH604

12CH605

12CH606

1712

1712

1712

734

734

734

5

5

5

2716

3

14CH605

14CH606

1912

1912

914

914

5

5

2

2

16

16CH606

2112

1058

18

18CH606

2412

1218

20

20CH606

2612

1312

24

3716

24CH607

3012

1612

10

12

14

4

4

8

8

3

8

11

M

Slot

Weight

Each

16 1116

16 1116

16 1116

16 1516

16 1516

16 1516

16 1516

9

16 1516

9

16 1516

16 1516

16 1516

16 11116

16 11116

16 11116

*For hangers with oil pipe add 0 to part number.

Style 70

No. 70 hangers are furnished with a

heavy duty, permanently lubricated

and sealed, self aligning ball bearing which permits temperatures up

to 245 F. and will allow for up to 4

shaft misalignment. This hanger is

mounted inside the trough. Grease

fitting can be furnished if specified.

Conveyor

Diameter

Coupling

Size

Part

Number*

112

6CH703

1 2

2

Bolts E

M Slot

412

412

4 2

412

1

1

8

8

9CH703

9CH704

10

10

6 8

618

112

2

10CH703

10CH704

11

11

638

638

412

412

1

1

8

8

2

2716

3

12CH704

12CH705

12CH706

13

13

13

734

734

734

5

5

5

114

114

114

2

2

1

2

2716

3

14CH705

14CH706

15

15

914

914

5

5

138

138

2

2

16

18

16CH706

17

1058

138

18CH706

19

1218

112

20

20CH706

21

1312

112

24

3716

24CH707

25

1612

158

10

12

14

Weight

Each

M

Slot

16

11116

11/2

4

4

11

1 16

134

1 4

134

8

9

4

4

11116

134

134

134

9

10

8

8

3

8

134

16364

21132

218

218

218

12

20

30

2

2

16364

21132

214

214

21

32

21132

214

35

21132

212

40

11

21132

212

45

11

21132

258

58

11

16 1116

16 1116

16 1116

16 1516

16 1516

16 1516

16 11116

16 11116

16 11116

*For hangers with oil pipe add 0 to part number.

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 8

Hangers

P = Size

of Pipe

Style 19B

The No. 19-B Hanger is similar in construction to the No. 18-B except they

are mounted on top of the trough

angles. Built-in ledges provide supports

for the ends of the cover. They are

streamlined in design and permit free

passage of the material.

H = Size

of Bolts

Top half is furnished with bronze bearing. Bottom half can be supplied in oil

impregnated wood, hard iron, or other

special caps may be furnished on

request.

Conveyor

Diameter

Bearing

Bore

Part Number

112

6CH19B3

112

2

9CH19B3

9CH19B4

10

112

2

10CH19B3

10CH19B4

12

2

2716

3

14

Weight

8.5

978

412

1516

834

13 1312

15.5

618

1312

134

618

1

134

1214

1

2

1214

14 1412

638

134

1314

12CH19B4

12CH19B5

12CH19B6

24 17

24.5

734

17

2

734

114

234

2716

3

14CH19B5

14CH19B6

37 1914

914

234

16

16CH19B6

45 2114

1058

18

18CH19B6

48.5

2334

1218

20

3716

20CH19B7

60.0

2614

1312

H

Bolt

P

Pipe

1

612

912

1

2

4

912

1012

4

1012

1534

112

1

2

1534

1212

1

2

1

4

1212

1212

134

1734

1412

1

4

1414

134

1934

1612

158

2214

11316

2414

1812

20

4

4

Hanger Bearing Catalog_HANGER BEARING 10/8/12 9:02 AM Page 9

Hanger

Bearings

Hanger Type

Shaft Diameter

Part Number

216

112

CHB2163*

CHB2164*

2716

CHB2165*

CHB2166*

3716

CHB2167*

230

316

*HHard Iron *WWood

*BR Bronze

*UUHMW

* Oil hole is furnished on hard iron and bronze standard.

Hanger Type

220

*GGatke

*ER Ertalyte

Shaft Diameter

Part Number

CHB2202*

112

CHB2203*

CHB2204*

2716

CHB2205*

CHB2206*

3716

CHB2207*

Bearing

*CCeramic

* StStellite

* UR - Urethane

* TIVAR 1000

Bearing

226

326

30

*H Cast Hard Iron with oil hole

*W Wood

MHI Martin Hard iron (oil impregnated)

*MBR Martin Bronze (oil impregnated)

Hanger Type

*P HDPE

*GGatke

*MCB Melamine (Furnished Less Flanges)

*C Ceramic

*WN White Nylon

*U UHMW

* MSB-PTFE 1-1/2" through 2-7/16"

Shaft Diameter

60

Ball

Bearing

70

Ball

Bearing

*N Nylatron

*UR Urethane

Part Number

112

CHB603

CHB604

2716

CHB605

CHB606

3716

CHB607

*ER Ertalyte

*TIVAR 1000

Bearing

Note: New style bearings are available with slinger shield one side.

Hanger Type

18B

19B

*WWood

*HHard Iron

Shaft Diameter

Part Number

112

CHB18B3*

CHB18B4*

2716

CHB18B5*

CHB18B6*

3716

CHB18B7*

*NNylatron

Bearing

*GGatke

Note: Furnished as bottom cap only

Ertalyte and TIVAR 1000 are Registered Trademarks of Quadrant Engineered Plastic Products

INVENTORY: Martin delivers with incredible

fill rates from one of its many facilities

strategically located across North

America.

SERVICE: Martin ships rebores and other

alterations within hours - not days...

MTOs in days - not weeks.

PEOPLE: When you call Martin you get a person,

not voice mail. We are ready, able and willing to

help...Now!

For more information contact a branch near you:

USA

General Offices

Sales and Manufacturing

Arlington, TX

3100 Sprocket Drive 76015-2898

P.O. Box 91588

Arlington, TX 76015-0088

817-258-3000 (FAX 817-258-3333)

Regional Manufacturing Plants

Albemarle, NC (Conveyor Pulley Div.)

306 Bethany Road

Albemarle, NC 28001-8520

704-982-9555 (FAX 704-982-9599)

Burleson, TX

555 N. Burleson Blvd.

Burleson, TX 76028

817-295-7151 (FAX817-447-3840)

Danielsville, PA

3376 Delps Road 18038-9515

P.O. Box 267 Danielsville, PA 18038-0267

610-837-1841 (FAX 610-837-7337)

Ft. Worth, TX (Conveyor Div.)

3600 McCart Avenue

Ft. Worth, TX76110-4692

817-258-3000 (FAX 817-258-3173)

Ft. Worth, TX (Tool & Forge Div.)

3600 McCart Avenue

Ft. Worth, TX76110-4692

817-258-3000 (FAX 817-258-3173)

Montpelier, OH

350 S. Airport Road

Montpelier, OH 43543-9329

419-485-5515 (FAX419-485-3565)

Sacramento, CA

1199 Vine Street

Sacramento, CA 95814-0426

916-441-7172 (FAX916-441-4600)

Scottdale, GA

3303 Church Street 30079-1395

P.O. Box 886 Scottdale, GA30079-0886

404-292-8744 (FAX404-292-7771)

Branch Manufacturing Centers

Boston, MA

357 Fortune Boulevard

Milford, MA01757-1723

508-634-3990 (FAX508-634-3998)

Denver, CO

10800 East 54th Avenue

Denver CO 80239-2124

303-371-8466 (FAX 303-371-7116)

Houston, TX

9910 Bent Oak Drive

Houston, TX 77040-3222

713-849-4330 (FAX713-849-4807)

Kansas City, MO

1520 North Commerce Avenue

Kansas City, MO 64120-4961

816-231-5575 (FAX816-231-1959)

Los Angeles, CA

5920 South Triangle Drive

Commerce, CA90040-3639

323-728-8117 (FAX323-722-7526)

Minneapolis, MN

10601 Hampshire Avenue South

Bloomington, MN55438-2395

952-829-0623 (FAX 952-944-9385)

Nashville, TN

732 Massman Drive

Nashville, Tennessee 37210

615-871-4730 (FAX 615-871-4125)

Portland, OR

3030 Northwest Industrial Street

Portland, OR 97210-1734

503-223-7261 (FAX503-221-0203)

Tampa, FL

3201 Queen Palm Drive

Tampa FL 33619-1331

813-623-1705 (FAX 813-626-8953)

Wayne, NJ

7 High Point Drive

Wayne, NJ 07470-7432

973-633-5700 (FAX 973-633-7196)

Manufacturing Only

Ayr, Ontario (Conveyor Div.)

320 Darrell Drive

Ayr, Ontario, Canada N0B 1E0

519-621-0546 (FAX 519-621-4413)

MEXICO

Sales and Manufacturing

Martin Sprocket & Gear

de Mxico, S.A. de C.V.

Guadalajara, JAL

Av. Coln Sur No. 6013, Edificio 1 Modulo 2

Colonia Santa Mara Tequepexpan

Tlaquepaque, Jalisco Mexico 45601

+52 33-3283-1188 (martin76@martinsprocket.com)

Monterrey, N.L.

Av. Industrial No. 100

Lote 6 y 7, Manzana 11

Parque Industrial La Silla Apodaca

Apodaca, N.L. Mxico 66648

+52 811 156 6830 (martin75@martinsprocket.com)

Toluca, MEX

Km 52 Carretera, Naucalpan-Toluca

Calle 3, Manzana VII, Lote 11

Parque Industrial Toluca 2000

Toluca, Edo. de Mxico 50233

+52 722 276 0800 (martin74@martinsprocket.com)

SOUTH AMERICA

Sales and Manufacturing

Martin Sprocket & Gear do Brazil

So Paulo, SP

SP 332 Km 154,5

Artur Nogueira So Paulo

CEP 13160-000

C.P. 138

Tel: 19 3877 4500

CHINA

Abilene, TX Clarksville, TX

Asia Division Headquarters

Dallas, TX Mansfield, TX

Martin Sprocket & Gear (Shanghai) Co., Ltd.

81 Tang Yao Road,

Hua Ting Town, Jiading District,

Shanghai 201816, P. R. China

Tel.: 86-021-67084888

Fax: 86-021-67084889

Paragould, AR

CANADA

Sales and Manufacturing

Martin Sprocket & Gear Canada Inc.

Charlotte, NC

3901 Scott Futrell Drive

Charlotte, NC 28208-3539

704-394-9111 (FAX704-394-9122)

Edmonton, Alberta

4023/4027 53rd Avenue,

Edmonton, Alberta, Canada T6B 3C6

780-450-0888 (Fax 780-465-0079)

Chicago, IL

1505 Birchwood Avenue

Des Plaines, IL 60018-3001

847-298-8844 (FAX 847-298-2967)

Mississauga, Ontario

896 Meyerside Drive

Mississauga, Ontario, Canada L5T 1R9

905-670-1991 (FAX905-670-2110)

Changzhou Fuzhou Wuhan

Zhongshan Tianjin Harbin

Martin Sprocket & Gear, Inc. 3100 Sprocket Drive Arlington, TX 76015 817-258-3000

www.martinsprocket.com

COPYRIGHT 2013 Martin SPROCKET & GEAR, INC. ALL RIGHTS RESERVED 1180 PTC-HDCP 0513

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Design of TowerDocumento4 pagineDesign of Towersyedbaseer100% (1)

- Overhead Munck Cranes - Crane and Trolleys Own WeightDocumento8 pagineOverhead Munck Cranes - Crane and Trolleys Own WeightWissam JarmakNessuna valutazione finora

- Hot Melt Adhesives - 2Documento8 pagineHot Melt Adhesives - 2QUALITY CONTROL100% (1)

- MITSUBOSHI - Timing BeltDocumento142 pagineMITSUBOSHI - Timing BeltAnonymous jW9BkgbQmE67% (3)

- ISO 13849 PL Calculations SimplifiedDocumento119 pagineISO 13849 PL Calculations SimplifiedAnonymous jW9BkgbQmENessuna valutazione finora

- BANDO V Belt Design ManualDocumento38 pagineBANDO V Belt Design ManualJie Lee Chuin Chee100% (1)

- Stainless Steel in The Food Industry PDFDocumento26 pagineStainless Steel in The Food Industry PDFAnonymous jW9BkgbQmENessuna valutazione finora

- Din 5463Documento4 pagineDin 5463Joel Sousa100% (1)

- Tds Flexible Anchor System Icaf44tDocumento1 paginaTds Flexible Anchor System Icaf44twandamektanNessuna valutazione finora

- Transmissionproducts PDFDocumento92 pagineTransmissionproducts PDFhalder_kalyan9216Nessuna valutazione finora

- Hoistway Same Side PlatformDocumento3 pagineHoistway Same Side PlatformAnonymous jW9BkgbQmENessuna valutazione finora

- Brochure ACCU-CHILL tcm17-4824Documento12 pagineBrochure ACCU-CHILL tcm17-4824Anonymous jW9BkgbQmENessuna valutazione finora

- U.s.inspected - Meat Packing PlantsDocumento78 pagineU.s.inspected - Meat Packing PlantsAnonymous jW9BkgbQmENessuna valutazione finora

- Percurso ChamineDocumento1 paginaPercurso ChamineAnonymous jW9BkgbQmENessuna valutazione finora

- Hydroxychloroquine and Azithromycin As A Treatment of COVID-19 PDFDocumento24 pagineHydroxychloroquine and Azithromycin As A Treatment of COVID-19 PDFCamilo OrtizNessuna valutazione finora

- DS8220 Standard EU ENDocumento6 pagineDS8220 Standard EU ENAnonymous jW9BkgbQmENessuna valutazione finora

- Eaton 041097 P1 25 EA SVB en - GBDocumento6 pagineEaton 041097 P1 25 EA SVB en - GBAnonymous jW9BkgbQmENessuna valutazione finora

- Sanitary Equipment Design BookletDocumento20 pagineSanitary Equipment Design BookletDiana BlueseaNessuna valutazione finora

- Series21&41 CatalogDocumento16 pagineSeries21&41 CatalogWillin08Nessuna valutazione finora

- Proiect Masa Ridicare PDFDocumento41 pagineProiect Masa Ridicare PDFEpure GabrielNessuna valutazione finora

- WP AAonDocumento36 pagineWP AAonmayukhguhanita2010Nessuna valutazione finora

- Projeto PiscinaDocumento50 pagineProjeto PiscinaNathalia SawadaNessuna valutazione finora

- Material AISI 420Documento2 pagineMaterial AISI 420Cebrac ItatibaNessuna valutazione finora

- Heavy Duty V-Belt Drive Design Manual PDFDocumento324 pagineHeavy Duty V-Belt Drive Design Manual PDFAnonymous jW9BkgbQmENessuna valutazione finora

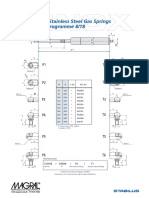

- Stabillus Gas - Inox 8 18Documento1 paginaStabillus Gas - Inox 8 18Anonymous jW9BkgbQmENessuna valutazione finora

- Manual Bomba Maxbloc - HDDocumento9 pagineManual Bomba Maxbloc - HDAnonymous jW9BkgbQmENessuna valutazione finora

- CAMB - Machine Knives InternationalDocumento38 pagineCAMB - Machine Knives InternationalAnonymous jW9BkgbQmENessuna valutazione finora

- Sec 22 Gas Struts Selector BRDocumento16 pagineSec 22 Gas Struts Selector BRAnonymous jW9BkgbQmENessuna valutazione finora

- Concept Plus LRDocumento2 pagineConcept Plus LRAnonymous jW9BkgbQmENessuna valutazione finora

- Proiect Masa Ridicare PDFDocumento41 pagineProiect Masa Ridicare PDFEpure GabrielNessuna valutazione finora

- 8803 CS Systems Brochure - EN 1 PDFDocumento20 pagine8803 CS Systems Brochure - EN 1 PDFAnonymous jW9BkgbQmENessuna valutazione finora

- Gear Calculations Rev3Documento5 pagineGear Calculations Rev3ghostghost123Nessuna valutazione finora

- HY18-0020 Refuse Cylinder Rev C PDFDocumento116 pagineHY18-0020 Refuse Cylinder Rev C PDFAnonymous jW9BkgbQmENessuna valutazione finora

- Glass Bottle ProductionDocumento5 pagineGlass Bottle ProductionAdare Oluwafemi Thomas100% (1)

- High - Strength - Low - Alloy - Structural - Steel-2019 - 2Documento30 pagineHigh - Strength - Low - Alloy - Structural - Steel-2019 - 2Exp KNessuna valutazione finora

- Aircraft Hangar WB Coating: AdvantagesDocumento4 pagineAircraft Hangar WB Coating: Advantagesjohn christian de leonNessuna valutazione finora

- StiffnessCoefficients PDFDocumento44 pagineStiffnessCoefficients PDFThanit ThanadirekNessuna valutazione finora

- 12 Plaxis Bulletin-With ShotcreteDocumento24 pagine12 Plaxis Bulletin-With ShotcreteGEOMAHESHNessuna valutazione finora

- HB Assignment 2Documento11 pagineHB Assignment 2Himanshu BishnoiNessuna valutazione finora

- Rheology Notes Introduction To RheologyDocumento30 pagineRheology Notes Introduction To RheologyDoug AmatoNessuna valutazione finora

- MyFLEX SFG 501A - SFG 510B (ENG Ver.3 September 2020)Documento1 paginaMyFLEX SFG 501A - SFG 510B (ENG Ver.3 September 2020)Wasif AzimNessuna valutazione finora

- Three Point Bending Test Research of Carbon FibreDocumento3 pagineThree Point Bending Test Research of Carbon FibrekishoreNessuna valutazione finora

- Teratile DiamondDocumento2 pagineTeratile Diamondhomeh3Nessuna valutazione finora

- Rockmount ASTM Steel Grades PDFDocumento1 paginaRockmount ASTM Steel Grades PDFkanteron6443Nessuna valutazione finora

- All JournalJournal Web Site and IF Web Site and IfDocumento60 pagineAll JournalJournal Web Site and IF Web Site and IfAdel EldenglaweyNessuna valutazione finora

- Chemistry Paper 3 130514Documento7 pagineChemistry Paper 3 130514ajakazNessuna valutazione finora

- Ash in A Graphite Sample: Standard Test Method ForDocumento2 pagineAsh in A Graphite Sample: Standard Test Method Forguadalupegomezperez100% (2)

- Alginate LectureDocumento12 pagineAlginate LectureAshley N. HarrisNessuna valutazione finora

- CSR-05-074-15001 NDI D13 Dark Grey Sol Gel PFD-FMEA-PCP Rev 00Documento54 pagineCSR-05-074-15001 NDI D13 Dark Grey Sol Gel PFD-FMEA-PCP Rev 00Wahyu Jumain HayarullahNessuna valutazione finora

- Design Guide For Ultrasonic Welding BransonDocumento12 pagineDesign Guide For Ultrasonic Welding BransonNam Cao HuỳnhNessuna valutazione finora

- Fiber Reinforced Concrete: Developments and Applications To BuildingsDocumento10 pagineFiber Reinforced Concrete: Developments and Applications To BuildingschkevinlyNessuna valutazione finora

- MAG-welding of Zn-Coated Steel, A Continued Process Study: Research ReportDocumento42 pagineMAG-welding of Zn-Coated Steel, A Continued Process Study: Research ReportbertilssonNessuna valutazione finora

- Universities in UKDocumento14 pagineUniversities in UKPuneet JainNessuna valutazione finora

- NPQS C3-20 ReinforcementDocumento0 pagineNPQS C3-20 ReinforcementCasimir Ghee Heng LimNessuna valutazione finora

- 03 Series, MIL-PRF-85285, Ty I, CL H, Polyurethane Topcoat, DEFT, 10-29CDocumento1 pagina03 Series, MIL-PRF-85285, Ty I, CL H, Polyurethane Topcoat, DEFT, 10-29C김도균Nessuna valutazione finora

- Material Grade S275Documento3 pagineMaterial Grade S275Tran Van DaiNessuna valutazione finora

- Supp Elements 17 For Machine DesignDocumento35 pagineSupp Elements 17 For Machine DesignCyron Elden Senarillos-Talita Bangis-BodegasNessuna valutazione finora

- DSI ALWAG-Systems Pantex Lattice Girders EDocumento8 pagineDSI ALWAG-Systems Pantex Lattice Girders Epramods_8Nessuna valutazione finora

- Nickel (II) and Zinc (II) Dibenzoylmethanates: Molecular and Crystal Structure, Polymorphism, and Guest-Or Temperature-Induced OligomerizationDocumento11 pagineNickel (II) and Zinc (II) Dibenzoylmethanates: Molecular and Crystal Structure, Polymorphism, and Guest-Or Temperature-Induced Oligomerizationrishav mansuriNessuna valutazione finora

- Is Phosphorus Bad For SteelDocumento19 pagineIs Phosphorus Bad For SteelKarun Dev100% (1)