Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Lesson Learnt For Piping and Mechanical

Caricato da

Manh Tien HoangDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

The Lesson Learnt For Piping and Mechanical

Caricato da

Manh Tien HoangCopyright:

Formati disponibili

The lesson learnt for Piping and Mechanical: There are some conflicts in specification which furnished by client.

. But these differences could not be found by during checking before award and during preparation of drawings. This mistake affected to engineering as well as construction so much. .. . . So we have to study carefully all specification and incorporate between disciplines in project. During checking P !D" we should pay more attention to #$ote% below. These can affect to &T'" specification" drawings (or e)ample" the length of fle)ible hose was determined in datasheet. *owever the connection from where to where usually noted in P !D. Based on these notes" the length of fle)ible hose can be changed in comparison with the length shown in data sheets. Sometimes the length too short or too long is also suitable for installation and operation. During checking !sometric from client" we should update the modifications and changes in to + common P !D in order to control easily. The performance &T' was no so good. There was still some Top,up &T' due to low contingency" wrong &T'" the changes lesson learnt for the ne)t project by many ways- ascending the contingency" the bulk material shall be ./0 and add more ./0 for *12 line" and more 3 D* lines as contingency" and add more gaskets for swing spool !n the design stage" we have to take care to ensure the hydro test can be done later. The spool shall have the vent- drain 4flageolet and blind flange5 at the pocket where water can be trapped. (or bolts at the joints where have insulation gasket or T67 should be longer than the length as normally case. !n the !sometric drawings" the bolts" nut and gaskets should be put on *12 lines at tie in point between onshore and offshore in order to avoid missing material during fabrication onshore lines. During review and incorporate vendor data" the orientation of jack up rig shall be considered in order to avoid clashing to the e8uipment" instrument such as fire water monitor" eye wash and shower" lighting 7lso pay more attention for SP items. The space around corrosion coupon has to be enough to connect 9etrieving Tool. (or 2ontinuous Drainers Trap" :e need do check carefully the direction of flow for model in PD&S and installation correctly. (lame 7rrestor location should be near the end of vent boom to arrest the flame as soon as possible. (or manual valves" e8uipment" the space around them shall ade8uate for operation and maintenance. :hen we establish the hydro test package register" to make sure all of lines included in this list. ;esson learn is the lines which connect to riser 4behind shutdown valve5 to be

performed hydro test onshore despite of *12 lines name to ensure one golden weld joint only. The connection joint inside e8uipment" especially is where storing pressure" the flange type must be used" no threaded type which is difficult for repairing and replacement. The self contain eye wash and shower is an e)ample. The leaking found at many threaded connection joints. !t takes time to repair it. The e8uipment lifting procedures were submitted late lead to comments from client. These procedures should be approved by client minimum one day before lifting e8uipment. <alve re8uirement of lock open and lock close. Some of manual valves don=t have the mechanism for lock open and lock close. 9e8uire to access this unit during TB>.

+. (or /? packages which scope supply of *;@'2 handover to P<2,&S for management" are delayed or effect to installation or operation due to these reason listed belowA , 'pen and 2losed Drain SkidA The *armonic (ilter delayed due to it had supplied by many sub of sub,contractor that caused more difficult to e)pedite. The lesson learnt of this is any package should define clearly main groupA Priority items group and normal items groups and e)pedite accordingly. Diesel 2onditioning SkidA The beam siBe had change according to the TC. But it did not inform to construction for the welding of skid=s foundation. !t took a long time for repair foundation to meet with the siBe of skid. (uel Das SkidA 7lco=s <alves had the wrong dimension hole. C2s Package witnessed to check material together <endor" they did not make sure all material shall be received with correct not only 8uantity but also good 8uality such as Dimension according to the re8uirements or not. :ell 2lean,up (ilterA The <endor Data not follow as the project communication line. That made missing many documents as well as information for all parties and their action. (7T informed and Package >ngineers witness at &anufacturer but C2 not re8uested to involve that reason why the good delivered with some descriptions not meet with the re8uirements. 7n e)ample" the insulation" grating" location and direction of Pressure gauges etc ;esson learnt is at (7T stage" (inal inspection to issue !nspection 9elease $ote C2 shall be re8uired to involve and limit the punch list. Pig ;auncherA *ydro Test at &anufacturer did not safety as some picture of the report. !t shown that the Blind flange was cut from a plate" although as the re8uirements it should

be a Standard item" and only 8ualified material used for the Test. ;esson ;earnt for this is before any hold point" all material and e8uipment are used for the Test shall be reviewed carefully and with all precondition. .. (or Pedestal 2rane PackageA This package is free issued by *;@'2. This package delayed one month that effected to construction at P<2,&S Site. The hydraulic horses were too long that caused the torsion and effected to the life of hose. 'therwise" the spare parts supplied not satisfy the actual re8uirement. !t takes a long time for buying when <endor run S7T at P<2,&S Site. Swagelok fitting had not supplied as the re8uirements. >specially" the hydraulic oil used for S7T mi)ed between two types with the same Standard but different &anufacturer. This thing caused identical oil and created problems with the *ydraulic System of 2rane. 7lthough it was accordingly the instruction of <endor" but it cannot acceptable. ;esson learnt of this is check carefully the spare parts based on actually re8uirements of parts at pre,commissioningE commissioning stagereview carefully B'& to confirm that all material shall be provided according to the specification re8uirements- all <endor=s instruction should be re,check and make sure follow the guide as 2odes and Standards. F. PS< and 9upture Disk Package G The calculation shown that the siBe of PS< changed. !t should be update to Detailed >ngineering and the isometric shall be changed accordingly. But it did not inform and effected to engineering and construction. ;esson learnt of this is taking notes for all packages that their calculation could be effected to other as P!D" isometric and it shall be made &T' and purchased timely. 3. 7ccess (itting Package G justification P' due to the re8uest from 2ustomer ?.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- CSWIP 3.1 New Book PDFDocumento590 pagineCSWIP 3.1 New Book PDFAsim90% (10)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Aspen HYSYS UpstreamDocumento211 pagineAspen HYSYS UpstreamManh Tien Hoang100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Cantilever Calculation ToolDocumento10 pagineCantilever Calculation ToolEnoch Twumasi50% (2)

- PACCON18 ProceedingBK FullpaperDocumento1.486 paginePACCON18 ProceedingBK FullpaperDo Ngoc Tram67% (3)

- Stone Blower 1Documento22 pagineStone Blower 1kbaker001Nessuna valutazione finora

- D6372-15-Design, Testing, and Construction of Micro SurfacingDocumento8 pagineD6372-15-Design, Testing, and Construction of Micro SurfacingEveling Vanegas NarváezNessuna valutazione finora

- EProcess DO Hydrocyclone Design Basis P1906Documento1 paginaEProcess DO Hydrocyclone Design Basis P1906Manh Tien HoangNessuna valutazione finora

- SDFSDFDSDSFDocumento211 pagineSDFSDFDSDSFManh Tien Hoang100% (1)

- HIPPS Detail EngineeringDocumento7 pagineHIPPS Detail EngineeringManh Tien HoangNessuna valutazione finora

- Clarification For 1749 & 2360 - ProcessDocumento1 paginaClarification For 1749 & 2360 - ProcessManh Tien HoangNessuna valutazione finora

- Layout Lau 9 - 26-10Documento1 paginaLayout Lau 9 - 26-10Manh Tien HoangNessuna valutazione finora

- 2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedDocumento166 pagine2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedManh Tien HoangNessuna valutazione finora

- Hysys PrintDocumento27 pagineHysys PrintManh Tien HoangNessuna valutazione finora

- Why Pigs Get StuckDocumento16 pagineWhy Pigs Get StuckAmir HoseiniNessuna valutazione finora

- Pigging Frequency For DewaxingDocumento10 paginePigging Frequency For DewaxingPNNessuna valutazione finora

- Why Pigs Get StuckDocumento16 pagineWhy Pigs Get StuckAmir HoseiniNessuna valutazione finora

- Why Pigs Get StuckDocumento16 pagineWhy Pigs Get StuckAmir HoseiniNessuna valutazione finora

- Pigging Frequency For DewaxingDocumento10 paginePigging Frequency For DewaxingPNNessuna valutazione finora

- PM3 - Corrosion StudyDocumento8 paginePM3 - Corrosion StudyManh Tien HoangNessuna valutazione finora

- Ansi Classes Body Material SelectionDocumento3 pagineAnsi Classes Body Material SelectionManh Tien HoangNessuna valutazione finora

- Controlling Vessels and TanksDocumento20 pagineControlling Vessels and TanksAndrew LarsonNessuna valutazione finora

- Materials SelectionasdfsfDocumento28 pagineMaterials SelectionasdfsfManh Tien HoangNessuna valutazione finora

- Thesis Reza MalekzadehDocumento180 pagineThesis Reza MalekzadehManh Tien HoangNessuna valutazione finora

- PFP MaterialsDocumento13 paginePFP MaterialsManh Tien Hoang100% (1)

- CRS For Comment From MoM - 23jan14 (FAS) - IntecseaDocumento5 pagineCRS For Comment From MoM - 23jan14 (FAS) - IntecseaManh Tien HoangNessuna valutazione finora

- 11 DMDP A B 1111 001 R4 Instrument CommentDocumento1 pagina11 DMDP A B 1111 001 R4 Instrument CommentManh Tien HoangNessuna valutazione finora

- Cynara - Material Balance SummaryDocumento1 paginaCynara - Material Balance SummaryManh Tien HoangNessuna valutazione finora

- Provision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectDocumento41 pagineProvision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectManh Tien HoangNessuna valutazione finora

- Cynara - Material Balance SummaryDocumento1 paginaCynara - Material Balance SummaryManh Tien HoangNessuna valutazione finora

- BUGEN-00-10-N01-0103 Rev 4 Isolation Philosophy PDFDocumento25 pagineBUGEN-00-10-N01-0103 Rev 4 Isolation Philosophy PDFManh Tien Hoang100% (1)

- Neotecpipesys V2.5.77.0: - Dh2-Design Case - 1-3 - Rev-Da - HSC 6inch Line (40Mm PP) - 2 ConnectionsDocumento28 pagineNeotecpipesys V2.5.77.0: - Dh2-Design Case - 1-3 - Rev-Da - HSC 6inch Line (40Mm PP) - 2 ConnectionsManh Tien HoangNessuna valutazione finora

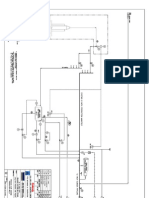

- 2007-4728-03-0100 Rev ASB Process Flow Diagram-Production Wells M PDFDocumento1 pagina2007-4728-03-0100 Rev ASB Process Flow Diagram-Production Wells M PDFManh Tien HoangNessuna valutazione finora

- Material Stream: To Drain Vessel: ConditionsDocumento2 pagineMaterial Stream: To Drain Vessel: ConditionsManh Tien HoangNessuna valutazione finora

- PVE BD 03 G 002 - Temporary Pig Receiver Typical Drawing - Rev.a.16.05Documento1 paginaPVE BD 03 G 002 - Temporary Pig Receiver Typical Drawing - Rev.a.16.05Manh Tien HoangNessuna valutazione finora

- GCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBODocumento2 pagineGCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBOKickingEdgarAllenPoeNessuna valutazione finora

- PPC Master MarchDocumento148 paginePPC Master MarchSandip JadhavNessuna valutazione finora

- Absolute LYFT Pulsed Eddy CurrentDocumento2 pagineAbsolute LYFT Pulsed Eddy CurrentgulmuhrNessuna valutazione finora

- Curriculum Vitae: John AyengahDocumento3 pagineCurriculum Vitae: John Ayengahjohn ayengahNessuna valutazione finora

- Slurry Pump The KproDocumento11 pagineSlurry Pump The Kpro4lk0nNessuna valutazione finora

- Y. S. Touloukian, J. Koolhaas Gerritsen, W. H. Shafer - Coatings, Systems, and Composites-Springer US (1973)Documento262 pagineY. S. Touloukian, J. Koolhaas Gerritsen, W. H. Shafer - Coatings, Systems, and Composites-Springer US (1973)slovvlistNessuna valutazione finora

- Ok Cien 30023 Construction Materials and TestingDocumento63 pagineOk Cien 30023 Construction Materials and TestingMark Luis QuejanoNessuna valutazione finora

- D2784Documento7 pagineD2784rimi7alNessuna valutazione finora

- 6 Big Losses in Manufacturing-2Documento3 pagine6 Big Losses in Manufacturing-2izzudinrozNessuna valutazione finora

- Weight of Marine PlywoodDocumento1 paginaWeight of Marine Plywooddanilo laraNessuna valutazione finora

- 2-1-2 - General Specification of Main Laying Materials For Waterworks LatestDocumento112 pagine2-1-2 - General Specification of Main Laying Materials For Waterworks LatestRaulSaavedra0% (1)

- End Sem Q PaperDocumento2 pagineEnd Sem Q PapersantkabirNessuna valutazione finora

- Chilled Beam Examples - Passive and ActiveDocumento3 pagineChilled Beam Examples - Passive and ActivesafdarNessuna valutazione finora

- Cooling Tower ReportDocumento11 pagineCooling Tower Reportbae zazNessuna valutazione finora

- Injection System VMUplusDocumento15 pagineInjection System VMUplusmohamed rafiNessuna valutazione finora

- Prevention of Mould Growth in BuildingsDocumento41 paginePrevention of Mould Growth in BuildingsmaxgyzerNessuna valutazione finora

- Dampers For Power Plant PDFDocumento31 pagineDampers For Power Plant PDFNikhil Mukesh Varshney100% (3)

- Iso 2528Documento8 pagineIso 2528nisa nurhidayatiNessuna valutazione finora

- Gas Turbine TrainingDocumento52 pagineGas Turbine TrainingNoble_Truth90% (10)

- Paint Coverage ConsumptionDocumento2 paginePaint Coverage ConsumptionSahilNessuna valutazione finora

- Literature Review Ema CpdicDocumento5 pagineLiterature Review Ema CpdicHemavathy RtNessuna valutazione finora

- Rele de Proteccion DGPT2 2Documento8 pagineRele de Proteccion DGPT2 2WALTERNessuna valutazione finora

- ROB StaircaseDocumento21 pagineROB StaircaseSambhav PoddarNessuna valutazione finora

- 0 - Pengantar Reaktor KimiaDocumento16 pagine0 - Pengantar Reaktor KimiaMuktafa AkmalNessuna valutazione finora

- hd1000 1 Inch Pump Specs v1.1Documento2 paginehd1000 1 Inch Pump Specs v1.1sf wNessuna valutazione finora