Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ASgb

Caricato da

athaya013Descrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ASgb

Caricato da

athaya013Copyright:

Formati disponibili

OIL PUMP TYPE AS GEAR SIZES 47-57-67

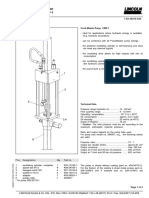

This is a general specification leaflet; for specific applications not covered herein, contact Suntec. The SUNTEC AS oil pump has a built in solenoid valve which controls the regulator cut-off valve giving fast cut-off and cut-on function independent of the rotational speed. APPLICATIONS - Kerosene, light oil. - One or two-pipe system. PUMP OPERATING PRINCIPLE The gear set draws oil from the tank through the built-in filter and transfers it to the valve that regulates the oil pressure to the nozzle line. All oil that does not go through the nozzle line will be dumped through the valve back to the return line in two pipe installation or, if it is a one-pipe installation, back to suction port in the gear set . In that case, the by-pass plug must be removed from the return port, and the return port sealed by steel plug and washer. The solenoid valve of the AS pump is of the "normally opened" type. When the solenoid valve is non-activated, the by-pass channel between the pressure and return sides of the valve is open. No pressure will then be built up to open the valve; it does not matter which speed the gear set has. When the solenoid is activated, this by-pass channel is closed and because of the full speed of the gear set, the pressure necessary to open the valve will be built up very rapidly, which gives a very sharp cut-on function. Cut-off : When the burner stops, the solenoid opens the by-pass at the same moment, which drains all the oil down to the return, and the nozzle valve closes immediately. This gives a very sharp cut-off function. The cut-on and cut-off can be actuated regardless of motor speed and have an extremely fast response. When the solenoid is not activated, the torque requirement is low up to full motor speed. Bleed : Bleeding in two pipe operation is automatic, but it may be accelerated by opening a pressure port. In one pipe operation, a pressure port must be opened to bleed the system.

AS

AS - 11 - Ed 15 - Feb. 2007

PUMP IDENTIFICATION

(Not all model combinations are available. Consult your Suntec representative) AS : pressure regulation and by-pass solenoid valve Gear set capacity (see pump capacity curves) Shaft rotation and nozzle location (seen from shaft end) A :clockwise rotation/ right hand nozzle. B : clockwise rotation/ left hand nozzle. C : anti clockwise rotation/ left hand nozzle. D : anti clockwise rotation/ right hand nozzle. K : Kerosene applications Pump series 1000 : standard 7000 : with side pressure ports 4 : hub 54 mm 5, 6 : hub 32 mm Model number

AS 47 C K 1

Revision number

xx

05 00

Installation P : by-pass plug inserted in return port for two-pipe operation M : without by-pass plug; return plugged for one-pipe operation Solenoid coil voltage 01 : 110 - 120 V ; 50/60 Hz 02 : 24 V ; 50/60 Hz 05 : 220 - 240 V ; 50/60 Hz Connector cable length 00 : no cable 35 : 35 cm 45 : 45 cm 60 : 60 cm 10 : 1 m

Solenoid valve (NO) open

Solenoid valve (NO) closed

Pressure adjustment Shaft seal

To nozzle

Pressure gauge port Gear set Oil under suction

Back to suction

By-pass plug removed Return plugged ONE PIPE INSTALLATION

By-pass plug inserted TWO PIPE INSTALLATION

Vacuum gauge port

Oil under pressure By-passed oil returned to tank, or to suction

Return

Inlet

SUNTEC INDUSTRIES FRANCE - 1, rue Lavoisier - BP 102 - 21603 LONGVIC Cedex - Tel. 33 3 80 70 60 70 - Fax 33 3 80 70 61 11 - http://www.suntec.fr

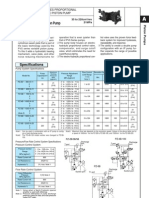

TECHNICAL DATA General

Mounting Connection threads Inlet and return Nozzle outlet Pressure gauge ports Vacuum gauge port Valve function Strainer Shaft By-pass plug Weight Flange or hub mounting according to EN 225. cylindrical according to ISO 228/1. G 1/4 (with facilities for conical sealing on revision 5 and 6 models) G 1/8 G 1/8 G 1/8 Pressure regulation and cut-off*. * cut-off function only assured for model pressure range. open area : 6 cm2 - opening size : 150 m. 8 mm according to European standard EN 225. inserted in return port for two-pipe system ; to be removed with a 4 mm Allen key for one pipe system. 1,1- 1,5 kg (depending on the model). Capacity (L/h)

100 90 80 70 60 50 40 30 20 10 0 4 5 6 7 8

Pump capacity

AS 67

Ref: SK241 - 23/04/99; SK318 - 27/01/07 Ref: SK241 - 23/04/99; SK318 - 27/01/07

AS 57 AS 67K AS 57K AS 47K

AS 47

Hydraulic Data

Gear size 47/47K 57/57K 67/67K Nozzle pressure range* Factory setting 7- 14 bars 9 bars 7- 14 bars 9 bars 10 - 15 bars 10 bars * other ranges available on request, refer to the specified range of the particular fuel unit. 2 - 12 mm/s (cSt) for AS 47/AS 57/AS 67 1 - 12 mm/s (cSt) for AS 47K/AS 57K/AS 67K 0 - 60C in the pump. 2 bars max. 2 bars max. 0,45 bars max. vacuum to prevent air separation from oil. 3600 rpm max. for AS 47/AS 47K/AS 57/AS 57K 2850 rpm max for AS 67/AS 67K 0,10 N.m for AS 47/AS 47K/AS 57/AS 57K 0,12 N.m for AS 67/AS 67K

10 11 12 13 14 15 16 17 18

Pressure (bars) Viscosity = 5 cSt - Rated speed = 2850 rpm 1,8 cst

Data shown take into account a wear margin. Do not oversize the pump when selecting the gear capacity.

Operating viscosity Oil temperature Inlet pressure Return pressure Suction height Rated speed Torque (@ 45 rpm)

Power (W)

120 110 100 90 80 70 60 50 40 30 20 4 5 6 7

Power consumption

AS 67 AS 67K AS 57 AS 57K AS 47K AS 47

Solenoid valve characteristics

Voltage Consumption Ambient temperature Maximum pressure Certified Protection class 220-240 or 110-120 or 24 V; 50/60 Hz. 9W 0 - 60C 25 bars TV Nr. stamped on pump cover. IP 54 according to EN 60529, when used with SUNTEC connector cable.

10 11 12 13 14 15 16 17 18

Viscosity =

Pressure (bars) 5 cSt - Rated speed = 2850 rpm 1,8 cst

PUMP DIMENSIONS

Pumps revision 1,3,5

25 41

Examples show "C" rotation and nozzle outlet.

51 39 25

Pumps revision 4,6

41

51 39

"

77 42

! $

74

77

"

42

! $

74

#

21 32 54 10,5 35

#

21 32 54 10,5 35

'

A-A

13 47 118 21 7 8

'

A-A 13,5 13,5 63 92

'

13 47 21 7 8

'

13,5 13,5 63 92

&

&

15

Inlet & and Return % with direct sealing for revision 5 and 6 models (sealing with washers can also be used)

& Suction %

Return and internal by-pass plug

! Pressure gauge port " Vacuum gauge port # Pressure adjustment '

Pressure port (only for "7000" series)

$ Nozzle outlet

G1/4

We reserve the right to change specifications without prior notice.

AS - 11 - Ed 15 - Feb. 2007

Potrebbero piacerti anche

- ValvesDocumento135 pagineValvesShivang Gaur100% (4)

- Performance Appraisal Form For ManagerDocumento12 paginePerformance Appraisal Form For Managervandana_dubey15Nessuna valutazione finora

- Valves Grese NDocumento92 pagineValves Grese NYair Alexis Muñoz Rojas100% (1)

- Bom A4VG - REXROTHDocumento44 pagineBom A4VG - REXROTHnamduong368100% (4)

- The Weir Direct-Acting Feed Pump - Working InstructionsDa EverandThe Weir Direct-Acting Feed Pump - Working InstructionsNessuna valutazione finora

- Astm A325mDocumento8 pagineAstm A325mChitra Devi100% (1)

- Automatic Recirculation Valve BrochureDocumento12 pagineAutomatic Recirculation Valve BrochureYuvaraj NithyanandamNessuna valutazione finora

- lt3 00032 2 A p24 p30sDocumento67 paginelt3 00032 2 A p24 p30sBruno SamaeianNessuna valutazione finora

- 50 58 Eng Concrete TestingDocumento92 pagine50 58 Eng Concrete TestingJimmy LopezNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- REXROTH Service Manual PVC PSSFDocumento6 pagineREXROTH Service Manual PVC PSSFRaghavendra DeshpandeNessuna valutazione finora

- Digital Control ValveDocumento8 pagineDigital Control Valvecnrk777100% (1)

- VMCDocumento32 pagineVMCJoanaRicardo FigueiredoNessuna valutazione finora

- Ra 92711Documento39 pagineRa 92711Agus Yulfizar100% (3)

- SPM Full Bore Emergency Unloading Valve Manual PDFDocumento9 pagineSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoNessuna valutazione finora

- Bul 36115 Servo Valve OperationDocumento12 pagineBul 36115 Servo Valve Operationrikkitech100% (1)

- Proportional Electro-Hydraulic ControlsDocumento31 pagineProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Management Information System KFCDocumento29 pagineManagement Information System KFCTamilSelvan0% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Thought Leadership Is The New Sales PitchDocumento8 pagineThought Leadership Is The New Sales PitchChad NelsonNessuna valutazione finora

- Prevention of Actuator Emissions in the Oil and Gas IndustryDa EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Axial Variable Duoble PumpDocumento40 pagineAxial Variable Duoble Pumpveljeg100% (1)

- Manual Técnico - Pump Haskel - MS 21Documento14 pagineManual Técnico - Pump Haskel - MS 21Bruno Pacheco100% (1)

- AP GBDocumento2 pagineAP GBTitu NicuNessuna valutazione finora

- SUNTEC Pompa AL Fisa-TehnicaDocumento2 pagineSUNTEC Pompa AL Fisa-TehnicaStroia Constantin MariusNessuna valutazione finora

- Oil Pump Type E 1001 Gear Sizes 4-6-7Documento2 pagineOil Pump Type E 1001 Gear Sizes 4-6-7Titu NicuNessuna valutazione finora

- PVR-108-2 Fueling Model SheetDocumento2 paginePVR-108-2 Fueling Model SheetLetycia RosalesNessuna valutazione finora

- Series 30: Operating PrincipleDocumento8 pagineSeries 30: Operating PrincipleDgek LondonNessuna valutazione finora

- Sur - Flo Turbine MeterDocumento40 pagineSur - Flo Turbine MeterCheng HuangNessuna valutazione finora

- Oil Pump Type D GEAR SIZES 45-47-55-57-67Documento2 pagineOil Pump Type D GEAR SIZES 45-47-55-57-67Titu NicuNessuna valutazione finora

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Documento8 pagineVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliNessuna valutazione finora

- Features: How To Order (AOC-08 Models Only)Documento4 pagineFeatures: How To Order (AOC-08 Models Only)CarmenLinoBedoyaNessuna valutazione finora

- SideWinder 40 60 80 CHMCL PMP BrchreDocumento4 pagineSideWinder 40 60 80 CHMCL PMP BrchreSH McNessuna valutazione finora

- Lift Check ValvesDocumento4 pagineLift Check Valveslejyoner62Nessuna valutazione finora

- A10v0 Variable Displacement Piston PumpDocumento23 pagineA10v0 Variable Displacement Piston PumpVanadia Nohan100% (1)

- Models A & B Automatic Pressure Maintenance DevicesDocumento4 pagineModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASNessuna valutazione finora

- NIMCO CV300newDocumento24 pagineNIMCO CV300newBruno SamaeianNessuna valutazione finora

- Dimensions Specifications: 125 Booster Pump ControlDocumento6 pagineDimensions Specifications: 125 Booster Pump ControlDheeraj ThakurNessuna valutazione finora

- Manual Balancing Valves CIM 747H: Technical InformationDocumento10 pagineManual Balancing Valves CIM 747H: Technical InformationblindjaxxNessuna valutazione finora

- SATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFDocumento20 pagineSATECH - Eagle Control-Matic - WHC System EH36 Series - Product Brochure (Ed011211 1214Hr) PDFuserscribd2011Nessuna valutazione finora

- Models A & B Automatic Pressure Maintenance DevicesDocumento4 pagineModels A & B Automatic Pressure Maintenance DevicesSavy PhanethNessuna valutazione finora

- Valves Grese NDocumento92 pagineValves Grese NRandall KirchbergNessuna valutazione finora

- PVS Series NachiDocumento19 paginePVS Series NachiDian Pramadi100% (1)

- SideWinder 42 62 82 CHMCL PMP IOMDocumento4 pagineSideWinder 42 62 82 CHMCL PMP IOMSH McNessuna valutazione finora

- 75A 38010 A03 ContiMasterDocumento4 pagine75A 38010 A03 ContiMasterjacklyn ade putra100% (1)

- Re10515 2005-10Documento32 pagineRe10515 2005-10Puchianu MarianNessuna valutazione finora

- Switch de PresiónDocumento2 pagineSwitch de PresiónCARLOS RAMOSNessuna valutazione finora

- Int Assm Regen PDFDocumento8 pagineInt Assm Regen PDFJuan Eduardo JeRicoNessuna valutazione finora

- Automatic Gas Manifolds Installation, Operation & Maintenance ManualDocumento20 pagineAutomatic Gas Manifolds Installation, Operation & Maintenance ManualtaibkNessuna valutazione finora

- fp50 fp100 fp200Documento10 paginefp50 fp100 fp200ducmanh83Nessuna valutazione finora

- 3-Way Dual Shut Off ValvesDocumento1 pagina3-Way Dual Shut Off ValvesPete DechaNessuna valutazione finora

- Trokraki On - Off VentilDocumento12 pagineTrokraki On - Off VentilAdvokat HadziTonicNessuna valutazione finora

- Cartridgevalves PDFDocumento15 pagineCartridgevalves PDFÂnderson Silva BrasilNessuna valutazione finora

- Spek PompaDocumento2 pagineSpek PompaYand's PermanaNessuna valutazione finora

- 01072Documento4 pagine01072윤병택Nessuna valutazione finora

- All About HidrolicDocumento7 pagineAll About Hidrolicpiteng1945100% (3)

- Abovegroundhydrants Dropdownpillar 84-25-27 P7 PDFDocumento4 pagineAbovegroundhydrants Dropdownpillar 84-25-27 P7 PDFLimhot SitanggangNessuna valutazione finora

- Pompe Combustibil As - Carte TehnicaDocumento2 paginePompe Combustibil As - Carte TehnicaLucian UrsuNessuna valutazione finora

- Ross Pump Control Valves BrochureDocumento6 pagineRoss Pump Control Valves BrochureHassan HaiderNessuna valutazione finora

- Series V100 Ball ValveDocumento20 pagineSeries V100 Ball ValvejenniferNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SDa EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNessuna valutazione finora

- Chapter 6 Tutorial PDFDocumento4 pagineChapter 6 Tutorial PDFAhmad NAz RaInNessuna valutazione finora

- Fifths emDocumento5 pagineFifths emcoolguy19895Nessuna valutazione finora

- Odisha Current Affairs 2019 by AffairsCloudDocumento27 pagineOdisha Current Affairs 2019 by AffairsCloudTANVEER AHMEDNessuna valutazione finora

- Utilisation of Electrical Energy May 2008Documento8 pagineUtilisation of Electrical Energy May 2008rajaniramNessuna valutazione finora

- Shannons ModelDocumento2 pagineShannons ModelransNessuna valutazione finora

- Aniuk SpecimenDocumento10 pagineAniuk SpecimenMario ParraNessuna valutazione finora

- Atm ProjectDocumento18 pagineAtm Projectsujit_ranjanNessuna valutazione finora

- Industrial Visit Report OnDocumento41 pagineIndustrial Visit Report OnLalit SharmaNessuna valutazione finora

- TWITCH INTERACTIVE, INC. v. JOHN AND JANE DOES 1-100Documento18 pagineTWITCH INTERACTIVE, INC. v. JOHN AND JANE DOES 1-100PolygondotcomNessuna valutazione finora

- Updated After 11th BoS Course Curriculum - B.tech CSEDocumento120 pagineUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNessuna valutazione finora

- ProKlima Entfeuchter ManualDocumento336 pagineProKlima Entfeuchter ManualJonNessuna valutazione finora

- Atul Gaonkar Resume 2017Documento6 pagineAtul Gaonkar Resume 2017Vinod KaleNessuna valutazione finora

- Spring Setting of Piping Connected To A CompressorDocumento4 pagineSpring Setting of Piping Connected To A CompressorSharun SureshNessuna valutazione finora

- CONTRIBN MADE by Deming, Juran and CrosbyDocumento14 pagineCONTRIBN MADE by Deming, Juran and CrosbySachin Methree100% (1)

- Vladimir Lopez Stem Teacher ResumeDocumento1 paginaVladimir Lopez Stem Teacher Resumeapi-325782374Nessuna valutazione finora

- Distributed Exam 2017Documento3 pagineDistributed Exam 2017Israel Oteka0% (1)

- Marina Bay SandsDocumento5 pagineMarina Bay SandsTauqeer A. BalochNessuna valutazione finora

- Fluid MechDocumento2 pagineFluid MechJade Kristine CaleNessuna valutazione finora

- HIU Range Design GuideDocumento24 pagineHIU Range Design Guidesachinsaklani23Nessuna valutazione finora

- Palmtop Computer (Report of Early Usage)Documento8 paginePalmtop Computer (Report of Early Usage)rodrigur8036100% (2)

- Be Katalog-Grabenfr 2013 Engl RZ KleinDocumento36 pagineBe Katalog-Grabenfr 2013 Engl RZ Kleincherif100% (1)

- Personal Data Sheet: Criminology Intern UnitDocumento1 paginaPersonal Data Sheet: Criminology Intern UnitJoseph RycheNessuna valutazione finora

- Quick Operation Guide of DS-7200-ST DVR (V1.2.0)Documento40 pagineQuick Operation Guide of DS-7200-ST DVR (V1.2.0)Roman MayurNessuna valutazione finora

- Method Statement of Refrigran Pipe Insulation and Cladding InstallationDocumento16 pagineMethod Statement of Refrigran Pipe Insulation and Cladding InstallationOdot Al GivaryNessuna valutazione finora