Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Determining Control Points LO1

Caricato da

GideonCavidaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Determining Control Points LO1

Caricato da

GideonCavidaCopyright:

Formati disponibili

Hawassa Polytechnic College

Surveying & Spatial Information Services II

(Occupation and Level)

Unit of Competence: Module Title: LG Code: TTLM Code:

Determine Control Points Determining Control Points

EIS SSI2 M06 L01-25

EIS SSI2 TTLM 1112 v. 1

LO 1: Plan & Prepare

Ethiopian TVET System Training, Teaching and Learning Materials

Instruction Sheet

Learning Guide 25

This learning guide is developed to provide you the necessary information regarding the following content coverage and topics

Preparing work instructions Safety requirement Selecting equipment for the job

This guide will also assist you to attain the learning outcome stated in the cover page. Specifically, upon completion of this Learning Guide, you will be able to

Obtain work instructions including plans, specifications Obtains Safety requirements Identify Signage requirements Select tools and equipment to carry out tasks

Learning Activities

1. 2.

Read the specific objectives of this Learning Guide. Read the information written in the Information Sheet __. Try to understand what are being discussed. Ask you teacher for assistance if you have hard time understanding them. Accomplish the Self-check in page __. If you earned a satisfactory evaluation proceed to Operation Sheet in page __. However, if your rating is unsatisfactory, see your teacher for further instructions or go back to Learning Activity #__. Read the Operation Sheet and try to understand the procedures discussed. Do the LAP test in page 21 (if you are ready) and show your output to your teacher. Your teacher will evaluate your output either satisfactory or unsatisfactory. If unsatisfactory, your teacher shall advice you on additional work. But if satisfactory you can proceed to Learning Guide 26.

3. 4.

5. 6.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 1 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Information Sheet-1

Overview

Preparing Work instructions

Planning and preparing for tasks includes confirming instructions, identifying any safety requirements and selecting the correct equipment for measuring and calculating materials. During the planning and preparation stage of any activity it is essential to consider all aspects of the task. This may include the task requirements, communication requirements, safety requirements, equipment requirements and the material requirements. Before starting to take measurements or make calculations, you should always check the equipment you will be using for serviceability and suitability for the tasks. During the entire measuring and calculations phase of a task, you should always remember measure twice, cut once. This adage is just as relevant with calculations, calculate twice, order once. This approach ensures you measure, calculate and complete the tasks efficiently and effectively and avoid making mistakes that will lead to wasted time, money or materials.

Confirming and applying work instructions

At the start of any activity or task it is important to confirm the work instructions. Instructions may be given to you verbally or in written form. Checking instructions can be done in a number of ways but questioning the person who has given you the instruction is the easiest. Other ways could include checking workplace procedures, company policies, plans or specifications. All tasks undertaken in the construction industry should have a variety of documentation that can be used to confirm and apply work instructions, including: diagrams, sketches, maps, signs, plans instructions from internal or external personnel manufacturer specifications and instructions safety data sheets (SDSs) the organisations work specifications, procedures and policies regulatory and legislative requirements, and Ethiopian standards safe work method statements (SWMSs) or procedures, job safety analysis sheets (JSAs) work bulletins, memos or schedules.

TTLM : Determining Control Points Date: November 2012 Author: Zerihun Muluneh/GPC

Page 2 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Copies of these documents can be found in the site office or the organisations main office. Most of this information will be included in your workplace policies and procedures. Everyone at the worksite needs to read, understand and follow the workplace policies and procedures to ensure all work is done safely and effectively. Once you have confirmed the instructions and are aware of the requirements for the task, you can then do what has been asked of you.

The Reason For Work Instructions

So what is the purpose of documented work instructions? Besides having them available for audit review, why do such documents exist? Work instructions are developed to guide workers in four key quality areas: training, reference, problem solving and continuous improvement. Each of these areas can be directly related to the Deming Cycle, a cycle that identifies fundamental quality planning as "Plan-Do-Check-Act." It is important to establish (plan) the instructions that your people must execute. The references must then be effectively implemented (do) so they are accessible to personnel. Documentation must be verified (check) so the instructions assist your problemsolving methodology. Finally, it is important to use (act) what has been defined in order to continuously improve.

Reason #1. Training (Plan). Training is the essential first step to ensuring that people are competent in their duties. It is important to define, within the quality

TTLM : Determining Control Points Date: November 2012 Author: Zerihun Muluneh/GPC

Page 3 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

planning activities, the type of training that each function is to receive. It is equally necessary to ensure that the trainers are executing the plan, including improvements made to the instructions. New employees should start their training with the process expert so they can observe how the process should be performed. It is here that detailed training discussions and hands-on activities take place between the expert and the trainee. The trainer uses the work instructions so new employees understand the basis for the tasks they are performing. The process is an opportunity for additional review of the work instruction content. The veteran can reaffirm the defined steps, and the new employee can confirm the validity of the process. Reason #2. Reference (Do). This quality activity should focus on both access and format of the instructions. The documentation must be implemented so workers are not wary of having to locate the information relative to their areas of responsibility. Once employees have been trained and have demonstrated that they can be effective performers, you must ensure that the work instructions are available in case of questions. The instructions must be presented in an easy-to-understand format so that access and review will not take up valuable time. Write out how the instruction is to be performed specific to each core task. Avoid defining why the activity is performed. There should be no need for an expert organization to reaffirm why core tasks are needed. If the "why" information must be defined, keep that separate from the work instructions and make the additional information available as reference-only training documents. Reason #3. Problem Solving (Check). Problem solving is a quality activity that focuses on ensuring that the supporting processes are properly defined to achieve product quality. Documentation should be referenced frequently to ensure that relevance is maintained. Work instructions are key documents to reference when internal or external nonconformances are identified. Make the review of the work instructions part of the corrective action process. Ask if the supporting instruction properly defines the process, then audit the instruction to confirm proper definition. The operator/employee cannot be held fully accountable if the records of training are written to an inadequately defined work instruction. If the task is properly defined, the manner by which training is conducted might need to be revisited. Reason #4. Continuous Improvement (Act). Work instructions should not be stagnant documents accessed only when auditors ask for them. Reviewing work instructions when improvement opportunities are identified demonstrates that they are "living documents." Instructions can be improved upon through document reviews, audits, a disciplined problem-solving process and, most importantly, the input from the experts who are performing the tasks. The current documentation should be the starting point for all

TTLM : Determining Control Points Date: November 2012 Author: Zerihun Muluneh/GPC Page 4 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

improvements. Always improve upon existing documentation before creating a new document. Volume does not equate to continuous improvement.

Basic Work instruction in Surveying

Taking the instrument safely to the site Setting out the instrument properly on the ground for adjusting Adjusting the instrument for working Collecting the necessary data from the field Office processing the collected data Controlling and changing to ground the processed data according its importance

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 5 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Self-Check 1

Name: _________________________

Written Test

Date: _______________

Directions: Answer all the questions listed below. Illustrations may be necessary to aid some explanations/answers. 1. What are the important aspects in planning and preparing for tasks? (3 pts.) 2. Explain the saying, measure twice, cut once. (2 pts.) 3. What is the purpose of documented work instructions? (2 pts.) 4. In your own words, explain each of the four key quality areas of planning with respect to work instructions. (8 pts.)

Note: Satisfactory rating - 15 points Unsatisfactory - below 15 points You can ask you teacher for the copy of the correct answers.

TTLM : Determining Control Points Date: November 2012 Author: Zerihun Muluneh/GPC Page 6 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Information Sheet-2 Safety requirement

Safety Requirement

To minimize the possibility of damage always keep the accessory port door closed Do not use out of the accepted rang of energy or out of the recommended rang of power which limited by the manufactured organization Do not aims the telescope at the sun use the solar filter to avoid casing internal damage to the instrument when observing the sun. Protect the instrument from heavy shocks or vibration Turn the power off before removing battery Adverse use can lead to injury, malfunction and damage. The person responsible for the product must ensure that it is used in accordance with the instruction

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 7 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Proper Use of Work Equipment

The suitability of work equipment equipment must be suitable by design and construction for the actual work it is provided to do. 1. Maintenance of work equipment in good repair from simple checks on hand tools such as loose hammer heads to specific checks on lifts and hoists. When maintenance work is carried out it should be done in safety and without risk to health. 2. Information and instruction on use of the work equipment including instruction sheets, manuals or warning labels from manufacturers or suppliers. Adequate training for the purposes of health and safety in the use of specific work equipment. 3. Dangerous parts of machinery guarding machinery to avoid the risks arising from mechanical hazards. The principal duty is to take effective measures to prevent contact with dangerous parts of machinery by providing: a) fixed enclosing guards; b) other guards or protection devices; c) protection appliances (jigs, holders); d) information, instruction, training and supervision. 4. Protection against specified hazards a) material falling from equipment; b) material ejected from a machine; c) parts of the equipment breaking off, e.g. grinding wheel bursting; d) parts of equipment collapsing, e.g. scaffolding; e) overheating or fire, e.g. bearing running hot, ignition by welding torch; f) explosion of equipment, e.g. failure of a pressure-relief device; g) explosion of substance in the equipment, e.g. ignition of dust. 5. High and very low temperature prevent the risk of injury from contact with hot (blast furnace, steam pipes) or very cold work equipment (cold store). 6. Controls and control systems starting work equipment should only be possible by using a control and it should not be possible for it to be accidentally or inadvertently operated nor operate itself (by vibration or failure of a spring mechanism). Stop controls should bring the equipment to a safe condition in a safe manner. Emergency stop controls are intended to effect a rapid response to potentially dangerous situations and should be easily reached and activated. Common types are mushroom headed buttons bars, levers, kick plates or pressure-sensitive cables. 7. Isolation from source of energy to allow equipment to be made safe under particular circumstances, e.g. when maintenance is to be carried out or when an unsafe condition develops. Isolation may be achieved by simply removing a plug from an electrical, socket or by operating an isolating switch or valve. 8. Stability there are many types of work equipment that might fall over, collapse or overturn unless they are fixed. Most machines used in a fixed position should be bolted down. Some types or work equipment such as mobile cranes may

TTLM : Determining Control Points Date: November 2012 Author: Zerihun Muluneh/GPC Page 8 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

need counterbalance weights. Ladders should be at the correct angle (a slope of four units up to each one out from the base), correct height (at least 1 metre above the landing place) and tied at the top or secured at the foot. 9. Lighting if the lighting in the workplace is insufficient for detailed tasks then additional lighting will need to be provided, e.g. local lighting on a machine 10. Markings there are many instances where marking of equipment is appropriate for health and safety reasons, e.g. start/stop controls, safe working load on cranes or types of fire extinguishers. 11. Warnings normally in the form of a permanent printed notice or similar, e.g. head protection must be worn (see page 19). Portable warnings are also necessary during temporary operations such as maintenance. Warning devices can be used which may be audible, e.g. reversing alarms on heavy vehicles, or visible, e.g. lights on a control panel. They may indicate imminent danger, development of a fault or the continued presence of a potential hazard. They must all be easy to see and understand, and they must be unambiguous. These Regulations set general requirements which are listed here in four broad areas: Working environment 1. ventilation; 2. temperature in indoor workplace; 3. lighting including emergency lighting; 4. room dimensions and space; 5. suitability of workstations and seating. Safety 1. safe passage of pedestrians and vehicles (e.g. traffic routes, must be wide enough and marked where necessary, and there must be enough of them); 2. windows and skylights (safe opening, closing and cleaning); 3. transparent or translucent surfaces in doors and partitions (use of safety material and marking); 4. doors, gates and escalators (safety devices); 5. floors (construction and maintenance, obstructions and slipping and tripping hazards); 6. falling from heights and into dangerous substances; 7. falling objects. Facilities 1. toilets; 2. washing, eating and changing facilities; 3. clothing storage; 4. drinking water; 5. rest areas (and arrangements to protect people from the discomfort of tobacco smoke). Housekeeping 1. maintenance of workplace, equipment and facilities; 2. cleanliness; 3. removal of waste materials.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 9 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Personal Protective Equipment

PPE is defined as all equipment which is intended to be worn or held to protect against risk to health and safety. This includes most types of protective clothing and equipment such as: eye, head, foot and hand protection; and protective clothing for the body. PPE should always be relied upon as a last resort to protect against risks to health and safety. The Trainer/Facilitator inside the Workshop has duties to: 1. assess the risks and PPE intended to be issued and that it is suitable; 2. maintain, clean and replace PPE; 3. provide storage for PPE when it is not being used; 4. ensure that PPE is properly used; and 5. give training, information and instruction to employees on the use of PPE and how to look after it. Kinds of PPE Eye protection: Serves as a guard against the hazards of impact, splashes from chemicals or molten metal, liquid droplets (chemical mists and sprays), dust, gases and welding arcs. Eye protectors include safety spectacles, eye-shields, goggles, welding filters, face shields and hoods

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 10 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Head protection: Includes industrial safety helmets to protect against falling objects or impact with fixed objects; industrial scalp protectors to protect against striking fixed obstacles, scalping or entanglement and caps and hairnets to protect against scalping and entanglement. Foot protection: Includes safety boots or shoes with steel toe caps; foundry boots with steel toe caps, which are heat resistance and designed to keep out molten metal; wellington boots to protect against water and wet conditions and anti-static footwear to prevent the build-up of static electricity on the wearer. Hand protection: Gloves of various design provide protection against a range of hazards including cuts and abrasions; extremes of temperature (hot and cold); skin irritation and dermatitis and contact with toxic or corrosive liquids. Barrier creams may sometimes be used as an aid to skin hygiene in situations where gloves cannot be used. Protective clothing: Types of clothing used for body protection include coveralls, overalls and aprons to protect against chemicals and other hazardous substances; outfits to protect against cold, heat and bad weather; and clothing to protect against machinery such as chain saws. Types of clothing worn on the body to protect the person include high-visibility clothing; life-jackets and buoyancy aids.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 11 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Using chemicals and other hazardous substances at work can put peoples health at risk. So the law requires employers to control exposure to hazardous substances to prevent ill health. Effects from hazardous substances include: skin irritation or dermatitis as a result of skin contact; asthma as a result of developing allergy to substances used at work; losing consciousness as a result of being overcome by toxic fumes; Cancer, which may appear long after exposure to the substances which caused it. Hazardous substances include: substances used directly in work activities, e.g. adhesives, paints and cleaning agents; substances generated during work activities, e.g. fumes from soldering or welding; naturally occurring substances, e.g. wood dust. Eight basic measures must take to comply to avoid Hazard 1. Assess the risks to health arising from hazardous substances present in their workplace. 2. Decide the precautions needed to avoid exposing anyone to hazardous substances. 3. Prevent or adequately control exposure of anyone to hazardous substances. 4. Ensure that control measures are used and maintained. 5. Monitor the exposure of anyone to hazardous substances if necessary. 6. Carry out appropriate health surveillance where there are sets for specific requirements. 7. Prepare plans and procedures to deal with accidents, incidents and emergencies. 8. Ensure that all are properly informed, trained and supervised. Trainers and Trainees must make full and proper use of any control measure; personal protective equipment (PPE) or any facility provided and report any defects found in these. Follow all instructions and safety information provided and only use and disposes of substances in the recommended manner. You should know the warning symbols and pay particular attention to any container bearing any of the symbols.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 12 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Electrical Hazard Electrical equipment of some kind is used in every factory. Electricity should be treated with respect it cannot be seen or heard, but it can kill. Even if it is not fatal, serious disablement can result through shock and burns. Also, a great deal of damage to property and goods can be caused, usually through fire or explosion as a result of faulty wiring or faulty equipment.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 13 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Safety Signs

Colours play an essential safety role in giving information for use in the prevention of accidents, for warning of health hazards, to identify contents of gas cylinders, pipeline and services, the identification and safe use of cables and components in electronic and electrical installations as well as the correct use of fire-fighting equipment. The purpose of a system of safety colours and safety signs is to draw attention to objects and situations which affect or could affect health and safety. The use of a system of safety colours and safety signs does not replace the need for appropriate accident prevention measures.

Information Sheet-2

Safety requirement

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 14 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

First Aid The minimum first aid provision for any workplace is 1. a suitably stocked first aid box 2. an appointed person to take charge of first aid arrangements. An appointed person is someone the employer chooses to 1. take charge when someone is injured or falls ill, including calling an ambulance if required. 2. look after the first aid equipment, e.g. restocking the first aid box. 3. Appointed persons should not attempt to give first aid for which they have not been trained. Depending on the category of risk and the number of people employed, it may be necessary to appoint a first aider. 4. A first aider is someone who has undergone a training course, approved by the Health and Safety Executive, in administering first aid at work and holds a current first aid at work certificate. 5. Employees must be informed of all first aid arrangements. Putting up notices, telling staff who and where the first aiders or appointed persons are, and where the first aid box is situated, will usually be sufficient.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 15 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Self-Check 2

Written Test

Name: _________________________

Date: _______________

Directions: Answer all the questions listed below. Illustrations may be necessary to aid some explanations/answers. 1. What is a personal protective equipment (PPE)? (1 pt.) 2. Give five (5) duties of the trainer in the workshop. (5 pts.) 3. List down five (5) examples of PPE for the eye protection. (5 pts.) 4. List down three (3) kinds of head PPEs. (3 pts.) 5. What are the protective clothing commonly used in the workshop? (3 pts.) 6. Why do we need to use hand gloves? (3 pts.) 7. Where can we find the instructions on how to use the equipments? (3 pts.) 8. How can we guard ourselves from dangerous parts of a machinery? (4 pts.) 9. What is the best thing to do when lighting is not sufficient in the workshop while working in an equipment? (1 pt.) 10. Give two (2) ways on how to maintain good housekeeping in the workshop. (2 pts.)

Note: Satisfactory rating -10 points Unsatisfactory - below _10_ points You can ask you teacher for the copy of the correct answers.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 16 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Information Sheet-3

Selecting Equipment For The Job

Selecting Equipment For The Job

Before starting any surveying work the surveyor should select measuring and calculating equipment to carry out tasks be consistent with the requirements of the job, checked for serviceability and any faults are rectified or reported

Surveying Equipments

1. A Transit is a surveying instrument having a horizontal circle divided into degrees, minutes, and seconds. It has a vertical circle or arc. Transits are used to measure horizontal and vertical angles. The graduated circles (plates) are on the outside of the instrument and angles have to be read by using a vernier.

2. A Theodolite is a precision surveying instrument; consisting of an alidade with a telescope and an accurately graduated circle; and equipped with the necessary levels and optical-reading circles. The glass horizontal and vertical circles, optical-reading system, and all mechanical parts are enclosed in an alidade section along with 3 leveling screws contained in a detachable base or tribrach

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 17 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

3. Staff is used for measuring distances vertically above or below points on which it is held relatively to a line of collimation as defined by the level. Many types of staff are in current use and marking can take different forms, but the E type staff face is the most common

4. Leveling instrument is used for determining the height or difference in height. above the ground form a horizontal reference surface.

5. GPS provides specially coded satellite signals that can be processed in a GPS receivers, enabling the receiver to compute position, velocity and time.

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 18 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Self-Check 3

Written Test

Name: _________________________

Date: _______________

Directions: Answer all the questions listed below. Illustrations may be necessary to aid some explanations/answers.

1. Why is it necessary to select the instruments prior to the job (4 points) ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ ___ 2. What is the use of GPS (2 points) ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ _____ 3. What is the difference between theodolite & leveling instrument ?(4points) ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ ______________________________________________________________________ _____

Note: Satisfactory rating -10 points Unsatisfactory - below 10 points You can ask you teacher for the copy of the correct answers.

TTLM : Determining Control Points Date: November 2012 Author: Zerihun Muluneh/GPC Page 19 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

Operation Sheet _1

Field Equipment Checklist

Important make sure you speak to a teacher or supervisor before you begin.

Equipment list

Documentation Site plan Appropriate area maps Field sheets Chain of custody Pens Equipment Theodolite Tripod Measuring Tape Ranging Rod Hammer Fixers & Binders GPS with full accessories

Check

Equipment list

Safety equipment

Check

First aid kit Sunscreen/sunglasses Drinking water Mobile phone/communication equipment PPE wide-brimmed hat overcoat

waders/rubber boots boots

long pants/sleeved shirt Antiseptic hand wash

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 20 of 21

Ethiopian TVET System Training, Teaching and Learning Materials

LAP Test

Practical Demonstration

Name: _____________________________ Time started: ________________________ Instructions: You are required to perform the following:

Date: ______________________ Time finished: ________________

1. Prepare a simple field equipment checklist. 2. List down the equipments necessary for field work and their uses. 3. Request your teacher for evaluation and feedback

TTLM : Determining Control Points

Date: November 2012 Author: Zerihun Muluneh/GPC

Page 21 of 21

Potrebbero piacerti anche

- Manual GNSS SolutionsDocumento468 pagineManual GNSS SolutionsRuben Aranguren100% (1)

- Individual AssignmentDocumento6 pagineIndividual AssignmentyhNessuna valutazione finora

- SurveyDocumento11 pagineSurveyEmmanuel AmehNessuna valutazione finora

- History of The Code of Ethics For EngineersDocumento19 pagineHistory of The Code of Ethics For EngineersPark EasyNessuna valutazione finora

- EXECUTIVE ORDER NO. 229 July 22, 1987 Providing The Mechanisms For The Implementation of The Comprehensive Agrarian Reform ProgramDocumento11 pagineEXECUTIVE ORDER NO. 229 July 22, 1987 Providing The Mechanisms For The Implementation of The Comprehensive Agrarian Reform ProgramDan LocsinNessuna valutazione finora

- GeodesiaDocumento50 pagineGeodesiaroberth coacalla aNessuna valutazione finora

- A Comparative Study On Rigid and Flexible Pavement-A Case Study at Addis Ababa To Awash Road Segment - Dec-2020Documento83 pagineA Comparative Study On Rigid and Flexible Pavement-A Case Study at Addis Ababa To Awash Road Segment - Dec-2020Amanuel NegaNessuna valutazione finora

- PD 27 of October 21, 1972Documento2 paginePD 27 of October 21, 1972anneNessuna valutazione finora

- Ch3 ProjectManDocumento30 pagineCh3 ProjectManSuzanna RamizovaNessuna valutazione finora

- 2 Peg TestDocumento37 pagine2 Peg TestJoseph Slattery100% (1)

- UNIT-1 Elements of Managament: The Project Cycle Can Be Represented by The Following Flow ChartDocumento27 pagineUNIT-1 Elements of Managament: The Project Cycle Can Be Represented by The Following Flow ChartShashank SinghNessuna valutazione finora

- L - II Land Administration Support Work-1Documento91 pagineL - II Land Administration Support Work-1kenna abdetenNessuna valutazione finora

- 4-Theodolite & Total Station-2011 PDFDocumento68 pagine4-Theodolite & Total Station-2011 PDFPratik Babu GhimireNessuna valutazione finora

- TrabasDocumento6 pagineTrabasFatin HazwaniNessuna valutazione finora

- Linear Survey ReportDocumento4 pagineLinear Survey ReportMbabazi IvanNessuna valutazione finora

- Faculty of ArchitectureDocumento7 pagineFaculty of ArchitecturegladysNessuna valutazione finora

- Chap 2 Geospatial Data Collection and Use Cases in RwandaDocumento6 pagineChap 2 Geospatial Data Collection and Use Cases in RwandaBizimenyera Zenza TheonesteNessuna valutazione finora

- Review of Srilankan DatumDocumento89 pagineReview of Srilankan Datummadumad1234Nessuna valutazione finora

- Issue Date: Week 1 Submission Date: 18 November 2020 Feedback Date: Week 6Documento8 pagineIssue Date: Week 1 Submission Date: 18 November 2020 Feedback Date: Week 6teck yuNessuna valutazione finora

- Similarities Between Estate Surveyors and Quantity SurveyorsDocumento3 pagineSimilarities Between Estate Surveyors and Quantity SurveyorsAmulieNessuna valutazione finora

- Concrete Form WorkDocumento3 pagineConcrete Form Workjack.simpson.changNessuna valutazione finora

- CmsinjsiDocumento3 pagineCmsinjsiFredie FerrerNessuna valutazione finora

- Ge-119 Photogrammetry-2 Topic-1 v090122017f For WebDocumento173 pagineGe-119 Photogrammetry-2 Topic-1 v090122017f For WebTardzenyuy GlenNessuna valutazione finora

- Manual Using CDSDocumento223 pagineManual Using CDSJAMES RITCHIE ANAK ROGERNessuna valutazione finora

- Basic SurveyingDocumento6 pagineBasic Surveyingervikas34Nessuna valutazione finora

- TheodoliteDocumento9 pagineTheodolitesuwashNessuna valutazione finora

- Leveling SurveyDocumento4 pagineLeveling SurveyCynthia EverettNessuna valutazione finora

- 8 TraverseDocumento8 pagine8 TraverseSubbu PemmasaniNessuna valutazione finora

- LevellingDocumento12 pagineLevellingAmir AdamNessuna valutazione finora

- Detailed Course Outline of Survey and Levelling Course (2 Weeks Course)Documento3 pagineDetailed Course Outline of Survey and Levelling Course (2 Weeks Course)Sagheer AhmedNessuna valutazione finora

- Fieldwork No. 1Documento6 pagineFieldwork No. 1jemeripolNessuna valutazione finora

- 436 33 Powerpoint Slides CHAPTER 1Documento69 pagine436 33 Powerpoint Slides CHAPTER 1Anonymous PeFQLw19Nessuna valutazione finora

- Geographic Information System and Civil EngineeringDocumento5 pagineGeographic Information System and Civil Engineeringsamwel100% (1)

- D ( (Y1 + + Y7) / 2 + Y2 + Y3 + Y4 + Y5 + Y6)Documento2 pagineD ( (Y1 + + Y7) / 2 + Y2 + Y3 + Y4 + Y5 + Y6)Ramnuj Orecul SoralcNessuna valutazione finora

- Manual To Read Survey MapDocumento106 pagineManual To Read Survey MapLaxmiprasad NagarapuNessuna valutazione finora

- Surveying IIDocumento19 pagineSurveying IIEr Santosh KaparNessuna valutazione finora

- Surveying - II PracticeI Lab Manual-NEWDocumento43 pagineSurveying - II PracticeI Lab Manual-NEWPathipati Narasimharao100% (1)

- Traverse Computations and Adjustments PDFDocumento37 pagineTraverse Computations and Adjustments PDFFrimeSarmientoAlfanteNessuna valutazione finora

- Module I CHAIN SURVEYING and Module II THEODOLITE SURVEYINGDocumento150 pagineModule I CHAIN SURVEYING and Module II THEODOLITE SURVEYINGvishnu vijayanNessuna valutazione finora

- Ghis Manual (New)Documento18 pagineGhis Manual (New)rookie100% (1)

- Construction Project CycleDocumento10 pagineConstruction Project CycleGeraldine Galing100% (1)

- University Tun Hussein Onn Malaysia Faculty of Civil and Environmental Engineering Department of Civil Engineering TechnologyDocumento3 pagineUniversity Tun Hussein Onn Malaysia Faculty of Civil and Environmental Engineering Department of Civil Engineering TechnologyFadzir AmirNessuna valutazione finora

- Lesson 6. Cartographic Principles & DesignDocumento14 pagineLesson 6. Cartographic Principles & Designsheil.cogay100% (1)

- TraverseDocumento13 pagineTraversebawanlavaNessuna valutazione finora

- StarNet V6 PRO ManualDocumento70 pagineStarNet V6 PRO ManualGilberto H. TiradoNessuna valutazione finora

- CE371 Survey11 Leveling 4Documento20 pagineCE371 Survey11 Leveling 4suraj shetNessuna valutazione finora

- Levelling: Unit 1Documento19 pagineLevelling: Unit 1Fausto Da GamaNessuna valutazione finora

- Survey Unit 1Documento46 pagineSurvey Unit 1Swati ChaudharyNessuna valutazione finora

- Intermediate Track II: September 2000 Minneapolis, MinnesotaDocumento60 pagineIntermediate Track II: September 2000 Minneapolis, MinnesotaFayDulNessuna valutazione finora

- PM PERT & Crashing 7Documento34 paginePM PERT & Crashing 7Anurag GuptaNessuna valutazione finora

- Earthworks FormulasDocumento4 pagineEarthworks FormulasJithesh SukumaranNessuna valutazione finora

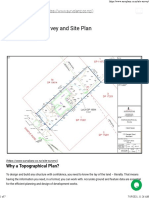

- Topographical Survey and Site Plan - SurvplanzDocumento7 pagineTopographical Survey and Site Plan - SurvplanzEndashaw DebruNessuna valutazione finora

- California PhogrammetryDocumento63 pagineCalifornia PhogrammetryNurul AmirahNessuna valutazione finora

- Site Survey PresentationDocumento24 pagineSite Survey PresentationAmir HafizuddinNessuna valutazione finora

- Leoworks 4 - Quick Start: Open Files and Display Image DataDocumento10 pagineLeoworks 4 - Quick Start: Open Files and Display Image DataodcardozoNessuna valutazione finora

- Geographical and Earth Sciences: Traversing Project ReportDocumento11 pagineGeographical and Earth Sciences: Traversing Project ReportManny SinghNessuna valutazione finora

- Threshold AnalysisDocumento19 pagineThreshold Analysislokesh singhNessuna valutazione finora

- Learning Guide No 6Documento23 pagineLearning Guide No 6Yitbarek Seyoum K.Nessuna valutazione finora

- FILE Procedures in Obtaining and Carrying Out Work InstructionsDocumento3 pagineFILE Procedures in Obtaining and Carrying Out Work InstructionsEmmerNessuna valutazione finora

- Conduct and Facilitate Ict Training Level Three Student: Prepared by Nuri.MDocumento25 pagineConduct and Facilitate Ict Training Level Three Student: Prepared by Nuri.Mnuri mohammedNessuna valutazione finora

- Cambridge November 2012 Answer KeyDocumento6 pagineCambridge November 2012 Answer KeyGideonCavidaNessuna valutazione finora

- Brief - Introducting Agro ProcessingDocumento2 pagineBrief - Introducting Agro ProcessingGideonCavidaNessuna valutazione finora

- GTZ CefeDocumento32 pagineGTZ CefeGideonCavidaNessuna valutazione finora

- Fish Culture Y2Documento139 pagineFish Culture Y2GideonCavidaNessuna valutazione finora

- Fish Culture Y3Documento110 pagineFish Culture Y3GideonCavida100% (7)

- CEFE ManualDocumento93 pagineCEFE ManualGideonCavidaNessuna valutazione finora

- Fish Culture CLMDocumento43 pagineFish Culture CLMGideonCavidaNessuna valutazione finora

- CBLM For Fish Processing Y2 PDFDocumento190 pagineCBLM For Fish Processing Y2 PDFGideonCavida91% (67)

- Fish Culture CBCDocumento64 pagineFish Culture CBCGideonCavida100% (1)

- Fish Processing CBCDocumento132 pagineFish Processing CBCGideonCavida100% (4)

- Knowledge at DevelopmentDocumento15 pagineKnowledge at DevelopmentGideonCavidaNessuna valutazione finora

- Fish Processing CLMDocumento61 pagineFish Processing CLMGideonCavida100% (1)

- Preparation of Practical Projects, Marking Sheets, Worksheets, Answer GuideDocumento19 paginePreparation of Practical Projects, Marking Sheets, Worksheets, Answer GuideGideonCavidaNessuna valutazione finora

- Steps in Conduct of AssessmentDocumento11 pagineSteps in Conduct of AssessmentGideonCavida100% (1)

- Designing Evidence Gathering Tools and Knowledge TestDocumento21 pagineDesigning Evidence Gathering Tools and Knowledge TestGideonCavidaNessuna valutazione finora

- Accreditation of AssessorsDocumento13 pagineAccreditation of AssessorsGideonCavidaNessuna valutazione finora

- Assignment 1-Instruments in Surveying Hadi, Martina BiancaDocumento10 pagineAssignment 1-Instruments in Surveying Hadi, Martina Biancamaria leonoraNessuna valutazione finora

- DAO 2007-29 Revised Regulations On Land SurveysDocumento19 pagineDAO 2007-29 Revised Regulations On Land SurveysJames Frank Ampil OlañoNessuna valutazione finora

- Lecture 6 - Hydrographic SurveyingDocumento29 pagineLecture 6 - Hydrographic SurveyingAbdul Haseeb100% (1)

- GE 104 Lecture 1Documento97 pagineGE 104 Lecture 1Jigg Pelayo100% (1)

- Appendix 1 Structure of The Syllabus of The Department of Forestry, SUST, Sylhet For The Period of 2008-2012 Session: 2008-2009 First Year Semester IDocumento36 pagineAppendix 1 Structure of The Syllabus of The Department of Forestry, SUST, Sylhet For The Period of 2008-2012 Session: 2008-2009 First Year Semester Ishajib_sustNessuna valutazione finora

- Module 1-Engineering SurveyDocumento116 pagineModule 1-Engineering SurveySurekha Abhishek RaoNessuna valutazione finora

- SurveyingDocumento26 pagineSurveyingUmed Abd-alsatar25% (8)

- Horizontal Curves-1 PDFDocumento14 pagineHorizontal Curves-1 PDFKarungi AroneNessuna valutazione finora

- DT 5A Theodolite Repair Manual PDFDocumento97 pagineDT 5A Theodolite Repair Manual PDFNuevaVidaNessuna valutazione finora

- Stadia SurveyingDocumento4 pagineStadia SurveyingMarc Dared Cagaoan38% (8)

- .+ ... Wse05101 Topographic Surveying Lecture Notes Chapter One TheodoliteDocumento12 pagine.+ ... Wse05101 Topographic Surveying Lecture Notes Chapter One Theodolitejoshua stevenNessuna valutazione finora

- Degree measure= π × Radian measure: Types Of Measurements Direct MeasurementDocumento14 pagineDegree measure= π × Radian measure: Types Of Measurements Direct MeasurementOnel TyNessuna valutazione finora

- Introduction To Surveying: Basics of TraversingDocumento33 pagineIntroduction To Surveying: Basics of TraversingReoeuele Duran CalzitaNessuna valutazione finora

- T1 - Introduction of Surveying PDFDocumento34 pagineT1 - Introduction of Surveying PDFAngelica TalandronNessuna valutazione finora

- Tunnel Surveys and Alignment Control: Peter K. Frobenius, William S. RobinsonDocumento2 pagineTunnel Surveys and Alignment Control: Peter K. Frobenius, William S. RobinsonDepi Lopiga GintingNessuna valutazione finora

- Total Station NotesDocumento13 pagineTotal Station NotesMian Waqar Ali ShahNessuna valutazione finora

- 3 Equipment082412Documento26 pagine3 Equipment082412KhoodyVamNessuna valutazione finora

- Theodolite Surveying: Presented By: Er. Sahil Sharma Civil Engineering DepartmentDocumento34 pagineTheodolite Surveying: Presented By: Er. Sahil Sharma Civil Engineering DepartmentSaHil ShaRmaNessuna valutazione finora

- Pythagoras ManualDocumento71 paginePythagoras ManualMirceaNessuna valutazione finora

- Traverse SurveyingDocumento7 pagineTraverse Surveyingmuhammathusinfar01Nessuna valutazione finora

- ASME B89.4.19 Performance Evaluation Tests and Geometric Misalignments in Laser Trackers VolumeDocumento15 pagineASME B89.4.19 Performance Evaluation Tests and Geometric Misalignments in Laser Trackers VolumeJDNessuna valutazione finora

- Surveying and Levelling Instruments Theoretically and Practically DescribedDocumento572 pagineSurveying and Levelling Instruments Theoretically and Practically DescribedRaju VrajuNessuna valutazione finora

- Surveying I Lab Manual PDFDocumento59 pagineSurveying I Lab Manual PDFHaris Alam70% (10)

- To Determine The Horizontal Angles of The Survey Scheme Using TheodoliteDocumento5 pagineTo Determine The Horizontal Angles of The Survey Scheme Using TheodoliteMuhammad AliNessuna valutazione finora

- TransportationDocumento216 pagineTransportationM.RAMANANNessuna valutazione finora

- Geodetic Equipment and BooksDocumento3 pagineGeodetic Equipment and BooksJohn Kevin De CastroNessuna valutazione finora

- Kuwait University College of Engineering & Petroleum Civil Engineering DepartmentDocumento7 pagineKuwait University College of Engineering & Petroleum Civil Engineering DepartmentmohammedNessuna valutazione finora

- Baseline For Setting Out TheodoliteDocumento70 pagineBaseline For Setting Out Theodolitemitualves100% (5)

- DT-200 / DT-200LDocumento2 pagineDT-200 / DT-200LTopcon Middle EastNessuna valutazione finora

- Field Work No. 9 Determination of Rectilinear Area by Radial TraversingDocumento6 pagineField Work No. 9 Determination of Rectilinear Area by Radial TraversingMNessuna valutazione finora