Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tapcon Avr-Ba1801003 - 05 - en - TC260 - Iec61850

Caricato da

prabhakaran_hdecTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tapcon Avr-Ba1801003 - 05 - en - TC260 - Iec61850

Caricato da

prabhakaran_hdecCopyright:

Formati disponibili

Voltage regulator TAPCON 260

Operating Instructions 1801003/05

Protocol description for IEC 61850

All rights reserved by Maschinenfabrik Reinhausen Copying and distribution of this document and utilization and communication of its contents are strictly prohibited unless expressly authorized. Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a patent, utility model or ornamental design registration. The product may have been modified after this document went to press. We expressly reserve the right to make changes to the technical data, the design or the scope of delivery. Generally, the information provided and the arrangements agreed during processing of the relevant quotations and orders are binding. The original operating instructions were drawn up in German.

2 Safety

Table of Contents

1

1.1 1.2 1.3 1.4 1.5 1.6

1.6.1 1.6.2 1.6.3

Introduction .................................................................................. 9

Manufacturer ........................................................................................... 9 Subject to change without notice ............................................................. 9 Completeness ......................................................................................... 9 Supporting documents........................................................................... 10 Safekeeping .......................................................................................... 10 Notation conventions ............................................................................. 10

Abbreviations used ............................................................................................. 11 Hazard communication system ........................................................................... 12 Information system .............................................................................................. 13

2

2.1 2.2 2.3 2.4 2.5

Safety .......................................................................................... 15

General safety information..................................................................... 15 Appropriate use ..................................................................................... 15 Inappropriate use .................................................................................. 16 Personnel qualification .......................................................................... 16 Operator duty of care............................................................................. 16

3

3.1 3.2

Product description ................................................................... 19

Performance features ............................................................................ 21 Relay of the signals via IEC 61850 ........................................................ 22

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

2 Safety

3.2.1 3.2.2 3.2.3 3.2.4 3.2.5 3.2.6 3.2.7

LLN0 - Logical node............................................................................................ 22 LPHD - Physical device ...................................................................................... 22 LPHD - Physical device ...................................................................................... 23 GGIO1 - IO card inputs ....................................................................................... 25 GGIO2 - UC1 card inputs ................................................................................... 26 GGIO3 - UC2 card inputs ................................................................................... 27 GGIO4 - UC3 card inputs (optional) ................................................................... 28

3.3 3.4 3.5

3.5.1 3.5.2

Operating modes................................................................................... 29 Scope of delivery................................................................................... 29 Hardware description ............................................................................ 30

Internal design .................................................................................................... 31 Communication Interfaces .................................................................................. 31

3.6

3.6.1 3.6.2 3.6.3 3.6.4

Operation and indicator elements .......................................................... 36

Operating concept .............................................................................................. 37 Description of the display.................................................................................... 38 Description of key functions ................................................................................ 40 Description of LEDs ............................................................................................ 41

4

4.1

4.1.1 4.1.2 4.1.3

Packaging, Transport and Storage ........................................... 43

Packaging ............................................................................................. 43

Purpose............................................................................................................... 43 Suitability, structure and production ................................................................... 43 Markings ............................................................................................................. 44

4.2 4.3

Transportation, receipt and handling of shipments ................................ 44 Storage of shipments ............................................................................ 45

5

5.1

Mounting ..................................................................................... 47

Unpacking ............................................................................................. 47

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

2 Safety

5.2 5.3

5.3.1 5.3.2 5.3.3 5.3.4 5.3.5 5.3.6

Mounting ............................................................................................... 47 Connection ............................................................................................ 48

Cable recommendation for standard connections .............................................. 48 Cable recommendation for optional connections ............................................... 49 Electromagnetic compatibility ............................................................................. 49 Connecting lines to the system periphery ........................................................... 56 Voltage regulator power supply .......................................................................... 57 Wiring the voltage regulator ................................................................................ 57

5.4

Function check ...................................................................................... 58

6

6.1

6.1.1 6.1.2 6.1.3

Commissioning .......................................................................... 59

Configuration ......................................................................................... 59

Setting the language ........................................................................................... 59 Selecting the control mode ................................................................................. 60 Controlling remote tap position indicator with BCD signal .................................. 61

6.2

6.2.1 6.2.2 6.2.3

Function tests ........................................................................................ 63

Function tests for control functions ..................................................................... 63 Function tests for additional functions ................................................................ 65 Function tests for parallel operation .................................................................... 68

7

7.1

7.1.1 7.1.2

Functions and settings .............................................................. 73

Key lock................................................................................................. 73

Activating key lock .............................................................................................. 73 Deactivating key lock .......................................................................................... 73

7.2

7.2.1 7.2.2 7.2.3

NORMset .............................................................................................. 74

Entering NORMset desired value 1 .................................................................... 76 Setting the primary voltage ................................................................................. 77 Setting the secondary voltage ............................................................................ 78

7.3

Parameters ............................................................................................ 79

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

2 Safety

7.3.1 7.3.2 7.3.3 7.3.4 7.3.5 7.3.6 7.3.7 7.3.8 7.3.9 7.3.10 7.3.11 7.3.12 7.3.13

Setting control parameters.................................................................................. 79 Setting desired value 1 ....................................................................................... 80 Setting desired value 2 ....................................................................................... 81 Setting desired value 3 ....................................................................................... 82 Bandwidth ........................................................................................................... 83 Setting delay time T1 .......................................................................................... 87 Setting control response T1 ................................................................................ 89 Activating/deactivating delay time T2 ................................................................. 90 Setting delay time T2 .......................................................................................... 91 Limit values ......................................................................................................... 91 Abnormal control response ............................................................................... 101 Compensation ................................................................................................... 105 Cross-monitoring .............................................................................................. 114

7.4

7.4.1 7.4.2 7.4.3 7.4.4 7.4.5 7.4.6 7.4.7 7.4.8

Configuration ....................................................................................... 123

Transformer data .............................................................................................. 123 General ............................................................................................................. 132 Parallel operation .............................................................................................. 145 Configuring analog inputs ................................................................................. 156 LED selection .................................................................................................... 164 Configuring transducer function ........................................................................ 167 Configuring measured value memory function (optional) ................................. 173 Communication interface SID ........................................................................... 190

7.5

7.5.1 7.5.2 7.5.3 7.5.4 7.5.5 7.5.6 7.5.7 7.5.8 7.5.9 7.5.10 7.5.11

Info ...................................................................................................... 195

Carrying out LED test ....................................................................................... 197 Querying status ................................................................................................. 198 Resetting parameters ....................................................................................... 200 Displaying real-time clock ................................................................................. 200 Displaying parallel operation ............................................................................ 200 Displaying data on CAN bus ............................................................................. 201 Displaying measured value memory ................................................................ 203 Displaying peak memory .................................................................................. 203 Displaying CIC1 card SCADA information........................................................ 204 Displaying CIC2 card SCADA information........................................................ 205 Displaying upcoming messages ....................................................................... 206

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

2 Safety

8

8.1 8.2 8.3

Interface description for IEC 61850 protocol ......................... 207

Physical connection ............................................................................. 207 Device-specific data points for TAPCON 260 .................................... 207 Downloading the ICD file ..................................................................... 208

9

9.1

9.1.1 9.1.2 9.1.3 9.1.4 9.1.5 9.1.6 9.1.7 9.1.8

Fault elimination ....................................................................... 209

Operating faults ................................................................................... 209

No control in AUTO mode ................................................................................. 209 Man Machine Interface ..................................................................................... 210 Incorrect measured values................................................................................ 211 Parallel operation faults .................................................................................... 212 Tap position capture incorrect .......................................................................... 213 Digital inputs ..................................................................................................... 214 General fault ..................................................................................................... 214 No solution ........................................................................................................ 214

9.2

Event message.................................................................................... 216

10

10.1 10.2 10.3 10.4 10.5 10.6 10.7

Technical Data .......................................................................... 217

Indicator elements ............................................................................... 217 Electrical data ...................................................................................... 217 Inputs and outputs ............................................................................... 217 Dimensions and weight ....................................................................... 218 Voltage and current measurement....................................................... 219 Ambient conditions .............................................................................. 219 Tests ................................................................................................... 219

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

2 Safety

10.7.1 10.7.2 10.7.3

Electrical safety................................................................................................. 219 EMC tests ......................................................................................................... 220 Environmental durability tests ........................................................................... 220

11

MR worldwide ........................................................................... 221

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

2 Safety

Introduction

This technical file contains detailed descriptions on the safe and proper mounting, connection, commissioning and monitoring of the product. It also includes safety instructions and general information about the product. This technical file is intended solely for specially trained and authorized personnel.

1.1

Manufacturer

The product is manufactured by: Maschinenfabrik Reinhausen GmbH Falkensteinstrae 8 93059 Regensburg Tel.: (+49) 9 41/40 90-0 Fax: (+49) 9 41/40 90-7001 E-Mail: sales@reinhausen.com Further information on the product and copies of this technical file are available from this address if required.

1.2

Subject to change without notice

The information contained in this technical file comprise the technical specifications approved at the time of printing. Significant modifications will be included in a new edition of the technical file. The document and version numbers of this technical file are shown in the footer.

1.3

Completeness

This technical file is incomplete without the supporting documentation.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

2 Safety

1.4

Supporting documents

The following documents apply to this product: Operating instructions Quick reference guide Connection diagrams

In addition, generally applicable legal and other binding regulations of European and national law and the regulations for accident prevention and environmental protection in force in the country of use must be complied with.

1.5

Safekeeping

This technical file and all supporting documents must be kept ready to hand and accessible for future use at all times.

1.6

Notation conventions

This section contains an overview of the abbreviations, symbols and textual emphasis used.

10

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

2 Safety

1.6.1

Abbreviations used

Abbreviation C A AC B BCD ca. CAN CIC CPU CT DC DIN DNP EMC ESC Hz I IEC IP kBaud kg kV LDC LED Fiber-optic cable max. MB MR MHz min. mm ms N PH Phi () ppm Definition Degrees Celcius Ampere Alternating Current Bandwidth Binary Coded Decimal circa Regulator Area Network Communication Interface Card Central Processing Unit Current Transformer Direct Current Deutsches Institut fr Normung (German Institute for Standardization) Distributed Network Protocol Electromagnetic compatibility Escape Hertz Current International Electrotechnical Commission Internet Protocol Kilobaud Kilogram Kilovolt Line Drop Compensation Light Emitting Diode Fiber-optic cable maximum Megabyte Maschinenfabrik Reinhausen Megahertz minimum Millimeter Millisecond Neutral Phase Phase angle Parts per million

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

11

2 Safety

Abbreviation s SCADA T TCP V VAct VRef V VT

Table 1

Definition Second Supervisory Control and Data Acquisition Time Transmission Control Protocol Voltage Actual voltage Reference voltage Volt Voltage Transformer

Abbreviations used

1.6.2

Hazard communication system

Warnings in this technical file use the following format: DANGER! Danger Consequences Action Action

The following signal words are used: Signal word Danger Warning Attention Note

Table 2

Hazard level Immediate threat of danger Possible threat of danger Possible dangerous situation Possible dangerous situation

Signal words in warning notices

Consequence of failure to comply Death or serious injury could occur Death or serious injury could occur Minor or moderate injury could occur Damage to property could occur

12

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

2 Safety

Pictograms warn of dangers: Picto gram Meaning Danger

Dangerous electrical voltage

Fire hazard

Danger of tipping

Table 3

Symbols used in warning notices

1.6.3

Information system

Information is designed to simplify and improve understanding of particular procedures. In this technical file they are laid out as follows: Important information

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

13

2 Safety

Safety

2.1

General safety information

This technical file contains detailed descriptions on the safe and proper mounting, connection, commissioning and monitoring of the product. Read this technical file through carefully to familiarize yourself with the product. Particular attention should be paid to the information given in this chapter.

2.2

Appropriate use

The product and associated equipment and special tools supplied with it comply with the relevant legislation, regulations and standards, particularly health and safety requirements, applicable at the time of delivery. If used as intended and in compliance with the specified requirements and conditions in this technical file as well as the warning notices in this technical file and attached to the product, then the product does not present any hazards to people, property or the environment. This applies throughout the product's full life, from delivery through installation and operation to disassembly and disposal. The operational quality assurance system ensures a consistently high quality standard, particularly in regard to the observance of health and safety requirements. Use is considered to be appropriate if the product is operated in accordance with this technical file and the agreed delivery conditions and technical data, and the associated equipment and special tools supplied with it are used solely for the intended purpose and in accordance with the specifications of this technical file. the product is used only with the transformer specified in the order.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

15

2 Safety

2.3

Inappropriate use

Use is considered to be inappropriate if the product is used other than as described in Appropriate use on page 15. Maschinenfabrik Reinhausen does not accept liability for damage resulting from unauthorized or inappropriate changes to the product. Inappropriate changes to the product without consultation with Maschinenfabrik Reinhausen can lead to personal injury, damage to property and operational disruption.

2.4

Personnel qualification

The product is designed solely for use in electrical energy systems and facilities operated by appropriately trained staff. This staff comprises people who are familiar with the installation, assembly, commissioning and operation of such products.

2.5

Operator duty of care

To prevent accidents, disruptions and damages as well as unacceptable adverse effects on the environment, those responsible for transport, installation, operation, maintenance and disposal of the product or parts of the product must ensure the following: All warning and hazard notices are complied with. Personnel are instructed regularly in all relevant aspects of operational safety, the operating instructions and particularly the safety instructions contained therein. Regulations and operating instructions for safe working as well as the relevant instructions for staff procedures in the case of accidents and fires are kept on hand at all times and are displayed in the workplace where applicable. The product is only used when in a sound operational condition and safety equipment in particular is checked regularly for operational reliability. Only replacement parts, lubricants and auxiliary materials which are authorized by the manufacturer are used. The specified operating conditions and requirements of the installation location are complied with.

16

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

2 Safety

All necessary devices and personal protective equipment for each activity are made available. The prescribed maintenance intervals and the relevant regulations are complied with. Fitting, electrical connection and commissioning of the product may only be carried out by qualified and trained personnel in accordance with this technical file. The operator must ensure appropriate use of the product.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

17

3 Product description

Product description

The voltage regulator serves to keep constant the output voltage of a transformer with an on-load tap-changer. To do this, the voltage regulator compares the transformer's measured output voltage (Vactual) with a defined reference voltage (Vreference). The difference between Vactual and Vdesired is the control deviation (dV). If the control deviation is greater than the specified bandwidth (B%), the voltage regulator emits a switching pulse after a defined delay time T1. The switching pulse triggers an on-load tap-changer tap change which corrects the transformer's output voltage. The voltage regulator parameters can be optimally adjusted to the line voltage behavior to achieve a balanced control response with a small number of on-load tap-changer operations. The following diagram (on page 20) shows an overview of voltage regulation.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

19

3 Product description

Figure 1

Overview of voltage regulation

20

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.1

Performance features

The voltage regulator is responsible for controlling tapped transformers. Apart from control tasks, the voltage regulator provides additional functions such as: Integrated protective functions: Undervoltage and overcurrent blocking Overvoltage detection with high-speed return Line drop compensation Z compensation to compensate for voltage fluctuations in the meshed grid Digital inputs and outputs which can be individually programmed on-site by the user Additional indicators using LEDs outside the display for freely selectable functions Display of all measured values such as voltage, current, active power, apparent power or reactive power, cos Cable connection using modern plug terminals Selection of 3 different desired values When ordering you can choose between tap position capture using analog signal 420 mA analog signal via resistor contact series digital signal via BCD code Additional digital inputs and outputs which can be freely parameterized by the customer Parallel operation of up to 16 transformers in 2 groups using the methods Master / Follower Circulating reactive current minimization

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

21

3 Product description

3.2

Relay of the signals via IEC 61850

The following signals are relayed via IEC 61850.

3.2.1

LLN0 class Attribute Name LN0 Data

LLN0 - Logical node

Attribute Type

Explanation Logical node zero Name

M/O/E

Remarks

Common Logical Node Information Mod Beh Health NamPlt

Table 4

ENC INS INS LPL

Mode Behaviour Health Name plate

M M M M

Status-only

IEC 61850 data points (LLNO - Logical node)

3.2.2

LPHD class Attribute Name LPHD Data

LPHD - Physical device

Attribute Type

Explanation Physical device information

M/O/E M

Remarks

Common Logical Node Information PhyNam PhyHealth Proxy

Table 5

DPL INS SPS

Physical device name plate Physical device health Indicates if this LN is a proxy

M M M

IEC 61850 data points (LPHD - Physical device)

22

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.2.3

ATCC class Attribute Name ATCC1

LPHD - Physical device

Attribute Type AVR

Explanation

M/O/E

Remarks

Common Logical Node Information Mod Beh Health ENC INS INS Mode Behaviour Health O M O status-only 1:=OK; 2:=function monitoring; 3:=no internal communication or parameter error

NamPlt Controls TapChg ParOp LTCBlk CirCur Master Follower SICmd1 SICmd2 SICmd3 VoltLvl1 VoltLvl2 VoltLvl3 Measured values CtlV LodA

LPL

Name plate

BSC DPC SPC SPC SPC SPC SPC SPC SPC SPC SPC SPC

Change Tap Position Parallel Independend Block Automatic Control Circulating current (parallel control) Master mode (parallel control) Follower mode (parallel control) Serial Interface Command 1 Serial Interface Command 2 Serial Interface Command 3 Voltage level 1 Voltage level 2 Voltage level 3

C M O E E E E E E E E E

direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security direct-with-normal-security

MV MV

Control Voltage Load Current (transformer secondary current)

M O

Unit: V Multiplier: none Unit: A Multiplier: none

Status Information Loc Auto SPS SPS Local operation Automatic Manual M O

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

23

3 Product description

OverV UnderV OverC MotDrv UInd1 UInd2 UInd3 UInd4 FuncMon ParErr Settings BndCtr BndWid CtlDlTmms LDCR LDCX BlkLV LimLodA LDC

SPS SPS SPS SPS SPS SPS SPS SPS SPS SPS

Voltage high limit reached Voltage low limit reached Current overload Motor drive running User indication 1 User indication 2 User indication 3 User indication 4 Function monitoring Parameter error

E E E E E E E E E E

ASG ASG ING ASG ASG ASG ASG SPG

TmDlChr LDCZ

SPG SPG

TapBlkR

ING

TapBlkL

ING

Band center voltage (actual reference) Band width voltage (as percent of nominal voltage, FPF presumed) Control intentional time delay (FPF presumed, in seconds) Line drop voltage due to line resistance component (voltage) Line drop voltage due to line reactance component (voltage) Control voltage below which auto Lower commands blocked (relative) Limit Load Current (LTC Block Load Current, percentage) Line Drop Compensation is R and X or Z model (0=R and X, 1=Z compensation) Time delay linear or inverse characteristic (0=lin., 1=inv.) Line drop voltage due to line total impedance (percentage of nominal voltage) Tap position of Load Tap Changer where automatic Raise commands are blocked Tap position of Load Tap Changer where automatic

O O O O O O O O

Unit: V Multiplier: none Unit: none Multiplier: c

Unit: V Multiplier: none Unit: V Multiplier: none Unit: none Multiplier: c Unit: none Multiplier: c

O O Unit: none Multiplier: c

24

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

Lower commands are blocked

Table 6 IEC 61850 data points (ATCC - Voltage regulation)

3.2.4

GGIO class Attribute Name GGIO1

GGIO1 - IO card inputs

Attribute Type GPIO IO

Explanation

M/O/E

Remarks

Common Logical Node Information Mod Beh Health NamPlt Controls Measured values ENC INS INS LPL Mode Behaviour Health Name plate O M O O status-only 1:=OK; 3:=no internal communication

Status Information Ind1 Ind2 Ind3 Ind4 Ind5 Ind6 Ind7 Ind8 Ind9 Ind10 Settings Table 7

SPS SPS SPS SPS SPS SPS SPS SPS SPS SPS

IO X1:31 IO X1:33 IO X1:16 IO X1:17 IO X1:14 IO X1:13 IO X1:11 IO X1:12 IO X1:29 IO X1:28

O O O O O O O O O O

IEC 61850 data points (GGIO1 - IO card inputs)

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

25

3 Product description

3.2.5

GGIO class Attribute Name GGIO2

GGIO2 - UC1 card inputs

Attribute Type

Explanation GPIO UC1

M/O/E

Remarks

Common Logical Node Information Mod Beh Health NamPlt Controls Measured values ENC INS INS LPL Mode Behaviour Health Name plate O M O O status-only 1:=OK; 3:=no internal communication

Status Information Ind1 Ind2 Ind3 Ind4 Ind5 Ind6 Ind7 Ind8 Ind9 Ind10 Settings Table 8

SPS SPS SPS SPS SPS SPS SPS SPS SPS SPS

UC1 X1:11 UC1 X1:12 UC1 X1:14 UC1 X1:15 UC1 X1:16 UC1 X1:17 UC1 X1:30 UC1 X1:31 UC1 X1:32 UC1 X1:33

O O O O O O O O O O

IEC 61850 data points (GGIO2 - UC1 card inputs)

26

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.2.6

GGIO class Attribute Name GGIO3

GGIO3 - UC2 card inputs

Attribute Type

Explanation GPIO UC2

M/O/E

Remarks

Common Logical Node Information Mod Beh Health NamPlt Controls Measured values ENC INS INS LPL Mode Behaviour Health Name plate O M O O status-only 1:=OK; 3:=no internal communication

Status Information Ind1 Ind2 Ind3 Ind4 Ind5 Ind6 Ind7 Ind8 Ind9 Ind10 Settings Table 9

SPS SPS SPS SPS SPS SPS SPS SPS SPS SPS

UC2 X1:11 UC2 X1:12 UC2 X1:14 UC2 X1:15 UC2 X1:16 UC2 X1:17 UC2 X1:30 UC2 X1:31 UC2 X1:32 UC2 X1:33

O O O O O O O O O O

IEC 61850 data points (GGIO3 - UC2 card inputs)

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

27

3 Product description

3.2.7

GGIO class Attribute Name GGIO4

GGIO4 - UC3 card inputs (optional)

Attribute Type

Explanation GPIO UC3

M/O/E

Remarks

Common Logical Node Information Mod Beh Health NamPlt Controls Measured values ENC INS INS LPL Mode Behaviour Health Name plate O M O O status-only 1:=OK; 3:=no internal communication

Status Information Ind1 Ind2 Ind3 Ind4 Ind5 Ind6 Ind7 Ind8 Ind9 Ind10 Settings Table 10

SPS SPS SPS SPS SPS SPS SPS SPS SPS SPS

UC3 X1:11 UC3 X1:12 UC3 X1:14 UC3 X1:15 UC3 X1:16 UC3 X1:17 UC3 X1:30 UC3 X1:31 UC3 X1:32 UC3 X1:33

O O O O O O O O O O

IEC 61850 data points (GGIO4 - UC3 card inputs)

28

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.3

Operating modes

The voltage regulator can be operated in the following operating modes: AUTO/MANUAL In automatic mode (AUTO), the voltage is automatically controlled in accordance with the set parameters. The voltage regulator settings cannot be changed in automatic mode. In manual mode (MANUAL), no automatic control occurs. The motor-drive unit can be controlled via the voltage regulator's operating panel. The voltage regulator settings can be changed. LOCAL/REMOTE In remote mode (REMOTE), commands from an external control interface are executed. In this mode, manual operation of the RAISE, LOWER, MANUAL and AUTO keys is disabled.

3.4

Scope of delivery

The following items are included in the delivery: Scope of delivery Voltage regulator TAPCON 260 Technical files

Table 13 Scope of delivery

Please note the following: 1. 2. Use dispatch documents to check that the delivery is complete. Store the parts in a dry place until installation.

The functional range of the product is dependent on the equipment ordered or the product version and not on the content of this technical file.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

29

3 Product description

3.5

Hardware description

The individual assemblies are fitted in a standardized 19-inch plug-in housing. The front panels of the assemblies are secured to the plug-in housing at the top and bottom. An IEC 60603-2 plug connector provides the electrical connection. The assemblies are connected to one another via a data bus and separate direct current (DC) supply. This allows for an upgrade with additional plug-in units and extension cards at a later date. An LCD graphic display, LEDs and function keys are integrated in the front panel of the product.

Figure 2 1 2 3

Front view of device

19-inch plug-in housing (in accordance with DIN 41494 Part 5) Operating panel with display and LEDs Assembly for optional add-ons (e.g. TAPCON 240 LV)

30

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.5.1

Internal design

The device is controlled by a microregulator and includes isolated optocoupler inputs and floating output relay contacts in addition to the voltage and current transformers.

3.5.2

3.5.2.1

Communication Interfaces

Serial interface The parameters for the product can be set using a PC. The COM 1 (RS232) serial interface on the front panel is provided for this purpose. TAPCONtrol software is needed for parameterization. It can be obtained from the Download Center on the Maschinenfabrik Reinhausen website (www.reinhausen.com).

Figure 3 1 2 3

Voltage regulator connection to a PC.

PC with TAPCON -trol software Connection cable with RS232 / USB port Voltage regulator

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

31

3 Product description

3.5.2.2

SID card The SID interface card is used to connect the device to the control station system. The IEC 61850 protocol transfers the data. The diagram below shows the interfaces available and the operating and display elements on the SID card.

Figure 4 1 2 3 4

SID card

Reset key Status LED Interface for SIC card updates Ethernet RJ45

32

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.5.2.3

MC1 card The optional MC1 card is used to convert the SID card's electrical connection into a FH-ST type fiber-optic cable connection. In this case the wave length of the fiber-optic cable is 1300 nm. Terminals 1 and 2 on the MC1 card should be used to connect the voltage supply. Before commissioning, the TAPCON 260 connection diagrams should be checked. The diagram below shows the interfaces available and the operating and display elements on the MC1 card.

Figure 5 1 2 3

MC1 card

Terminal 1 and terminal 2 for the voltage supply Switch M/L ON/LINK TST Switch A/N ON/OFF

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

33

3 Product description

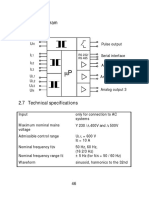

3.5.2.3.1

Technical Data Power supply Voltage Frequency Power consumption Insulation Temperature range Operation Transportation and storage 0...40 C -20...85 C 85~ V AC 110 V DC, 220 V DC 47...63 Hz approx. 6 W 4242 V DC

Requirement of the fiber-optic cable Connection type Fiber type Max. cable length Wave length Transmitted power (dBm) Received power (dBm)

Table 14

FH-ST Multimode 2 km 1310 nm Max. -14.0; typ. -16.8; min. -19.0 Min. rec. -31.8; typ. rec. -34.5; saturation -14.0

Technical data for MC1 card

3.5.2.3.2

Voltage supply connection The voltage is supplied via terminals 1 and 2 on the MC1 card. Terminal 1 2

Table 15

AC 85...264 V

DC 110/220 V GND

Voltage supply connection

34

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.5.2.3.3

Configuration The table below lists the positions and descriptions of the switches on the MC1 card. Switch MDI MDI-X A/N ON A/N OFF M/L ON LNK TST Description Switch position

When using a crossed or so-called Button not pressed patch cable between SID and MC1 card. 100 Mbit for TX and RX position in Button pressed "full duplex" or "half duplex" mode. If "M/L" (missing link) is activated, Button pressed an incorrect fiber-optic cable connection also indicates a fault with the electrical cable between the SID and MC1 card.

Positions and descriptions of the switches on the MC1 card

Table 16

3.5.2.3.4

LED status The MC1 card features various LEDs for displaying the current status. You will find an overview in the table below. LED PWR ON FDX LINK ACT M/L ON

Table 17

Status ON ON OFF ON ON ON OFF

Color Green Green Green Green Green

Description Supply created on MC1 card The connection operates in full duplex mode The connection operates in half duplex mode A connection has been established on the port Network traffic on port MissingLink is activated MissingLink is deactivated, the MC1 card operates in link test mode

LED status of MC1 card

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

35

3 Product description

3.6

Operation and indicator elements

The front of the voltage regulator is split into different areas for operating the device and displaying information. Below you can see an overview of the individual elements.

Figure 6 1 2 3 4 5 6

Voltage regulator operating panel

LEDs Keys for parameterization and configuration COM1 serial interface (RS232) Keys for operating the device Labeling strip for LEDs Setting options for display contrast

36

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.6.1

Operating concept

The voltage regulator's operating panel is split into an operation control level and a level for parameterization and configuration. The keys for operating the device are completely separate from those used for parameterization. At the operation control level, key activation is signaled visually by means of LEDs. The LEDs integrated in the RAISE/LOWER keys are illuminated during the entire tap change operation of the on-load tap-changer if "motor running" is signaled at the status input. This signal must have previously been parameterized. This visual monitoring option simplifies operation of the voltage regulator. The voltage regulator is equipped with a key lock to protect against unintentional operation. To activate or deactivate, press the ESC and F5 keys simultaneously.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

37

3 Product description

3.6.2

Description of the display

Figure 7 1 2 3 4 5 6 7 8 9 10

Main screen

Status line Measured voltage Vactual Reference voltage Vreference Other measured values (use Tap position (n-1, n, n+1) Bandwidth (upper and lower limit) Time bar for delay time T1 Highlighting for reference voltage Highlighting for measured voltage Remaining delay time T1 or to switch between them)

In auto and manual mode the measured value display can be set using the or keys. The following measured values can be displayed:

Control deviation (dV:) Current (I:)

38

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

Apparent power (Powr.:) Active power (P:) Reactive power (Q:) Phase angle (Phase:) Cosine (Cos:)

In the case of an event or a setting, the associated comments are displayed in the status line (display text "Messages").

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

39

3 Product description

3.6.3

Key RAISE

Description of key functions

Symbol Function In manual mode the motor-drive unit can be operated directly using the RAISE key. When RAISE is used, the motor-drive unit changes the on-load tap-changer and therefore the step voltage. In manual mode the motor-drive unit can be operated directly using the LOWER key. When LOWER is used, the motor-drive unit changes the on-load tap-changer and therefore the step voltage. Key without function. "Remote" operating mode is enabled or disabled via input IO-X1:31. Manual mode. For manual control of the motor-drive unit and parameterization of the voltage regulator. Auto mode. Voltage is controlled automatically. In auto and manual mode, the measured value display can be set using the arrow keys. They can also be used to switch between windows in the submenus. Confirms or saves a changed parameter in the parameter menu. Pressing the ESC key takes you to the menu level above, in other words, always back one menu level. Pressing this key displays the menu selection window. The function keys are menu selection keys. They are also used to scroll through the menu subgroups and input screens and to highlight decimal points which can be set by the user.

LOWER

REMOTE MANUAL AUTO Arrow keys NEXT/ PREV

ENTER ESC MENU F1-F5

The parameters can only be changed in manual mode, see table above.

key in the

40

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

3 Product description

3.6.4

Description of LEDs

The voltage regulator has 10 LEDs above the display. These indicate various operating statuses or events.

Figure 8 1 2 3 4 5 6 7 8 9 10

Description of LEDs Operating display Overcurrent blocking Undervoltage blocking Overvoltage blocking Parallel operation On NORMset On Freely configurable (LED1) Freely configurable (LED2) Freely configurable (LED3) Freely configurable (LED4)

Green Red Red Red Green Green Yellow Yellow Yellow Green/yellow/red

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

41

4 Packaging, Transport and Storage

Packaging, Transport and Storage

4.1

4.1.1

Packaging

Purpose

The packaging is designed to protect the packaged goods both during transport and for loading and unloading as well as during periods of storage in such a way that no (detrimental) changes occur. The packaging must protect the goods against permitted transport stresses such as vibration, knocks and moisture (rain, snow, condensation). The packaging also prevents undesired position changes of the packaged goods within the packaging during storage. The packaged goods must be prepared for shipment before actually being packed so that the goods can be transported safely, economically and in accordance with regulations.

4.1.2

Suitability, structure and production

The goods are packaged in a sturdy cardboard box. This ensures that the shipment remains in the intended transport position and that none of its components touches the load surface during transport or the floor after it is unloaded. The box is designed for a maximum load of 10 kg. Inlays inside the box stabilize the goods, preventing impermissible changes of position, and protect them from vibration.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

43

4 Packaging, Transport and Storage

4.1.3

Markings

The packaging bears a signature with symbols with instructions for safe transport and correct storage. The following symbols apply to the dispatch (of non-hazardous goods). Adherence to these symbols is mandatory.

Protect against moisture

Figure 9 Shipping pictograms

Top

Fragile

4.2

Transportation, receipt and handling of shipments

In addition to oscillation and shock stress, jolts must also be expected during transportation. In order to prevent possible damage, avoid dropping, tipping, knocking over and colliding with the product. If a crate falls from a particular height (e.g. when slings tear) or experiences an unbroken fall, damage must be expected regardless of the weight. Before acceptance, all deliveries must be checked by the recipient (acknowledgement of receipt) for the following: Completeness based on the delivery slip External damage of any type.

The checks must take place after unloading when the crate can be accessed from all sides. If external transport damage is detected on receipt of the shipment, proceed as follows: Immediately record the transport damage found in the shipping documents and have this countersigned by the carrier. In the event of severe damage, total loss or high damage costs, immediately notify the sales department at Maschinenfabrik Reinhausen and the relevant insurance company.

44

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

4 Packaging, Transport and Storage

After identifying the damage do not modify the condition of the shipment further and also retain the packaging material, until an inspection decision has been made by the transport company or the insurance company. Record the details of the damage immediately together with the carrier involved. This is essential for any claim for damages! If possible, photograph damage to packaging and packaged goods. This also applies to signs of corrosion on the packaged goods due to moisture inside the packaging (rain, snow, condensation). Name the damaged parts.

When damages are hidden, i.e. damages which are not determined until unpacking after the receipt of the shipment, proceed as follows: Make the party responsible for the damage liable as soon as possible by telephone and in writing, and prepare a damage report. Observe, in this regard, the time periods applicable to such actions in the respective country. Inquire about these in good time.

With hidden damage, it is very hard to make the transportation company (or other responsible party) liable. Any insurance claims for such damages can only be successful if relevant provisions are expressly included in the insurance terms and conditions.

4.3

Storage of shipments

Selection and arrangement of the storage location should meet the following requirements: Stored goods are protected against moisture (flooding, water from melting snow and ice), dirt, pests such as rats, mice, termites and so on, and against unauthorized access. Store the box on timber beams and planks as a protection against rising damp and for better ventilation. Carrying capacity of the ground under the goods is sufficient. Entrance and exit paths are kept free.

Check stored goods at regular intervals. Also take appropriate action after storms, heavy rain or snow and so on.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

45

5 Mounting

Mounting

5.1

Unpacking

The goods are packaged in a sturdy cardboard box. This ensures that the shipment remains in the intended transport position and that none of its components touches the load surface during transport or the floor after it is unloaded. Inlays inside the box stabilize the goods, preventing impermissible changes of position, and protect them from vibration. Unpack the voltage regulator as follows: 1. Remove the lid from the lower part of the cardboard box. The upper inlay contains the accessories supplied, the separate box labeled "Documentation" contains the device documents. 2. 3. 4. 5. 6. Check scope of supply for accessories. Take the box labeled "Documentation" out of the cardboard box. Remove the upper inlay from the packaging. The voltage regulator in the underlying inlay can now be freely accessed. Remove voltage regulator from the packaging.

The voltage regulator has been unpacked and can be mounted. For mounting, proceed as described in the Mounting section.

5.2

Mounting

After unpacking, the voltage regulator can be mounted. The voltage regulator's standardized plug-in housing is intended for fitting in a 19-inch control cabinet. We would recommend a design with a pivoting frame to allow easy access to the connections on the rear of the voltage regulator. The voltage regulator can be mounted in 4 different ways: Flush panel mounting 19" housing Flush panel mounting for half 19" housing Wall mounting for half 19" housing Wall mounting with terminal strip for half 19" housing

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

47

5 Mounting

5.3

5.3.1

Connection

Cable recommendation for standard connections

When wiring the voltage regulator, comply with the following recommendations from Maschinenfabrik Reinhausen.

Cable Power supply Voltage measurement Current measurement Relay* Relay* Signal inputs Signal inputs CAN bus

Table 18

Card SU MI/MI1 MI/MI1 IO

Terminal

Cable type

Wire diameter Max. length 2000 m

X1: 1/2 unshielded 1.5 mm 1/2 shielded 1.5 mm 5/6/9/10 unshielded 4 mm X1:1...10 unshielded 1.5 mm X1:19...26 UC X1:1...10 unshielded 1.5 mm IO X1:11...17 shielded 1.0 mm X1:27...34 UC X1:11...17 shielded 1.0 mm X1:27...34 CPU 1...5 shielded 1.0 mm * Observe notices (see below)

Recommendation for connection cable

NOTE Output relay malfunction Excessive electrical power can prevent the relay contacts from breaking the contact current. The effect of the cable capacitance of long control lines in control circuits operated with alternating current on the function of the relay contacts must be taken into account.

48

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

5 Mounting

5.3.2

Cable AC Analog inputs

Cable recommendation for optional connections

Card SU AD/AD 1 AN/AN 1 CIC CIC SID CIC MC1 Terminal X1/2:1/2 X1:1...3 X1 X8 X9 RJ45 X7 Cable type unshielded shielded shielded shielded shielded shielded, CAT 7 Optical fiber with MTRJ-ST duplex patch cable Wire diameter Max. length 1.5 mm 1.5 mm 1mm 0.25 mm 0.75 mm 400 m (< 25 /km) 25 m 1000 m (< 50 /km) 100 m -

Analog outputs RS-232 RS-485 Ethernet Media converter

Table 19

Recommendation for connection cable

5.3.3

Electromagnetic compatibility

The product was developed in compliance with the relevant EMC standards. To ensure compliance with the EMC standards, please note the following points.

5.3.3.1

Wiring requirement of installation site Note the following when selecting the installation site: The system's overvoltage protection must be effective. The system's ground connection must comply with all technical regulations. Separate system parts must be joined by a potential equalization. The voltage regulator and its wiring must be at least 10 m away from circuit-breakers, load disconnectors and busbars.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

49

5 Mounting

5.3.3.2

Wiring requirement of operating site Note the following when wiring the operating site: The connection cables must be laid in metallic cable ducts with a ground connection. Do not route lines which cause interference (e.g. power lines) and lines susceptible to interference (e.g. signal lines) in the same cable duct. Maintain a gap of at least 10 cm between lines causing interference and those susceptible to interference. Reserve lines must be grounded at both ends. The voltage regulator must never be connected using four-pin collective cables.

Figure 10 1 2 3 4

Recommended wiring

Cable duct for lines causing interference Interference-causing line (e.g. power line) Cable duct for lines susceptible to interference Line susceptible to interference (e.g. signal line)

50

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

5 Mounting

Signal lines must be routed in shielded cables. The individual conductors in the cable core (outgoing/return conductors) must be twisted in pairs. The shield must be fully (360) connected to the voltage regulator or a nearby ground rail.

Figure 11

Recommended shielding connection, do not extend the shield to the grounding point with a wire (pigtail).

NOTE Reduced effectiveness of the shielding. Using "pigtails" may considerably reduce the effectiveness of the shielding. Connect shield to cover all areas.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

51

5 Mounting

5.3.3.3

Wiring requirement in control cabinet Note the following when wiring the control cabinet: The control cabinet for fitting the voltage regulator must be prepared in accordance with EMC requirements: functional division of control cabinet (physical separation) constant potential equalization (all metal parts are joined) line routing in accordance with EMC requirements (separation of lines which cause interference and those susceptible to interference) optimum shielding (metal housing) overvoltage protection (lightning protection) collective grounding (main grounding rail) cable bushings in accordance with EMC requirements any protective inductors present must be interconnected The voltage regulator's connection cables must be laid in contact with the grounded metal housing or in metallic cable ducts with a ground connection. Signal and power/switching lines should be laid in separate cable ducts.

52

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

5 Mounting

The voltage regulator must be grounded at the screw provided using a ground strap (cross-section min. 8 mm). The voltage regulator's ground connection is a functional ground and serves to dissipate interfering currents.

Figure 12

Ground strap connection

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

53

5 Mounting

5.3.3.4

Information about shielding the CAN bus To ensure that the CAN bus operates correctly, the shielding must be connected as detailed for the following variants. Both voltage regulators share the same potential To ensure potential equalization between the voltage regulators, all voltage regulators must be connected to the same potential equalization rail. If the voltage regulators share the same potential, the CAN bus cable's shielding must be connected to both voltage regulators. Both voltage regulators have different potentials If the voltage regulators have different potentials, the CAN bus cable's shielding may only be connected to one voltage regulator. Note that the effectiveness of the shielding is less than if connected to both voltage regulators. NOTE Damage to the voltage regulator If the CAN bus cable's shielding is connected to 2 voltage regulators with different potentials, current may flow over the shielding. This current may damage the communication cards. Ensure that the CAN bus cable's shielding is only connected to one voltage regulator if both voltage regulators have different potentials. If neither connection variant is possible, we would recommend using fiber optic cables. Fiber optic cables decouple the voltage regulators and are not sensitive to electromagnetic interferences (surge and burst).

54

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

5 Mounting

Connecting the shielding The CAN bus cable's shielding must be secured to the intended point on the housing using the cable clips provided (see diagram below).

Figure 13

Securing the CAN bus cable's shielding to the intended point on the housing

Securing the CAN bus cable's shielding

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

55

5 Mounting

5.3.4

Connecting lines to the system periphery

Connect the lines, which are to be wired with the voltage regulator, to the system periphery, as shown in the connection diagrams supplied. WARNING! Electric shock Connection mistakes may endanger life Earth the voltage regulator using the grounding screw attached to the housing. Pay attention to the phase difference of the secondary terminals for the current and voltage transformers. Connect the output relays correctly to the motor-drive unit. NOTE Damages to the voltage regulator and system periphery An incorrectly connected voltage regulator can lead to damages in the monitoring system and system periphery. Prior to commissioning, be sure to check the entire configuration and the measuring and operating voltage.

To obtain a better overview when connecting cables, only use as many leads as necessary.

Use only the specified cables for connection. You will find a cable recommendation in the corresponding section (see "Cable recommendation for standard connections" on page 54). The voltage regulator is fully connected and can be wired up. To carry out the wiring, proceed as described in the Wiring (see "Wiring the voltage regulator" on page 63) section.

56

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

5 Mounting

5.3.5

Voltage regulator power supply

In the standard design, the voltage regulator is supplied with power via a multi-voltage mains unit. The permissible supply voltage is 93...265 V AC, DC. Alternatively the voltage regulator can be supplied with a supply mains unit for the 18...36 V DC or 36...72 V DC range.

5.3.6

Wiring the voltage regulator

Wire the voltage regulator as shown in the connection diagram. WARNING! Electric shock Connection mistakes may endanger life Earth the voltage regulator using the grounding screw attached to the housing. Pay attention to the phase difference of the secondary terminals for the current and voltage transformers. Connect the output relays correctly to the motor-drive unit. NOTE Damages to the voltage regulator and system periphery An incorrectly connected voltage regulator can lead to damages in the monitoring system and system periphery. Prior to commissioning, be sure to check the entire configuration and the measuring and operating voltage.

To obtain a better overview when connecting cables, only use as many leads as necessary.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

57

5 Mounting

5.4

Function check

Carry out a function check to test that the voltage regulator is wired correctly. Check the following: After being switched on, the screen displays the MR logo and then a voltage value. The green "Operating display" LED in the top left on the voltage regulator lights up.

The voltage regulator can now be configured. The actions required for this are described in the following chapter (see "Commissioning" on page 65).

58

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

6 Commissioning

Commissioning

Several parameters need to be set and function tests performed before commissioning the device. These are described in the following chapter.

6.1

Configuration

The relevant settings for commissioning are described in more detail in the following sections. A detailed description of the functions can be found in the associated operating instructions.

6.1.1

Setting the language

The display language can be set or changed as desired. The following languages are available: 1. English German French Spanish Italian Portuguese > Configuration > <00> Language. or General.

2. Press language. 3. Press .

to select the required

The language is set.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

59

6 Commissioning

6.1.2

Selecting the control mode

The voltage regulator can be commissioned in NORMset mode or manually. Instead of parameterizing the voltage regulator manually, the NORMset mode enables easy and user-friendly commissioning of the voltage regulator with a limited set of parameters. When this mode is selected, the factory settings for voltage regulation are accepted. NOTE Damages to the voltage regulator and system periphery An incorrectly connected voltage regulator can lead to damages in the monitoring system and system periphery. Prior to commissioning, be sure to check the entire configuration and the measuring and operating voltage.

We recommend using a registration device to record the transformer voltage (actual value) in order to evaluate how the voltage regulator is functioning.

1. 2. 3. 4. 5. 6.

Press

to select manual mode.

Select the NORMset mode. Set desired value 1. Set the primary voltage. Set the secondary voltage. Execute one tap-change operation manually.

When these parameters have been set, the regulator is ready to operate. The compensation settings cannot be carried out in NORMset mode. The desired value will be compared with the measured voltage on the voltage regulator. The actual value display can be set in V (voltage transformer secondary voltage) or kV (voltage transformer primary voltage) depending on the setting.

60

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

6 Commissioning

6.1.3

Controlling remote tap position indicator with BCD signal

The voltage regulator is equipped with a digital tap position indicator. The indicator is controlled as standard with a BCD signal or optionally with an analog signal. The tap position indicator signal must be converted into and transferred in BCD code if the digital remote tap position indicator is to function. The following is necessary in the motor-drive unit: a resistor contact series a downstream diode matrix the corresponding transfer lines between motor-drive unit and voltage regulator

Figure 14

BCD signal transfer between motor-drive unit and voltage regulator

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

61

6 Commissioning

1 2 3 4

Resistor contact series Diode matrix Transfer line Voltage regulator

Thanks to the diode matrix's linking function, the relevant parallel BCD signal is assigned to every on-load tap-changer operating position which is reproduced by the motor-drive unit's resistor contact series. BCD signal Operating position 10 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Table 20

8 0 0 0 0 0 0 0 1 1 0 0 0 0 0 0 0 0 1 1

4 0 0 0 1 1 1 1 0 0 0 1 0 0 1 1 1 1 0 0

2 0 1 1 0 0 1 1 0 0 0 0 1 1 0 0 1 1 0 0

1 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1 0 1

0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1

BCD code table for operating positions

62

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

6 Commissioning

6.2

Function tests

Before switching the voltage regulator from manual to automatic mode and therefore activating the automatic voltage regulation for your system, Maschinenfabrik Reinhausen recommends carrying out function tests. These function tests are described in the following sections. HINWEIS Schden an Spannungsregler und Anlagenperipherie Ein unsachgem angeschlossener Spannungsregler kann zu Schden an Spannungsregler und Anlagenperipherie fhren. Kontrollieren Sie vor Inbetriebnahme die Gesamtschaltung sowie Ist- und Betriebsspannung.

We recommend using a registration device to record the transformer voltage (actual value) in order to evaluate how the voltage regulator is functioning.

6.2.1

Function tests for control functions

The on-load tap-changer can only be controlled in manual mode using the or keys.

1. 2. 3. 4.

Establish supply voltage Press to select manual mode.

Set transformation ratios for voltage and current transformers and measuring set-up. Measure actual voltage and compare with that displayed by the voltage regulator. several times to display the operating values for current, Press output and phase angle. Compare operating values with operating measurement devices.

5. 6.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

63

6 Commissioning

7. 8. 9.

To set the desired value, manually control the on-load tap-changer until the desired voltage value is reached. Set desired voltage value Vdesired to this value. Set bandwidth "B %" depending on step voltage. Vn-1 Un [B % ] 0.6 Vnominal 100 %

10. Set switch time delay T1 to 20 s and control response to T1 linearly. 11. Press 12. Press to raise the on-load tap-changer 1 step. to select automatic mode.

� After 20 s, the voltage regulator returns the on-load tap-changer to the

original operating position. 13. Press 14. Press to select manual mode. to lower the on-load tap-changer 1 step.

15. Activate the time delay T2 and set it to 10s. 16. Press 17. Press twice to raise the on-load tap-changer 2 steps. to select automatic mode.

� After 20 s, the voltage regulator lowers the on-load tap-changer one

step and after another 10 seconds another step. to select manual mode. 18. Press

19. Set the delay times T1 and T2 to the desired values. If T2 is not used, it must be set to "OFF". We recommend a temporary setting of 100 seconds for the delay time T1 when commissioning the transformer. Depending on the operating conditions, you can also specify the delay time following a longer observation period. In this regard, it is useful to register the actual voltage process and the number of tap-change operations per day. If you wish the voltage regulator to exhibit an integral time response, set an integral control response for time delay T1. The greater the control deviation, the shorter the delay time.

64

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

6 Commissioning

6.2.2

Function tests for additional functions

The on-load tap-changer can only be controlled in manual mode using the or keys.

Checking and setting undervoltage blocking V< 1. 2. 3. Press to select manual mode.

Set the undervoltage blocking V< to 85 %. The desired voltage value should be adjusted such that the actual voltage is below the undervoltage blocking V<. Example: Actual voltage = 100 V, set desired value to a value greater than 100 V / 0.85 = 117 V.

� The undervoltage V< LED will light up. � After around 10 seconds the undervoltage message appears and the

signaling relay is activated. Contact IO-X1:18/19 opens and contact IO-X1:18/20 closes. to select automatic mode.

4.

Press

� The regulator is blocked and does not therefore issue any control

commands. 5. 6. Press to select manual mode.

Set the operating values you want for desired value and undervoltage blocking.

Checking and setting overvoltage detection V> 1. 2. 3. Press to select manual mode.

Set overvoltage detection V> to 115 %. The desired voltage value should be adjusted such that the actual voltage is above the overvoltage detection V>. Example: Actual voltage = 100 V, set desired value to a value less than 100 V / 1.15 = 87 V.

� The overvoltage V> LED will light up.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

65

6 Commissioning

� The overvoltage message appears and the signaling relay is acti4. Press to select automatic mode.

vated. Contact IO-X1:18/19 opens and contact IO-X1:18/20 closes.

� The LOWER output relay periodically emits a control command at approx. 1.5 s intervals. 5. 6. Press to select manual mode.

Set the operating values you want for desired value and overvoltage detection.

Set overcurrent blocking I> (and optionally undercurrent blocking I<). 1. Set overcurrent blocking I> (optionally undercurrent blocking I<) to the desired value. A function test is not necessary. Checking and setting activation of desired value 2 and desired value 3 1. 2. 3. Set desired value 2 to the value you want. Press to select manual mode.

Apply voltage L+ to terminal X4:17 (X4:17 = default setting).

� Desired value 2 is shown on the main screen.

4. 5. 6. Set desired value 3 to the value you want. Press to select manual mode.

Apply voltage L+ to terminal X4:18 (X4:18 = default setting).

� Desired value 3 is shown on the main screen.

7. Press to select automatic mode.

Checking and setting line drop compensation (LDC) A load current of 10 % of the nominal transformer current is needed for the following function tests in order to better detect the effects of control deviation.

Before you can check Z compensation, you must use the control system (IEC 61850) to check that the value of the LDC attribute in the ATCC node is 0.

66

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

6 Commissioning

1. 2. 3.

Press

to select manual mode.

Set parameters for line drop compensation and Z compensation to 0. Select the control deviation (dV) display on the main screen (press if necessary).

� The measured voltage must be within the bandwidth.

4. Set line drop compensation "Vr line drop comp." to 20.0V.

� The control deviation dV must be negative.

5. Set line drop compensation "Vr line drop comp." to -20.0V.

� The control deviation dV must be positive.

If the control deviation appears in the opposite direction, change the polarity of the current transformer.

6.

Set line drop compensation "Vr line drop comp." to the operating value you want.

Checking and setting Z compensation Before you can check Z compensation, you must use the control system (IEC 61850) to check that the value of the LDC attribute in the ATCC node is 1.

1. 2. 3.

Press

to select manual mode.

Set parameters for line drop compensation and Z compensation to 0. Select the control deviation (dV) display on the main screen (press if necessary).

� The measured voltage must be within the bandwidth.

4. Set the "Z compensation" and "Z comp. limit value" parameters to 15 %.

� The control deviation dV must be negative.

If the control deviation appears in the opposite direction, change the polarity of the current transformer.

5.

Set the "Z compensation" and "Z comp. limit value" parameters to the operating values you want.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

67

6 Commissioning

Installation of the voltage regulator is now complete and it is commissioned for simplex mode. During operation, note the operating instructions provided. If the voltage regulator is to be used for parallel operation, then continue to the next section.

6.2.3

Function tests for parallel operation

To obtain perfect functioning in parallel operation, the voltage regulator must be commissioned in simplex mode. Make sure that the conditions below have been fulfilled.

All voltage regulators are set to the same operating parameters for voltage value, sensitivity and delay time T1. Set the circulating reactive current sensitivity to 0 % and the circulating reactive current blocking to 20 % (see operating instructions) for all voltage regulators. All settings should be undertaken in manual mode. Give each voltage regulator an individual address on the CAN bus (see operating instructions). 6.2.3.1 Function tests in accordance with the circulating reactive current method The following sections describe how to carry out function tests for parallel operation in accordance with the circulating reactive current method. 6.2.3.1.1 Setting circulating reactive current sensitivity 1. Adjust both transformers in simplex mode to the same voltage by means of the on-load tap-changer.

� When both voltage regulators are in a state of equilibrium, then the

2. Connect the transformers in parallel and enable the parallel control.

value of the control deviation "dV [%]" is smaller than the set bandwidth "B %" and the time bar is not filled.

� The two voltage regulators must still be in a state of equilibrium. � The "Parallel operation" LED on the front panel is illuminated.

3. Switch one of the two transformers up one voltage step and the other transformer down one voltage step.

� The two voltage regulators must still be in a state of equilibrium.

68

TAPCON 260

1801003/05 EN

Maschinenfabrik Reinhausen 2013

6 Commissioning

4.

Adjust the "circulating reactive current sensitivity" until the result displayed exceeds the set value for the bandwidth by approx. 0.2 % to 0.3 %.

� The value for the result changes in the help text in the last line of the

display. 5. 6. Set the value given in step 4 for all voltage regulators in parallel operation. Select the AUTO operating mode for both voltage regulators.

� The voltage regulators return the on-load tap-changers to the earlier

operating positions. If the earlier operating positions are not reached, then the "circulating reactive current sensitivity" should be increased. If the on-load tap-changers pass each other, then the "circulating reactive current sensitivity" should be reduced. After the parameter "circulating reactive current sensitivity" has been set, continue by setting the circulating reactive current blocking (see "Setting circulating reactive current blocking" on page 75). 6.2.3.1.2 Setting circulating reactive current blocking 1. 2. Press on 1 voltage regulator to select manual mode.

Using manual control, adjust the relevant motor-drive unit upwards (e.g. 1 - 2 steps) by the maximum permitted difference in operating positions between the parallel operating transformers.

When setting the circulating reactive current blocking in the following process step, wait approx. 2 to 3 seconds between the individual steps.

3.

From the set value of 20 %, reduce the circulating reactive current blocking in 1% intervals until the message "Parallel operation error: circulating reactive current limit exceeded" appears.

� The LED lights up when the circulating reactive current blocking limit

is reached.

� The voltage regulators block any further regulation. � After 30 seconds (time adjustable) the signaling relay X5:12 (X5:12 =

default setting) responds. 4. Increase the circulating reactive current blocking again until the message "Parallel operation error: circulating reactive current limit exceeded" disappears.

Maschinenfabrik Reinhausen 2013

1801003/05 EN

TAPCON 260

69

6 Commissioning

5.

Press position.

to select automatic mode.

� The motor-drive unit is automatically returned to the original operating

6. Set the value determined for the circulating reactive current blocking on the other regulators as well.