Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Synthesis and Characterization of Nanocomposite Based On Waste Polystyrene and Cellulose Nanowhiskers

Caricato da

Alexander DeckerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Synthesis and Characterization of Nanocomposite Based On Waste Polystyrene and Cellulose Nanowhiskers

Caricato da

Alexander DeckerCopyright:

Formati disponibili

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.

15, 2013

www.iiste.org

Synthesis and Characterization of Nanocomposite Based on Waste Polystyrene and Cellulose Nanowhiskers

Manal El Hefnawy (a), Samy Bader (b). (a) Natural Science Department , Faculty of Engineering ,Benha University , shoubra, Egypt (b)Chemistry Department, Faculty of Science, Benha University, Egypt. * E-mail of the corresponding author: manalelhefnawy@yahoo.com Abstract A superabsorbent nanocomposite composed of waste polystyrene chitosan acrylic and cellulose nanowhiskers(CNWs) were synthesized and characterized by Fourier transform infrared spectroscopy (FTIR) and scanning electron microscope (SEM).The effect of major factors on water absorbency were investigated to obtain optimum conditions with high swelling capacity.It was found that the incorporation of CNWs improved the swelling capacity as well as improved the mechanical properties.The composite showed responsive behavior in relation to pH and salt solution which make these smart materials suitable for several technological applications. Finally the use of waste polystyrene provided a new method for converting waste resources into variable products. Keyword: waste polystyrene, cellulose nanowhiskers, chitosan, superabsorbent, hydrogel. 1. Introduction: Polystyrene is a synthetic hydrophobic polymer that is not biodegradable. Thus it can cause environmental pollution [1]. There are different alternatives for reducing the problem of its disposal and for converting it into valuable product, including polymer modification and functionalization [2, 3]. The introduction of polar groups into synthetic polymers causes the induction of hydrophilicity [4, 5] functionalized polystyrene has different applications for instance, as a polyelectrolyte for water treatment processes [6]. Hydrogels are three dimensional networks of hydrophilic polymer that can swell to an equilibrium state that retains a significant amount of water and/ or biological fluid .Among the class of hydrogels, the superabsorbent ones can exhibit fast swelling rate, Absorbing extraordinary amounts of water [7, 8]. These properties are observed because the hydrogel pores disposed in interconnected networks with diameters of several hundred microns create upon channels that allow water movement inward the matrix for capillarity. Studies have been reported on the preparation of superabsorbent hydrogels using natural polymer which could increase their biocompatibility, biodegradability, water uptake capacity as well as decrease the toxicity, broadening their potential of application [9, 10]. From the main polymers used in hydrogels preparation are chitosan . Chitosan is a well known polymer derived from the biopolymer chitin, shows interesting physical, chemical and biological properties, antibacterial, haemostatic activities and chelating potential [11-13]. However, the use of chitosan to form superabsorbent materials has been limited because of their usually poor mechanical properties when compared to other polymer. The addition of reinforcing filler into the hydrogel matrix can enhance their mechanical properties and improve their handling.CNWs have been incorporated in a wide variety of materials to improve strength properties [14, 15]. Some works have reported that cross linked composites CNWs showed unique properties that were distinctly from the starting components and of special interest are the hydrogel [16, 17]. In this work the purpose was to prepared superabsorbent hydrogel using waste polystyrene, chitosan and cellulose nanowhiskers as a filler to reduce the cost of the final product, to help decrease environmental pollution with waste polystyrene also to study effect cause by the incorporation of CNWs into the hydrogel matrix on the water uptake capacity also on the mechanical properties. 2. Experimental Materials Potassium persulfate (KPS), benzoyl peroxide (BP), and Sodium hydroxide were obtained from Merck. Acrylic acid (AA) from Fluka was used without further purification. Toluene, n-hexane and ethylene acetate were obtained from Merck. Waste polystyrene foam (from food containers) was washed with distilled water before use. N.N methylene bis-acrylamide (MBA) and span 60 were purchased from Aldrich. Chitosan (code KB002) was purchased from Funakoshi Co, m LTD, Japan .Egyptian cotton fibers.

46

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

Preparation of Cellulose Nanowhiskers (CNWs) Cotton fibers were firstly washed under mechanic stirring for 1h at room temperature to remove some impurities (waxy for instance).After this the fibers were soaked in deionizer water for 1h at 80 C0 and then oven dried for 5h at 50 C0 The cellulose nanowhiskers were obtained through acid hydrolysis reaction using concentrate HCL at 45C0 for 1h under vigorous magnetic stirring at cellulose HCL ratio 1/20 (g/mL).The resulting suspension was then treated as described in the literature to obtain the cellulose nanocrystals[18] in brief the resulting solution was centrifuged at 7.000 rpm for15min (three times)and washed using deionizer water up to pH = 7 . The resultant material was freeze -dried 48h). Then CNWs were characterized by Fourier transformed infrared spectroscopy technique. Preparation of Polystyrene Grafting Poly (Acrylic Acid) co-Chitosan / CNWs. (PS g PAA-co-CTS/ CNWs) superabsorbent hydrogel). A proper amount of waste (PS) was dissolved in a mixture of solvents including n-hexane-toluene and ethyl acetate. Appropriate amount of span 60 (as emulsifier) and an oil soluble initiators benzoyl peroxide (BP), were added to the solution in a four- necked reaction flask equipped with a thermometer, a mechanical stirrer and a hydrogen line. A definite amount of acrylic acid (AA) was partially neutralized with NaOH solution (3M) with cooling (ice bath) then the solution was added to the reaction flask and heated to 45C0 for a few minutes. A proper amount of chitosan was solubilized under magnetic stirrer in 30 ml of acetic acid solution (V/V %), the chitosan solution was bubbled with N2 (g) for 30 min to remove oxygen and then added to the reaction flask and the solution was heated to 60C0, appropriate amounts of cross linker (MBA), CNWs (5-20%), and initiator (KPS) were added to the solution after a few minutes. The temperature was increased to 70C0 for 2h then the sample were precipitated into the ethanol, filtrate and dried at 80C0 for 12hr.Acrylic acid homopolymers and unreacted monomers were extracted from the product by soxhlet extraction using an ethanol water mixture (80: 20) for 8h [19] the extraction was carried out three times for the samples to obtain the constant weight of grafted samples. In addition, a blank sample, without CNWs was synthesized according to procedures described above. Characterization Techniques FTIR spectroscopy All the dried samples were characterized by infrared spectroscopy technique using a transform infrared spectrophotometer (Shimadzu Scientific Instruments, Model 8300)operating in the range from 4000 to500 Cm1.The dried material was blended with KBr powder and pressed into tablets before spectrum acquisition. Scanning electron microscopy The hydrogel nanocomposite morphologies were evaluated through SEM images obtained from scanning electron microscopy (Shimadza Model SS550super scan) Water Absorbent Measurement A certain amount of samples (0.15 0.01 g) were placed in 30 mL filter crucibles (porosity no.0) pre moistened and with a dry outer wall. This set was inserted in water in such a way that the gel was completely submerged. The crucible/ composite hydrgel samples sets were removed at various time intervals, with the external wall of the set dried and the system weighed .For each sample 3 assays were performed (n=3).The swelling capacity of the samples was determined according to the Eq.(1) . W = (m/mo) -1 (1) Where w is the gained water mass (in grams) per gram of composite hydrogel, m is the mass of the swollen absorbent and mo is the mass of the dry materials. Effect of salt solution on the water uptake capacity The hydrogel composite were immersed in distinct salt aqueous solutions (concentrations 0.15mol / L) and their swelling capabilities were determined according to the procedures described previously .Aqueous solutions of NaCl, CaCl2 and AlCl3 at 25C0, were used as swelling fluid. All solutions presented constant ionic strength (I=0.1M). All the procedures were done in triplicate (n=3).

47

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

Effect of pH on the water uptake capacity The effect of pH on the water up take capacity was also evaluated using buffer solutions (pH=2-12) with constant ionic strength (I=0.1) the experimental procedures were the same described in the previous subsection, the procedures were done in triplicate (n=3) Mechanical properties The mechanical properties of the prepared hydrogel nanocomposite with different contents of CNWs were determined through compressive tests in aTexturometer equipments. All samples were previously swelled in distilled water overnight the superficial water excess was removed and then they were cut in small samples before the compression tests. The tests were performed at temp. (25C0) and relative humidity (50%) The Young, modules were calculated according to the following equation:Young's Modulus =

F L1 A (L2 L1 )

(2)

Where F is the force necessary to compress the sample (N) A is the area (m2) of the transversal section of the samples, L1is the samples initial length (mm) and L2 is the samples length (mm) before the rupture point, respectively. 3. Results and discussion Fig (1) a, b shows the FTIR spectra of raw cotton fibers and cellulose nanowhiskers respectively, which are quite similar. Both presented band at 3344, 2900 and 1646 cm-1 which are assigned to stretching of - OH groups, C-H stretching, and OH bending of the adsorbed water. Therefore , the band of H-C-H and O-C-H in plane bending vibrations appeared at 1432 cm-1 and the C-H deformation vibration appeared at 1367 cm-1 , the C-O-C , C-C-O and C-C-H deformation modes and stretching vibrations, in which the motion of the C-5 and C-6 were observed at 897 cm-1 [20,21] and the band referent to the C-OH out of the plane bending at 670 cm-1. From these FTIR spectra, it was found that the acid hydrolysis reaction performed to obtain the cellulose nanofibrilis did not affect the chemical structure of the cellulose fragment [22].

Fig (1) FTIR spectra of (a) a raw cotton fibers, (b) CNWs, (c) PS gPAA co CTS (d) PS g PAA co CTS/CNWs hydrogel

48

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

FTIR spectrum of the chitosan graft (poly AA co polystyrene) exhibited a characteristics shoulder at 1686 cm-1 assigned to COOH stretching and bands at 1573 and 1410 cm-1 assigned to asymmetric and symmetric stretching of C=O .The band at 1326 cm-1 should contribute to the stretching and bending vibration of the C-N bond of the amide III band . The characteristic absorption band of chitosan [N-H 1598 and 1380 cm-1] and C3OH (1094 cm-1) could not be found [23] such information confirm that [NH2-NH-CO and -OH] from chitosan took part in the grafting reaction with acrylic acid and polystyrene. According to FTIR spectra the bands of 2923 cm-1, corresponds to the asymmetric and symmetric stretching vibrations of CH2 from PS. The peak at 1585 cm1 is due to the C=C of the vinyl groups from PS while the band at 1452 cm-1 results from the deformational vibrations of CH2 and (B1) of the benzene ring of the styrene molecule [24] . FTIR spectrum of CTS g poly (AA CO PS) / CNWs exhibited a similarity with the FTIR spectrum of chitosan g poly (AA CO PS) as can be seen from fig (1c,d).Bands at 1169 and 1118 and 1056 cm-1are assigned to C-O-C asymmetric valence vibration, vibrational stretching C-C and C-O asymmetric pyran ring and C-O deformation in secondary alcohols and aliphatic ether ,regarding to cellulose nanofibrils which confirms the hydrogl nanocomposite formation[20,21] Morphologies of Hydrogel Composite The change on morphology of chitosan graft PAA composite, hydrogel promoted by the addition of cellulose nanofibers were investigated through SEM image fig (2). As can be seen (CTS g PAA- co-PS) hyrogel fig (2a) show interlaced network and highly porous morphology. The pores should small average size and are homogeneously distributed into the hydrogel matrix which could be associated with the lower liquid uptake capacity of CTS g (PAA co PS) .The CTS g PAA co PS / CNWs hydrogel composite morphology fig (2b) seem to be more irregular with large pores and follaceous aspect. The presence of CNWs into the hydrogel matrix increases the amount of hydrophilic groups, which make diffusion of liquid inward the matrix easier and faster. This fact increases the average pore size as can be seen in SEM image.

Fig (2) SEM images of (a) PS g PAA co CTS and (b) PS g PAA co CTS/CNWs Evaluation of Water Uptake Capacity Effect of the weight ratio of acrylic acid to polystyrene on water absorbency: Table (1); shows that the water absorbency increased with increasing AA content. The maximum swelling capacity was obtained when the sample was synthesized with an AA to PS ratio of 10:1.This could be due to the fact that the increase in amount of AA from the ratio of 4:1 to 10:1 resulted in an increase in the molecular weight and grafting of poly acrylic acid chains [25]. With further increases in the AA content, the water absorbency decreased. This could be due to preferential homopolymerization of acrylic acid over graft copolymerization or increased medium viscosity which hinders the movement of the monomers molecules and free radicals [26].

49

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

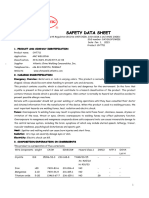

Table (1) Effect of Different Variables on the water absorbencies of PS g PAA co CTS superabsorbent composites Neutralization degree Chitosan MBA BP Sample AA/PS KPSwt% of AA wt% wt% wt% Effect of AA to PS weight 4 60 0.15 0.07 0.8 0.6 ratio 6 60 0.15 0.07 0.8 0.6 8 60 0.15 0.07 0.8 0.6 10 60 0.15 0.07 0.8 0.6 12 60 0.15 0.07 0.8 0.6 14 60 0.15 0.07 0.8 0.6 Effect of neutralization 10 40 0.15 0.07 0.8 0.6 degree of AA 10 50 0.15 0.07 0.8 0.6 10 60 0.15 0.07 0.8 0.6 10 70 0.15 0.07 0.8 0.6 10 80 0.15 0.07 0.8 0.6 10 90 0.15 0.07 0.8 0.6 Effect of chitosan 10 60 0.05 0.07 0.8 0.6 10 60 0.1 0.07 0.8 0.6 10 60 0.15 0.07 0.8 0.6 10 60 0.2 0.07 0.8 0.6 10 60 0.25 0.07 0.8 0.6 10 60 0.3 0.07 0.8 0.6 Effect of cross linker 10 60 0.15 0.03 0.8 0.6 contents 10 60 0.15 0.05 0.8 0.6 10 60 0.15 0.07 0.8 0.6 10 60 0.15 0.09 0.8 0.6 10 60 0.15 0.11 0.8 0.6 10 60 0.15 0.13 0.8 0.6 Effect of water soluble 10 60 0.15 0.07 0.2 0.6 initiator 10 60 0.15 0.07 0.4 0.6 10 60 0.15 0.07 0.6 0.6 10 60 0.15 0.07 0.8 0.6 10 60 0.15 0.07 1.00 0.6 10 60 0.15 0.07 1.2 0.6 Effect of oil soluble initiator 10 60 0.15 0.07 0.8 0.2 10 60 0.15 0.07 0.8 0.4 10 60 0.15 0.07 0.8 0.6 10 60 0.15 0.07 0.8 0.8 10 60 0.15 0.07 0.8 1.00 10 60 0.15 0.07 0.8 1.2

WH2O 260 330 360 420 320 280 330 360 420 280 230 210 330 390 420 280 230 190 360 390 420 320 220 190 190 280 310 420 380 340 170 240 420 360 340 320

Effect of neutralization degree of AA on water absorbency As shown from Table (1) the water absorbency increases as the neutralization degree increases from 40% to 60% and decreases with further increases in the neutralization degree of AA . The maximum water absorbency is obtained when the neutralization degree of AA is 60%. When acrylic acid was neutralized with sodium hydroxide solution the negatively charged carboxyl groups attached to the polymer chains produced on electrostatic repulsion resulting in an expansion of the network. The electrostatic repulsion raise as the neutralization degree increased from 40% to 60% leading to increased water absorbency. The further increase in the neutralization degree of AA resulted in the decreased water absorbency of the prepared superabsorbent. This behavior could be due to a rise in the chain stiffness and counter ion condensation on the polyion [27]. ( as the amount of Na+increase with increasing AA neutralization degree, the condensation of counter ion (Na+)that cover COO- ion increased ,resulting in a decreased formation of hydrogen bonds between the COO- groups and H2O.This phenomena causes the water absorbency of the superabsorbent hydrogel to decreased.

50

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

Effect of initiator content on water absorbency Table (1) illustrates the effect of the oil soluble initiator and the water soluble initiator on the water absorbency of prepared sample. The water absorbency increases as BP and KPS content increase from 0.2 to 0.8 % and from 0.2 to 0.6% respectively, but decreases with further increases in BP and kPS content. The maximum water absorbency (420) is obtained when the total amount of initiator (KBS and BP) is 1.4%.which causes the graft polymerization rate to increase consequently, the final water absorbency increases. When the total amount of initiator is higher than the optimum value, the water absorbency is decrease. This phenomenon is most likely due to an increase in the number of radical centers, which increases the cross linking density .The greater cross linking density prevents the network from expanding to its greatest extent. Furthermore, an increase in the number of radical centers leads to a decrease in the chain length of the grafted AA co CTS of the hydrogel and a decrease in molecular weight of the grafted AA co CTS of the hydrogel. As a result, the water absorbency decreases. This may be due to the inverse relationship between the initiator content and the molecular weight [28]. Effect of cross linker content on water absorbency Table (1) shows the effect of cross linker content on water absorbency. An increase in the cross linker content from 0.07 to 0.13% leads to a decreased water absorbency. This phenomenon due to the fact that as the amount of cross linker increases, more cross link points are produced during polymerization and the crosslinking density increases. The increased crosslinking density lead to a highly cross linked and rigid structure and the polymer network cannot expand enough to retain a large amount of water [25]. The maximum water absorbency is achieved when the amount of cross linker is 0.07% . Effect of chitosan on water absorbency Table (1) shows the effect of different amount of chitosan on water absorbency in distilled water .It can be seen that, the water absorbency increased from 330 to420 as the ratio of chitosan in the feed increased from0.05 to 0.15 wt% and further increase in the amount of chitosan in the feed decreased the water absorbency. First with the increasing of chitosan, there were many available monomer molecules around chitosan large molecular free radical chain that would be grafted onto chitosan backbone. Large molecular chain would grow and network structure of polymers extended and thus formed three dimensional structures at the same time, due to the increasing of the hydrophilic hydroxyl contents, hydrophilic properties of composite resins enhanced, and therefore, its water absorbency rate increased. When chitosan increased from 0.15 to 0.3 water absorbency rate reduced. This due to the generation of more crosslink point in the polymeric network which could cause the crosslink density of the superabsorbent hydrogel to increase therefore , there would be a decrease in the water absorbency [29] . Effect of CNWs content on water absorbency The influence of CNWs content on the water absorbency of PS g PAA co CTS/CNWs superabsorbent composite is shown in table (2). It is obvious that CNWs content has an important effect on the water absorbency of the superabsorbent composite. According to the result the water absorbency of the superabsorbent composite in distilled water increased from 420 to 540 g/g as 4% CNWs was introduced and when 8wt% CNWs was filling into the hydrogel matrix water absorbency achieved the highest value 580. This behavior can be attributed to the presence of hydroxyl groups which provides greater hydrophilic character. The increasing in the interaction of the hydrogel surface with the water molecules allows a higher absorption capacity. On the other hand a further increase in CNWs content to 12% leads to a decreased water absorbency of 510. The excess of CNWs into the hydrogel network avoids that greater amount of water could held. In this stage the CNWs shows a typical behavior of inert filler [30]. Greater amount of CNWs enhanced the crosslinking density of nanocomposite and minimized the network voids, responsible for adsorbing and holding water molecules [22]. In addition with the excess of CNWs the ratio of hydrophilic groups per volume unit decreased leading to nanocomposite with lower hydrophilic character.

51

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

Table (2) Effect of CNWs content on water absorbency Reaction conditions : reaction temperature 700 C, 60% neutralization degree of AA , weight ratio of AA/PS in feed 10:1 , weight ratios of chitosan, water soluble intiator , oil soluble intiator and cross linker in the feed of 0.15 , 0.8 , 0.6 and 0.07 wt% respectively . Sample PS g PAA co CTS/CNWS0 PS g PAA co CTS/CNWS1 PS g PAA co CTS/CNWS2 PS g PAA co CTS/CNWS3 PS g PAA co CTS/CNWS4 PS g PAA co CTS/CNWS5 Cellulose Nanowhiskers wt%

0

W( g/g) 420 540 580 510 570 430

4 8 12 16 20

Effect of salt solution on water absorbency The influence of some ions cations and anions on swelling capability of hydrogels was tested by the addition of different saline solution, including monovalent (NaCl), divalent (CaCl2) and trivalent (AlCl3) ions (concentration: 0.15 mol L-1) and at 25.0 C0 as the swelling fluid. To achieve a comparative measure of sensitivity of the hydrogel, a dimensionless salt sensitivity factors (f) [31] is defined as follow: F=1

Wsaline Wwater

(3)

Where Wsaline and Wwater are the swelling capacity in saline solution and in deionized water, respectively. It is obvious that the swelling decreasing strongly depended on the type of salt added to the swelling medium. The effect of cation type (cation with different radius and charge) and sensitivity factor f on swelling behavior is shown in fig (3) The higher cation charges the higher degree of crosslinking and the smaller swelling value .Therefore the absorbency for the hydrogel in the studied salt solutions is in the order of monovalent > divalent > trivalent cations .The (f) values indicate that the CTS g PAA Co PS /CNWs hydrogels undergo less influence to the presence of salt than CTS g (PAA Co PS). The increase in the ions strength reduces the difference in the concentration of movable ions between the polymer matrix and the external solution (osmotic swelling pressure) and leads to an immediate contraction of gel. The decreasing is more significant to Ca++ and Al+3 which can be additionally caused by the complex formation ability of carboxamide or carboxylate groups including interamolecular and intermolecular complex formation or because one multivalent ion is able to neutralize several charge inside the gel consequently the crosslinking density of the net work increased while water absorption capacity decreased .

52

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

Fig (3): Water absorbency of PS g PAA co CTS and PSg PAA co CTS/CNWs hydrogel composites at aqueous solutions from different salt

(conc. Equal 0.15 mg L-1)

Swelling behavior at various pH

The swelling behavior of PS g PAA co CTS/CNWs and PS g PAA co CTS hydrogel composite at various pHs were observed with the use of buffer solution at pHs 2-12 maintaining the ionic strength equal to 0.1.According to Fig(4) the absorbency increased as the pH increased from 2.0 to 8.0 and then decreased at pH higher than 8.0.The water absorption is low in acidic pH values(4) but dramatically increases until a plateau was reached when the pH 4 .In acidic medium COO- converted to COOH groups .The hydrogen bonding interaction among OH and COOH groups was strengthened and the degree of physical cross linking was increased. As a result, the water absorption was decreased .However, as the pH increased to the basic medium COOH groups transform into COO- groups and the hydrogen bonding interaction was broken .In addition the electrostatic repulsion among polymer chains was increased due to the rapid increase in the number of negatively charged COO-groups .This effect causes to the hydrogel matrix an expansion and the amount of water absorbed increases considerably [32].

(Water absorbency g/g)

53

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

PHs of Buffer solution

Fig (4): Effect of PH in the swelling properties of PSg PAA co CTS and PSg PAA co CTS/CNWs hydrogel composites with 8wt% of cellulose nanofibrils.

Mechanical Properties Fig (5) shows the mechanical properties of CTS g PAA co PS hydrogl nanocomposite as a function of CNWs incorporated into the hydrogel matrix .As can be seen the incorporation of CNWs into the hydrogel decreased considerably the Young, modulus. This happen because the CNWs contributes to increase the water up take capacity which consequently became the hydrogel softer than the hydrogel without CNWs. Further increase in CNWs from 4% to 20% increases the Young,s modulus again . The CNWs acts as efficient filler and contribute to improve the mechanical resistance against compressive stress.

50 45 40

Young's moduli (KPa)

35 30 25 20 15 10 5 0 0 4 8 12 16 20

contents of CNWs(%)

Fig (5): mechanical properties of PS g PAA co CTS/CNWs hydrogel nanocomposite as a function of % CNWs

54

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

4. Conclusion A superabsorbent composed of waste polystyrene, chitosan ,acrylic acid and cellulose nanofibrils which were obtained from cotton linters was prepared through emulsion polymerization .The effect of major factors such as the weight ratio of acrylic acid to polystyrene,crosslinker,initiator and cellulose nanowhisker content on water absorbency were investigated to obtain optimum conditions with high swelling capacity, The superabsorbent hydrogel was characterized by Fourier transform infrared (FTIR) spectroscopy and scanning electron microscope(SEM).The addition of cellulose nanowhiskers improved the swelling capacity as well as improved the mechanical properties of the hydrogel. SEM images showed that the hydrogel CNWs morphology changed due to the incorporation of cellulose nanowhiskers .The nanocomposite presented good responsive behavior in relation to pH and salt solution , such characteristics make these smart materials suitable for several technological applications .Furthermore , the use of waste polystyrene not only can reduce the production cost of superabsorbent hydrogel, but can also provide a new method for converting waste resources into valuable products.

Reference:

[1] Yang,H.S., Yoon, J.S. & Kim, M.N. (2005). Dependence of biodegradability of plastics in composite on the shape of specimens, Polym. Degrad. Stab., 87 ,131-135 [2] Gao, Y.,Li,H. & Wang, X. (2007). Synthesis and characterization of syndiotactic polystyrene graft poly (glycidyl methacrylate) copolymer by atom transfer radical polymerization, Eur-Poly. J., 43,1258-1266 [3] Subramanian, S. & Lee,S. (1998). Graft copolymerization of acrylic acid onto polystyrene using the solid phase grafting technique, J.Appl. Polym. Sci.,70(5),1001-1007 [4] Subramanian,S., & Lee,S. (1999). Polystyrene graft acrylic acid as compatibilizer of polystyrene / nylon 6,6 blends, Polym. Eng.Sci. ,39(11) ,2274-2281 [5] Bergbreiter,D.E. & Zhong,Z. (2005). Anionic grafting onto divinylbenzene-cross-linked polystyrene, Ind Eng.Chem .Res., 44(23), 8616-8620 [6] Bajdur,W., Pajaczkowska,J., makaruch, B., Sulkowsk, A., & Sulkowsk, W.W. (2002). Effective polyelectrolytes synthesized from expanded polystyrene wastes; Europ. Polym.J., 38(2),299-304 [7] Kung, J., Yuk, K., Huh, & K.M. (2011). Polysaccharide-based superporous hydrogel with fast swelling and superabsorbent properties,Carbohyd. Polym., 83,284-290 [8] Omidian,H.; Rocca ,J.G., & Park, K. (2005). Advances in superporous hydrogel, J. Control Rel.,102,3-12 [9] Salimi,H., Paurjavadi,F., Seidi,F., Jabromi,P.E., & Soleyman,R. (2010) .New smart carrageenan-based superabsorbent hydrogel hybrid: investigation of swelling rate and environmental responsiveness; J Appl . Polym. Sci., 117,3228-3238 [10] Li,H.,.Lian.;Hu.J.,Fan,Y., & Zhang, X. (2011). Superabsorbent polysaccharide hydrogel based on pullulan derivativesas antibacterial release wound dressing, J.Biomed.Mater. Res. A, 98, 31-38 [11] Ebringerova,A., Hromadkova,Z., & Heinze (2005). Hemicellulose. Advanced in Polymer Science, 186, 1-67 [12] Muzzarelli, R.A.A., (2009). Chitins and chitosans for the repair of wounded skin, nerve ,cartilage and bone, Carbohydrate Polym., 76,167-182 [13] Wang,Li.H., Luz,Y. & Wang, Z. (1997). Studies on chitosan and poly(acrylic acid) interpolymer complex; J.Appl.Polym. Sci., 65,1445-1453 [14] Siqueria,G.,Brass,J., & Dufresne. A., (2009) .Cellulose whiskers versus microfibirls , influence of the nature of the nanoparticle and its surface functionalization on the thermal and mechanical properties of nanocomposites, Biomacromolecules, 10(2),425-429 [15] Pandey,J.K.,Lee,C.S. & Ahn, S.H. (2010). Preparation and properties of bio-nanocomposite from biodegradable polymer matrix and cellulose whiskers , J Appl. Polym. Sci., 115,2493-2501 [16] Barcus,R.L. & Bjorkquist, D.W.,(1991)US Patent Office, Pat No.5,049,235 [17] Goetz, L.,Mathew,A.,Oksman,K.;Gatenholm , P., & Ragauskas ,A.J. (2009). A novel nanocomposite film prepared from crooslinked cellulosic whiskers., Carbohydrate Polym., 75,85-89. [18] Labet,M., and & Thielemans,W. (2011). Improving the reproducibility of chemical reaction on the surface of cellulose nanocrystals, Cellulose, 18,607-617 [19] Teli,M.D. & Waghmare, N.G. (2009). Synthesis of superabsorbent from carbohydrate waste, Carbohyd.Polym., 78,492-496 [20] S.Y.Oh.,;D.Yoo & Y.Shin, G.Seo (2005). FTIR analysis of cellulose treated with sodium hydroxide and cotton dioxide, Carbohyd.Res., 340(3),417-425

55

Chemical and Process Engineering Research ISSN 2224-7467 (Paper) ISSN 2225-0913 (Online) Vol.15, 2013

www.iiste.org

[21] Satyamurthy, P., Jain, P., Balasubramanya, R.H. & Vigneshwaran, N. (2011). Preparation and characterization of cellulose nanowhiskers from cotton fibers by controlled microbial hydrolysis, Carbohyd. Polym., 83,122-129 [22] Spagnol, C., Rodrigues, F.H.A; Pereira, A.G.B.; Fajardo, A.R; .Rubira, A.F.; & Muniz, E.C. (2012) .Nanocomposite based on poly(acrylamide- co-acrylate) and cellulose nanowhiskers; Eur.Polym. J., 48(3),454-459 [23] Liu,Y.;Zheng,Y., & Wang, A. (2010). Enhanced adsorption of methlene blue from aqueous solution by chitosan-g-poly(acrylic acid) vermiculite hydrogel composites; Journal of Enviromental Science, 22,486493 [24] Chen. G.; Liu, S.; Chen, S.; & Qi,Z. (2001). FTIR spectra, thermal properties and dispersibilty of polystyrene/montmorillonite nanocomposite; Macromol.Chem.Phys.; 7:1189-1193 [25] Li,A.,Zhang,J.,Wang,A. (2007). Utilization of starch and clay for the preparation of superabsorbent composite., Bioresour. Technol., 98(2),327-332 [26] Pourjavad.,A., Harzandi, A.M. & Hassienzada, H. (2004). Modified carrageenan 3.synthesis of a novel polysaccharide based superabsorbent hydrogel via-graft copolymerization of acrylic acid onto kappa-carrageenan in air ,Eur.polym. J., 40(7),1363-1370 [27] Ende,M.T.,Hariharan,D. & Peppas, N.A (1995). Factor influencing drug and protein transport and release from ionic hydrogels, React.Polym., 25,127-137 [28] Pourjavadi,A.,Barzegar,S. & Zeidabadi, F. (2007). Synthesis and properties of biodegradable hydrogels of carrageenan grafted acrylic acid co-2-acrylamido-2-methylpropane sulfonic acid as candidates for drug delivery systems, React.Funct.Polym., 67(7):644-654 [29] Liang ,R.; yuan ,H.;Xi,G. & Zhou,Q. (2009). Synthesis of wheat straw-g-poly(acrylic acid) superabsorbent composites and release of urea from it, Carbolyd. polym.; 77(2) ,181-187 [30] Dai,Q., & Kadla , J.F. (2009). Effect of nanofillers on carboxymethyl cellulose/hydrxyethyl cellulose hydrogels, J. App. Polym. Sci., 114(3) ,1664-1669 [31] El Hamshary, H. (2007). Swelling and diffusion behaviors of pH sensitive poly(acrylamide-co-itaconic acid) hydrogels, Eur-polym . J., 43,4830-4839 [32] Karadag,E.,Uzum,O.B. & Saraydin, D. (2005). Water uptake in chemically cross linked poly (acrylamide-co-crotonic acid) hydrogels, Mater Design; 26,265-270

56

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org CALL FOR JOURNAL PAPERS The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Theres no deadline for submission. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. MORE RESOURCES Book publication information: http://www.iiste.org/book/ Recent conferences: http://www.iiste.org/conference/ IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

Potrebbero piacerti anche

- Asymptotic Properties of Bayes Factor in One - Way Repeated Measurements ModelDocumento17 pagineAsymptotic Properties of Bayes Factor in One - Way Repeated Measurements ModelAlexander DeckerNessuna valutazione finora

- Availability, Accessibility and Use of Information Resources and Services Among Information Seekers of Lafia Public Library in Nasarawa StateDocumento13 pagineAvailability, Accessibility and Use of Information Resources and Services Among Information Seekers of Lafia Public Library in Nasarawa StateAlexander DeckerNessuna valutazione finora

- Assessment of Housing Conditions For A Developing Urban Slum Using Geospatial AnalysisDocumento17 pagineAssessment of Housing Conditions For A Developing Urban Slum Using Geospatial AnalysisAlexander DeckerNessuna valutazione finora

- Barriers To Meeting The Primary Health Care Information NeedsDocumento8 pagineBarriers To Meeting The Primary Health Care Information NeedsAlexander DeckerNessuna valutazione finora

- Assessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaDocumento10 pagineAssessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaAlexander DeckerNessuna valutazione finora

- Assessment of The Skills Possessed by The Teachers of Metalwork in The Use of Computer Numerically Controlled Machine Tools in Technical Colleges in Oyo StateDocumento8 pagineAssessment of The Skills Possessed by The Teachers of Metalwork in The Use of Computer Numerically Controlled Machine Tools in Technical Colleges in Oyo StateAlexander Decker100% (1)

- Assessment of Some Micronutrient (ZN and Cu) Status of Fadama Soils Under Cultivation in Bauchi, NigeriaDocumento7 pagineAssessment of Some Micronutrient (ZN and Cu) Status of Fadama Soils Under Cultivation in Bauchi, NigeriaAlexander DeckerNessuna valutazione finora

- Assessment of Relationships Between Students' Counselling NeedsDocumento17 pagineAssessment of Relationships Between Students' Counselling NeedsAlexander DeckerNessuna valutazione finora

- Assessment of The Practicum Training Program of B.S. Tourism in Selected UniversitiesDocumento9 pagineAssessment of The Practicum Training Program of B.S. Tourism in Selected UniversitiesAlexander DeckerNessuna valutazione finora

- Availability and Use of Instructional Materials and FacilitiesDocumento8 pagineAvailability and Use of Instructional Materials and FacilitiesAlexander DeckerNessuna valutazione finora

- Attitude of Muslim Female Students Towards Entrepreneurship - A Study On University Students in BangladeshDocumento12 pagineAttitude of Muslim Female Students Towards Entrepreneurship - A Study On University Students in BangladeshAlexander DeckerNessuna valutazione finora

- Assessment of Teachers' and Principals' Opinion On Causes of LowDocumento15 pagineAssessment of Teachers' and Principals' Opinion On Causes of LowAlexander DeckerNessuna valutazione finora

- Assessment of Productive and Reproductive Performances of CrossDocumento5 pagineAssessment of Productive and Reproductive Performances of CrossAlexander DeckerNessuna valutazione finora

- Assessment of Survivors' Perceptions of Crises and Retrenchments in The Nigeria Banking SectorDocumento12 pagineAssessment of Survivors' Perceptions of Crises and Retrenchments in The Nigeria Banking SectorAlexander DeckerNessuna valutazione finora

- Application of The Diagnostic Capability of SERVQUAL Model To An Estimation of Service Quality Gaps in Nigeria GSM IndustryDocumento14 pagineApplication of The Diagnostic Capability of SERVQUAL Model To An Estimation of Service Quality Gaps in Nigeria GSM IndustryAlexander DeckerNessuna valutazione finora

- Assessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaDocumento10 pagineAssessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaAlexander DeckerNessuna valutazione finora

- Applying Multiple Streams Theoretical Framework To College Matriculation Policy Reform For Children of Migrant Workers in ChinaDocumento13 pagineApplying Multiple Streams Theoretical Framework To College Matriculation Policy Reform For Children of Migrant Workers in ChinaAlexander DeckerNessuna valutazione finora

- Are Graduates From The Public Authority For Applied Education and Training in Kuwaiti Meeting Industrial RequirementsDocumento10 pagineAre Graduates From The Public Authority For Applied Education and Training in Kuwaiti Meeting Industrial RequirementsAlexander DeckerNessuna valutazione finora

- Antibiotic Resistance and Molecular CharacterizationDocumento12 pagineAntibiotic Resistance and Molecular CharacterizationAlexander DeckerNessuna valutazione finora

- Assessment in Primary School Mathematics Classrooms in NigeriaDocumento8 pagineAssessment in Primary School Mathematics Classrooms in NigeriaAlexander DeckerNessuna valutazione finora

- Assessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaDocumento11 pagineAssessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaAlexander DeckerNessuna valutazione finora

- Assessment of Factors Responsible For Organizational PoliticsDocumento7 pagineAssessment of Factors Responsible For Organizational PoliticsAlexander DeckerNessuna valutazione finora

- An Investigation of The Impact of Emotional Intelligence On Job Performance Through The Mediating Effect of Organizational Commitment-An Empirical Study of Banking Sector of PakistanDocumento10 pagineAn Investigation of The Impact of Emotional Intelligence On Job Performance Through The Mediating Effect of Organizational Commitment-An Empirical Study of Banking Sector of PakistanAlexander DeckerNessuna valutazione finora

- Application of Panel Data To The Effect of Five (5) World Development Indicators (WDI) On GDP Per Capita of Twenty (20) African Union (AU) Countries (1981-2011)Documento10 pagineApplication of Panel Data To The Effect of Five (5) World Development Indicators (WDI) On GDP Per Capita of Twenty (20) African Union (AU) Countries (1981-2011)Alexander DeckerNessuna valutazione finora

- An Overview of The Environmental Policies To Ensure SafeDocumento9 pagineAn Overview of The Environmental Policies To Ensure SafeAlexander DeckerNessuna valutazione finora

- Antioxidant Properties of Phenolic Extracts of African Mistletoes (Loranthus Begwensis L.) From Kolanut and Breadfruit TreesDocumento8 pagineAntioxidant Properties of Phenolic Extracts of African Mistletoes (Loranthus Begwensis L.) From Kolanut and Breadfruit TreesAlexander DeckerNessuna valutazione finora

- Analysis The Performance of Life Insurance in Private InsuranceDocumento10 pagineAnalysis The Performance of Life Insurance in Private InsuranceAlexander DeckerNessuna valutazione finora

- Analysis of Teachers Motivation On The Overall Performance ofDocumento16 pagineAnalysis of Teachers Motivation On The Overall Performance ofAlexander DeckerNessuna valutazione finora

- Analyzing The Economic Consequences of An Epidemic Outbreak-Experience From The 2014 Ebola Outbreak in West AfricaDocumento9 pagineAnalyzing The Economic Consequences of An Epidemic Outbreak-Experience From The 2014 Ebola Outbreak in West AfricaAlexander DeckerNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Msds RenalinDocumento4 pagineMsds Renalinfriska yuni utariNessuna valutazione finora

- Application of Permeable Pavements in Highways ForDocumento15 pagineApplication of Permeable Pavements in Highways ForYEGAR SAHADUTA HEBZIBAH K 08211942000015Nessuna valutazione finora

- Msds Hidrogen PeroxideDocumento6 pagineMsds Hidrogen PeroxideIntan Yeti SeptiyaniNessuna valutazione finora

- Optiflo RC: Pulse-Jet Cylindrical Cartridge Dust CollectorDocumento6 pagineOptiflo RC: Pulse-Jet Cylindrical Cartridge Dust CollectorJuan Manuel Bedoya AcevedoNessuna valutazione finora

- Carbozinc 11: Performance DataDocumento4 pagineCarbozinc 11: Performance Datakanha15102003Nessuna valutazione finora

- Chapter 10 Solution Lecture Solution Ecture NotesDocumento37 pagineChapter 10 Solution Lecture Solution Ecture NotesLiew KahJiannNessuna valutazione finora

- DIY Homemade HHO Hydrogen Generator - RMCyberneticsDocumento6 pagineDIY Homemade HHO Hydrogen Generator - RMCyberneticsharisaryono100% (1)

- ACI 215R - Consideration For Design of Concrete Structures Subjected To Fatigue LoadingDocumento24 pagineACI 215R - Consideration For Design of Concrete Structures Subjected To Fatigue LoadingAlbertoNessuna valutazione finora

- Assessment PN1096617Documento14 pagineAssessment PN1096617Amr TarekNessuna valutazione finora

- Sand ManufacturingDocumento5 pagineSand ManufacturingJournalNX - a Multidisciplinary Peer Reviewed JournalNessuna valutazione finora

- Duct Tape and Insulation Tape GuideDocumento2 pagineDuct Tape and Insulation Tape GuideDhanish AhsenNessuna valutazione finora

- Astm A-6 PDFDocumento1 paginaAstm A-6 PDFFrank Berrios GarcesNessuna valutazione finora

- 1.5 Reservoir Drilling FluidsDocumento39 pagine1.5 Reservoir Drilling FluidsThắng NguyễnNessuna valutazione finora

- LNG Light Hydrocarbon Separation with Cryogenic Energy UtilizationDocumento4 pagineLNG Light Hydrocarbon Separation with Cryogenic Energy UtilizationphantanthanhNessuna valutazione finora

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Documento5 pagineSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezNessuna valutazione finora

- Building TechnologyDocumento3 pagineBuilding TechnologyClaro III TabuzoNessuna valutazione finora

- Metallurgical Characterization of Electrical Discharge Textured Roll SurfaceDocumento8 pagineMetallurgical Characterization of Electrical Discharge Textured Roll Surfacevishalbhojak vishalbhojakNessuna valutazione finora

- Slurry Shield AdditivesDocumento8 pagineSlurry Shield AdditivesfabiodbdbNessuna valutazione finora

- Aashto M288Documento29 pagineAashto M288jong_hao_su5167% (3)

- Datasheet Potassium Formate KFORMSOLpdfDocumento1 paginaDatasheet Potassium Formate KFORMSOLpdfJuan MancipeNessuna valutazione finora

- China's First Ministry of Machine-Building Standard for Radiography of WeldsDocumento133 pagineChina's First Ministry of Machine-Building Standard for Radiography of Weldsmsiddique1Nessuna valutazione finora

- Revised PT Program April-May 2021 30% Discount Metal TestingDocumento2 pagineRevised PT Program April-May 2021 30% Discount Metal TestingSaravanan PNessuna valutazione finora

- Assignment 2015 1Documento1 paginaAssignment 2015 1manishNessuna valutazione finora

- Non-Classical Reactor SystemsDocumento22 pagineNon-Classical Reactor SystemsManuelNessuna valutazione finora

- Processes: A Techno-Economic Assessment of Fischer-Tropsch Fuels Based On Syngas From Co-ElectrolysisDocumento42 pagineProcesses: A Techno-Economic Assessment of Fischer-Tropsch Fuels Based On Syngas From Co-ElectrolysisMuhammad SalmanNessuna valutazione finora

- Mechanics of Materials Beer 7th Edition Solutions ManualDocumento5 pagineMechanics of Materials Beer 7th Edition Solutions Manualjosephpetersonjaczgqxdsw100% (45)

- Lecture 1Documento7 pagineLecture 1Dr. Aung Ko LattNessuna valutazione finora

- Cat. IV Toughened Glass InsulatorDocumento8 pagineCat. IV Toughened Glass InsulatorFernando GasparNessuna valutazione finora

- Literature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Documento115 pagineLiterature Study Castings: TC-10: Sub-Study 'Non-Standard Connections'Patricia BrandNessuna valutazione finora

- Tut 9 - PH 102 - 30052023Documento1 paginaTut 9 - PH 102 - 30052023PS SuryaNessuna valutazione finora