Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bonald: Dhofar Power Company SAOG

Caricato da

54045114Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bonald: Dhofar Power Company SAOG

Caricato da

54045114Copyright:

Formati disponibili

Dhofar Power Company SAOG

l111 ~~~bonald

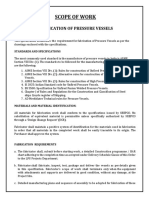

LevelS: 10 percent of each welder's output shall be ultrasonic tested, with a further 10 percent of each welder's output magnetic particle tested - both to the acceptance criteria in BS 5135, Table 18, Category B expect for porosity. (See Note A) for butt welds. Note A All welds, especially butt welds, must be continuous to ensure a pickle-tight connection when galvanised. Ultrasonic testing to be in accordance with BS EN 1714. Magnetic particle testing to be in accordance with BS EN 1290 and acceptance levels to be in accordance with BS EN 1291.

Note B Note C

All weld inspection/testing shall be undertaken a minimum of 48 hours after the completion of the respective weld. This is a Notification point. Copies of the NDT inspection reports for weld inspection levels 5 and 4 shall be made available to the Owner/Engineer. Copies of the NDT inspection reports for weld inspection levels 3 and 2 shall be made available to the Owner/Engineer upon request.

7.7.3 Check Erection

Prototype structures (and, where required by the Owner/Engineer repeat structures) shall be check erected in order to verify the accuracy of detailing and fabrications, including forming, location and size of bolt holes, clipping and shearing. The degree of check erection shall be sufficient to verify not only the main structure, but also all ancillary steelwork such as platforms.

In the case of lattice towers, the minimum check erection required shall be one face lying horizontally and the adjacent face erected in the vertical plane, complete with hip and plan bracings. Cross arms and earth wire peaks shall be completely assembled.

Sufficient blocking and support shall be provided to prevent distortion and overstressing of the members to ensure proper fit. Assembly shall be accomplished without extraordinary effort to align boltholes or to force pieces into position. Boltholes shall not be reamed or enlarged. All modifications found necessary at the time of check erection shall be accurately recorded and the Contractors drawings, NC tapes etc., shall be amended. Where necessary, modified G.A. drawings shall be forwarded to the OwnerlEngineer. Unless otherwise specified the check erection may be undertaken in either the black or galvanised condition. Where materials are check erected galvanised, all modified items, those subjected to damage or prolonged contact with black steel, shall be re-galvanised at the supplier's cost. The Contractor shall give the Owner/Engineer the requisite period of notice prior to a check erection being ready for inspection. This is a Hold Point.

7.7.4 Galvanising

Construction of 132kV Overhead line between Awqad GSS & SFZ GSS and Associated Works (Package-1) Volume 2 Overhead Line Specification Section 7 Supports

,

Rev. No. Date

:A : December 2010 :Page 22 of 38

......--_ .._....

...,.,_... ...... _ ..'.

,~

Page

_-

Potrebbero piacerti anche

- PRL SOW-HP Steam Line ModificationDocumento3 paginePRL SOW-HP Steam Line ModificationM Waqas HabibNessuna valutazione finora

- API 650 tank repair worksDocumento3 pagineAPI 650 tank repair worksenggmohanNessuna valutazione finora

- Standard Specification for Underground Piping InstallationDocumento22 pagineStandard Specification for Underground Piping Installationt_solanki2001100% (1)

- Technical Information For Modification Off Existing MCCDocumento5 pagineTechnical Information For Modification Off Existing MCCYo Wee LiamNessuna valutazione finora

- Job Procedure For Eriction of TankDocumento13 pagineJob Procedure For Eriction of TankAnonymous i3lI9M100% (2)

- 3 66 KV CT PT R6 Metering Dec 12Documento34 pagine3 66 KV CT PT R6 Metering Dec 12dkshtdkNessuna valutazione finora

- B2020-TDC-VF-009 Vessel Fabrication R0Documento5 pagineB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNessuna valutazione finora

- 14 A 66 KV CT PT R5 Metering Jan 10Documento33 pagine14 A 66 KV CT PT R5 Metering Jan 10Ramesh Ananthanarayanan100% (1)

- Lighting and Small PowerDocumento3 pagineLighting and Small PowerYo Wee LiamNessuna valutazione finora

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Documento4 pagineApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNessuna valutazione finora

- Central Business District CBD EAST - Phase 1 of The New Administrative CapitalDocumento20 pagineCentral Business District CBD EAST - Phase 1 of The New Administrative CapitalLi LiuNessuna valutazione finora

- DG BusductDocumento16 pagineDG BusductanandpurushothamanNessuna valutazione finora

- Underground Power Cable For AirportsDocumento12 pagineUnderground Power Cable For AirportsDevrim GürselNessuna valutazione finora

- Tech - Spec. LA For WBSEDCL Sept.07, ArresterDocumento6 pagineTech - Spec. LA For WBSEDCL Sept.07, ArresterThanh NguyenNessuna valutazione finora

- Scope of Work-Fabrication of Heat ExchangersDocumento3 pagineScope of Work-Fabrication of Heat ExchangersAsad KhanNessuna valutazione finora

- Enbridge Pipeline Repair Workplan WeldingDocumento23 pagineEnbridge Pipeline Repair Workplan WeldingJesus MaestreNessuna valutazione finora

- Electrical Plant ChecklistDocumento5 pagineElectrical Plant ChecklistAjish Rajan TNessuna valutazione finora

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Documento57 pagineBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNessuna valutazione finora

- Enbridge Pipeline Repair Workplan Welding PDFDocumento23 pagineEnbridge Pipeline Repair Workplan Welding PDFquiron2014Nessuna valutazione finora

- GTTPL Technical Specifications Full EpcDocumento10 pagineGTTPL Technical Specifications Full EpcPinku MaitiNessuna valutazione finora

- Shop Welding InspectionDocumento4 pagineShop Welding InspectionIndra Nath MishraNessuna valutazione finora

- Wsdot 6-03.3Documento3 pagineWsdot 6-03.3Dave MulvihillNessuna valutazione finora

- C. Specifications For Cone Roof TKDocumento21 pagineC. Specifications For Cone Roof TKFajar Sidiq AliwiyonoNessuna valutazione finora

- Annexure To SOW 3 STD Specification For Welding and NDT PipingDocumento15 pagineAnnexure To SOW 3 STD Specification For Welding and NDT PipingASHISH GORDENessuna valutazione finora

- Bundle Spacer: Engineering DepartmentDocumento4 pagineBundle Spacer: Engineering DepartmentpvenkyNessuna valutazione finora

- PTL Rev1HartlepoolDocumento4 paginePTL Rev1Hartlepoolharry_1981Nessuna valutazione finora

- 5 Clamps Connectors 220 400kv SsDocumento12 pagine5 Clamps Connectors 220 400kv SsJaswanth SaiNessuna valutazione finora

- Rob PSC1Documento17 pagineRob PSC1Rohit BaliNessuna valutazione finora

- Vol II Ts RevisionDocumento75 pagineVol II Ts RevisionGirish NautiyalNessuna valutazione finora

- Kansas Department of Transportation Special Provision To The Standard Specifications, Edition 2015Documento3 pagineKansas Department of Transportation Special Provision To The Standard Specifications, Edition 2015Vpln SarmaNessuna valutazione finora

- 04 HW Accs Zebra Conductor PDFDocumento23 pagine04 HW Accs Zebra Conductor PDFelsayedNessuna valutazione finora

- Scope of Work-Fabrication of Pressure VesselsDocumento3 pagineScope of Work-Fabrication of Pressure VesselsAsad Khan100% (2)

- Api 510 PTR 7Documento3 pagineApi 510 PTR 7HemaNessuna valutazione finora

- Piping and Ducting SupportDocumento7 paginePiping and Ducting SupportphilipyapNessuna valutazione finora

- No Mesh/Net: RequirementsDocumento3 pagineNo Mesh/Net: RequirementsSABEASNNessuna valutazione finora

- N0Tes: Sectional Elevation D-D Section A-ADocumento1 paginaN0Tes: Sectional Elevation D-D Section A-ASamuel HannahNessuna valutazione finora

- Quality Control Procedure Strcture-SSDocumento16 pagineQuality Control Procedure Strcture-SSKamran AliNessuna valutazione finora

- Hydromechanical - Technical SpecificationsDocumento16 pagineHydromechanical - Technical SpecificationsdishkuNessuna valutazione finora

- SECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsDocumento8 pagineSECTION 20710 Flash Butt Rail Welding: Caltrain Standard SpecificationsminchanmonNessuna valutazione finora

- Dhofar Power Company SAOG transmission line testingDocumento1 paginaDhofar Power Company SAOG transmission line testing54045114Nessuna valutazione finora

- 2 Welding Procedure 2 PDFDocumento6 pagine2 Welding Procedure 2 PDFMustafa MubderNessuna valutazione finora

- Specification For Subsea Flange FittingDocumento16 pagineSpecification For Subsea Flange FittingMuzammil Makandar100% (1)

- Technical Specification OF Tower Material For66Kv-Panther Transmission LineDocumento15 pagineTechnical Specification OF Tower Material For66Kv-Panther Transmission LineMl JainNessuna valutazione finora

- 40MV Transformer TS 2791 FINALDocumento12 pagine40MV Transformer TS 2791 FINALRanchak KumarNessuna valutazione finora

- Caltrain Thermite Rail Welding SpecificationsDocumento7 pagineCaltrain Thermite Rail Welding SpecificationsPeem'zPlNessuna valutazione finora

- Quality control and fabrication of composite bridge girdersDocumento7 pagineQuality control and fabrication of composite bridge girdersradhakrishnangNessuna valutazione finora

- RCC PILE SPECS JSW STEELDocumento16 pagineRCC PILE SPECS JSW STEELmkpasha55mp100% (1)

- Transformers 10 KVADocumento39 pagineTransformers 10 KVARajuNessuna valutazione finora

- WBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONDocumento8 pagineWBSEB TUBULAR STEEL POLES TECHNICAL SPECIFICATIONVarun SharmaNessuna valutazione finora

- Gi Earth SpikeDocumento5 pagineGi Earth SpikemangalamtestingbureaNessuna valutazione finora

- Government Guidelines on Fabrication of Steel GirdersDocumento55 pagineGovernment Guidelines on Fabrication of Steel GirdersradhakrishnangNessuna valutazione finora

- STD Spec For Piping WeldingDocumento14 pagineSTD Spec For Piping WeldingknsaravanaNessuna valutazione finora

- Spaceframe DetailsDocumento9 pagineSpaceframe DetailsgorvjndlNessuna valutazione finora

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Bill2 Jan Paschimanchal Vidyut Vitran Nigam LTDDocumento1 paginaBill2 Jan Paschimanchal Vidyut Vitran Nigam LTD54045114Nessuna valutazione finora

- Check Aadhaar StatusDocumento2 pagineCheck Aadhaar Status54045114Nessuna valutazione finora

- Untitled 1Documento68 pagineUntitled 154045114Nessuna valutazione finora

- sssssss10 17 PDFDocumento1 paginasssssss10 17 PDF54045114Nessuna valutazione finora

- sssssss10 17Documento1 paginasssssss10 1754045114Nessuna valutazione finora

- sssssss10 04Documento1 paginasssssss10 0454045114Nessuna valutazione finora

- Construction Types: Split CoreDocumento1 paginaConstruction Types: Split Core54045114Nessuna valutazione finora

- Minnesota and Wisconsin county home sale prices 2012-2013Documento80 pagineMinnesota and Wisconsin county home sale prices 2012-201354045114Nessuna valutazione finora

- sssssss10 17 PDFDocumento1 paginasssssss10 17 PDF54045114Nessuna valutazione finora

- Equipment Exceptions List Sheet 1 of 1Documento1 paginaEquipment Exceptions List Sheet 1 of 154045114Nessuna valutazione finora

- Insulation of A Core Pile: January 19, 2016Documento1 paginaInsulation of A Core Pile: January 19, 201654045114Nessuna valutazione finora

- Current Transformer Secondary Types: IEEE C57.13 IEC 60044-1Documento1 paginaCurrent Transformer Secondary Types: IEEE C57.13 IEC 60044-154045114Nessuna valutazione finora

- 23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.00Documento1 pagina23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.0054045114Nessuna valutazione finora

- Current Transformer Basics GuideDocumento1 paginaCurrent Transformer Basics Guide54045114Nessuna valutazione finora

- sssssss10 01Documento1 paginasssssss10 0154045114Nessuna valutazione finora

- Oil Gas Industry GuidelinesDocumento90 pagineOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNessuna valutazione finora

- Questions ?: Thank YouDocumento1 paginaQuestions ?: Thank You54045114Nessuna valutazione finora

- Viewtenddoc 6Documento1 paginaViewtenddoc 654045114Nessuna valutazione finora

- Viewtenddoc 13Documento1 paginaViewtenddoc 1354045114Nessuna valutazione finora

- Electrical maintenance tender detailsDocumento1 paginaElectrical maintenance tender details54045114Nessuna valutazione finora

- Earnest Money Bank Guarantee TitleDocumento1 paginaEarnest Money Bank Guarantee Title54045114Nessuna valutazione finora

- Government of India Department of Posts (Civil Wing) : Notice Inviting TenderDocumento1 paginaGovernment of India Department of Posts (Civil Wing) : Notice Inviting Tender54045114Nessuna valutazione finora

- Government of India Department of Posts (Civil Wing) : Notice Inviting TenderDocumento1 paginaGovernment of India Department of Posts (Civil Wing) : Notice Inviting Tender54045114Nessuna valutazione finora

- Viewtenddoc 6Documento1 paginaViewtenddoc 654045114Nessuna valutazione finora

- Viewtenddoc 3Documento1 paginaViewtenddoc 354045114Nessuna valutazione finora

- Rated Voltage of Circuit Breaker: Current CurrentDocumento2 pagineRated Voltage of Circuit Breaker: Current Current54045114Nessuna valutazione finora

- CTDocumento1 paginaCT54045114Nessuna valutazione finora

- 23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.00Documento1 pagina23 2x4'-40 W MO Fitting (R) 2 Each 2,704.00 24 1x4'-40 W BT Fitting With EB 2 Each 668.0054045114Nessuna valutazione finora

- 11 KW Tertiary Treatment Feed PumpDocumento4 pagine11 KW Tertiary Treatment Feed Pump54045114Nessuna valutazione finora

- EOCR CatalogueDocumento12 pagineEOCR Catalogue54045114Nessuna valutazione finora

- A320 321 PW1100G - Question Bank5412481902795341096Documento12 pagineA320 321 PW1100G - Question Bank5412481902795341096Trần Việt Cường100% (2)

- Use of CFD To Predict and Reduce Erosion in An Industrial Slurry Piping SystemDocumento6 pagineUse of CFD To Predict and Reduce Erosion in An Industrial Slurry Piping Systemcybot112100% (1)

- ForgingDocumento4 pagineForgingMubashar Khalil HashmiNessuna valutazione finora

- Problems Open Channel FlowDocumento3 pagineProblems Open Channel Flow8986103t100% (1)

- (PPL) - Eqc C172M PDFDocumento2 pagine(PPL) - Eqc C172M PDFDiego CatindigNessuna valutazione finora

- Instruction Manual: P/N 30-2131-XXX Pressure SensorsDocumento2 pagineInstruction Manual: P/N 30-2131-XXX Pressure SensorsG C D Nuevo AmanecerNessuna valutazione finora

- Uniform Circular MotionDocumento6 pagineUniform Circular MotionShekhar YaduvanshiNessuna valutazione finora

- MCS-7100 Series Satellite Communications: Honeywell Offers A Full Range of SATCOM ProductsDocumento4 pagineMCS-7100 Series Satellite Communications: Honeywell Offers A Full Range of SATCOM ProductsMikeNessuna valutazione finora

- PTC Maintenance Procedures Module 7 Sub Module 7.20Documento22 paginePTC Maintenance Procedures Module 7 Sub Module 7.20shareyhou100% (1)

- Advanced Fusion Energy SystemDocumento11 pagineAdvanced Fusion Energy SystemPhilip KadickNessuna valutazione finora

- Aerodynamics Lab 1 - Cylinder Lift and DragDocumento17 pagineAerodynamics Lab 1 - Cylinder Lift and DragDavid Clark100% (4)

- Purlin Z Sag Rod DesignDocumento4 paginePurlin Z Sag Rod DesignanbukgiNessuna valutazione finora

- Aircraft Load Analysis and Sizing ReportDocumento62 pagineAircraft Load Analysis and Sizing ReportRizqy AgungNessuna valutazione finora

- Bronkhorst 2017 WindDocumento21 pagineBronkhorst 2017 WindMohamed HNessuna valutazione finora

- Primus Weather-Radars PDFDocumento4 paginePrimus Weather-Radars PDFJuanOñateNessuna valutazione finora

- EDF AfterburnerDocumento58 pagineEDF AfterburnerBagas Pramana Putra FadilaNessuna valutazione finora

- Basics of Fluid FlowDocumento2 pagineBasics of Fluid FlowCharan RanaNessuna valutazione finora

- Book 02 AGK1 SystemsDocumento421 pagineBook 02 AGK1 SystemsCosmin Alexandru GrosariuNessuna valutazione finora

- Company ProfileDocumento13 pagineCompany Profiletaufik pathanNessuna valutazione finora

- VP Operations Manufacturing Purchasing in Salt Lake City UT Resume Jolene KawaDocumento2 pagineVP Operations Manufacturing Purchasing in Salt Lake City UT Resume Jolene KawaJoleneKawaNessuna valutazione finora

- Slab Analysis: Gato, Jocelyn BSCE-IVBDocumento24 pagineSlab Analysis: Gato, Jocelyn BSCE-IVBjoanNessuna valutazione finora

- Steel and Concrete Arch Bridges DesignDocumento133 pagineSteel and Concrete Arch Bridges Designhala012100% (2)

- Cryogenic Nano-Actuator: ProceedingsDocumento14 pagineCryogenic Nano-Actuator: ProceedingsAmirNessuna valutazione finora

- 737 Flight PlanDocumento101 pagine737 Flight PlanMason IrelandNessuna valutazione finora

- B777F Brochure-4 ApprovedDocumento13 pagineB777F Brochure-4 ApprovedAnonymous 4agxDZhwNessuna valutazione finora

- A3c Electrical Flight Control System B1Documento1 paginaA3c Electrical Flight Control System B1kpilNessuna valutazione finora

- Jane's Usaf ManualDocumento278 pagineJane's Usaf ManualManuel ShupingahuaNessuna valutazione finora

- Heat Resisting AlloysDocumento3 pagineHeat Resisting AlloysElMacheteDelHuesoNessuna valutazione finora

- BlueprintDocumento42 pagineBlueprintYagmurNessuna valutazione finora

- Sany Sy75cDocumento4 pagineSany Sy75cAkhmad SebehNessuna valutazione finora