Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

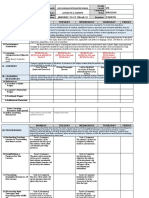

ENG3048-2008 Outline Qualitative Solutions

Caricato da

Usman Qadir0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni0 pagineChampions are senior leaders who "own" the areas relevant to the lean six sigma projects. They regularly assess and communicate progress, identify specific savings gained from LSS applications, and review the project to ensure everything is running smoothly. Champions also translate their company's vision, missions, goals, and metrics into individual unit tasks.

Descrizione originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoChampions are senior leaders who "own" the areas relevant to the lean six sigma projects. They regularly assess and communicate progress, identify specific savings gained from LSS applications, and review the project to ensure everything is running smoothly. Champions also translate their company's vision, missions, goals, and metrics into individual unit tasks.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni0 pagineENG3048-2008 Outline Qualitative Solutions

Caricato da

Usman QadirChampions are senior leaders who "own" the areas relevant to the lean six sigma projects. They regularly assess and communicate progress, identify specific savings gained from LSS applications, and review the project to ensure everything is running smoothly. Champions also translate their company's vision, missions, goals, and metrics into individual unit tasks.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 0

2008

Outline Answer A1a

Define

What is the business case for the project?

Identify the customer

Current state map

Future state map

What is the scope of this project?

Deliverables

Due date

Measure

What are the key metrics for this business process?

Are metrics valid and reliable?

Do we have adequate data on this process?

How will I measure progress?

How will I measure project success?

Analyze

Current state analysis

Is the current state as good process can do?

Who will help make the changes?

Resource requirements

What could cause this change to fail?

What major obstacles do I face in completing this project?

Improve

What is the work breakdown structure?

What specific activities are necessary to meet the project's goals?

How will I re-integrate the various subprojects?

Control

During the project, how will I control risk, quality, cost, schedule, scope, and changes to the

plan?

What types of progress reports should I create?

How will I assure that the business goals of the project were accomplished?

How will I keep the gains made?

Outline Answer A2a

Conditions, which will inhibit the successful implementation of Statistical Process Control include:

- Fear of stats

- Lack of top management commitment

- Lack of middle management support

- Failure to stay on course

- Haphazard approach

- Failure to provide adequate training including stats

- Focus on short term profit

- Failure to solicit worker input

- Lack of funds to remedy problems

- Failure to understand fitness for purpose

Outline Answer B1

Champions (or Project Sponsors) are senior leaders, usually Commanding

Officers and Program Directors who own the areas relevant to the LSS projects.

They support the Belts by sponsoring the project and implementing the solutions that

are developed through the DMAIC process. They regularly assess and communicate

progress, identify specific savings gained from LSS applications, and review the

project to ensure everything is on track and running smoothly. They also provide the

resources to implement the LSS plan and manage communications between team

players. Champions lead the change to Lean Six Sigma! Project Champions take

their company's vision, missions, goals, and metrics and translate them into

individual unit tasks. Additionally, Champions must remove any roadblocks to the

program's success.

Master Black Belts work full time to train and coach Black/Green Belts and also to

provide statistical problem solving expertise. Though there are currently no Master

Black Belts within Navy Region Southeast, it is expected that a few will emerge after

Commander, Navy Installations Command (CNIC) trains several Black Belts. These

Master Black Belts, assigned to CNIC, will work with Black Belts across the entire

command. Master Black belt train black belts, they must know everything the black

belts know, as well as understand the mathematical theory on which the statistical

methods are based.

Black Belts also devote 100% of time to LSS activities. They lead LSS project

teams, and they train and mentor Green Belts. Black Belts have completed in-depth

training in LSS methods and tools. Generally they possess the following

competencies: team facilitating; problem solving; process orientation/systems

thinking; change facilitation; communications skills; computer knowledge; program

and project management; and financial analysis. Black belt, also called technical

leader are technically oriented individuals held in high regard by their peers and they

are the doers.

Green Belts are the backbone of the LSS teams. They lead small-scale projects,

Kaizens, and Rapid Improvement Events (RIEs) and assist in Black Belt projects

within their functional area. They receive a basic level of training in LSS tools and

concepts. Green Belts provide internal team support to Black Belts. Typically, a

Green Belt will be a respected worker who can manage the team in the absence of

the Black Belt.

Yellow Belts are members of the team who devote 5% -15% of their time to their

assigned LSS project.

Outline Answer B2

The leader's personal qualities and characteristics are those, which create the willingness to

follow in those persons being led. Terms like trustworthy, courageous, compassionate, visionary,

persuasive, and charismatic are often used to describe leadership behaviour.

Leadership in TQM requires the manager to provide an inspiring vision, make strategic directions

that are understood by all and to instil values that guide subordinates. For TQM to be successful

in the business, the supervisor must be committed in leading his employees. A supervisor must

understand TQM, believe in it and then demonstrate their belief and commitment through their

daily practices of TQM. The supervisor makes sure that strategies, philosophies, values and

goals are transmitted down through out the organization to provide focus, clarity and direction. A

key point is that TQM has to be introduced and led by top management. Commitment and

personal involvement is required from top management in creating and deploying clear quality

values and goals consistent with the objectives of the company and in creating and deploying well

defined systems, methods and performance measures for achieving those goals.

In any organization where people have had jobs of "supervising" or "managing" others, Dr.

Deming says the traditional activities associated with these jobs should be replaced by

"Leadership." Traditional supervisory activities include auditing and inspection of the performance

of others. Such activities are reactive rather than proactive. Deming gives very specific examples

of what Leadership means with emphasis on organizational management. He comments on what

a Leader will know, will do, and what beliefs and assumptions the Leader will operate under to do

his/her job in accordance with the Fourteen Points.

Shortcomings include:

employees submersed in dealing with each day's crisis or quota,

improvement efforts stalled by focusing on conformance rather than improvement,

people unable to achieve their potential,

employees blamed for problems that are actually faults of the system,

employees asked to explain variation which results from causes which are common

to all outcomes and can only be removed by management action to change the way

the system operates,

"program-of-the-month" management (lack of constancy of purpose) resulting in

employee cynicism,

employees frustrated and demoralized by being prevented from doing high quality

work and being powerless to change the system,

adversarial relationships with customers, suppliers and employees,

the cost of products and services bloated by waste,

product of unpredictable quality,

dissatisfied customers,

stagnant or eroding market position.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Revista Newsflash 7 3Documento56 pagineRevista Newsflash 7 3Lenguaextranjera uscoNessuna valutazione finora

- B.Ed. Syllabus Final 15.06.2016-8-7-16Documento209 pagineB.Ed. Syllabus Final 15.06.2016-8-7-16manish.cdmaNessuna valutazione finora

- Lesson Plan Body Image ViiiDocumento6 pagineLesson Plan Body Image ViiiIchigo kurosaki 22Nessuna valutazione finora

- UCSP Chapter 2 SlidesDocumento10 pagineUCSP Chapter 2 SlidesKyle Darren PunzalanNessuna valutazione finora

- English GrammarDocumento5 pagineEnglish GrammarJav Thỏ100% (1)

- Budgeted Lesson/Topic Allocation Curriculum AuditDocumento4 pagineBudgeted Lesson/Topic Allocation Curriculum AuditAgnes RamoNessuna valutazione finora

- Don't Think of An Elephant - Know Your Values and Frame The Debate - George LakoffDocumento142 pagineDon't Think of An Elephant - Know Your Values and Frame The Debate - George LakoffBreno ModestoNessuna valutazione finora

- Professor William Allan KritsonisDocumento104 pagineProfessor William Allan KritsonisAnonymous aDHOj5Nessuna valutazione finora

- Imposter Phenomenon 1Documento24 pagineImposter Phenomenon 1گل میوہNessuna valutazione finora

- FagotDocumento2 pagineFagotThalia VladimirouNessuna valutazione finora

- PSYCHOLOGICAL TEST CONSTRUCTION AND VALIDATION (grp6)Documento36 paginePSYCHOLOGICAL TEST CONSTRUCTION AND VALIDATION (grp6)JANE ACEVEDONessuna valutazione finora

- 1) Importing Python Packages For GANDocumento8 pagine1) Importing Python Packages For GANHilman OvicNessuna valutazione finora

- Perfeval Prob 6MO PDFDocumento2 paginePerfeval Prob 6MO PDFAnonymous KwzVdSVOILNessuna valutazione finora

- Econ 409 - 46 - Assignment 02 - Group 06Documento3 pagineEcon 409 - 46 - Assignment 02 - Group 06Najia TasnimNessuna valutazione finora

- Summary and Outline of ReportDocumento4 pagineSummary and Outline of ReportRhaine Esteban100% (1)

- Why Is It Important To Study The Development of History of Science and TechnologyDocumento4 pagineWhy Is It Important To Study The Development of History of Science and TechnologyElmoNessuna valutazione finora

- Important Info On PhilIRIDocumento8 pagineImportant Info On PhilIRIAinie Shen BoloNessuna valutazione finora

- Sources of Self-Efficacy PDFDocumento13 pagineSources of Self-Efficacy PDFthenimadhavanNessuna valutazione finora

- DLL - 4th QRTR - Week 1Documento6 pagineDLL - 4th QRTR - Week 1Jaycelyn BaduaNessuna valutazione finora

- Lesson Plan ArraysDocumento11 pagineLesson Plan ArraysErika MytnikNessuna valutazione finora

- 30 Quick Wins RebrandDocumento11 pagine30 Quick Wins Rebrandshivangi guptaNessuna valutazione finora

- Imaginarium Unlocking The Creative Power WithinDocumento27 pagineImaginarium Unlocking The Creative Power WithinShacory HammackNessuna valutazione finora

- Reasons Why Campus Journalism Is Important: Ppt#2 Prof. Bernardita C. BautistaDocumento11 pagineReasons Why Campus Journalism Is Important: Ppt#2 Prof. Bernardita C. BautistaMarie Angeline B. Estores3180201Nessuna valutazione finora

- The Influence of AustinDocumento17 pagineThe Influence of AustinErickson SantosNessuna valutazione finora

- UNIT TEST in Oral CommunicationDocumento4 pagineUNIT TEST in Oral CommunicationKit MaddenNessuna valutazione finora

- Business Math1Documento9 pagineBusiness Math1Pat Che Sabaldana100% (2)

- Republic of The Philippines Nueva Vizcaya State University Bayombong, Nueva VizcayaDocumento8 pagineRepublic of The Philippines Nueva Vizcaya State University Bayombong, Nueva VizcayaNica Hannah100% (2)

- Q1W4MAPEH9 Oct10-14,2022Documento6 pagineQ1W4MAPEH9 Oct10-14,2022beanila barnacheaNessuna valutazione finora

- Understanding Culture, Society and Politics Module 8Documento2 pagineUnderstanding Culture, Society and Politics Module 8Joyce CasemNessuna valutazione finora

- Functional TranslationDocumento6 pagineFunctional TranslationCẩm Tiên MaiNessuna valutazione finora