Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Student Slides M8

Caricato da

Ompal SinghCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Student Slides M8

Caricato da

Ompal SinghCopyright:

Formati disponibili

MODULE 8

BOILING AND CONDENSATION

8.1 Boiling: General considerations

Boiling is associated with transformation of liquid to vapor at a

solid/liquid interface due to convection heat transfer from the

solid.

Agitation of fluid by vapor bubbles provides for large

convection coefficients and hence large heat fluxes at low-to-

moderate surface-to-fluid temperature differences

Special form of Newtons law of cooling:

e sat s s

T h T T h q A = = ' ' ) (

where is the saturation temperature of the liquid, and

sat

T )

sat s e

T T T = A

is the excess temperature.

8.2 Special cases

Pool Boiling:Liquid motion is due to natural convection and

bubble-induced mixing.

Forced Convection Boiling:Fluid motion is induced by external

means, as well as by bubble-induced mixing.

Saturated Boiling:Liquid temperature is slightly larger than

saturation temperature

Subcooled Boiling:Liquid temperature is less than saturation

temperature

8.3 The boiling curve

The boiling curve reveals range of conditions associated with

saturated pool boiling on a

s

q ' ' vs.

e

T A plot.

Water at Atmospheric Pressure

Free Convection Boiling ( <5C)

e

T A

Little vapor formation.

Liquid motion is due principally to single-phase natural

convection.

Onset of Nucleate Boiling ONB (

e

T A ~5C)

Nucleate boiling (5C < <30C)

e

T A

Isolated Vapor Bubbles (5C <

e

T A <10C)

Liquid motion is strongly influenced by nucleation

of bubbles at the surface.

h and

s

q ' ' rise sharply with increasing

e

T A

Heat transfer is principally due to contact of liquid

with the surface (single-phase convection) and not

to vaporization

J ets and Columns (10C <

e

T A <30C)

Increasing number of nucleation sites causes

bubble interactions and coalescence into

jets and slugs.

Liquid/surface contact is impaired.

continues to increase with

s

q ' '

e

T A while h begins to decrease

Critical Heat Flux - CHF, (

e

T A ~30C)

Maximum attainable heat flux in nucleate boiling.

2

max

1MW/m for water at atmospheric pressure. q'' ~

Potential Burnout for Power-Controlled Heating

An increase in

s

q ' ' beyond

max

q ' ' causes the surface to be

blanketed by vapor and its temperature to spontaneously achieve

a value that can exceed its melting point

If the surface survives the temperature shock, conditions are

characterized by film boiling

Film Boiling

Heat transfer is by conduction and radiation across the vapor

blanket

A reduction in

s

q ' ' follows the cooling the cooling

curve continuously to the Leidenfrost point corresponding to the

minimum heat flux

min

q ' ' for film boiling.

A reduction in

s

q ' ' below

min

q ' ' causes an abrupt reduction in

surface temperature to the nucleate boiling regime

Transition Boiling for Temperature-Controlled Heating

Characterised by continuous decay of

s

q ' ' (from

max

q ' ' to

min

q ' ' )

with increasing

e

T A

Surface conditions oscillate between nucleate and film

boiling, but portion of surface experiencing film boiling

increases with

e

T A

Also termed unstable or partial film boiling.

8.4 Pool boiling correlations

Nucleate Boiling

Rohsenow Correlation, clean surfaces only, 100% errors

( )

Critical heat flux:

Film Boiling

,

3

1/ 2

,

Pr

p l

l v

l fg

n

s f f

e

g l

s

c T

q

g

h

C h

A

o

| |

(

=

|

(

\

'

|

'

.

,

, Surface/Fluid Combination (

s f

C n

( )

1/ 4

max

2

0.149

l v

fg v

v

g

q h

o

(

''

=

(

( )

( )

1/

3

l v fg

conv

D

v v v s sat

g h D

h D

Nu C

k k T T

v

'

4

(

= =

(

Geometry

Cylinder(Hor.) 0.62

C

Sphere 0.67

8.5 Condensation: General considerations

Condensation occurs when the temperature of a vapour is

reduced below its saturation temperature

Condensation heat transfer

Film condensation

Dropwise condensation

Heat transfer rates in dropwise condensation may be as much as

10 times higher than in film condensation

8.6 Laminar film condensation on a vertical wall

Condensate Film

g

y

( y

x

T

sat

( (x)

A

T

(

y

x

A

A

y A

y

y

u

l

|

|

.

|

c

c

y y

y

u

l

A +

c

c

|

|

.

|

y gA )

v

l

( A

A

4 / 1

3

4 / 1

) ( 4

) (

) (

) (

) ( 4

) (

(

=

(

(

=

l w sat

l v l fg

v l fg

l w sat l

T T x

k g h

x h

g h

T T xk

x

v

v

o

fg

w sat L

fg

w sat L

l w sat

l v l fg

L

h

T T A h

h

q

m

T T A h q

T T L

k g h

h

) (

) (

) (

) (

943 . 0

4 / 1

3

= =

=

(

=

& : rate on Condensati

: rate transfer heat Total

length. plate the is L where

coeff. Average

v

Potrebbero piacerti anche

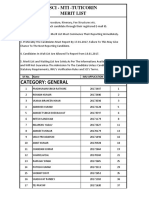

- Sci Merit List - Tuticorin-2b8a2eDocumento4 pagineSci Merit List - Tuticorin-2b8a2eOmpal SinghNessuna valutazione finora

- Demo Weld Cost Calc XL-UnprotectedDocumento10 pagineDemo Weld Cost Calc XL-UnprotectedA R0% (1)

- Public Health BNNNDocumento8 paginePublic Health BNNNOmpal SinghNessuna valutazione finora

- Application Form:: 2471860245: Mumbai:: NoDocumento2 pagineApplication Form:: 2471860245: Mumbai:: NoOmpal SinghNessuna valutazione finora

- Photograph: Passport Size Photograph (3.5 CM X 4.5 CM)Documento3 paginePhotograph: Passport Size Photograph (3.5 CM X 4.5 CM)Ompal SinghNessuna valutazione finora

- S.P. Form-44: Ticket Size Photo To Be Pasted (Not To Be Stapled) SignatureDocumento1 paginaS.P. Form-44: Ticket Size Photo To Be Pasted (Not To Be Stapled) SignatureOmpal SinghNessuna valutazione finora

- Confidential: 107 D IPR Questionnaire No. 107-A (Revised) O.I.RDocumento2 pagineConfidential: 107 D IPR Questionnaire No. 107-A (Revised) O.I.ROmpal SinghNessuna valutazione finora

- 1st Year CurriculumDocumento67 pagine1st Year CurriculumOmpal SinghNessuna valutazione finora

- HydraulicsDocumento22 pagineHydraulicsOmpal Singh100% (1)

- Safety in Engineering Paper IIIDocumento42 pagineSafety in Engineering Paper IIIOmpal Singh100% (1)

- Strength of MaterialDocumento1 paginaStrength of MaterialOmpal SinghNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Thermodynamic CYCLESDocumento67 pagineThermodynamic CYCLESviperNessuna valutazione finora

- MIT2 080JF13 Recitation2Documento9 pagineMIT2 080JF13 Recitation2Sudipta NathNessuna valutazione finora

- Application of Diferential Scanning CalorimetryDocumento4 pagineApplication of Diferential Scanning CalorimetryUsman GhaniNessuna valutazione finora

- ViscosityDocumento9 pagineViscosityisele1977Nessuna valutazione finora

- CSE 2261 Structural Analysis II: Course OutlineDocumento38 pagineCSE 2261 Structural Analysis II: Course OutlinezakheusNessuna valutazione finora

- Thermal Analysis of Indoor SubstationDocumento8 pagineThermal Analysis of Indoor SubstationEnriqueGD100% (1)

- Discussion & Conclusion Drag Force Prism-FaizDocumento2 pagineDiscussion & Conclusion Drag Force Prism-FaizFaiz Irfan RozahiNessuna valutazione finora

- Seismic WavesDocumento4 pagineSeismic WavesJanai MarngarNessuna valutazione finora

- Making and Using U-Bend Stress-Corrosion Test Specimens: Standard Practice ForDocumento7 pagineMaking and Using U-Bend Stress-Corrosion Test Specimens: Standard Practice ForHadi HowaidaNessuna valutazione finora

- Basic of AcousticsDocumento22 pagineBasic of AcousticsDonavan Tadia Cabantac100% (1)

- Solid MechanicDocumento7 pagineSolid MechaniczinilNessuna valutazione finora

- Fault-Releated Deformation Within The Britle-Ductile Transition Field Observation - Microstructural Analysis and Mechanical Modeing - Nevitt PDFDocumento279 pagineFault-Releated Deformation Within The Britle-Ductile Transition Field Observation - Microstructural Analysis and Mechanical Modeing - Nevitt PDFJackson Gonzalez BermudezNessuna valutazione finora

- Diagrama Moliere T - S - AguaDocumento1 paginaDiagrama Moliere T - S - AguaElingenioso FlorentinoNessuna valutazione finora

- We Learn This Course As Gas Dynamics For PropulsionDocumento9 pagineWe Learn This Course As Gas Dynamics For PropulsionTomble BravoNessuna valutazione finora

- ENCI 317 - Lab 2 Material - Fall 2022Documento17 pagineENCI 317 - Lab 2 Material - Fall 2022Sherry YousafNessuna valutazione finora

- Beyond Kolmogorov CascadesDocumento63 pagineBeyond Kolmogorov CascadesMarco GhianiNessuna valutazione finora

- SFP'LPFQV: A TutorialDocumento15 pagineSFP'LPFQV: A Tutorialcoleiro0% (1)

- COSMOS FloWorks TutorialDocumento238 pagineCOSMOS FloWorks Tutorialblacklili123Nessuna valutazione finora

- Displacement Based Seismic Design Chapter 01 (Points)Documento14 pagineDisplacement Based Seismic Design Chapter 01 (Points)MuhammadNomanKNessuna valutazione finora

- Masoneilan Noise Control PDFDocumento24 pagineMasoneilan Noise Control PDFwindoutNessuna valutazione finora

- Introduction To Reactor DesignDocumento44 pagineIntroduction To Reactor DesignRodolfoSottoJr.100% (1)

- Finite Element Formulations For Hyperelastic Transverly Hyperelastic Biphasic Soft TissuesDocumento26 pagineFinite Element Formulations For Hyperelastic Transverly Hyperelastic Biphasic Soft TissuesTalha HashmiNessuna valutazione finora

- EFMDocumento2 pagineEFMMurugan ShanmugamNessuna valutazione finora

- Environmental Fluid Mechanics: Benoit Cushman-RoisinDocumento10 pagineEnvironmental Fluid Mechanics: Benoit Cushman-Roisinpawn1000kNessuna valutazione finora

- Carrier Chart Psychometric ChartDocumento2 pagineCarrier Chart Psychometric Chartletmez90% (10)

- Heat ExchangersBasics Design ApplicationsDocumento598 pagineHeat ExchangersBasics Design ApplicationsPujara Manish100% (3)

- Endplmc9 AsdDocumento25 pagineEndplmc9 AsdmangeshNessuna valutazione finora

- Structural Design and Drawing of Clarifloculator Chiragaon 10MLDDocumento4 pagineStructural Design and Drawing of Clarifloculator Chiragaon 10MLDShashank0% (1)

- HT 02 Intro Tut 07 Radiation and ConvectionDocumento46 pagineHT 02 Intro Tut 07 Radiation and ConvectionrbeckkNessuna valutazione finora