Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CaSO4 Mass Loss

Caricato da

cuongtran_siegenCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CaSO4 Mass Loss

Caricato da

cuongtran_siegenCopyright:

Formati disponibili

2004 ASHRAE.

ABSTRACT

Sorption isotherms of a number of gypsum building materials have been measured using different drying protocols. The results

show that the isotherms are sensitive to the initial drying conditions. The current ASTM test method recommends that gypsum

materials be dried at 40C (104F), but the drying relative humidity is not specified. The intent of the relatively low drying temper-

ature is to remove the hygroscopically bound water and to prevent the loss of chemically bound water. It was found that drying

at 40C (104F) and about 0.2% relative humidity in an oven flushed with dry air results in loss of the chemically bound water,

while drying at 40C (104F) and 11-12% relative humidity in a vented oven does not sufficiently dry the material. Drying at

23C (73F) and ~0.5% relative humidity as obtained in an oven or enclosure flushed with dry air or in a desiccator is recom-

mended for these types of materials.

INTRODUCTION

Moisture damage in buildings amounts to about $9 billion

per year in the U.S. Our laboratory is engaged in an extensive

program of hygrothermal engineering aimed at reducing the

impact of moisture damage in the exterior envelopes of build-

ings. A significant part of this project involves mathematical

modeling of moisture transport and storage in envelope

components. Mathematical modeling of these processes

requires knowledge of the moisture transport and storage

properties of the various building materials, one of which is the

sorption isotherm.

A sorption isotherm is a curve of moisture content versus

relative humidity at a fixed temperature. The isotherm is

measured by first drying the material to remove hygroscopi-

cally bound water and then exposing it to constant relative

humidity (RH) conditions until equilibrium mass has been

reached. The moisture content at a given RH is expressed as a

percentage of the dry mass. Measurements of sorption

isotherms are covered by ASTM Test Method C 1498 (ASTM

2003a) and ISO 12571:2000 (E) (ISO 2000a).

ASTM C 1498-01 specifies drying temperatures as:

a) for materials which do not change either structure or

dimensions at 105C (221F), for example, some

mineral materials, use 105 4C (221 8F); b) for

materials in which structural or dimensional changes

occur between 70C (158F) and 105C (221F), for

example for some cellular plastics, use 70 2C (158

4F); c) for materials in which elevated temperatures

bring about chemical or physical changes, for example

crystalline water in gypsum or blowing agent solubility

in some cellular plastics, use 40 2C (104 4C).

ASTM C 1498-01 considers drying to be complete when five

successive daily weighings produce mass changes of less than

0.1% of the specimen mass. ISO 12571:2000 (E) references

ISO 12570:2000 (E) (ISO 2000b) for drying conditions,

which are the same as for ASTM C 1498-01. ASTM C 1498-

01 does not address the RH conditions for drying, while ISO

12570:2000 (E) specifies an RH of less than 10%.

Gypsum is a mineral with the chemical formula

CaSO

4

2H

2

O (molecular mass = 172.17). Related minerals

are hemidydrate, CaSO

4

H

2

O (molecular mass = 145.15),

and anhydrite, CaSO

4

(molecular mass = 136.14). Loss of

water of hydration from gypsum to form hemihydrate or anhy-

Effect of Drying Protocols on

Measurement of Sorption Isotherms

of Gypsum Building Materials

Kenneth E. Wilkes, Ph.D., P.E. Jerald A. Atchley Phillip W. Childs

Member ASHRAE

K.E. Wilkes is a distinguished R&D staff member, J.A. Atchley is a research technician, and P.W. Childs is a staff engineer, Building Enve-

lopes Group, Engineering Science and Technology Division, Oak Ridge National Laboratory, Oak Ridge, Tenn.

2 Buildings IX

drite upon heating is a well-known phenomenon. It contributes

directly to the effectiveness of gypsum board as a fire barrier.

When one surface of gypsum board is exposed to a fire, the

water of hydration is slowly released as steam. Since the

chemical reaction is endothermic, heat transmission through

the board is retarded. A dehydrated zone propagates through

the thickness of the board, with the temperature on the other

side of the zone never greatly exceeding 100C (212F). This

is below the temperature at which lumber begins to ignite or

at which steel begins to lose its strength (Gypsum Association

1982).

The loss of water of hydration is also utilized in ASTM

Test Method C 471M-01 for quantitative chemical analysis of

gypsum and gypsum products. The amount of free water

contained in a sample is determined by heating to 453C

(1136C) for two hours and measuring the mass loss. The

amount of chemically combined water is determined by heat-

ing to 215-230C (419-446F) for two hours and measuring

the mass loss. The mass loss at the higher temperature is used

to calculate the purity of gypsum or the amount of gypsum or

gypsum plaster in gypsum products (ASTM 2003b).

Gypsum usually dehydrates in a two-step process,

converting first to hemihydrate and then to anhydrite.

However, under low water vapor partial pressure (or low RH),

gypsum can convert directly to anhydrite. Gypsum is usually

considered to be stable at temperatures lower than 40C

(104F), and the dehydration reactions are kinetically inhib-

ited (Wirsching 1985).

The specification in ASTM C 1498-01 of drying at 40C

(104F) is intended to prevent the transformation of gypsum to

hemihydrate or anhydrite so that the measured sorption

isotherm will correspond to gypsum. This paper presents

results of sorption isotherm measurements on several

commercial gypsum building materials, performed with

several drying procedures. Also presented are results of drying

experiments on gypsum with the paper facing removed and on

the thermodynamics of the chemical reactions involved in the

loss of water of hydration.

EXPERIMENTAL PROCEDURES

Two ovens were used to dry the specimens. One oven

was ventilated with openings to the ambient air. It is expected

that the dew point within this oven would be nearly the same

as in the ambient air and, thus, the RH within the oven would

be a function of the oven temperature and the temperature

and RH of the air surrounding the oven. The other oven was

tightly sealed and was continuously flushed with

compressed air piped in from the laboratorys power plant.

The air was dried at the power plant to a dew point that varied

between 40C (40F) and 51C (60F), depending upon

the condition of the drying columns.

After drying, the specimens were placed in airtight desic-

cators containing saturated salt solutions that maintained RHs

between 11.3% and 97.4% at a temperature of 23C (73F)

(ASTM 2003a, 2003c). The desiccators were placed inside

controlled temperature/humidity cabinets where the tempera-

ture was controlled at 23.00.1C (73.40.2F). Measure-

ments were started at the lowest RH and, after equilibrium was

reached, the specimens were transferred to the next higher RH

until measurements had been made over the range of RHs.

The specimens consisted of about 10 to 15 grams (0.02 to

0.03 lb) of material cut roughly into 13 mm (0.5 in.) cubes. The

specimens were contained in 60 mL (2 fluid oz) flint glass jars

with tightly fitting polypropylene lids from which the card-

board liners had been removed. The lids were placed on the

jars for weighings on a balance that had a capacity of 5 kg (11

lb) and a resolution of 1 mg (2 10

6

lb). Each data point is the

average of three replicates, as specified by C 1498.

MATERIALS TESTED

Sorption isotherm tests were performed on the following

commercially available materials:

Nominal 12.7 mm (0.5 in.) thick regular gypsum wall-

board (SHEETROCK Brand Gypsum Panels manufac-

tured by the United States Gypsum Company, a division

of USG Corporation). Gypsum wallboard consists of a

noncombustible core that is essentially gypsum, sur-

faced with paper bonded to the core (ASTM 2004a,

2004b, 2004c). Tests were also performed on the gyp-

sum core of the wallboard.

Nominal 12.7 mm (0.5 in.) thick regular treated core

gypsum sheathing board (SHEETROCK Brand Gypsum

Sheathing manufactured by the United States Gypsum

Company). Treated core gypsum sheathing board con-

sists of a noncombustible core that is essentially gypsum

with a water-resistant material incorporated into it, sur-

faced on both sides with water-repellent paper bonded to

the core (ASTM 2004a, 2004c, 2004d).

Nominal 12.7 mm (0.5 in.) thick glass mat gypsum sub-

strate (DensGlass Gold Exterior Guard manufactured by

the G-P Gypsum Corporation, a subsidiary of Georgia-

Pacific Corporation). Glass mat gypsum substrate con-

sists of a noncombustible water-resistant core that is

essentially gypsum, surfaced with glass mat that is par-

tially or completely embedded in the core (ASTM

2004e). The glass mat gypsum substrate tested also had

a primer coating.

(Proprietary trade names are listed only as an aid to identify

the material tested and do not constitute an endorsement of

that product either by the authors or by the U.S. Government

or by ASHRAE. The reader is cautioned that manufacturers

may change products over time while retaining the same

brand name.)

Buildings IX 3

RESULTS AND DISCUSSION

Sorption Isotherms

The first set of specimens was dried at 40C (104F) in the

oven flushed with dry air. Based on the power plants dew

point, the RH should be less than ~0.2%. Mass losses observed

during drying at this condition ranged from 15% to 18% (see

Table 1). The second set of specimens was dried at a lower

temperature of about 23C (73F), at which the RH should be

less than ~0.5%. As shown in Table 1, the mass losses were

much smaller, ranging from 0.2% to 0.7%. It is considered that

the mass losses at the lower drying temperature are due to loss

of hygroscopic moisture, with the higher losses for the wall-

board and sheathing board being due to moisture in the paper

facings. The much higher mass losses during drying at 40C

(104F) are attributed to loss of water of hydration as the

gypsum (CaSO

4

2H

2

O) was transformed to anhydrite

(CaSO

4

). Conversion of pure gypsum to pure anhydrite would

be accompanied by a mass loss of 20.9%. The smaller mass

losses in Table 1 are due to other materials in the products,

such as the paper and glass facing materials, as well as silica

and other constituents within the gypsum core.

An additional specimen of wallboard core was dried first

at 40C (104F) and ~0.2% RH and then at 204C (399F) in

the vented oven (204C [399F] is the recommended temper-

ature for recharging of calcium sulfate desiccants, at which

temperature essentially all water should be removed). The

mass loss during the first drying step was 16.8% (the same as

the similar specimen in Table 1), and it was 17.8% after the

high temperature drying. The extra mass loss at the high

temperature is at least partly due to volatilization of other

constituents of the gypsum core. Evidence for this was the

appearance of a white coating on the insides of the jars.

Specimens of wallboard and wallboard core were dried in

the vented oven at 40C (104F) and ~11-12% RH. These two

specimens experienced mass losses of only 0.2% and 0.1%,

respectively; this is considered to be due to loss of part of the

hygroscopic water.

As noted in Table 1, the specimens were preconditioned

prior to drying at somewhat different conditions. The largest

difference is that the specimens dried at 40C (104F) and

~0.2% RH were preconditioned at 23C (73F) and 50% RH,

while the other specimens were conditioned at lower RHs of

25-35%. From the sorption isotherm data in Table 3 (to be

discussed later), it can be seen that the main effect of these

differences in preconditioning would be that the mass losses

for specimens dried at 40C (104F) and ~0.2% RH would

have been about 0.1-0.2% lower than the values in Table 1 if

these specimens had been preconditioned at 32.9% RH instead

of 50% RH. The large difference in mass loss between these

specimens and the others remains. The differences in precon-

ditioning have no effect on the sorption isotherms to be

discussed next.

Sorption isotherms for the specimens dried at 40C

(104F) and ~0.2% RH are given in Table 2 and Figure 1.

Isotherms for the four specimens were very similar. The mois-

ture content (MC) increased to about 4-5% at 11.3% RH, then

increased slowly as the RH was increased to 75.4% or 84.6%,

after which it increased sharply to about 17-20%, and finally

ended at around 20-23% at the final RH of 97.4%. The first

increase is attributed to transformation of anhydrite (CaSO

4

)

to hemihydrate (CaSO

4

H

2

O). An increase of 6.6% would

be expected for pure materials, and the lower measured values

are due to other constituents, such as paper, glass, and silica as

mentioned earlier. The large increase at 84.6% or 94.0% is

attributed to transformation of hemihydrate (CaSO

4

H

2

O)

back to gypsum (CaSO

4

2H

2

O). Conversion from pure anhy-

drite to pure gypsum would be accompanied by a 26.5%

increase in MC and, again, the smaller measured MCs are due

to the other constituents.

Sorption isotherms for specimens dried at 23C (73F)

and ~0.5% RH are given in Table 3 and Figure 2. The MCs

with these drying conditions are much smaller than those for

drying at 40C (104F) and ~0.2% RH and are considered to

be entirely due to hygroscopic moisture. The sorption

isotherms for the wallboard and sheathing board were nearly

identical, and were about a factor of two higher than the

isotherms for the wallboard core and the glass mat substrate.

The difference between these two groups of isotherms is due

to absorption of moisture in the paper facings of the wallboard

and sheathing board.

Sorption isotherms for wallboard and wallboard core

dried at 40C (104F) and ~11-12% RH are listed in Table 4

and are compared in Figure 3 with isotherms for drying at

23C (73F) and ~0.5% RH. The isotherms for drying at 40C

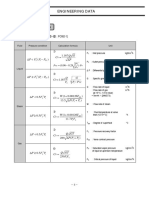

Table 1. Mass Loss During Drying of Gypsum Sorption Isotherm Specimens

Drying Conditions

Mass Loss, %

Wallboard Core Wallboard Sheathing Board Glass Mat Substrate

40C (104F), ~0.2% RH 16.8

*

15.2

*

17.9

*

23C (73F), ~0.5% RH 0.25

0.57

-0.64

0.68

0.23

40C (104F),

11-12% RH

0.09

-0.13

0.21

*

Preconditioned at 23C (73F), 50% RH

Preconditioned at laboratory conditions, ~22-25C (~72-77F), ~25-35% RH

Preconditioned at 23C (73F), 32.9% RH

4 Buildings IX

Table 2. Sorption Isotherms for Gypsum Materials Dried at 40C (104F) and ~0.2% RH

Relative Humidity, %

Moisture Content, %

Wallboard Core

No. 1

Wallboard Core

No. 2

Sheathing

Board

Glass Mat

Substrate

11.3 4.9 4.9 4.2 5.4

32.9 5.3 5.3 4.8 5.8

53.5 6.1 6.0 5.6 6.6

75.4 6.6 6.5 6.4 7.3

84.6 18.0 6.8 16.8 20.6

94.0 19.6 20.2 18.8 21.8

97.4 20.4 21.6 20.3 22.6

Note: Wallboard Core No.2 was dried at 40C (104F) and ~0.2% RH and then at 204C (399F).

Table 3. Sorption Isotherms for Gypsum Materials Dried at 23C (73F) and ~0.5% RH

Relative Humidity, %

Moisture Content, %

Wallboard Core Wallboard

Sheathing

Board

Glass Mat

Substrate

11.3 0.11 0.29 0.30 0.08

32.9 0.18 0.51 0.51 0.14

53.5 0.25 0.71 0.73 0.22

75.4 0.34 1.02 1.06 0.34

84.6 0.46 1.40 1.36 0.79

94.0 0.86 2.26 2.11 1.02

97.4 1.43 3.39 3.29 1.56

Figure 1 Sorption isotherms of gypsum materials dried at

40C (104F) and ~0.2% RH.

Figure 2 Sorption isotherms of gypsum materials dried at

23C (73F) and ~0.5% RH.

Buildings IX 5

(104F) and ~11-12% RH are lower than those for drying at

23C (73F) and ~0.5% RH and are offset by roughly constant

values. While the MC difference for the wallboard core is only

about 0.1-0.2%, it is much larger for the wallboard. The

isotherms for drying at 40C (104F) and ~11-12% RH inter-

sect the x-axis near 10%, implying that no moisture is gained

from 0 to ~10% RH. On the other hand, the isotherms for

drying at 23C (73F) and ~0.5% RH have the shape that is

typical of porous building materials (Kumaran 2001). These

data show that drying in a vented oven at 40C (104F) is not

adequate to remove all of the hygroscopic moisture from

gypsum building materials, especially those containing paper

facings.

Comparison with Literature Data

Figure 4 compares sorption isotherms for wallboard

obtained with the three drying procedures with data from the

literature. Richards et al. (1992) noted the importance of

drying temperature and dried their specimens at room temper-

ature in a desiccator containing dry CaCl

2

, for which the RH

was taken to be 1.4%. Their data are intermediate between our

curves for drying at 23C (73F)/~0.5% RH and 40C

(104F)/~11-12% RH. Cunningham and Sprott (1984) dried

their specimens in an oven at an unspecified temperature.

Since their data are close to our curve for drying at 40C

(104F)/~0.2% RH, it appears that their specimens were trans-

formed nearly to anhydrite, and that their curve includes the

effect of transformation back to hemihydrate with subsequent

sorption of hygroscopic moisture and then transformation to

dihydrate near 100% RH. Lucks (1964) data do not show any

sorption of moisture until RHs above 80% and may be low due

to inadequate drying. The curve from Kumarans (2001)

compilation of data is intermediate between our curves for

drying at 23C (73F)/~0.5% RH and 40C (104F)/~0.2%

RH, and it appears to be influenced by partial transformation

to dehydrated phases.

Drying Experiments

It is apparent that drying conditions can introduce large

differences in the sorption isotherms for gypsum materials. In

order to determine preferred drying conditions, a series of

drying experiments was conducted on specimens of wallboard

Table 4. Sorption Isotherms for Gypsum Materials Dried at 40C (104F) and 11-12% RH

Relative Humidity, %

Moisture Content, %

Wallboard Core Wallboard

11.3 0.01 0.01

32.9 0.06 0.18

53.5 0.14 0.35

75.4 0.22 0.61

84.6 0.35 0.87

94.0 0.78 1.48

97.4 1.27 2.28

Figure 3 Sorption isotherms of gypsum wallboard and

wallboard core.

Figure 4 Comparison of sorption isotherms for gypsum

wallboard with data from literature.

6 Buildings IX

core. The first set of experiments was conducted in the sealed

oven flushed with dry air. Curves of mass loss versus time are

given in Figure 5, where each curve corresponds to a separate

set of specimens. Drying at temperatures as low as 30C

(86F) was adequate to remove a large amount (if eventually

not all) of the water of hydration, but drying at 23C (73F) for

a month appears to result only in removal of the hygroscopi-

cally bound water. Note that apparent anomalies in the drying

curves marked by the arrows have simple explanations: (1)

The curves for drying at 40C (104F) have a dip at about Day

15 because some other sources of moisture were placed in the

oven that day, and the gypsum specimens picked up moisture

from them; after these moisture sources were removed, then

the mass loss continued as before. (2) The small dip in the

drying curve for Spec. No. 1 at 30C (86F) at about Day 22

occurred after a very heavy rainfall that may have influenced

the dryness of the flushing air. Again, there were some slight

differences in preconditioning prior to drying. The specimens

dried at 40C (104F) were preconditioned at 23C (73F) and

50% RH, while the other specimens were preconditioned at

laboratory conditions of ~22-25C (~72-77F) and 30-40%

RH. From the sorption isotherm data in Table 3, these differ-

ences should cause less than ~0.1% difference in starting MC.

Taking the time to reach one-half of the total mass loss of

~17% as a measure of the speed of drying yields the Arrhenius

plot of logarithm of time versus the inverse of the absolute

temperature in Figure 6. Extrapolation to 23C (73F) predicts

that it would take 78 days to lose one-half of the water of

hydration. Electron microscope studies by Hudson-Lamb et

al. (1996) show that decomposition of gypsum to anhydrite

proceeds by formation and growth of nuclei. The results in

Figure 5 suggest that a temperature of 23C (73F) may be too

low to allow nucleation of anhydrite. Support for this interpre-

tation comes from the curves (see Figure 5) at 30C (86F),

which show a four- to six-day nucleation period during which

the mass loss remains less than about 0.6% before starting to

increase significantly.

It is interesting that the slope of the plot in Figure 6 gives

an activation energy of about 93.9 kJ/mol (40.4 kBtu/lb-mol)

(H = slope gas constant). This is in excellent agreement with

activation energies of 88-107 kJ/mol (38-46 kBtu/lb-mol),

determined by Hudson-Lamb et al. (1996), using thermogravi-

metric and differential scanning calorimetry. Because of their

high heating rate of 5C (9F) per minute, significant mass loss

in their experiments was delayed to higher temperatures of

about 100C (212F) to 130C (266F).

A second set of drying experiments was conducted on a

single set of specimens in the vented oven. Mass losses were

recorded for this set of specimens as the oven temperature was

increased in stages. Figure 7 shows drying at temperatures

between 40C (104F) and 60C (140F), along with the RHs

Figure 5 Drying the gypsum wallboard core in dry air. See

text for explanation of events marked with arrows.

Figure 6a Arrhenius plot for drying of gypsum wallboard

core in dry air.

Figure 6b Arrhenius plot for drying of gypsum wallboard

core in dry air.

Buildings IX 7

in the oven, as calculated from the laboratory dew point

temperature. The heavy horizontal dashed line is the mass loss

of similar specimens after drying for 30 days at 23C (73F)

in the oven flushed with dry air (both specimens were precon-

ditioned at ~22-25C (72-77F) and 30-33% RH prior to

drying). Figure 7 shows that small mass losses occurred as the

specimen was heated in steps, but the mass loss did not equal

that from drying in dry air until 60C (140F) (or possibly

55C [131F] if given more time). Since x-ray diffraction stud-

ies by Hudson-Lamb et al. (1996) showed the presence of a

very small amount of hemihydrate at ~60C (~140F), the

continuous mass loss at 60C (140F) may be due to formation

of subcritical nuclei of hemidydrate. Continuation of drying at

higher temperatures is shown in Figure 8. The mass loss of

12.9% at 65C (149F) clearly indicates the transformation to

hemihydrate, with a nucleation period of two to three days and

a growth period through about 19 days. Further heating at

70C (158F) to 90C (194F) produced only minor additional

mass loss, and heating for one day at 103C (217F) produced

transformation to anhydrite with a final mass loss of about

17%. Figure 9 summarizes the vented oven drying experi-

ments by plotting the mass loss and oven RH as functions of

the drying temperature. The theoretical mass loss for transfor-

mation from gypsum to hemihydrate is three-fourths of that

for transformation from gypsum to anhydrite. The measured

mass losses in Figure 9 are in almost exact agreement with this

ratio (12.9/17.0 = 0.76). The agreement of this ratio confirms

that the mass losses are due to the transformations from

gypsum to hemidydrate or anhydrite.

The results presented in this section were obtained only

on the core material of regular wallboard. Some variations in

percent mass loss and speed of drying would be expected for

materials with paper or glass facers and with other types of

admixes and impurities. However, it is expected that the trends

would be qualitatively similar.

Figure 7 Drying of gypsum wallboard core in vented oven.

Figure 8 Drying of gypsum wallboard core in vented oven.

Figure 9a Drying of gypsum wallboard core in vented oven.

Figure 9b Drying of gypsum wallboard core in vented oven.

8 Buildings IX

These results show the difficulty in choosing conditions

for drying of gypsum materials in preparation for sorption

isotherm measurements. Drying in a vented oven at too low a

temperature does not remove all of the hygroscopic moisture

(this will also be the case for paper facings), but drying at too

high a temperature causes loss of chemically bound water.

Likewise, drying in a very low RH environment at too high a

temperature will also cause loss of chemically bound water.

Drying in a very low RH environment at the same temperature

as the isotherm measurements are performed appears to be the

logical choice.

Thermodynamic and Kinetic Considerations

Existing thermodynamic data were used to predict RHs

for equilibrium among water vapor and the various phases of

calcium sulfate. The following chemical reactions were

considered:

2/3CaSO

4

2H

2

O = 2/3 CaSO

4

H

2

O + H

2

O(g) (1)

CaSO

4

2H

2

O = CaSO

4

+ H

2

O(g) (2)

2 CaSO

4

H

2

O = 2 CaSO

4

+ H

2

O(g) (3)

Equations 1 to 3 are for the equilibria between (1) gypsum

and hemihydrate, (2) gypsum and anhydrite, and (3) hemihy-

drate and anhydrite, respectively.

Four solid phases of calcium sulfate can exist at room

temperature: dihydrate (gypsum), hemihydrate, anhydrite III,

and anhydrite II (Wirsching 1985). In addition, hemihydrate

exists in two forms, and . These two forms differ in parti-

cle morphology and formation conditions. At low tempera-

tures and low water vapor partial pressures, -hemihydrate is

the type that is formed. Anhydrite III exists in similar - and

- forms. Anhydrite II is produced by dehydration at elevated

temperatures. The types of interest here are dihydrate, -

hemihydrate, and -anhydrite III.

Data on heats of formation, entropies, and specific heats

from the literature (Garvin et al. 1987; Cox et al. 1989; Kelley

et al. 1941) were used to calculate the change in bulk Gibbs

energies for the reactions by Pitzer (1995):

(4)

Since the chemical reactions are normalized to one mole

of water on the right-hand side, the equilibrium water vapor

pressure (in bars) is given by

(5)

Figure 10 shows the calculated RHs for the dehydration

transformations, along with the RH for the vented oven used

in the drying experiments. For each of the thermodynamic

equilibrium curves, the phase with more water would be stable

(or at least metastable in the case of hemidydrate) above the

curve, and the phase with less water would be stable (or meta-

stable) below the curve. The theory predicts that heating above

30C (86F) in the vented oven should transform dihydrate to

hemihydrate and that heating above about 43C (109F)

should transform dihydrate to anhydrite. However, the vented

oven drying data show that no transformation occurs until

about 65C (149F) and then the transformation is to hemihy-

drate. The theory predicts that heating to about 103C (217F)

would transform hemihydrate to anhydrite, in agreement with

the drying data.

Thermodynamics is only able to predict the reactions that

are energetically possible, while speeds of reactions are deter-

mined by kinetics. Some reactions are kinetically inhibited,

and the transformation of dihydrate to anhydrite is one of them

(Wirsching 1985; Knacke et al. 1991). Kelley et al. (1941)

noted that dehydration of dihydrate requires a breakdown of

the crystal lattice (monoclinic to rhombohedral). This would

G

T

0

H

298.15K

0

T S

298.15K

0

=

C

P

dT

298.15K

T

T C

P

d T ln ( )

298.15K

T

+

G

T

0

RT P

v

( ) ln =

Figure 10a Thermodynamic equilibria for gypsum

dehydration reactions.

Figure 10b Thermodynamic equilibria for gypsum

dehydration reactions.

Buildings IX 9

be accompanied by additional surface energy and lattice strain

energies (not included in Equations 4 and 5) that would require

higher temperatures or lower relative humidities to nucleate

hemihydrate or anhydrite within the dihydrate crystal lattice.

On the other hand, Kelly et al. note that dehydration of hemi-

hydrate does not require a significant change in the lattice

(rhombohedral to hexagonal), and the thermodynamics curve

correctly predicts this transformation. Studies by Hudson-

Lamb et al. (1996) and by Paulik et al. (1992) also confirm that

these transformations occur by the nucleation and growth

mechanism. Impurities and admixes within the dihydrate

would tend to provide sites for heterogeneous nucleation. This

would be accompanied by a defect contribution to the Gibbs

energy that would tend to offset some of the surface and lattice

strain energies. The net effect, however, is that the present data

confirm that the reactions are kinetically inhibited. (For

general discussions of nucleation and growth within solid

phases and contributions to the Gibbs energy due to surface

energy, lattice strain energy, and defect energies, see Kingery

[1960] and Porter and Easterling [1992]).

For drying in the oven flushed with dry air, the thermo-

dynamics curves predict transformation from dihydrate to

anhydrite below 6-8% RH for temperatures of 23-40C (73-

104F). This transformation was observed for temperatures as

low as 30C (86F). However, the transformation did not occur

within 30 days at 23C (73F), probably because of the diffi-

culty of nucleation of anhydrite at this temperature.

CONCLUSIONS AND RECOMMENDATIONS

Drying conditions can have a very significant effect on

sorption isotherms measured on gypsum building materials.

Drying conditions must be sufficient to remove hygroscopi-

cally bound water, but not so severe as to remove chemically

bound water. Drying at 40C (104F) in a vented oven does not

remove all of the hygroscopically bound water, especially for

gypsum materials that include paper facings. Drying at higher

temperatures in a vented oven runs the risk of removal of

chemically bound water. Drying under desiccated conditions

(such as a desiccator or an oven flushed with dry air) at slightly

elevated temperatures will remove chemically bound water.

Drying under desiccated conditions at room temperature

(~23C [73F]) over a 30-day period did not remove chemi-

cally bound water and is the recommended procedure. The

large variations in literature data on sorption isotherms of

gypsum building materials appear to be related to the (often

unreported) drying conditions. Data reported here on speci-

mens dried at room temperature and ~0.5% RH are recom-

mended for use in modeling efforts.

ACKNOWLEDGMENTS

Funding for this project was provided by the U.S. Depart-

ment of Energy, Office of Building Technology, State, and

Community Programs under contract number DE-AC05-

00OR22725 with the Oak Ridge National Laboratory,

managed by UT-Battelle, LLC.

NOMENCLATURE

C

P

= specific heat at constant pressure difference between

products and reactants, kJ/mol

G = Gibbs energy difference between products and

reactants, kJ/mol

H = enthalpy difference between products and reactants,

kJ/mol

S = entropy difference between products and reactants,

kJ/mol

P

v

= vapor pressure, bar

R = gas constant

T = temperature, K

0 = quantity evaluated at the standard state (298.15 K, 1 bar)

REFERENCES

ASTM. 2003a. ASTM C 1498-01, Standard test method for

hygroscopic sorption isotherms of building materials. In

2003 Annual Book of ASTM Standards, Vol. 04.06. West

Conshohocken, Pa.: American Society for Testing and

Materials.

ASTM. 2003b. ASTM C 471M-01, Standard test methods

for chemical analysis of gypsum and gypsum products.

In 2003 Annual Book of ASTM Standards, Vol. 04.01.

West Conshohocken, Pa.: American Society for Testing

and Materials.

ASTM. 2003c. ASTM E 104-02, Standard practice for main-

taining constant relative humidity by means of aqueous

solutions. In 2003 Annual Book of ASTM Standards,

Vol. 11.03. West Conshohocken, Pa.: American Society

for Testing and Materials.

ASTM. 2004a. ASTM C 11-03d, Standard terminology

relating to gypsum and related building materials and

systems, in 2004 Annual Book of ASTM Standards, Vol.

04.01. West Conshohocken, PA: American Society for

Testing and Materials.

ASTM. 2004b. ASTM C 36/C 36M-03, Standard specifica-

tion for gypsum wallboard. In 2004 Annual Book of

ASTM Standards, Vol. 04.01. West Conshohocken, Pa.:

American Society for Testing and Materials.

ASTM. 2004c. ASTM C 1396/C 1396M-03a, Standard spec-

ification for gypsum board. In 2004 Annual Book of

ASTM Standards, Vol. 04.01. West Conshohocken, Pa.:

American Society for Testing and Materials.

ASTM. 2004d. ASTM C 79/C 79M-04, Standard specifica-

tion for treated core and nontreated core gypsum sheath-

ing board. In 2004 Annual Book of ASTM Standards,

Vol. 04.01. West Conshohocken, Pa.: American Society

for Testing and Materials.

ASTM. 2004e. ASTM C 1177/C 1177M-04, Standard speci-

fication for glass mat gypsum substrate for use as

sheathing. In 2004 Annual Book of ASTM Standards,

Vol. 04.01. West Conshohocken, Pa.: American Society

for Testing and Materials.

10 Buildings IX

Cox, J.D., D.D. Wagman, and V.A Medvedev, eds. 1989.

CODATA Key Values for Thermodynamics, p. 164. New

York: Hemisphere.

Cunningham, M.J., and T.J. Sprott. 1984. Sorption properties

of New Zealand building materials. Research Report

R43, Building Research Association of New Zealand (as

reported by Richards, et al.).

Garvin, D., V.B. Parker, and H.J. White, Jr., eds. 1987.

CODATA Thermodynamic Tables, Selections for Some

Compounds of Calcium and Related Mixtures: A Proto-

type Set of Tables, pp. 182-183, 246. New York: Hemi-

sphere.

Gypsum Association. 1982. Fire Resistance Design Manual,

10th ed., p. 7. Evanston, Ill.

Hudson-Lamb, D.L., C.A. Strydom, and J.H. Potgieter.

1996. The thermal dehydration of natural gypsum and

pure calcium sulphate dihydrate (gypsum). Thermo-

chimica Acta, Vol. 282/283, pp. 483-492. Amsterdam:

Elsevier.

ISO. 2000a. ISO-12571:2000(E), Hygrothermal perfor-

mance of building materials and productsDetermina-

tion of hygroscopic sorption properties. Geneva,

Switzerland: International Standards Organization.

ISO. 2000b. ISO-12570:2000(E), Hygrothermal perfor-

mance of building materials and productsDetermina-

tion of moisture content by drying at elevated

temperature. Geneva, Switzerland: International Stan-

dards Organization.

Kelley, K.K., J.C. Southard, and C.T. Anderson. 1941. Ther-

modynamic Properties of Gypsum and Its Dehydration

Products. Washington D.C.: U.S. Bureau of Mines

Technical Paper 625, U.S. Government Printing Office.

Kingery, W.D. 1960. Introduction to Ceramics, pp. 286-341.

New York: John Wiley & Sons.

Knacke, O., O. Kubaschewski, K. Hesselmann (eds.). 1991.

Thermochemical Properties of Inorganic Substances,

Vol. I, pp. 12, 56. New York: Springer-Verlag.

Kumaran, M.K. 2001. Hygrothermal properties of building

materials. Moisture Analysis and Condensation Control

in Building Envelopes, H. R. Trechsel, ed., pp. 29-65. W.

Conshohocken, Pa.: American Society for Testing and

Materials.

Luck, W. 1964. Fenchtigheit, Grundlagen, Messen, Regeln.

Munich, Vienna: R. Oldenburn (as reported by Rich-

ards, et al.).

Paulik, F., J. Paulik, and M. Arnold. 1992. Thermal decom-

position of gypsum. Thermochimica Acta, Vol. 200, pp.

195-204. Amsterdam: Elsevier.

Pitzer, K.S. 1995. Thermodynamics, 3rd. ed., pp. 104-114.

New York: McGraw-Hill Series in Advanced Chemistry,

McGraw-Hill, Inc.

Porter, D.A., and K.E. Easterling. 1992. Phase Transforma-

tions in Metals and Alloys, 2nd ed., pp. 263-290. Lon-

don: Chapman & Hall.

Richards, R.F., D.M. Burch, and W.C. Thomas. 1992. Water

vapor sorption measurements of common building

materials. ASHRAE Transactions 98(2). Atlanta: Ameri-

can Society of Heating, Refrigerating and Air-Condi-

tioning Engineers, Inc.

Wirsching, F. 1985. Calcium sulfate. Ullmanns Encyclope-

dia of Industrial Chemistry, 5th ed., Vol. A4, pp. 555-

584. Deerfield Beach, Fla.: VCH Publishers.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- High School Chemistry Grade 10-12Documento486 pagineHigh School Chemistry Grade 10-12Todd95% (39)

- Crosslinking - PDMSDocumento139 pagineCrosslinking - PDMScuongtran_siegenNessuna valutazione finora

- Crystal Gallery: AccountabilityDocumento15 pagineCrystal Gallery: AccountabilityJitesh ManwaniNessuna valutazione finora

- PMMADocumento7 paginePMMAcuongtran_siegenNessuna valutazione finora

- DLS Terms Defined MalvernDocumento6 pagineDLS Terms Defined Malverncuongtran_siegenNessuna valutazione finora

- Sem 4Documento29 pagineSem 4Raluca CristacheNessuna valutazione finora

- Paper 3. Funct. SiO2-NP. 5.jan.2014Documento8 paginePaper 3. Funct. SiO2-NP. 5.jan.2014cuongtran_siegenNessuna valutazione finora

- Paper 2. Funct. SiO2-NP. 5.jan.2014Documento52 paginePaper 2. Funct. SiO2-NP. 5.jan.2014cuongtran_siegenNessuna valutazione finora

- Lecture 3 Conventional-MicroscopeDocumento45 pagineLecture 3 Conventional-Microscopearul1987Nessuna valutazione finora

- Light Microscopy HandoutDocumento24 pagineLight Microscopy HandoutDevaprakasam DeivasagayamNessuna valutazione finora

- Paper 1. Funct. SiO2-NP. 5.jan.2014Documento4 paginePaper 1. Funct. SiO2-NP. 5.jan.2014cuongtran_siegenNessuna valutazione finora

- OrganicChemistryAbout 1H-NMRDocumento25 pagineOrganicChemistryAbout 1H-NMRcuongtran_siegenNessuna valutazione finora

- XrayDocumento8 pagineXraycuongtran_siegenNessuna valutazione finora

- Sem 4Documento29 pagineSem 4Raluca CristacheNessuna valutazione finora

- Light Microscopy HandoutDocumento24 pagineLight Microscopy HandoutDevaprakasam DeivasagayamNessuna valutazione finora

- Light Microscopy HandoutDocumento24 pagineLight Microscopy HandoutDevaprakasam DeivasagayamNessuna valutazione finora

- PMMA - SynthesisDocumento8 paginePMMA - Synthesiscuongtran_siegenNessuna valutazione finora

- Pmma - 3Documento5 paginePmma - 3cuongtran_siegenNessuna valutazione finora

- MDW QCM Web StuffDocumento19 pagineMDW QCM Web Stuffcuongtran_siegenNessuna valutazione finora

- Pmma - 2Documento20 paginePmma - 2cuongtran_siegenNessuna valutazione finora

- P 2006nanotechnologyDocumento6 pagineP 2006nanotechnologycuongtran_siegenNessuna valutazione finora

- Mma PmmaDocumento14 pagineMma Pmmacuongtran_siegenNessuna valutazione finora

- A Simple Way For Synthesis of Alkyne-Telechelic Poly (Methyl Methacrylate) Via Single Electron Transfer Radical Coupling ReactionDocumento4 pagineA Simple Way For Synthesis of Alkyne-Telechelic Poly (Methyl Methacrylate) Via Single Electron Transfer Radical Coupling Reactioncuongtran_siegenNessuna valutazione finora

- ICHO07Documento18 pagineICHO07MacxsimusNessuna valutazione finora

- QCMDocumento2 pagineQCMmanish_keswani01Nessuna valutazione finora

- Instructions For Quartz Crystal Microbalance (QCM) : Picture From: HTTP://WWW - Yb.Gmm - Gu.Se/UploadimagesDocumento9 pagineInstructions For Quartz Crystal Microbalance (QCM) : Picture From: HTTP://WWW - Yb.Gmm - Gu.Se/Uploadimagescuongtran_siegenNessuna valutazione finora

- EDX Course NotesDocumento13 pagineEDX Course Notescuongtran_siegenNessuna valutazione finora

- Photon Scanning Tunneling Microscope: Detection of Evanescent WavesDocumento5 paginePhoton Scanning Tunneling Microscope: Detection of Evanescent Wavescuongtran_siegenNessuna valutazione finora

- Heat Conduction CalorimeterDocumento7 pagineHeat Conduction Calorimetercuongtran_siegenNessuna valutazione finora

- EDX Course NotesDocumento13 pagineEDX Course Notescuongtran_siegenNessuna valutazione finora

- Avenger 220 Cruise Street BS IVDocumento79 pagineAvenger 220 Cruise Street BS IVShubham AatopartsNessuna valutazione finora

- Alsabei ThesisDocumento279 pagineAlsabei Thesisrayzo2182Nessuna valutazione finora

- When A Transformer Has Stomach Pain and Wants ToDocumento4 pagineWhen A Transformer Has Stomach Pain and Wants ToRobert GalarzaNessuna valutazione finora

- Best Actor and Actress Adjudication Rubric 41950cb9a3Documento3 pagineBest Actor and Actress Adjudication Rubric 41950cb9a3Sarah Jhoy SalongaNessuna valutazione finora

- Recommendation Letter MhandoDocumento2 pagineRecommendation Letter MhandoAnonymous Xb3zHio0% (1)

- Ballsim DirectDocumento58 pagineBallsim DirectDiego GaliciaNessuna valutazione finora

- H5P Active Learning Guide: HERDSA Workshop MaterialDocumento7 pagineH5P Active Learning Guide: HERDSA Workshop Materialgeorgemarian_manea100% (1)

- PT2 Exam CLASS XI CS 2023Documento2 paginePT2 Exam CLASS XI CS 2023Aditya AurangeNessuna valutazione finora

- Asl Scroll Wuxi 2hp - 8hp 2930719180Documento142 pagineAsl Scroll Wuxi 2hp - 8hp 2930719180Roy MokNessuna valutazione finora

- Student Teacher InterviewDocumento3 pagineStudent Teacher InterviewLauren ColeNessuna valutazione finora

- Lab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveDocumento7 pagineLab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveSyed Waqas ShahNessuna valutazione finora

- Engineering Data: 2. CV CalculationDocumento1 paginaEngineering Data: 2. CV Calculationdj22500Nessuna valutazione finora

- List of BooksDocumento13 pagineList of Booksbharan16Nessuna valutazione finora

- Cultural Diversity in Vikram Seth's A Suitable Boy'Documento3 pagineCultural Diversity in Vikram Seth's A Suitable Boy'Sneha PradhanNessuna valutazione finora

- Acceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderDocumento2 pagineAcceptance To An Offer Is What A Lighted Matchstick Is To A Train of GunpowderAnushka SharmaNessuna valutazione finora

- NewspaperDocumento1 paginaNewspaperMustafa Nabeel ZamanNessuna valutazione finora

- Paket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Documento3 paginePaket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Nadiah PutriNessuna valutazione finora

- Activity On The Layers of The Earth 1Documento1 paginaActivity On The Layers of The Earth 1Ian MarianoNessuna valutazione finora

- One Word SubstitutionDocumento5 pagineOne Word SubstitutionPranaykant Singh PanwarNessuna valutazione finora

- Dr./Ar. Jocelyn A. Rivera-Lutap, Fuap, FriaDocumento1 paginaDr./Ar. Jocelyn A. Rivera-Lutap, Fuap, FriaShanaia BualNessuna valutazione finora

- Antennas L01Documento15 pagineAntennas L01Domenico RizzoNessuna valutazione finora

- CP2405 Assignment 1 Ontology DesignDocumento8 pagineCP2405 Assignment 1 Ontology DesignFredrick Oduor OmondiNessuna valutazione finora

- CNSB Bypass Separator Commissioning and Maintenance Guide: Conder® Tanks Covered by This GuideDocumento4 pagineCNSB Bypass Separator Commissioning and Maintenance Guide: Conder® Tanks Covered by This GuidesterlingNessuna valutazione finora

- Chapter 5 (6) Concrete MaterialDocumento134 pagineChapter 5 (6) Concrete Materialraju_420034520Nessuna valutazione finora

- UntitledDocumento44 pagineUntitledFrancesco TauroNessuna valutazione finora

- NA BR 1177 EN Dematic AutoStore SubsystemDocumento8 pagineNA BR 1177 EN Dematic AutoStore SubsystemDaniel Garnando KristianNessuna valutazione finora

- English Is The Window To The World. MimieDocumento2 pagineEnglish Is The Window To The World. MimieFARAH NADIANessuna valutazione finora

- Pepperdine Resume Ico William Kong Updated BDocumento1 paginaPepperdine Resume Ico William Kong Updated Bapi-278946246Nessuna valutazione finora

- AquaMapPublic v202Documento26 pagineAquaMapPublic v202engfeupNessuna valutazione finora