Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Martensite RetainedAustenite

Caricato da

saborsita666Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Martensite RetainedAustenite

Caricato da

saborsita666Copyright:

Formati disponibili

A Publication 20,500 Circulation The Largest And Most Preferred Industry Publication www.industrialheating.

com

April 2009

Martensite

and Retained

Austenite

George F. Vander Voort

Buehler Ltd., Lake Bluff, Ill.

epending upon the carbon

content of the parent aus-

tenite phase, either lath

(low-carbon) or plate (high-

carbon) martensite may form, as well as

mixtures of the two. In general, lath mar-

tensite is associated with high toughness

and ductility but low strength, while plate

martensite structures are much higher

strength but may be rather brittle and

non-ductile.

Increasing the carbon content of the

austenite also depresses the martensite

start (M

s

) temperature and the marten-

site nish (M

f

) temperature, which leads

to difculties in converting all of the aus-

tenite to martensite. When this happens,

we have retained austenite, which may be

either extremely detrimental or desirable

under certain conditions.

History

Up to about 100 years ago, the heat treat-

ment of steels was certainly an art as the

science behind what was happening was

just starting to be understood. The con-

trol of grain size in carburizing was just be-

coming possible by the work of McQuaid

and Ehn. They discovered that small ad-

ditions of aluminum would keep the grain

size ne after a long exposure, generally

8-10 hours, at the carburizing tempera-

ture. Prior to that, coarse prior-austenite

grain structures would be observed in the

carburized case that would initiate brittle

intergranular fractures at minor loads.

Next, Grossman and Bain developed

the theory of hardenability

where the ideal critical diameter

(D

I

) could be calculated from

the prior-austenite grain size and

the composition. Then, the D

I

could be used to estimate the

as-quenched hardness prole of

a uniformly shaped bar given a

particular strength quench.

About the same time, isother-

mal transformation (IT) diagrams

were developed, and it became

easier to identify these lesser-

understood microstructures of

upper and lower bainite. An IT

diagram, while it is helpful in

understanding microstructures

and in developing annealing

cycles, is not particularly useful

for understanding heat-treat-

ment structures. This problem

was solved by developing con-

tinuous cooling transformation

(CCT) diagrams. Shortly before

the writer joined the Homer

Research Laboratories of Beth-

lehem Steel, they had developed

CCT diagrams using the arrested-Jominy-

bar method a rather painful process in-

deed. Dilatometer-based CCT diagrams

were far easier to develop and in less time,

but this equipment came later.

e

c

t

(

D

900

800

700

600

500

400

300

200

100

68

65

60

50

40

30

20

10

0

Marder (27)

Hodge and Orehoski (28)

Burns et al. (29)

Irvine et al. (30)

Kelly and Nutting (31)

Kurjumov (32)

Litwinchuk et al. (33)

Bain and Paxton (34)

Jaffe and Gordon (35)

Materkowski (36)

H

a

r

d

n

e

s

s

,

D

P

H

Carbon, wt %

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3

H

a

r

d

n

e

s

s

,

R

o

c

k

w

e

l

l

C

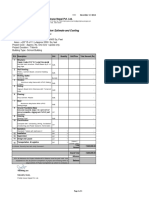

Fig. 1. Summary of extensive as-quenched

hardness data from the literature for Fe-C alloys

and steels by Krauss

[2]

Martensite and Retained Austenite

George F. Vander Voort Buehler Ltd., Lake Bluff, Ill.

Martensite development is critical to many heat-treatment processes. This paper

examines the conditions under which austenite is retained and the problems

associated with its presence, with detecting it and with measuring it.

FEATURE

|

Materials

Characterization & Testing

DDDD3333 ---

wwwwiiiinnnnssss

DDD3333 ---

wwwwiiinnnnssss

1111000000000000xxxx ---- BBBB

ttttttt

1111

xxx ---- BBB

tttt

1111000000000000xxxx ---- BBB

ttttttt

1111

nnnntttt

11111111

nnnntttt

1111

nnnntttt

DDDDDDDDDDD3333 ttttooooooolll sssttteeeeeellll ---

DDDD3333 tttoooooooolll sssttteeeeeelll

DDDDDDDDDDDD33333333 DDDDDDDD

ttttttoooooooooooooollllll ssssss oooooooooooo tttttteeeeeeeeeeeelllllll eeeee --- eeeee

DDDDDDDDDDDDDDDDDDDD33333333 DDDDDDDD

ttttttooooooooooooooollllll ssssss ooooooooooooooo tttttteeeeeeeeeeeelllllll eeeeeeeeeeee ---

@@@@22222222000000000000 FFFF

@@@@222222200000000FFFF

@@@@@@@@22222 222222222222222 22

FFFFFFF

222222220000000000000000000

@@@@@@

FFF FFFFFFF

@@@@@@@@2222222200 222222200000000000 2222 00000000 FFFFFFFF 0000000000000000000 FFFF FFFF

555500000000xxx

aaaaggggggggeeeennnntttt

55550000

gggggggg

00000000xxx

aaaa eeeennnnt aaaa ntttt gggg ttt eee

55550000

gggggggg

00000000xxx

aaaagggeeeennnnttt aaaa nnntttt ggggeeee

WWWWWWWWWWWWWWWWWWWWWWWWWWWWW

00000000xxx

ggggeeeennnntttt

5555000000000000

ggggeeeennnntttt

55550000000000 00000000xxx

ggggeeeennnntttt

555500000000000

Reprinted from Industrial Heating April 2009

Technological Advantages

Development of thin-foil technology for

the transmission electron microscope

(TEM) produced a far-deeper understand-

ing of the ne details of steel microstruc-

tures because these features were well

beyond the resolution of the light optical

microscope (LOM). The development of

IT and CCT diagrams had shown that

martensite began transforming at temper-

atures relative to the composition of the

austenite, with its carbon content being

most critical.

Problems due to excessive retained aus-

tenite had plagued the tool-steel industry

since the late 19

th

century. X-ray diffrac-

tion had been the primary tool for the

study of retained austenite and certainly

for its quantication, but it could not im-

age this microstructure. LOM could not

image retained austenite until it was at

least present in the 10-15% range. TEM

thin foils could detect and image retained

austenite even at levels somewhat under

2% with careful use of dark-eld illumi-

nation. The morphology of the marten-

site makes it difcult to distinguish small

particles of retained austenite within the

complex plate-martensite patterns. With

low-carbon lath martensite, thin lms of

retained austenite could be seen with very

careful TEM work, but this was very dif-

cult work.

Tool Steels

In the tool-steel industry, excessive re-

tained austenite is universally considered

to be detrimental. Exactly what consti-

tutes excessive is difcult to dene as not

enough data exists, and what is excessive

will vary with the grade and application.

For example, relatively low-carbon 5%-Cr

hot-work die steels such as H11 and H13

have been used for years as guage blocks.

Any dimensional change with time is to

be avoided. Consequently, these steels are

triple tempered at a relatively high tem-

perature where retained austenite will be

converted to either fresh martensite or

bainite, and they will be tempered with

the next tempering cycle.

In other applications, any observable

(by LOM) retained austenite is highly det-

rimental. Service stresses will convert the

retained austenite on the rst use. As the

carbon content of the retained austenite is

high, the martensite that forms is highly

tetragonal and the resulting expansion

cracks the steel because the matrix is not

ductile enough to tolerate the expansion

stresses.

With carburized gears, on the other

hand, only a very thin layer at the surface

is carburized and may contain 20-25% re-

tained austenite. The bulk of the gear is a

highly ductile (compared to a tool steel),

low-carbon alloy steel. Gears are usually

not impact loaded like a tool-steel die,

so the stresses are much lower and the

retained austenite usually does not trans-

form substantially during service. If the

retained austenite did transform, the steel

around it and below it is ductile enough

to accommodate the strains without frac-

ture. Retained austenite does become

stable with time, and some will transform

to martensite at room temperature. Samu-

els

[1]

states that up to 5% of the austenite

present after quenching and low-temper-

ature tempering (<200C) will transform

to martensite soon after quenching or over

a period of some months.

Inuence of Carbon Content of the

Austenite

Starting in the 1930s with the develop-

ment of hardenability concepts, a number

of investigators have demonstrated that

the hardness of as-quenched martensite

increases in a relatively linear fashion

from about 0.05 to 0.5 wt. % carbon. Fig-

ure 1 shows data from a number of inves-

tigators summarized by Krauss.

[2]

Note

that when the carbon content of the aus-

tenite is >0.8%, the as-quenched hard-

ness drops. This is due to the presence of

retained austenite, which is much softer

than plate martensite. Litwinchuk et al.

[3]

took this curve to nearly 2% carbon which

demonstrates the effect of retaining large

70

60

50

40

30

0

1600

1400

1200

1000

800

600

400

200

0

871

760

649

538

427

316

204

93

0

0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Greninger (8)

Toriano and Greninger (10)

Cohen et al (24)

Digges (25)

Greninger and Troiano (26)

Kaufman and Cohen (27)

Esser et al (28)

Bibby and Parr (29)

H

a

r

d

n

e

s

s

,

R

o

c

k

w

e

l

l

C

M

s

T

e

m

p

e

r

a

t

u

r

e

,

F

T

e

m

p

e

r

a

t

u

r

e

,

C

Lath Plate Mixed

Carbon, wt % Carbon, wt %

Fig. 2. As-quenched of brine quenched Fe-C alloys up to

nearly 2 wt. % by Litwinchuk et al.

[3]

Fig. 3. Relationship between carbon content, martensite type and M

s

temperature

[4]

amounts of retained austenite upon the

as-quenched hardness.

Figure 3, from the work of Marder and

Krauss

[4]

, shows the relationship between

the type of martensite observed and the

carbon content and martensite-start

temperature for Fe-C alloys. Figures 4

and 5 illustrate the appearance by LOM

of carbon-free martensite in a maraging

steel and lath martensite in an ultrahigh-

strength, low-carbon steel (AerMet 100).

Figure 6 shows plate martensite, retained

austenite and both intergranular and

transgranular cementite in carburized

9310 alloy steel. Plate martensite fre-

quently contains microcracks from the

impact of one plate into a previously

formed plate. These cracks can initiate

subsequent failures.

Speich and Leslie

[5]

showed how in-

creasing carbon in the austenite caused

the percentage of retained austenite to

increase, the M

s

to decrease and the

change in martensite type from lath to

plate. A number of studies between Pay-

son and Savage in 1944 and Andrews in

1965 have developed empirical formulas

to calculate the M

s

based on composi-

tion, not simply from the carbon con-

tent. Carbon, of course, has the largest

effect, but the inuence of alloying ele-

ments upon lowering the M

s

cannot be

ignored. The M

f

temperature falls with

the M

s

, so the formulas predict only the

M

s

temperature.

Detecting Retained Austenite

Over the years, the writer has tried many

etchants, plus tint etchants, in an effort to

try to preferentially color retained austenite.

In almost all cases, these efforts have failed.

Many years ago, an investigator published

a short paper claiming that the addition of

1% zephiran chloride a wetting agent fre-

quently added to 4% picral to increase the

speed of etching

[6]

would reveal retained

austenite by creating a strong contrast

between the dark martensite and the un-

etched austenite. This author claimed to be

able to see and measure, by point counting,

retained austenite down to ~2% in steels.

The writer has tried to duplicate this

experiment using railroad cone bearings of

carburized 8720 alloy steel. Unfortunately,

details of how these bearings were processed

and then prepared for metallography were

unknown. But at some earlier time they

were analyzed by X-ray diffraction (XRD).

Three pieces claimed to contain 25.4, 19.7

and 16.2% retained austenite were given

to the writer, who mounted them in a low-

temperature-curing epoxy compound and

ground and polished them. Nital plus ze-

phiran chloride did reveal the retained aus-

tenite much better than nital without the

addition, and higher amounts of retained

austenite were recorded when zephirian

chloride was added. The image-analysis

results, however, were very low compared

to the XRD results. Of course, it is possible

that some of the retained austenite had iso-

thermally transformed between the time

when the XRD work was done and when

the image analysis work was done a time

that may have been a few years.

Figure 8 shows the microstructure of

the cone bearing that was reported to

contain 25.4% retained austenite etched

with 4% nital plus 1% zephiran chloride.

The image, by eye, does not appear to be

one-fourth retained austenite, and image

analysis measured only 13.3% with this

etch (and less with other etchants). The

specimen with 19.7% retained austenite

was measured as 8.5% by image analysis

with this etch, and the specimen with

16.2% retained austenite was measured

as only 1.2% retained austenite by image

analysis with this etch. In general, this

is the type of difference that the writer

has always seen when doing such experi-

ments previously.

A new technique utilizing the scan-

ning electron microscope (SEM) has been

developed. Called electron backscatter

diffraction (EBSD), it has the ability to

map microstructures according to crystal-

structure differences. The writer has tried

recently (about ve years after the image-

analysis work was done) to determine the

percent retained austenite of the 25.4%

specimen by EBSD.

Some authors have claimed that EBSD

can detect and measure retained austen-

ite down to ~2% and get data that agrees

with XRD data. The specimen with 25.4%

Fig. 4. Carbon-free martensite in 18Ni250

maraging steel (Fe<0.03% C18.5%

Ni7.5% Co4.85% Mo0.4% Ti0.1% Al)

etched with Frys reagent (1000x marker

bar is 10 m long)

Fig. 5. Low-carbon martensite in Carpen-

ter Technologys AerMet 100 ultrahigh-

strength steel (Fe0.23% C13.5%

Co11.1% Ni3.1% Cr1.2% Mo) heat

treated (1093 C, AC, age at 675 C for 6 h,

AC) to coarsen the grain size and etched

with 10% sodium metabisulte (100x)

Fig. 6. High-carbon plate martensite (blue

and brown), retained austenite (white),

plus intergranular and intragranular ce-

mentite in a carburized specimen of 9310

alloy steel etched with Berahas reagent

(100 mL water, 10 g Na

2

S

2

O

3

and 3 g

K

2

S

2

O

5

) at 1000x (marker bar is 5 m long).

retained austenite was re-prepared metal-

lographically using the best procedures

for EBSD and analyzed by Stefan Zaef-

ferer of the Max Planck Institute for Steel

Research in Dsseldorf, Germany. EBSD

showed only about 5% retained austen-

ite in this specimen. Examination of the

mapped pixels around the patches of re-

tained austenite revealed that there were

many that appeared black on an index of

quality map, indicating that they were not

producing an indexable diffraction pat-

tern. It is possible that these pixels were

from austenite that had transformed to

fresh martensite. But even if these pixels

were added to the pixels that were from

FCC austenite, the percentage would still

be much less than 25.4%.

Future Work

Working with a carburized specimen pres-

ents difculties due to the variation in car-

bon and microstructure in the case. The

writer is planning additional EBSD work

with Dr. Zaefferer using 1.25-inch-diame-

ter bars (to avoid mounting and conduc-

tivity problems) of O1 and 52100 alloy

steels, high-carbon steels with enough

hardenability to be through-hardened and

with enough carbon and alloy content to

produce >10% retained austenite. As their

alloy content is not high, carbide interfer-

ence peaks and texture problems by XRD

should be minimal. Transverse and lon-

gitudinal specimens will be prepared and

tested by XRD, then by LOM and EBSD.

These tests will be performed quickly, and

other labs will participate to evaluate the

reproducibility of the data. Some experi-

ments will be run at a later date to access

the inuence of time since heat treatment

upon the data. IH

References:

1. L.E. Samuels, Light Microscopy of Carbon

Steels, ASM International, Materials Park,

OH, 1999, p. 273.

2. G. Krauss, Martensitic Transformation,

Structure and Properties in Hardenable

Steels, in Hardenability Concepts with

Applications to Steel, D.V. Doane and J.S.

Kirkaldy, eds., AIME, Warrendale, PA, 1978,

pp. 229-248.

3. A. Litwinchuk et al., J. Material Science, Vol.

11, 1976, p. 1200.

4. G. Krauss, Principles of Heat Treatment of

Steel, ASM, Metals Park, OH, 1980, p. 52.

5. G.R. Speich and W.C. Leslie, Met. Trans., Vol.

3, 1972, p. 1043.

6. G.F. Vander Voort, Metallography: Prin-

ciples and Practice, McGraw-Hill Book Co.,

NY, 1984; ASM International, Materials Park,

OH, 1999.

For more information: Contact George F.

Vander Voort, director, Research & Technol-

ogy, Buehler Ltd., 41 Waukegan Road, Lake

Bluff, IL 60044; tel: 847-295-4590; e-mail:

George.VanderVoort@buehler.com; web:

www.buehler.com

100

75

50

25

0

0 0.4 0.8 1.2 1.6

M

s

Temperature

Relative

volume PCT

lath martensite

Volume PCT

retained

700

500

300

100

40

20

0

R

e

l

a

t

i

v

e

v

o

l

u

m

e

%

l

a

t

h

m

a

r

t

e

n

s

i

t

e

Carbon, wt %

M

s

T

e

m

p

e

r

a

t

u

r

e

,

C

V

o

l

u

m

e

P

C

T

Fig. 7. Inuence of carbon content of the austenite on the percent-

ages of lath (or plate) martensite, Ms temperature and percentage of

retained austenite

[5]

Fig. 8. Surface of a carburized 8720 alloy-steel railroad-cone bear-

ing etched with nital plus 1% zephiran chloride. Image analysis

yielded 13.3% retained austenite vs 25.4% by XRD (1000x).

Reprinted from Industrial Heating April 2009

Tired of the old and boring daily grind? Sample

preparation has never been more exciting than with

Buehlers NEW family of EcoMet 250 Grinder-Polishers

and AutoMet 250 Semi-Automatic Power Heads! Let

Buehler help with your heat treating and thermal

processing sample preparation applications.

Features include:

Sealed membrane keypad or user-friendly touch-screen

controls

Unique LED lighting illuminates platen and specimens

Durable cast aluminum base construction

Stain, chip and corrosion resistant finish

High torque motors

Retractable water hose and 360 bowl rinse system

Repeatable specimen preparation every time!

Now, thats something to get excited about! Call your

Buehler Sales Engineer today for more information.

PROVI DI NG SOLUTI ONS FOR OVER 70 YEARS

Worldwide Headquarters

Buehler Ltd 41 Waukegan Road Lake Bluff, Illinois 60044 USA

Tel: (847) 295-6500 Fax: (847) 295-7979

Email: info@buehler.com Web Site: http://www.buehler.com

Buehler is redefining the look of material analysis equipment!

The Future is Here...

Potrebbero piacerti anche

- 1 s2.0 S2212827114000523 Main PDFDocumento6 pagine1 s2.0 S2212827114000523 Main PDFsaborsita666Nessuna valutazione finora

- 1 s2.0 S1877705814003245 Main PDFDocumento6 pagine1 s2.0 S1877705814003245 Main PDFsaborsita666Nessuna valutazione finora

- Introduction To The Mechanical Behavior of MetalsDocumento4 pagineIntroduction To The Mechanical Behavior of Metalssaborsita666Nessuna valutazione finora

- ArcelorMittal Automotive Product Offer enDocumento131 pagineArcelorMittal Automotive Product Offer enqshaathNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- FRP Radiator GrillDocumento5 pagineFRP Radiator GrillJamal AliNessuna valutazione finora

- Widia Technical PSEinch 544-560Documento0 pagineWidia Technical PSEinch 544-560hugobscottNessuna valutazione finora

- Types of PavementDocumento4 pagineTypes of Pavementibrahim0007100% (1)

- Potential BuyerDocumento4 paginePotential BuyerFazlie IslamNessuna valutazione finora

- Vboard BrochureDocumento2 pagineVboard BrochureAmit Abhishek TopnoNessuna valutazione finora

- Normas ASTM e ISO Metalografia TestmatDocumento4 pagineNormas ASTM e ISO Metalografia TestmatAndre Luiz DuarteNessuna valutazione finora

- Design of Pavement Structure-Odd 2015 - Print 01Documento11 pagineDesign of Pavement Structure-Odd 2015 - Print 01BISUNessuna valutazione finora

- Complete DWV Installation GuideDocumento22 pagineComplete DWV Installation GuidebhabdiNessuna valutazione finora

- SCI Catalog CurrentDocumento165 pagineSCI Catalog Currenthenryvl78Nessuna valutazione finora

- REVISED Concrete Technology BOOK - by Sri P. SURESHDocumento63 pagineREVISED Concrete Technology BOOK - by Sri P. SURESHV Venkata Narayana100% (1)

- Tds Lotader Hx8290 2010Documento1 paginaTds Lotader Hx8290 2010mikehenrysamNessuna valutazione finora

- Construction: MethodologyDocumento18 pagineConstruction: MethodologyAnthony MestiolaNessuna valutazione finora

- Estimate detaildUnitPriceDocumento32 pagineEstimate detaildUnitPriceNeco Carlo PalNessuna valutazione finora

- X-Pruf Crystal Mix PowderDocumento2 pagineX-Pruf Crystal Mix PowderVenkat Uday KiranNessuna valutazione finora

- HVOF HardFactsDocumento2 pagineHVOF HardFactsAli OmumiNessuna valutazione finora

- Thermal SprayDocumento42 pagineThermal Spraykac147100% (1)

- Metal Composition of 1 Rs CoinDocumento15 pagineMetal Composition of 1 Rs Coinrupali parmarNessuna valutazione finora

- Framing GuideDocumento15 pagineFraming Guidend_prasetya9706Nessuna valutazione finora

- Hebei Haihao Group - ProfileDocumento6 pagineHebei Haihao Group - ProfileJesse Zhu100% (1)

- Gomplast RollerDocumento4 pagineGomplast RollerRafiqul AlamNessuna valutazione finora

- Elementis-Nalzin 2Documento2 pagineElementis-Nalzin 2Onesany TecnologiasNessuna valutazione finora

- Textile TestingDocumento4 pagineTextile TestingveselieNessuna valutazione finora

- Timber SectionsDocumento58 pagineTimber Sectionsgayathrimr68Nessuna valutazione finora

- Paints and CoatingsDocumento29 paginePaints and CoatingsRai JeanNessuna valutazione finora

- Manning's N ValuesDocumento5 pagineManning's N ValuesSuraj Mani LamichhaneNessuna valutazione finora

- KolothermDocumento2 pagineKolothermtodotodiNessuna valutazione finora

- Cutting ToolsDocumento60 pagineCutting ToolsKedar Altekar0% (1)

- Civil Engineering TestDocumento21 pagineCivil Engineering TestGanesh Prasad BhatNessuna valutazione finora

- Detailed Specification/ Estimate and Costing: Prefab House Nepal Pvt. LTDDocumento1 paginaDetailed Specification/ Estimate and Costing: Prefab House Nepal Pvt. LTDspellbindguyNessuna valutazione finora

- Research Proposal 1 PDFDocumento5 pagineResearch Proposal 1 PDFMunem BushraNessuna valutazione finora