Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

How To Make Black Powder

Caricato da

elvergonzalez1Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

How To Make Black Powder

Caricato da

elvergonzalez1Copyright:

Formati disponibili

How ToMake Black Powder

|Page 1

WPAG 2011 Black Powder Manufacturing Workshop Instructions

By: Chris Szot

INTRODUCTION: Each group, of 6 groups, will make at least three (3) batches of BP (Black Powder). The purpose of this workshop is to make 2FA or 4FA BP for use by WPAG members and secondly demonstrate a way to make BP without the need to ball mill live BP in a closed container for hours. All ball milling is done to reduce the oxidizer (KNO3) and the fuel (Charcoal/Sulfur and Dextrin) to a very fine powder, only 20 30 minutes of milling is necessary. The oxidizer and fuel are milled separately. The charcoal used to make this BP is young branches from sugar maple, 2 or less in diameter with the bark left on. The YM charcoal will be combined with sulfur and dextrin and milled in a ball mill for 20 - 30 minutes. The Potassium nitrate plus 1% anti cake reagent (Cab-O-Sil optional) was also ball milled for 30 minutes prior to the workshop. The standard BP formula used is as follows (Each batch total weight is 103 grams). Potassium nitrate, KNO3 Charcoal, C Sulfur, S Dextrin, Dx Cab-O-Sil (optional) 75 parts 15 parts 10 parts 2 parts 1 part

Figure 1 Safety glasses & gloves; 100 mesh screen, mixing container & lid, wooden paddles & plastic laminate; Potassium nitrate (oxidant), Fuel (charcoal, sulfur & dextrin).

Figure 2 Distilled water, syringe & cup, red plastic putty knife, 8 mesh screen, rubber mallet & wooden ram, special round cutter.

How ToMake Black Powder

|Page 2

MIXING PROCEDURE: 1) Place a 100 mesh screen over a piece of clean news print paper. 2) Empty the Potassium nitrate (oxidizer) and the pre-milled fuel (charcoal, sulfur, dextrin) into a clean mixing container. 3) Using a wood paddle, mix for 20 to 30 revolutions. 4) Holding the screen in a vertical position, place the top of the mixing container against the screen and lower unto the paper. Rotate the container, as demonstrated, over the screen until most of the mix passes through. 5) Force the remaining mix through the screen using the plastic laminate paddle, breaking up any lumps by squeezing or pressing them through the screen. 6) Dump the screened mix back into the mixing container. 7) Mix for 80 to 100 revolutions. 8) Repeat steps 4 thru 7 above two more times then go to step 9. 9) Carefully measure out 14 mls of distilled water, using a syringe, and discharge into a paper cup. Add the water to the green mix. 10) Use the wooden paddle to work the water into the mix until uniformly moist. When the mix has all turned to a dark charcoal color (no more light gray spots) you are done. 11) With a wooden rammer, pound the mix to form a hard cake in the bottom of the mixing container. 12) Place the lid on the container and let it stand for at least 15 minutes. 13) To make 2FA use (4 mesh) screen, for 4FA use 1/8 (8 mesh) screen. Place the screen on a piece of clean news print. 14) Invert the mixing container over the screen and tap the bottom to dump the BP cake onto the screen.

15) Break up the cake using the plastic putty knife and the rolling cutter until all the pieces fall thru the 4 (2FA) or 8 (4FA) mesh screen. 16) Dump the grained BP back into the mixing container and place a label on the container e.g. BP1 (your group ID) and the type of charcoal fuel use e.g. YM (young maple) or TMRK (Tamarack) or JP (Jack Pine). Drying will be done at a designated area per WPAG safety rules. 17) Spread the moist grained BP on a doubled sheet of news print and place into a drier or . . . air dry using a fan

to improve air movement. 18) Dump the dried BP unto an 8 mesh screen (for 2FA) or a 12 mesh screen (for 4FA) and vibrate the screen to sift the BP. What stays on an 8 mesh screen is 2FA and what stays on a 12 mesh screen is 4FA. What passes through the 12 mesh screen is 6FA and finer.

Potrebbero piacerti anche

- Alex Eubank GGIIDocumento40 pagineAlex Eubank GGIIOliver Sleiman94% (16)

- Black Powder ManufacturingDocumento210 pagineBlack Powder ManufacturingMike Nichlos100% (13)

- All Load Data For The 45 ACP Handgun CartridgeDocumento18 pagineAll Load Data For The 45 ACP Handgun Cartridgeblowmeasshole1911100% (2)

- Chemical Wisdom - Horse Chestnuts and The Fermentation of Powerful PowdersDocumento67 pagineChemical Wisdom - Horse Chestnuts and The Fermentation of Powerful PowdersPeter JansenNessuna valutazione finora

- High Explosives Index PDFDocumento9 pagineHigh Explosives Index PDFCivil WarNessuna valutazione finora

- Improvised Domestic WeaponsDocumento1 paginaImprovised Domestic WeaponsnunukantaNessuna valutazione finora

- Digital Thermometer Circuit.Documento2 pagineDigital Thermometer Circuit.elvergonzalez1100% (1)

- Small Wonders - Registered Drop in Auto SearsDocumento5 pagineSmall Wonders - Registered Drop in Auto SearsMarcos Morsch100% (8)

- HK 91, SR9,93,94, SP89Documento3 pagineHK 91, SR9,93,94, SP89elvergonzalez1Nessuna valutazione finora

- Pigeon Disease - The Eight Most Common Health Problems in PigeonsDocumento2 paginePigeon Disease - The Eight Most Common Health Problems in Pigeonscc_lawrence100% (1)

- Scope: Procter and GambleDocumento30 pagineScope: Procter and GambleIrshad AhamedNessuna valutazione finora

- Exercises - Fluid MechanicsDocumento3 pagineExercises - Fluid MechanicsgemnikkicNessuna valutazione finora

- 6 Kuliah Liver CirrhosisDocumento55 pagine6 Kuliah Liver CirrhosisAnonymous vUEDx8100% (1)

- CXC - Past - Paper - 2022 Solutions PDFDocumento17 pagineCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- Flash PowderDocumento2 pagineFlash Powderelvergonzalez1Nessuna valutazione finora

- Black Powder GradesDocumento2 pagineBlack Powder GradesPhileasNessuna valutazione finora

- Chapter 5: How To Make Flying-Fish-Fuse Mines (Make 10 Mines)Documento13 pagineChapter 5: How To Make Flying-Fish-Fuse Mines (Make 10 Mines)tophunterNessuna valutazione finora

- 6in White Elephant Pattern ShellDocumento2 pagine6in White Elephant Pattern Shellkrstas774Nessuna valutazione finora

- Lovex Reloading GuideDocumento56 pagineLovex Reloading GuideDavid LegatNessuna valutazione finora

- E Igniter2 PDFDocumento19 pagineE Igniter2 PDFWilliam OsburnNessuna valutazione finora

- Smoke ScreensDocumento3 pagineSmoke ScreensGaryoNessuna valutazione finora

- Potassium Chlorate SynthesisDocumento3 paginePotassium Chlorate SynthesisJohn RhodesNessuna valutazione finora

- Standard Flash, Concussion, Concussion XL, Super Sparkle Silver, Super Sparkle Gold Instructions For Use WARNING! Not For Consumer UseDocumento1 paginaStandard Flash, Concussion, Concussion XL, Super Sparkle Silver, Super Sparkle Gold Instructions For Use WARNING! Not For Consumer UseWayne Lund100% (1)

- Making CartridgesDocumento19 pagineMaking CartridgesGrimm CaoNessuna valutazione finora

- MmgunboatsdesignguideDocumento13 pagineMmgunboatsdesignguideapi-210899798Nessuna valutazione finora

- Evil Detonator: Owner'S ManualDocumento5 pagineEvil Detonator: Owner'S ManualMichael BrownNessuna valutazione finora

- Perspectives On Pentaerythritol Tetranitrate PETN DecompositionDocumento20 paginePerspectives On Pentaerythritol Tetranitrate PETN DecompositionStefano Martin Lizarbe WongNessuna valutazione finora

- Charge Block Demolition TNTDocumento1 paginaCharge Block Demolition TNTBlentica FlajicNessuna valutazione finora

- Explosives - ANFO (Ammonium Nitrate - Fuel Oil)Documento3 pagineExplosives - ANFO (Ammonium Nitrate - Fuel Oil)Mithelesh Purohit100% (1)

- The Recipe of Black PowderDocumento5 pagineThe Recipe of Black PowderRonda Anderson-Huston100% (1)

- Pressure Air GunDocumento7 paginePressure Air GunyuehanNessuna valutazione finora

- Black Powder ManualDocumento6 pagineBlack Powder ManualRyan Castendyke0% (1)

- Concealing PETNDocumento2 pagineConcealing PETNWolfgangNessuna valutazione finora

- Smoke BombDocumento4 pagineSmoke BombMurali Krishna GbNessuna valutazione finora

- This Is An Instructable For How To Make Gunpowder FromDocumento13 pagineThis Is An Instructable For How To Make Gunpowder FromnekOzumi12100% (1)

- Fireworks IgniterDocumento10 pagineFireworks Igniterjoescrotom100% (1)

- Rocket Propellant (Whistling) - PyroDataDocumento2 pagineRocket Propellant (Whistling) - PyroDataProvat mondalNessuna valutazione finora

- Catalyzed KNSU Propellant (PP)Documento6 pagineCatalyzed KNSU Propellant (PP)Chingyg100% (1)

- How To Make Gunpowder in The WildDocumento19 pagineHow To Make Gunpowder in The WildIqroAlam100% (1)

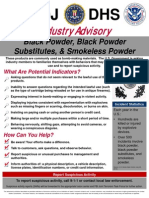

- Industry Advisory - Black Powder, Black Powder Substitutes, & Smokeless PowderDocumento1 paginaIndustry Advisory - Black Powder, Black Powder Substitutes, & Smokeless PowderAmmoLand Shooting Sports NewsNessuna valutazione finora

- M84 StunGranadeDocumento19 pagineM84 StunGranadeNatuv Hoang100% (1)

- Shooting TC Side Lock Black Powder GunsDocumento92 pagineShooting TC Side Lock Black Powder Gunscaj411Nessuna valutazione finora

- Trijicon RECOIL TargetDocumento1 paginaTrijicon RECOIL TargetK Scott WyattNessuna valutazione finora

- Nitrocellulose PDFDocumento14 pagineNitrocellulose PDFTalha SheikhNessuna valutazione finora

- Explosives & Mixtures Used in AmmnDocumento10 pagineExplosives & Mixtures Used in AmmnVikas Chandra100% (1)

- Document ( (Pyrotechnic Chemical List)Documento11 pagineDocument ( (Pyrotechnic Chemical List)jesse1361Nessuna valutazione finora

- Operator'S and Unit Maintenance Manual (Including Repair Parts and Special Tools List)Documento143 pagineOperator'S and Unit Maintenance Manual (Including Repair Parts and Special Tools List)desmohead0% (1)

- Explosive Materials: Composition C4 (Plastic Explosives)Documento4 pagineExplosive Materials: Composition C4 (Plastic Explosives)GerbenNessuna valutazione finora

- Civil War Explosive OrdnanceDocumento171 pagineCivil War Explosive Ordnancejbart252100% (2)

- General-Purpose Machine Gun - WikipediaDocumento4 pagineGeneral-Purpose Machine Gun - WikipediasorinartistuNessuna valutazione finora

- TM31 210 Improvised Munitions Handbook SDocumento254 pagineTM31 210 Improvised Munitions Handbook SDan O'HaraNessuna valutazione finora

- PHF-89 Plastic ExplosiveDocumento2 paginePHF-89 Plastic ExplosivehorscriNessuna valutazione finora

- MyrolDocumento6 pagineMyrolmattman328Nessuna valutazione finora

- In Applied ChemistryDocumento5 pagineIn Applied ChemistryEM Delos Santos RelevoNessuna valutazione finora

- Explosives 110221233815 Phpapp01Documento20 pagineExplosives 110221233815 Phpapp01Jean Marco Candiotti Campos0% (1)

- Joseph Abrusci - Professional Homemade Cherry BombsDocumento26 pagineJoseph Abrusci - Professional Homemade Cherry BombsLê Nguyên ĐứcNessuna valutazione finora

- Impact Firecrackers - John Donner PDFDocumento33 pagineImpact Firecrackers - John Donner PDFwarrior_2008Nessuna valutazione finora

- Make Black PowderDocumento7 pagineMake Black PowderosintbNessuna valutazione finora

- 4in Color Wstrobe ReportsDocumento3 pagine4in Color Wstrobe Reportskrstas774Nessuna valutazione finora

- ExplosivesDocumento35 pagineExplosivesChetan SuranaNessuna valutazione finora

- Remington 870 & Mossberg 590 UnloadDocumento2 pagineRemington 870 & Mossberg 590 Unloadkhalilv3x6739Nessuna valutazione finora

- Standard Burn Rates of Black Powder To 100 Atmospheres.Documento35 pagineStandard Burn Rates of Black Powder To 100 Atmospheres.Lukasz Olszewski100% (1)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Da EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Valutazione: 5 su 5 stelle5/5 (1)

- Hunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunDa EverandHunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunNessuna valutazione finora

- 20 - Metalwork and Machining Hints and TipsDocumento49 pagine20 - Metalwork and Machining Hints and Tipsbatazivo0% (1)

- Parts List For A Miniature Low RateDocumento1 paginaParts List For A Miniature Low Rateelvergonzalez1Nessuna valutazione finora

- Workshop Practice Series - BooksDocumento8 pagineWorkshop Practice Series - Bookscatapix100% (5)

- Digital Tachometer Using Arduino Plus Speed Control.Documento3 pagineDigital Tachometer Using Arduino Plus Speed Control.elvergonzalez1Nessuna valutazione finora

- Lsi/Csi: Digital Lock For Automotive IgnitionsDocumento4 pagineLsi/Csi: Digital Lock For Automotive Ignitionselvergonzalez1Nessuna valutazione finora

- Low Cost Fire Alarm CircuitDocumento2 pagineLow Cost Fire Alarm CircuitmohitNessuna valutazione finora

- Magnetic Proximity Switch.Documento1 paginaMagnetic Proximity Switch.elvergonzalez1Nessuna valutazione finora

- Ignition For Old CarsDocumento2 pagineIgnition For Old Carselvergonzalez1Nessuna valutazione finora

- RF Based Wireless Remote Control SystemDocumento4 pagineRF Based Wireless Remote Control Systemelvergonzalez1Nessuna valutazione finora

- Thermostat Using LM56Documento2 pagineThermostat Using LM56elvergonzalez1Nessuna valutazione finora

- KW High SchemDocumento1 paginaKW High Schemelvergonzalez1Nessuna valutazione finora

- KW Low SchemDocumento1 paginaKW Low Schemelvergonzalez1Nessuna valutazione finora

- Digital Code Lock Using Arduino With LCD Display and User Defined PasswordDocumento7 pagineDigital Code Lock Using Arduino With LCD Display and User Defined Passwordelvergonzalez1100% (1)

- Electronic Combination Lock CircuitDocumento2 pagineElectronic Combination Lock Circuitelvergonzalez1Nessuna valutazione finora

- Magnetic Proximity Switch.Documento1 paginaMagnetic Proximity Switch.elvergonzalez1Nessuna valutazione finora

- Erii4 Ic History Op AmpsDocumento10 pagineErii4 Ic History Op Ampselvergonzalez1Nessuna valutazione finora

- Digital Tachometer Using Arduino Plus Speed Control.Documento3 pagineDigital Tachometer Using Arduino Plus Speed Control.elvergonzalez1Nessuna valutazione finora

- Air Flow Detector Circuit.Documento1 paginaAir Flow Detector Circuit.elvergonzalez1Nessuna valutazione finora

- Design and Construction of A Remote Controlled Fan RegulatorDocumento8 pagineDesign and Construction of A Remote Controlled Fan RegulatorDeepak ParasharNessuna valutazione finora

- Everything That Moves ALARM CircuitDocumento1 paginaEverything That Moves ALARM Circuitelvergonzalez1Nessuna valutazione finora

- Electronic Combination Lock CircuitDocumento2 pagineElectronic Combination Lock Circuitelvergonzalez1Nessuna valutazione finora

- Electronic Siren CircuitDocumento2 pagineElectronic Siren Circuitelvergonzalez1Nessuna valutazione finora

- Stinger ManualDocumento59 pagineStinger Manualelvergonzalez1Nessuna valutazione finora

- Mod Firearm Beretta - US Patent 5596162Documento9 pagineMod Firearm Beretta - US Patent 5596162luanfunari100% (1)

- Air Flow Detector Circuit.Documento1 paginaAir Flow Detector Circuit.elvergonzalez1Nessuna valutazione finora

- Colt AR-15 Rifle Lightning LinkDocumento5 pagineColt AR-15 Rifle Lightning Linkelvergonzalez1100% (2)

- Colt AR-15 Rifle Lightning LinkDocumento5 pagineColt AR-15 Rifle Lightning Linkelvergonzalez1100% (2)

- G1 Series User Manual Ver. 1.2Documento101 pagineG1 Series User Manual Ver. 1.2unedo parhusip100% (1)

- Crime Data Analysis 1Documento2 pagineCrime Data Analysis 1kenny laroseNessuna valutazione finora

- Cover Letter UchDocumento1 paginaCover Letter UchNakia nakia100% (1)

- DT 2107Documento1 paginaDT 2107Richard PeriyanayagamNessuna valutazione finora

- 'Bubble Kid' Success Puts Gene Therapy Back On TrackDocumento5 pagine'Bubble Kid' Success Puts Gene Therapy Back On TrackAbby Grey Lopez100% (1)

- 208-Audit Checklist-Autoclave Operation - FinalDocumento6 pagine208-Audit Checklist-Autoclave Operation - FinalCherry Hope MistioNessuna valutazione finora

- AFMAN91-201 NewDocumento458 pagineAFMAN91-201 NewbombtechNessuna valutazione finora

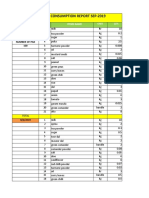

- Daily Staff Food Consumption Reports Sep-2019Documento4 pagineDaily Staff Food Consumption Reports Sep-2019Manjit RawatNessuna valutazione finora

- Analysis of Pure Copper - A Comparison of Analytical MethodsDocumento12 pagineAnalysis of Pure Copper - A Comparison of Analytical Methodsban bekasNessuna valutazione finora

- Comprehensive Safe Hospital FrameworkDocumento12 pagineComprehensive Safe Hospital FrameworkEbby OktaviaNessuna valutazione finora

- DOWSIL™ 2-9034 Emulsion: Features & BenefitsDocumento5 pagineDOWSIL™ 2-9034 Emulsion: Features & BenefitsLaban KantorNessuna valutazione finora

- Epicor Software India Private Limited: Brief Details of Your Form-16 Are As UnderDocumento9 pagineEpicor Software India Private Limited: Brief Details of Your Form-16 Are As UndersudhadkNessuna valutazione finora

- Pay Details: Earnings Deductions Code Description Quantity Amount Code Description AmountDocumento1 paginaPay Details: Earnings Deductions Code Description Quantity Amount Code Description AmountVee-kay Vicky KatekaniNessuna valutazione finora

- Refinería Kirkuk PDFDocumento11 pagineRefinería Kirkuk PDFcesarinarragaNessuna valutazione finora

- Interviewing Skill Workshop (KAU)Documento54 pagineInterviewing Skill Workshop (KAU)DrKomal KhalidNessuna valutazione finora

- Covid-19 Mitigation PlanDocumento8 pagineCovid-19 Mitigation PlanEkum EdunghuNessuna valutazione finora

- Employment Offer: 1. Employer InformationDocumento2 pagineEmployment Offer: 1. Employer InformationnavidNessuna valutazione finora

- Phardose Lab Prep 19 30Documento4 paginePhardose Lab Prep 19 30POMPEYO BARROGANessuna valutazione finora

- Carboset CA-600 - CST600 - CO - enDocumento3 pagineCarboset CA-600 - CST600 - CO - enNilsNessuna valutazione finora

- Education in America: The Dumbing Down of The U.S. Education SystemDocumento4 pagineEducation in America: The Dumbing Down of The U.S. Education SystemmiichaanNessuna valutazione finora

- EV Hammer Impact Crusher - ENDocumento8 pagineEV Hammer Impact Crusher - ENKeshav NandaNessuna valutazione finora

- HVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionsDocumento1 paginaHVAC (Heating, Ventilation and Air Conditioning) : SRS PrecautionssoftallNessuna valutazione finora

- Solo ParentsDocumento1 paginaSolo ParentsOZ CincoNessuna valutazione finora

- ACF5950 - Assignment # 7 Semester 2 2015: The Business Has The Following Opening Balances: Additional InformationDocumento2 pagineACF5950 - Assignment # 7 Semester 2 2015: The Business Has The Following Opening Balances: Additional InformationkietNessuna valutazione finora