Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Operating Instructions Sealed Stationary Lead Acid Batteries En0612

Caricato da

hino_kaguCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Operating Instructions Sealed Stationary Lead Acid Batteries En0612

Caricato da

hino_kaguCopyright:

Formati disponibili

Operating instructions

Valve regulated stationary lead-acid batteries

Specifications: Nominal voltage UN: 2.0 V x number of cells connected in series Nominal Capacity CN = C10: 10 hour discharge (see type label) Nominal discharge current: IN = I10:

CN 10 h

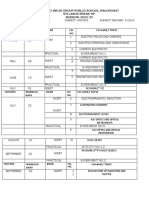

Installation by: on: Commissioning by: on: Safety markings affixed by:

Final discharge voltage Us: 1.80 V/Cell Nominal temperature TN: 20C Valve regulated stationary lead-acid batteries consist of cells which for their entire service life must not be topped up with water. Excess pressure valves are used as vent plugs and will be destroyed if opened. Observe operating instructions and display visibly near to the battery. Work on batteries only after instruction by qualified staff. No smoking. No open flame, embers or sparks in the vicinity of the battery, to avoid risk of explosion and fire. Wear eye protection and protective clothing when working with batteries. Observe accident prevention regulations, also DIN EN 50272 T2, DIN EN 50110 Part 1! Acid splashes in the eyes or on the skin must be washed out or off with plenty of water. Then see a doctor immediately. Acid splashes on clothing should be washed out with water! Explosion and fire risk, avoid short-circuits. Warning! Metal parts of the battery cells are always live. Never place foreign objects or tools on the battery. Electrolyte is highly corrosive. In normal operation there is no possibility of contact with the electrolyte. Should the casing be destroyed, the combined electrolyte released is as corrosive as liquid electrolyte. Monobloc batteries/cells are very heavy! Ensure secure installation! Use only suitable conveying equipment! Dangerous electrical voltage. on: 1. Commissioning Before commissioning all cells/blocks must be inspected for mechanical damage, cells must be connected with the correct polarity and connectors firmly seated. The following torque applies for screw connectors: M8 with 20 Nm 1 Nm, M5/M6 with 8 Nm 1 Nm. If necessary the terminal covers must be put on. With charger off and loads isolated, connect battery to the direct current power supply, maintaining correct polarity (positive terminal to positive post). Switch on the charger and charge as described in section 2.2. 2. Operation For the assembly and operation of stationary battery installations DIN EN 50272 Part 1 and DIN EN 50272 Part 2 resp. IEC 624852 apply. The battery must be installed in such a way that an ambient temperature difference of > 3C cannot occur between individual cells/blocks. 2.1 Discharging Never allow the final discharge voltage of the battery to drop below that assigned for the discharge current. Unless the manufacturer has specified otherwise, no more than the nominal capacity is to be consumed. Charge immediately after discharge, including partial discharge. 2.2 Charging The charging procedure with limit values as defined under DIN 41 773 (IU characteristic) may be used. Depending on the system at hand, charging may be carried out under the following operating modes (in accordance with DIN EN 50272 Part 1 draft). a) Stand-by parallel operation and floating operation Here the load, direct current source and battery are continuously connected in parallel.

This means that the charging voltage is the operating voltage of the battery and at the same time the battery system voltage. Under stand-by parallel operation, the direct current source is at any time capable of supplying the maximum load current and the battery charging current. The battery only supplies current when the direct current source fails. The charge voltage should be set at 2.25 V 1% x number of cells in series, measured at the batterys terminals. To reduce the recharging time a charging stage can be applied in which the charging voltage is max. 2.35 V x number of cells (stand-by parallel operation with recharging stage). Automatic changeover to the charging voltage of 2.25 V 1% (2,27 V 1% for power.com H.C, power.com XC, dry.power and net.power 12 V 92 as well as 12 V 170) x number of cells in series follows. With floating operation the direct current source is not able to supply the maximum load current at all times. The load current intermittently exceeds the nominal current of the direct current source. During this period the battery supplies power. It is not fully charged at all times. Therefore, depending on the load, the charge voltage must be set at approx. 2.27 to 2.30 V x number of cells following consultation with the battery manufacturer. b) Switch mode operation When charging, the battery is separated from the load. The charge voltage of the battery is max. 2.35 V/cell. The charging process must be monitored. When the charge current has decreased to 1.5 A/100 Ah nominal capacity at 2.35 V/cell, the battery is switched to float charging as under section 2.3 or switching takes place on reaching 2.35 V/cell. c) Battery operation (charge/discharge) operation The load is supplied only by the battery. The charging method depends on the user and must be clarified with the battery manufacturer. 2.3 Maintaining the full charge (float charging) Devices complying with the provisions of DIN 41773 must be used. They are to be set so that the average cell voltage is 2.25 V 1% (2,27 V 1% for power.com H.C, power.com XC, dry.power and net.power 12 V 92 as well as 12 V 170). 2.4 Equalising charge Because it is possible to exceed the permitted load voltages, appropriate measures must be taken, e.g. disconnection of the load. An equalising charge is necessary after an exhaustive discharge and/or after an inadequate charge; it can be carried out at a constant voltage of max. 2.35 V/cell for up to 48 hours. The end of equalising charge is rea-

ched when the electrolyte densities and cell voltages no longer rise within a period of 2 hours. The charging current should not exceed 20 A per 100 Ah nominal capacity. Should the maximum temperature of 45C be exceeded, the charging process must be interrupted or temporarily switched to float charge to allow the temperature to drop. 2.5 Superimposed alternating currents While recharging up to 2.35 V/cell in accordance with the operating modes of section 2.2, the actual value of the alternating current is occasionally permitted to reach a max. 20 A per 100 Ah nominal capacity. After recharging and continuous charging (float charging) in standby parallel operation or floating operation, the effective value of the alternating current must not exceed 5 A per 100 Ah nominal capacity. 2.6 Charging currents During continuous battery power supply or floating operation without a recharging stage, the charging currents are not limited. The charging current should lie between 10 A and 20 A per 100 Ah nominal capacity (standard value). 2.7 Temperature The recommended operating temperature range for lead-acid batteries is 10C to 30C. The ideal operating temperature range is 20C 5K. Higher temperatures will reduce battery service life. The technical data apply to the nominal temperature of 20C. Lower temperatures reduce the available capacity. The maximum temperature of 55C must nor be exceeded. Continuous operating temperatures in excess of 45C are to be avoided. 2.8 Temperature-related charge voltage Within the operating temperature range of 15C to 25C, temperature-related adjustment of the charge voltage is not necessary. Should the operating temperature constantly lie outside this temperature range, the voltage should be adjusted. The temperature correction factor is 0.005 V/Cell per K. Temperature -10 0 [C] 10 20 30 40

3. Battery maintenance and inspection To avoid leakage currents keep the battery clean and dry. Cleaning the battery should be carried out as specified in the ZVEI pamphlet on battery cleaning. Plastic battery components, in particular the cell containers, must only be cleaned with pure water. At least every 6 months the following must be measured and recorded: - battery voltage; - voltage of a few selected cells/monobloc batteries; - surface temperature of a few selected cells/monobloc batteries; - temperature in the battery room. Should the cell voltage deviate from the average float charge voltage by +0.2 V/cell or -0.1 V/cell and/or should the surface temperature of different cells deviate more than 5K, customer services must be called in. Note: Voltages of batteries with electrolyte fixed in gel can vary within approximately the first 2 to 4 years after commissioning. Hence the cell voltage in float charge can differ from 2.12V/cell 1% to 2.5 V/cell 1%. These variations are normal phenomenon for gel type batteries without negative influence on capacity resp. efficiency of single battery cells or blocs. The following must be measured and recorded annually: - voltage of all cells/monobloc batteries; - surface temperature of all cells/monobloc batteries; - temperature in the battery room. Annual visual checks: - on bolted connectors (check that unsecured bolt connectors are firmly seated), - on battery installation or arrangement, - on ventilation. 4. Tests Tests must be conducted in accordance with DIN 60896 Part 21 / Part 22. In addition, special test in-structions, e.g. as set out in DIN VDE 0100-710 and DIN 0100-718 should be observed. 5. Faults Should faults be detected in the battery or the charging device, customer services should be called in immediately. Measured data as under section 3 simplify fault detection and elimination. A service contract with us facilitates the timely detection of faults. HOPPECKE service number: + 49 (0) 800 246 77 32

Type

6. Storage and taking out of operation Should cells/batteries be stored or be taken out of operation for extended periods, they must be stored fully charged in a dry, frostfree room. Direct sunlight must be avoided. To prevent damage, the following charging conditions should be chosen: 1. Equalizing charges as defined under 2.4 above, to be given twice a year. At average ambient temperatures in excess of 20C, shorter intervals may be necessary. Note: Battery charge acceptance might be restricted by the end of max. storage period. We recommend application of a different charging method to ensure gentle and full recharge. Refer to corresponding section in the detailed installation, commissioning and operating instructions. 2. Float charging as under 2.3 above. The period of use commences with delivery of the filled and charged battery from the HOPPECKE plant. Storage times are to be added to the period of use in full. In addition, batteries require recharging. Note: Max. two recharges during storage period. Battery has to be operated under permanent float voltage thereafter. 7. Transport Filled lead-acid batteries which are undamaged, show no leaks and are firmly secured on pallets with protection against sliding, over turning and short-circuits are not treated as dangerous goods for conveyance by road so long as there are no dangerous traces (acid, lye) visible on the outside of the package. ATTENTION: It is essential that loads on road vehicles are properly secured! 8. Technical data The nominal voltage, the number of cells/blocks, the nominal capacity (C10 = CN) and the battery type can be obtained from the identification plate. 8.1 Example Identification plate: 4 OPzV 200 4 = number of positive plates OPzV = battery type 200 = nominal capacity C10 (capacity for discharge with ten hours current (I10) over a discharge time of 10 h (t10))

Charge voltage 2.40 2.35 2.30 2.25 2.20 2.15 [V/Cell] 2.9 Electrolyte The electrolyte is dilute sulphuric acid.

Float charge voltage 2,25 1% 2,27 1% 6V 12 V -0,17 V/+0,35 V -0,25 V/+0,50 V

HOPPECKE OPzV, power.bloc OPzV, net.power 12 V 100 and 12 V 150 Ah, power.com SB, power.com HC, OPzV solar.power, OPzV bloc solar.power, solar.bloc net.power 12 V 92 and 170 Ah, power.com XC Voltage per unit Tolerance for float charge voltage for single cells/blocks 2V -0,10 V/+0,20 V 4V -0,14 V/+0,28 V

Pb

Old batteries with this marking are recyclable goods and must be sent for recycling. Used batteries which are not sent for recycling are to be disposed of as special waste under the relevant regulations.

HOPPECKE Batterien GmbH & Co. KG P .O. Box 1140 D-59914 Brilon Bontkirchener Strae 1 D-59929 Brilon-Hoppecke Phone +49(0)2963 61-0 Fax +49(0)2963 61-449 Email info@hoppecke.com www.hoppecke.com

Teil-Nr. 7340204011/06.12/3 K Printed in Germany

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Crane Cables - General Catalogue - Prysmian Group 2016 - Low - 5 PDFDocumento166 pagineCrane Cables - General Catalogue - Prysmian Group 2016 - Low - 5 PDFhino_kaguNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Failure Pump ShaftDocumento7 pagineFailure Pump Shaftahmedabdelaziz851647100% (1)

- KAT0130-0004-E Cables For Reeling Systems PDFDocumento76 pagineKAT0130-0004-E Cables For Reeling Systems PDFhino_kaguNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Medium Voltage Cables PDFDocumento50 pagineMedium Voltage Cables PDFhino_kaguNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Conductix Wampfler Crane Cables Festoon Systems CatalogueDocumento60 pagineConductix Wampfler Crane Cables Festoon Systems Cataloguehino_kaguNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Fan Engineering Guide - Twin City FansDocumento12 pagineFan Engineering Guide - Twin City FansHafiz KamalNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Fan Engineering Guide - Twin City FansDocumento12 pagineFan Engineering Guide - Twin City FansHafiz KamalNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- ECM AFDriveCatalogDocumento12 pagineECM AFDriveCataloghino_kaguNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Crane Cables - General Catalogue - Prysmian Group 2016 - Low - 5 PDFDocumento166 pagineCrane Cables - General Catalogue - Prysmian Group 2016 - Low - 5 PDFhino_kaguNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Electrical Grounding SystemsDocumento17 pagineElectrical Grounding SystemsAndrew WrightNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Ei 1148Documento2 pagineEi 1148hino_kaguNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Crane CalculationDocumento1 paginaCrane Calculationhino_kaguNessuna valutazione finora

- Delta VE Fault Code Info and MaintenanceDocumento5 pagineDelta VE Fault Code Info and Maintenancehino_kaguNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- FAG Mounting Handbook PDFDocumento196 pagineFAG Mounting Handbook PDFBahim BahimanNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 3RT10656AP36 Datasheet enDocumento10 pagine3RT10656AP36 Datasheet enhino_kaguNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- A Case Study On Failure of Dry Type Transformers in Distribution SystemDocumento14 pagineA Case Study On Failure of Dry Type Transformers in Distribution Systemhino_kaguNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- 7SX8 PIXIT A2 V040100 UsDocumento182 pagine7SX8 PIXIT A2 V040100 Ushino_kaguNessuna valutazione finora

- Effects of Water Content On Dielectric Properties of Mineral Transformer OilDocumento5 pagineEffects of Water Content On Dielectric Properties of Mineral Transformer Oilhino_kaguNessuna valutazione finora

- Effects of Water Content On Dielectric Properties of Mineral Transformer OilDocumento5 pagineEffects of Water Content On Dielectric Properties of Mineral Transformer Oilhino_kaguNessuna valutazione finora

- MGE Static Transfer Switches - STS250 - APCDocumento2 pagineMGE Static Transfer Switches - STS250 - APChino_kaguNessuna valutazione finora

- Wound Rotor Repair Tips: Testing, Application and Failure AnalysisDocumento14 pagineWound Rotor Repair Tips: Testing, Application and Failure Analysishino_kaguNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Wound Rotor Repair Tips: Testing, Application and Failure AnalysisDocumento14 pagineWound Rotor Repair Tips: Testing, Application and Failure Analysishino_kaguNessuna valutazione finora

- MD10 KVXDocumento2 pagineMD10 KVXhino_kaguNessuna valutazione finora

- A Case Study On Failure of Dry Type Transformers in Distribution SystemDocumento14 pagineA Case Study On Failure of Dry Type Transformers in Distribution Systemhino_kaguNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- SICOP Contactors For Hoisting DutyDocumento4 pagineSICOP Contactors For Hoisting Dutyhino_kaguNessuna valutazione finora

- OLTC - Circulating CurrentDocumento16 pagineOLTC - Circulating CurrentAsif MominNessuna valutazione finora

- Understanding Complete Test Performed On Induction MotorsDocumento5 pagineUnderstanding Complete Test Performed On Induction Motorshino_kaguNessuna valutazione finora

- Quick Start UpDocumento8 pagineQuick Start Uphino_kaguNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Calculation Exaple For X To R RatioDocumento1 paginaCalculation Exaple For X To R Ratiohino_kaguNessuna valutazione finora

- Trihal TransformerDocumento4 pagineTrihal Transformerhino_kaguNessuna valutazione finora

- Microsoft Word - Half Cell ArtDocumento3 pagineMicrosoft Word - Half Cell Artzmst2013Nessuna valutazione finora

- Science Revision Yr7 PDFDocumento29 pagineScience Revision Yr7 PDFalopezas88% (8)

- WonATech Accessory Brochure - 2015Documento21 pagineWonATech Accessory Brochure - 2015samsarajustNessuna valutazione finora

- Mazda Bt50 WL C & We C Wiring Diagram f198!30!05l11Documento1 paginaMazda Bt50 WL C & We C Wiring Diagram f198!30!05l11staff055Nessuna valutazione finora

- Magnetism and Its Effects On The Living SystemDocumento155 pagineMagnetism and Its Effects On The Living SystemAbhishek Hebballi100% (11)

- Research Task GraphDocumento1 paginaResearch Task Graphapi-419834532Nessuna valutazione finora

- III. 2. Understand The Basic Concepts and Principles of Electricity As Used in Home Circuit ConnectionsDocumento8 pagineIII. 2. Understand The Basic Concepts and Principles of Electricity As Used in Home Circuit ConnectionsMarivic AmperNessuna valutazione finora

- Introduction Electrical SafetyDocumento14 pagineIntroduction Electrical SafetyKameran RaoofNessuna valutazione finora

- Fluent 6.1 Magnetohydrodynamics (MHD) Module Manual: February 2003Documento45 pagineFluent 6.1 Magnetohydrodynamics (MHD) Module Manual: February 2003abdullaalakourNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Class - Xii Sub-Physics - Syllabus Break Up-2022-23 TigpsDocumento4 pagineClass - Xii Sub-Physics - Syllabus Break Up-2022-23 TigpsSuman HaldarNessuna valutazione finora

- Electricity 1 Nov01 4. Nov 02Documento6 pagineElectricity 1 Nov01 4. Nov 02Coolman PoonNessuna valutazione finora

- The Other Electric Hazard - Electric Arc BurnsDocumento6 pagineThe Other Electric Hazard - Electric Arc BurnsKarthik SriramakavachamNessuna valutazione finora

- C.B.S.E. 2012 Sample Papers For X Science (5 Sets)Documento79 pagineC.B.S.E. 2012 Sample Papers For X Science (5 Sets)Vinod Kumar0% (1)

- Problem in Phy - PW - MirtitlesDocumento443 pagineProblem in Phy - PW - MirtitlesGkid Gkid0% (1)

- Abb Type CoordinationDocumento98 pagineAbb Type CoordinationGaurav SinghNessuna valutazione finora

- List of IEC Standards - Wikipedia, The Free EncyclopediaDocumento7 pagineList of IEC Standards - Wikipedia, The Free Encyclopediamohannad87Nessuna valutazione finora

- EMCS Technology Solutions V2Documento78 pagineEMCS Technology Solutions V2alexosi7Nessuna valutazione finora

- Arc - Wleding Final ExamDocumento13 pagineArc - Wleding Final ExamJhonalyne Estioco CamachoNessuna valutazione finora

- Automotive Electrical-Electronic Systems: Fundamentals of Electrics & ElectronicsDocumento39 pagineAutomotive Electrical-Electronic Systems: Fundamentals of Electrics & ElectronicsMinh TríNessuna valutazione finora

- Powerpoint - Determination of Planck's ConstantDocumento37 paginePowerpoint - Determination of Planck's ConstantTroy Giuseppe Tolentino100% (1)

- Manual Ameritron 572BDocumento38 pagineManual Ameritron 572BFabio JbsNessuna valutazione finora

- Switching Power Supply Design - EMIDocumento95 pagineSwitching Power Supply Design - EMIteja0% (1)

- Nothing Is Something - by Floyd SweetDocumento12 pagineNothing Is Something - by Floyd Sweetbob13542Nessuna valutazione finora

- Otqs Moving Charges and MagnetismDocumento9 pagineOtqs Moving Charges and MagnetismHemanth KNessuna valutazione finora

- Ca VD4G (En) B 1VCP000671 2018.09 PDFDocumento46 pagineCa VD4G (En) B 1VCP000671 2018.09 PDFkienNessuna valutazione finora

- Deltabar BuswayDocumento24 pagineDeltabar BuswayMuneer YousofNessuna valutazione finora

- Classic 750VDC Rail ElectrificationDocumento17 pagineClassic 750VDC Rail ElectrificationSemifallen100% (1)

- Bentley 1997Documento17 pagineBentley 1997michael arjonaNessuna valutazione finora

- Sim Power SystemsDocumento8 pagineSim Power SystemsPhan Giang ChâuNessuna valutazione finora