Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Starting Systems

Caricato da

Art DoeCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Starting Systems

Caricato da

Art DoeCopyright:

Formati disponibili

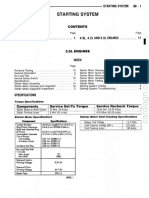

TJ STARTING SYSTEMS 8B - 1

STARTING SYSTEMS

CONTENTS

page page

GENERAL INFORMATION CONTROL CIRCUIT TEST . . . . . . . . . . . . . . . . . . 6

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1 FEED CIRCUIT TEST . . . . . . . . . . . . . . . . . . . . . . 3

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 STARTER NOISE - 2.5L ENGINE . . . . . . . . . . . . 8

DESCRIPTION AND OPERATION STARTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . 2

STARTER RELAY . . . . . . . . . . . . . . . . . . . . . . . . 2 REMOVAL AND INSTALLATION

STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 STARTER RELAY . . . . . . . . . . . . . . . . . . . . . . . 10

STARTING SYSTEM . . . . . . . . . . . . . . . . . . . . . . 1 STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DIAGNOSIS AND TESTING SPECIFICATIONS

COLD CRANKING TEST . . . . . . . . . . . . . . . . . . . 3 STARTING SYSTEM . . . . . . . . . . . . . . . . . . . . . 10

GENERAL INFORMATION • Clutch pedal position switch (manual transmission)

• Park/neutral position switch (automatic trans-

OVERVIEW mission)

The battery, starting, and charging systems oper- • Wire harness and connections.

ate with one another, and must be tested as a com- This group covers diagnosis of the complete start-

plete system. In order for the vehicle to start and ing system, except the battery. However, this group

charge properly, all of the components involved in only covers service procedures for the starter and

these systems must perform within specifications. starter relay. Service procedures for other starting

Group 8A covers the battery, Group 8B covers the system components can be located as follows:

starting system, and Group 8C covers the charging • Battery - refer to Group 8A - Battery for the

system. Refer to Group 8W - Wiring Diagrams for diagnostic and service procedures

complete circuit descriptions and diagrams. We have • Ignition switch - refer to Group 8D - Ignition

separated these systems to make it easier to locate Systems for the service procedures

the information you are seeking within this Service • Clutch pedal position switch - refer to Group 6 -

Manual. However, when attempting to diagnose any Clutch for the service procedures

of these systems, it is important that you keep their • Park/neutral position switch - refer to Group 21

interdependency in mind. - Transmission for the service procedures

The diagnostic procedures used in these groups • Wire harness and connections - refer to Group

include the most basic conventional diagnostic meth- 8W - Wiring Diagrams for the service procedures.

ods, to the more sophisticated On-Board Diagnostics

(OBD) built into the Powertrain Control Module

DESCRIPTION AND OPERATION

(PCM). Use of a induction milliampere ammeter, volt/

ohmmeter, battery charger, carbon pile rheostat (load

STARTING SYSTEM

tester), and 12-volt test lamp may be required.

The starting system components form two separate cir-

All OBD-sensed systems are monitored by the

cuits. A high-amperage feed circuit that feeds the starter

PCM. Each monitored circuit is assigned a Diagnos-

between 150 and 350 amperes, and a low-amperage con-

tic Trouble Code (DTC). The PCM will store a DTC in

trol circuit that operates on less than 20 amperes.

electronic memory for any failure it detects. See the

If the vehicle is equipped with an automatic trans-

On-Board Diagnostics Test in Group 8C - Charging

mission, battery voltage is supplied through the low-

System for more information.

amperage control circuit to the coil battery terminal

of the starter relay when the ignition switch is

INTRODUCTION

turned to the Start position. The park/neutral posi-

The starting system consists of:

tion switch is installed in series between the starter

• Battery

relay coil ground terminal and ground. This normally

• Starter relay

open switch prevents the starter relay from being

• Starter with an integral solenoid

energized unless the automatic transmission gear

• Ignition switch

selector is in the Neutral or Park positions.

8B - 2 STARTING SYSTEMS TJ

DESCRIPTION AND OPERATION (Continued)

If the vehicle is equipped with a manual transmis- magnet field consists of four high-strength perma-

sion, it has a clutch pedal position switch installed in nent magnets. The magnets are aligned according to

series between the ignition switch and the coil battery their polarity, and are permanently mounted in the

terminal of the starter relay. This normally open starter field frame.

switch prevents the starter relay from being energized The starter motors for all engines are activated by

unless the clutch pedal is depressed, preventing starter a solenoid mounted to the overrunning clutch hous-

operation while the clutch disc and the flywheel are ing. However, the starter motor and solenoid are ser-

engaged. The starter relay coil ground terminal is viced only as a complete assembly. If either

always grounded on vehicles with a manual transmis- component is faulty or damaged, the entire starter

sion. assembly must be replaced.

When the starter relay coil is energized, the nor-

mally open relay contacts close. The relay contacts CAUTION:

connect the relay common feed terminal to the relay • Permanent magnet starters are highly sensitive

normally open terminal. The closed relay contacts to hammering, shocks, and external pressure. The

energize the starter solenoid coil windings. permanent magnets may be damaged and the

The energized solenoid pull-in coil pulls in the sole- starter rendered unserviceable, if subjected to any

noid plunger. The solenoid plunger pulls the shift of these conditions.

lever in the starter. This engages the starter overrun- • The starter motor must not be clamped in a

ning clutch and pinion gear with the starter ring vise by the starter field frame. Doing so may dam-

gear on the manual transmission flywheel, or on the age the permanent magnets. The starter should

automatic transmission torque converter drive plate. only be clamped by the mounting flange.

As the solenoid plunger reaches the end of its • Do not connect the starter motor incorrectly

travel, the solenoid contact disc completes the high- when testing. Reverse polarity may damage the per-

amperage starter feed circuit and energizes the sole- manent magnets and render the starter unservice-

noid plunger hold-in coil. Current now flows between able.

the solenoid battery terminal and the starter motor,

energizing the starter.

Once the engine starts, the overrunning clutch pro- STARTER RELAY

tects the starter from damage by allowing the starter The starter relay is a International Standards Orga-

pinion gear to spin faster than the pinion shaft. nization (ISO)-type relay. The starter relay is a elec-

When the driver releases the ignition switch to the tromechanical device that switches battery current to

On position, the starter relay coil is de-energized. the pull-in coil of the starter solenoid when the igni-

This causes the relay contacts to open. When the tion switch is turned to the Start position. See the

relay contacts open, the starter solenoid plunger Diagnosis and Testing section of this group for more

hold-in coil is de-energized. information on the operation of the starter relay.

When the solenoid plunger hold-in coil is de-ener- The starter relay is located in the Power Distribu-

gized, the solenoid plunger return spring returns the tion Center (PDC), in the engine compartment. Refer

plunger to its relaxed position. This causes the con- to the PDC label for relay identification and location.

tact disc to open the starter feed circuit, and the shift The starter relay cannot be repaired and, if faulty

lever to disengage the overrunning clutch and pinion or damaged, it must be replaced.

gear from the starter ring gear.

DIAGNOSIS AND TESTING

STARTER

The starter motor incorporates several features to STARTING SYSTEM

create a reliable, efficient, compact, and lightweight For circuit descriptions and diagrams, refer to 8W-21

unit. A planetary gear system (intermediate trans- - Starting System in Group 8W - Wiring Diagrams.

mission) is used between the electric motor and the

pinion gear. This feature makes it possible to reduce WARNING: ON VEHICLES EQUIPPED WITH AIR-

the dimensions of the starter. At the same time, it BAGS, REFER TO GROUP 8M - PASSIVE RESTRAINT

allows higher armature rotational speed and delivers SYSTEMS BEFORE ATTEMPTING ANY STEERING

increased torque through the pinion gear to the WHEEL, STEERING COLUMN, OR INSTRUMENT

starter ring gear on the automatic transmission PANEL COMPONENT DIAGNOSIS OR SERVICE. FAIL-

torque converter or torque converter drive plate, or URE TO TAKE THE PROPER PRECAUTIONS COULD

on the manual transmission flywheel. RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

The use of a permanent magnet field also reduces AND POSSIBLE PERSONAL INJURY.

the size and weight of the starter. The permanent

TJ STARTING SYSTEMS 8B - 3

DIAGNOSIS AND TESTING (Continued)

INSPECTION Refer to the PDC label for relay identification and

Before removing any unit from the starting system location.

for repair or diagnosis, perform the following inspec- (6) Rotate and hold the ignition switch in the Start

tions: position. Note the cranking voltage and current

• Battery - Visually inspect the battery for indi- (amperage) draw.

cations of physical damage and loose or corroded (a) If the voltage reads below 9.6 volts, remove

cable connections. Determine the state-of-charge and the starter for bench testing. If the starter bench

cranking capacity of the battery. Charge or replace test is OK, refer to Group 9 - Engine for further

the battery, if required. Refer to Group 8A - Battery diagnosis of the engine. If the starter bench test is

for more information. not OK, replace the faulty starter.

• Ignition Switch - Visually inspect the ignition (b) If the voltage reads above 9.6 volts and the

switch for indications of physical damage and loose current (amperage) draw reads below specifica-

or corroded wire harness connections. tions, see the Feed Circuit Test procedures in this

• Clutch Pedal Position Switch - Visually group.

inspect the clutch pedal position switch for indica- (c) If the voltage reads 12.5 volts or greater and

tions of physical damage and loose or corroded wire the starter does not turn, see the Control Circuit

harness connections. Test procedures in this group.

• Park/Neutral Position Switch - Visually (d) If the voltage reads 12.5 volts or greater and

inspect the park/neutral position switch for indica- the starter turns very slowly, see the Feed Circuit

tions of physical damage and loose or corroded wire Test procedures in this group.

harness connections.

• Starter Relay - Visually inspect the starter NOTE: A cold engine will increase the starter cur-

relay for indications of physical damage and loose or rent (amperage) draw reading, and reduce the bat-

corroded wire harness connections. tery voltage reading.

• Starter - Visually inspect the starter for indica-

tions of physical damage and loose or corroded wire

harness connections. FEED CIRCUIT TEST

• Starter Solenoid - Visually inspect the starter The starter feed circuit test (voltage drop method)

solenoid for indications of physical damage and loose will determine if there is excessive resistance in the

or corroded wire harness connections. high-amperage circuit. For circuit descriptions and

• Wiring - Visually inspect the wire harness for diagrams, refer to 8W-21 - Starting System in Group

damage. Repair or replace any faulty wiring, as 8W - Wiring Diagrams.

required. When performing these tests, it is important to

remember that the voltage drop is giving an indica-

COLD CRANKING TEST tion of the resistance between the two points at

For circuit descriptions and diagrams, refer to which the voltmeter probes are attached.

8W-21 - Starting System in Group 8W - Wiring Dia- Example: When testing the resistance of the bat-

grams. The battery must be fully-charged and load- tery positive cable, touch the voltmeter leads to the

tested before proceeding. Refer to Group 8A - Battery battery positive cable clamp and the cable connector

for more information. at the starter solenoid. If you probe the battery pos-

(1) Connect a suitable volt-ampere tester to the itive terminal post and the cable connector at the

battery terminals (Fig. 1). Refer to the operating starter solenoid, you are reading the combined volt-

instructions provided with the tester being used. age drop in the battery positive cable clamp-to-termi-

(2) Fully engage the parking brake. nal post connection and the battery positive cable.

(3) If the vehicle is equipped with an automatic The following operation will require a voltmeter

transmission, place the gearshift selector lever in the accurate to 1/10 (0.10) volt. Before performing the

Park position. If the vehicle is equipped with a man- tests, be certain the following procedures are accom-

ual transmission, place the gearshift selector lever in plished:

the Neutral position and fully depress the clutch • Battery is fully-charged. Refer to Group 8A -

pedal. Battery for more information.

(4) Verify that all lamps and accessories are • Fully engage the parking brake.

turned off. • If the vehicle is equipped with an automatic

(5) To prevent the engine from starting, unplug transmission, place the gearshift selector lever in the

the Automatic ShutDown (ASD) relay. The ASD relay Park position. If the vehicle is equipped with a man-

is located in the Power Distribution Center (PDC). ual transmission, place the gearshift selector lever in

the Neutral position and fully depress the clutch

pedal.

8B - 4 STARTING SYSTEMS TJ

DIAGNOSIS AND TESTING (Continued)

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO ENGAGE. 1. Battery discharged or faulty. 1. Refer to Group 8A - Battery.

2. Starting circuit wiring faulty. Charge or replace battery, if

3. Starter relay faulty. required.

4. Ignition switch faulty. 2. See Cold Cranking Test, in this

5. Park/Neutral position switch (auto group. Test and repair feed and/or

trans) faulty or misadjusted. control circuits, if required.

6. Clutch pedal position switch (man 3. See Relay Test, in this group.

trans) faulty. Replace relay, if required.

7. Starter solenoid faulty. 4. See Ignition Switch Test, in this

8. Starter assembly faulty. group. Replace switch, if required.

5. See Park/Neutral Position Switch

Test, in this group. Replace switch, if

required.

6. See Clutch Pedal Position Switch

Test, in this group. Replace switch, if

required.

7. See Solenoid Test, in this Group.

Replace starter assembly, if

required.

8. If all other starting system

components and circuits check OK,

replace starter assembly.

STARTER ENGAGES, FAILS TO 1. Battery discharged or faulty. 1. Refer to Group 8A - Battery.

TURN ENGINE. 2. Starting circuit wiring faulty. Charge or replace battery, if

3. Starter assembly faulty. required.

4. Engine seized. 2. See Cold Cranking Test, in this

group. Test and repair feed and/or

control circuits, if required.

3. If all other starting system

components and circuits check OK,

replace starter assembly.

4. Refer to Group 9 - Engine, for

diagnostic and service procedures.

STARTER ENGAGES, SPINS 1. Broken teeth on starter ring gear. 1. Remove starter as described in

OUT BEFORE ENGINE STARTS. 2. Starter assembly faulty. this group. Inspect ring gear and

replace, if required.

2. If all other starting system

components and circuits check OK,

replace starter assembly.

STARTER DOES NOT 1. Starter improperly installed. 1. Install starter as described in this

DISENGAGE. 2. Starter relay faulty. group. Tighten starter mounting

3. Ignition switch faulty. hardware to correct torque

4. Starter assembly faulty. specifications.

2. See Relay Test, in this group.

Replace relay, if required.

3. See Ignition Switch Test, in this

group. Replace switch, if required.

4. If all other starting system

components and circuits check OK,

replace starter assembly.

TJ STARTING SYSTEMS 8B - 5

DIAGNOSIS AND TESTING (Continued)

Fig. 1 Volts-Amps Tester Connections - Typical

• Unplug the Automatic ShutDown (ASD) relay to Fig. 3 Test Battery Positive Connection Resistance -

prevent the engine from starting. The ASD relay is Typical

located in the Power Distribution Center (PDC). the ignition switch in the Start position. Observe the

Refer to the PDC label for ASD relay identification voltmeter. If the reading is above 0.2 volt, clean and

and location. tighten the battery cable connection at the solenoid.

(1) Connect the positive lead of the voltmeter to Repeat the test. If the reading is still above 0.2 volt,

the battery negative terminal post. Connect the neg- replace the faulty battery positive cable.

ative lead of the voltmeter to the battery negative

cable clamp (Fig. 2). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor contact between

the cable clamp and the terminal post.

Fig. 4 Test Battery Positive Cable Resistance -

Typical

(4) Connect the voltmeter to measure between the

battery negative terminal post and a good clean

ground on the engine block (Fig. 5). Rotate and hold

the ignition switch in the Start position. Observe the

Fig. 2 Test Battery Negative Connection Resistance voltmeter. If the reading is above 0.2 volt, clean and

- Typical tighten the battery negative cable attachment on the

(2) Connect the positive lead of the voltmeter to engine block. Repeat the test. If the reading is still

the battery positive terminal post. Connect the nega- above 0.2 volt, replace the faulty battery negative

tive lead of the voltmeter to the battery positive cable cable.

clamp (Fig. 3). Rotate and hold the ignition switch in (5) Connect the positive lead of the voltmeter to

the Start position. Observe the voltmeter. If voltage the starter housing. Connect the negative lead of the

is detected, correct the poor contact between the voltmeter to the battery negative terminal post (Fig.

cable clamp and the terminal post. 6). Rotate and hold the ignition switch in the Start

(3) Connect the voltmeter to measure between the position. Observe the voltmeter. If the reading is

battery positive terminal post and the starter sole- above 0.2 volt, correct the poor starter to engine

noid battery terminal stud (Fig. 4). Rotate and hold block ground contact.

8B - 6 STARTING SYSTEMS TJ

DIAGNOSIS AND TESTING (Continued)

(1) Remove the wire from the solenoid field coil

terminal.

(2) Check for continuity between the solenoid ter-

minal and field coil terminal with a continuity tester

(Fig. 7). There should be continuity. If OK, go to Step

3. If not OK, replace the faulty starter assembly.

Fig. 5 Test Ground Circuit Resistance - Typical Fig. 7 Continuity Test Between Solenoid Terminal

and Field Coil Terminal

(3) Check for continuity between the solenoid ter-

minal and the solenoid case (Fig. 8). There should be

continuity. If OK, go to Step 4. If not OK, replace the

faulty starter assembly.

Fig. 8 Continuity Test Between Solenoid Terminal

Fig. 6 Test Starter Ground - Typical and Solenoid Case

If the resistance tests detect no feed circuit prob- (4) Connect the solenoid field coil wire to the field

lems, remove the starter and see the Solenoid Test coil terminal.

procedure in this group. (5) Install the starter as described in this group.

CONTROL CIRCUIT TEST RELAY TEST

For circuit descriptions and diagrams, refer to The starter relay is located in the Power Distribu-

8W-21 - Starting System in Group 8W - Wiring Dia- tion Center (PDC) in the engine compartment. Refer

grams. The starter control circuit consists of: to the PDC label for relay identification and location.

• Battery Remove the starter relay from the PDC as

• Starter relay described in this group to perform the following tests:

• Starter solenoid (1) A relay in the de-energized position should

• Ignition switch have continuity between terminals 87A and 30, and

• Park/neutral position switch (automatic trans- no continuity between terminals 87 and 30. If OK, go

mission) to Step 2. If not OK, replace the faulty relay.

• Clutch pedal position switch (manual transmis- (2) Resistance between terminals 85 and 86 (elec-

sion) tromagnet) should be 75 6 5 ohms. If OK, go to Step

• Wire harness and connections. 3. If not OK, replace the faulty relay.

Test procedures for these components should be (3) Connect a battery to terminals 85 and 86.

performed in the order in which they are listed, as There should now be continuity between terminals

follows: 30 and 87, and no continuity between terminals 87A

and 30. If OK, see the Relay Circuit Test procedure

SOLENOID TEST in this group. If not OK, replace the faulty relay.

Remove the starter as described in this group.

Then proceed as follows:

TJ STARTING SYSTEMS 8B - 7

DIAGNOSIS AND TESTING (Continued)

vehicles with a manual transmission, it is grounded

at all times. Check for continuity to ground at the

cavity for relay terminal 85. If not OK with an auto-

matic transmission, check for an open or short circuit

to the park/neutral position switch and repair, if

required. If the circuit is OK, see the Park/Neutral

Position Switch Test procedure in this group. If not

OK with a manual transmission, repair the circuit to

ground as required.

PARK/NEUTRAL POSITION SWITCH TEST

(1) Place the transmission gear selector lever in

the Park position.

(2) Disconnect and isolate the battery negative

cable.

(3) Raise and support the vehicle.

Starter Relay (4) Unplug the park/neutral position switch wire

harness connector.

RELAY CIRCUIT TEST (5) Check for continuity between the center switch

(1) The relay common feed terminal cavity (30) is terminal and a good chassis ground. There should be

connected to battery voltage and should be hot at all continuity. If OK, go to Step 6. If not OK, replace the

times. If OK, go to Step 2. If not OK, repair the open faulty switch.

circuit to the PDC fuse as required. (6) Move the transmission gear selector to the

(2) The relay normally closed terminal (87A) is Reverse position and check for continuity between

connected to terminal 30 in the de-energized position, the center switch terminal and a good chassis

but is not used for this application. Go to Step 3. ground. There should be no continuity. If not OK,

(3) The relay normally open terminal (87) is con- replace the faulty switch.

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage CLUTCH PEDAL POSITION SWITCH TEST

to the starter solenoid field coils. There should be The clutch pedal position switch is integral to the

continuity between the cavity for relay terminal 87 clutch pedal pushrod. It is located near the dash

and the starter solenoid terminal at all times. If OK, panel under the instrument panel. The wire harness

go to Step 4. If not OK, repair the open circuit to the connector for the switch is wrapped with foam tape.

starter solenoid as required.

(4) The coil battery terminal (86) is connected to WARNING: ON VEHICLES EQUIPPED WITH AIR-

the electromagnet in the relay. It is energized when BAGS, REFER TO GROUP 8M - PASSIVE RESTRAINT

the ignition switch is held in the Start position. On SYSTEMS BEFORE ATTEMPTING ANY STEERING

vehicles with a manual transmission, the clutch WHEEL, STEERING COLUMN, OR INSTRUMENT

pedal must be fully depressed for this test. Check for PANEL COMPONENT DIAGNOSIS OR SERVICE. FAIL-

battery voltage at the cavity for relay terminal 86 URE TO TAKE THE PROPER PRECAUTIONS COULD

with the ignition switch in the Start position, and no RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

voltage when the ignition switch is released to the AND POSSIBLE PERSONAL INJURY.

On position. If OK, go to Step 5. If not OK with an

automatic transmission, check for an open or short (1) Disconnect and isolate the battery negative

circuit to the ignition switch and repair, if required. cable.

If the circuit to the ignition switch is OK, see the (2) Unplug the clutch pedal position switch wire

Ignition Switch Test procedure in this group. If not harness connector.

OK with a manual transmission, check the circuit (3) Check for continuity between the two cavities

between the relay and the clutch pedal position in the switch-half of the wire harness connector with

switch for an open or a short. If the circuit is OK, see the clutch pedal released. There should be no conti-

the Clutch Pedal Position Switch Test procedure in nuity. If OK, go to Step 4. If not OK, replace the

this group. faulty switch.

(5) The coil ground terminal (85) is connected to (4) Check for continuity between the two cavities in

the electromagnet in the relay. On vehicles with an the switch-half of the wire harness connector again with

automatic transmission, it is grounded through the the clutch pedal depressed. There should now be conti-

park/neutral position switch only when the gearshift nuity. If OK, see the Ignition Switch Test procedure in

selector lever is in the Park or Neutral positions. On this group. If not OK, replace the faulty switch.

8B - 8 STARTING SYSTEMS TJ

DIAGNOSIS AND TESTING (Continued)

IGNITION SWITCH TEST chart, correction can be made by shimming the

starter using the following procedures:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE CAUTION: Disconnect the battery negative cable to

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY prevent the engine from starting.

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR (1) If the complaint is similar to Condition 1, the

SERVICE. FAILURE TO TAKE THE PROPER PRE- starter must be moved toward the starter ring gear

CAUTIONS COULD RESULT IN ACCIDENTAL AIR- by removing shims (Fig. 10).

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY. NOTE: The shim thickness is 0.381 mm (0.015 in.),

and the shims may be stacked if additional thick-

(1) Disconnect and isolate the battery negative ness is required.

cable.

(2) Remove the steering column shrouds and

unplug the ignition switch wire harness connector.

Refer to Group 8D - Ignition Systems for the proce-

dures.

(3) With the ignition switch in the On position,

check for continuity between the ignition switch

fused B(+) circuit terminal and the ignition switch

output (start) circuit terminal. There should be no

continuity. If OK, go to Step 4. If not OK, replace the

faulty switch.

(4) With the ignition switch held in the Start posi-

tion, check for continuity between the ignition switch

fused B(+) circuit terminal and the ignition switch

output (start) circuit terminal. There should now be

continuity. If not OK, replace the faulty switch.

Fig. 10 Starter Shim

STARTER NOISE - 2.5L ENGINE

See the Starter Noise Diagnosis chart (Fig. 9). If (2) If the complaint is similar to Condition 2, the

the complaint is similar to Conditions 1 and 2 in the starter must be moved away from the starter ring

gear. This is done by installing shim(s) across both

Fig. 9 Starter Noise Diagnosis

TJ STARTING SYSTEMS 8B - 9

DIAGNOSIS AND TESTING (Continued)

starter mounting pads. More than one shim may be NOTE: Shim thickness available is 0.381 mm (0.015

required. in.). See Starter Noise - 2.5L Engine in this group

for more information.

NOTE: This is a condition that will generally cause

broken starter (flywheel/drive plate) ring gear teeth (5) Reverse the removal procedures to install.

or broken starter housings. Tighten the starter hardware as follows:

• Mounting screws - 45 N·m (33 ft. lbs.)

• Solenoid battery cable nut - 10 N·m (90 in. lbs.)

• Solenoid terminal nut - 6 N·m (55 in. lbs.).

REMOVAL AND INSTALLATION

4.0L ENGINE

STARTER (1) Disconnect and isolate the battery negative

cable.

2.5L ENGINE

(2) Raise and support the vehicle.

(1) Disconnect and isolate the battery negative

(3) Disconnect the battery cable and solenoid feed

cable.

wire from the starter solenoid (Fig. 12).

(2) Raise and support the vehicle.

(3) Disconnect the battery cable and solenoid feed

wire from the starter solenoid (Fig. 11).

Fig. 12 Starter Remove/Install - 4.0L Engine

(4) Remove the lower starter mounting screw.

Fig. 11 Starter Remove/Install - 2.5L Engine (5) Remove the upper starter mounting screw and

the starter motor.

(4) Remove the two starter mounting screws, the

(6) Reverse the removal procedures to install.

starter motor, and any starter motor shims.

Tighten the starter hardware as follows:

• Upper mounting screw (rear screw) - 55 N·m (40

ft. lbs.)

• Lower mounting screw (front screw) - 41 N·m

(30 ft. lbs.)

• Solenoid battery cable nut - 10 N·m (90 in. lbs.)

• Solenoid terminal nut - 6 N·m (55 in. lbs.).

8B - 10 STARTING SYSTEMS TJ

REMOVAL AND INSTALLATION (Continued)

STARTER RELAY SPECIFICATIONS

(1) Disconnect and isolate the battery negative

cable. STARTING SYSTEM

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 13). Starter and Solenoid

Manufacturer Mitsubishi

Engine Application 2.5L, 4.0L

Power Rating 1.2 Kilowatt - 2.5L

1.4 Kilowatt - 4.0L

Voltage 12 Volts

Number of Fields 4

Number of Poles 4

Number of Brushes 4

Drive Type Planetary Gear Reduction

Free Running Test 11.2 Volts

Voltage

Free Running Test 90 Amperes

Maximum Amperage

Draw

Free Running Test 2600 rpm - 2.5L

Minimum Speed 2500 rpm - 4.0L

Fig. 13 Power Distribution Center Solenoid Closing 7.8 Volts

Maximum Voltage

(3) Refer to the label on the PDC for starter relay

identification and location. *Cranking Amperage 130 Amperes - 2.5L

(4) Unplug the starter relay from the PDC. Draw Test 160 Amperes - 4.0L

(5) Install the starter relay by aligning the relay * Test at operating temperature. Cold engine, tight

terminals with the cavities in the PDC and pushing (new) engine, or heavy oil will increase starter

the relay firmly into place. amperage draw.

(6) Install the PDC cover.

(7) Connect the battery negative cable.

(8) Test the relay operation.

Potrebbero piacerti anche

- 98DN - 8B Starting SystemsDocumento8 pagine98DN - 8B Starting SystemsylescorNessuna valutazione finora

- 1999 Jeep TJ Wrangler Service Manual - 08. Electrical SystemsDocumento434 pagine1999 Jeep TJ Wrangler Service Manual - 08. Electrical Systemsbfranklin3390% (10)

- Starting Systems: Description and Operation Starting SystemDocumento14 pagineStarting Systems: Description and Operation Starting SystemLiliana Rebeca Santos santosNessuna valutazione finora

- WJ - 00 - 08B - Starting SystemDocumento12 pagineWJ - 00 - 08B - Starting SystemCesar BartzNessuna valutazione finora

- ZG Starting Systems 8B - 1Documento14 pagineZG Starting Systems 8B - 1ensmartisNessuna valutazione finora

- Eja 8CDocumento14 pagineEja 8CLuis Oswaldo Roa PerezNessuna valutazione finora

- ZJ Starting Systems 8B - 1Documento10 pagineZJ Starting Systems 8B - 1Dalton WiseNessuna valutazione finora

- PL Starting 8B - 1Documento8 paginePL Starting 8B - 1Pelis CloneNessuna valutazione finora

- PL Charging System 8C - 1Documento12 paginePL Charging System 8C - 1Pelis CloneNessuna valutazione finora

- Chime Buzzer Warning SystemsDocumento4 pagineChime Buzzer Warning SystemsArt DoeNessuna valutazione finora

- ZG Charging System 8C - 1Documento10 pagineZG Charging System 8C - 1ensmartisNessuna valutazione finora

- 303-06 Starting System - Diagnosis and Testing - Starting SystemDocumento22 pagine303-06 Starting System - Diagnosis and Testing - Starting SystemCARLOS LIMADANessuna valutazione finora

- Gen Set Replacement Control Panel MODEL 540: Installation - Operation ManualDocumento13 pagineGen Set Replacement Control Panel MODEL 540: Installation - Operation ManualBrianHazeNessuna valutazione finora

- Chrysler AS Town Country Caravan Voyager 1994 Service Manual Electrical PDFDocumento438 pagineChrysler AS Town Country Caravan Voyager 1994 Service Manual Electrical PDFİsmail Erçay PehlivanNessuna valutazione finora

- 6-06 Starting SystemDocumento23 pagine6-06 Starting SystemJ.A.G.ANessuna valutazione finora

- Electrical: Group GroupDocumento24 pagineElectrical: Group GroupderekrichnerNessuna valutazione finora

- SSV 2018 (Charging) Defender XMR Suppl 219100939-015 enDocumento6 pagineSSV 2018 (Charging) Defender XMR Suppl 219100939-015 enAlex CachuNessuna valutazione finora

- 90-879172243 - 4c - Sistema ElectricoDocumento14 pagine90-879172243 - 4c - Sistema ElectricoJorge SoberanoNessuna valutazione finora

- ZG Charging System 8C - 1Documento8 pagineZG Charging System 8C - 1Dalton WiseNessuna valutazione finora

- 94XJ 8A ElectricalDocumento20 pagine94XJ 8A ElectricalFurRelKTNessuna valutazione finora

- FR 60003Documento11 pagineFR 60003Geovany Melvin SolorzanoNessuna valutazione finora

- Generator & RegulatorDocumento132 pagineGenerator & Regulatordima65Nessuna valutazione finora

- Stearns SINPAC Catalog 2 2023Documento24 pagineStearns SINPAC Catalog 2 2023Eddy SanchezNessuna valutazione finora

- Speed Control SystemDocumento8 pagineSpeed Control SystemDalton WiseNessuna valutazione finora

- 93ZJ Secc 8D Ignition SystemsDocumento40 pagine93ZJ Secc 8D Ignition Systemshelgith74Nessuna valutazione finora

- Horn SystemsDocumento4 pagineHorn SystemsArt DoeNessuna valutazione finora

- ChassisElectrical PDFDocumento111 pagineChassisElectrical PDFDhany SiregarNessuna valutazione finora

- SINPACDocumento32 pagineSINPACFV AllanNessuna valutazione finora

- Description and Operation Charging SystemDocumento6 pagineDescription and Operation Charging SystemMike KrothNessuna valutazione finora

- El - SRP - STP 550 Up To 4500Documento44 pagineEl - SRP - STP 550 Up To 4500waleedyehiaNessuna valutazione finora

- Tracer An Sms El v1.0Documento44 pagineTracer An Sms El v1.0Jason KettleNessuna valutazione finora

- 00DN 8C PDFDocumento6 pagine00DN 8C PDFJuggling CirkusNessuna valutazione finora

- Superseder Ii A-V Operator Manua Rev.3.01 26-Jul-1996Documento47 pagineSuperseder Ii A-V Operator Manua Rev.3.01 26-Jul-1996Roman DNessuna valutazione finora

- ASM720A-002: Data & Application NotesDocumento4 pagineASM720A-002: Data & Application Notesdargom salamanNessuna valutazione finora

- Lichtmaschine BoschDocumento23 pagineLichtmaschine BoschJames PonzoNessuna valutazione finora

- Start TestDocumento2 pagineStart Testhelp3rNessuna valutazione finora

- ZJ Charging System 8C - 1Documento8 pagineZJ Charging System 8C - 1Dalton WiseNessuna valutazione finora

- WJ - 00 - 08C - Charging SystemDocumento5 pagineWJ - 00 - 08C - Charging SystemCesar BartzNessuna valutazione finora

- SM - 5 Jeep ElectricoDocumento32 pagineSM - 5 Jeep Electricoedgar danielNessuna valutazione finora

- Challeger Testeo y AjusteDocumento304 pagineChalleger Testeo y AjusteCarlos Irabedra100% (1)

- Chrysler Dakota Part7Documento24 pagineChrysler Dakota Part7Sašo Brunšek-BrunoNessuna valutazione finora

- Charging System Troubleshooting (1406) : Instrucción EspecialDocumento16 pagineCharging System Troubleshooting (1406) : Instrucción EspecialMiguel GutierrezNessuna valutazione finora

- Description and Operation Charging SystemDocumento6 pagineDescription and Operation Charging Systemthomas rulduNessuna valutazione finora

- Grand Cherokee WJ 2000Documento14 pagineGrand Cherokee WJ 2000العقار امين عيسىNessuna valutazione finora

- 08G - Horn SystemsDocumento6 pagine08G - Horn SystemsEinar OftebroNessuna valutazione finora

- RR trts-0070Documento100 pagineRR trts-0070Jose Alanis100% (1)

- Fuller Heavy Duty Transmissions TRTS0020 EN-US: Troubleshooting GuideDocumento194 pagineFuller Heavy Duty Transmissions TRTS0020 EN-US: Troubleshooting GuideLuis MedinaNessuna valutazione finora

- Longer Motor Life Starts With A Switch: Brief Operating DescriptionDocumento25 pagineLonger Motor Life Starts With A Switch: Brief Operating DescriptionAndreNessuna valutazione finora

- Oly Changeover SystemsDocumento5 pagineOly Changeover SystemsCandiano PopescuNessuna valutazione finora

- Diagrama Del Sistema Electrico de Carga Grand Cherokee Laredo 95Documento22 pagineDiagrama Del Sistema Electrico de Carga Grand Cherokee Laredo 95ALONSO GONZALEZ DURANNessuna valutazione finora

- 2006-2008-Cbf1000-A-19 Ignition SystemDocumento8 pagine2006-2008-Cbf1000-A-19 Ignition Systemdrkrassas100% (1)

- Null 5Documento23 pagineNull 5Sergio DolmusNessuna valutazione finora

- Transmission AW30-40LE ModelDocumento266 pagineTransmission AW30-40LE ModelIRAKLI DVALADZE50% (2)

- Automotive Electronic Diagnostics (Course 2)Da EverandAutomotive Electronic Diagnostics (Course 2)Valutazione: 4 su 5 stelle4/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Da EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Nessuna valutazione finora

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorDa EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNessuna valutazione finora

- Switching in Electrical Transmission and Distribution SystemsDa EverandSwitching in Electrical Transmission and Distribution SystemsNessuna valutazione finora

- Turn Signal and Hazard Warning SystemsDocumento6 pagineTurn Signal and Hazard Warning SystemsArt DoeNessuna valutazione finora

- SteeringDocumento34 pagineSteeringArt DoeNessuna valutazione finora

- Vehicle Theft and Security SystemsDocumento6 pagineVehicle Theft and Security SystemsArt DoeNessuna valutazione finora

- Wiper and Washer SystemsDocumento14 pagineWiper and Washer SystemsArt DoeNessuna valutazione finora

- SuspensionDocumento16 pagineSuspensionArt Doe100% (1)

- Lubrication and MaintenanceDocumento12 pagineLubrication and MaintenanceArt DoeNessuna valutazione finora

- Passive Restraint SystemsDocumento12 paginePassive Restraint SystemsArt DoeNessuna valutazione finora

- Electrically Heated SystemsDocumento6 pagineElectrically Heated SystemsArt DoeNessuna valutazione finora

- TJ Starting Systems 8B - 1Documento10 pagineTJ Starting Systems 8B - 1Art DoeNessuna valutazione finora

- Lamps 1Documento12 pagineLamps 1Art DoeNessuna valutazione finora

- Lamps: Lamp DiagnosisDocumento16 pagineLamps: Lamp DiagnosisArt DoeNessuna valutazione finora

- Instrument Panel SystemsDocumento30 pagineInstrument Panel SystemsArt DoeNessuna valutazione finora

- Vehicle Identification Number Decoding Chart: Position Interpretation Code DescriptionDocumento10 pagineVehicle Identification Number Decoding Chart: Position Interpretation Code DescriptionArt DoeNessuna valutazione finora

- Frame and Bumpers 1Documento2 pagineFrame and Bumpers 1Art DoeNessuna valutazione finora

- Horn SystemsDocumento4 pagineHorn SystemsArt DoeNessuna valutazione finora

- Emisipn Control SystemsDocumento4 pagineEmisipn Control SystemsArt Doe100% (1)

- Frame and BumpersDocumento14 pagineFrame and BumpersArt DoeNessuna valutazione finora

- ClutchDocumento14 pagineClutchArt DoeNessuna valutazione finora

- Wiring DiagramsDocumento246 pagineWiring DiagramsArt DoeNessuna valutazione finora

- Cooling SystemDocumento32 pagineCooling SystemArt DoeNessuna valutazione finora

- SuspensionDocumento16 pagineSuspensionArt Doe100% (1)

- Lamps: Lamp DiagnosisDocumento16 pagineLamps: Lamp DiagnosisArt DoeNessuna valutazione finora

- Wiring DiagramsDocumento246 pagineWiring DiagramsArt DoeNessuna valutazione finora

- Chime Buzzer Warning SystemsDocumento4 pagineChime Buzzer Warning SystemsArt DoeNessuna valutazione finora

- Charging SystemDocumento8 pagineCharging SystemArt DoeNessuna valutazione finora

- Lubrication and MaintenanceDocumento12 pagineLubrication and MaintenanceArt DoeNessuna valutazione finora

- SteeringDocumento34 pagineSteeringArt DoeNessuna valutazione finora

- Tires and WheelsDocumento10 pagineTires and WheelsArt DoeNessuna valutazione finora

- Wiper and Washer SystemsDocumento14 pagineWiper and Washer SystemsArt DoeNessuna valutazione finora

- Vehicle Identification Number Decoding Chart: Position Interpretation Code DescriptionDocumento10 pagineVehicle Identification Number Decoding Chart: Position Interpretation Code DescriptionArt DoeNessuna valutazione finora