Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automation in Machines

Caricato da

kathirvelus9408Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Automation in Machines

Caricato da

kathirvelus9408Copyright:

Formati disponibili

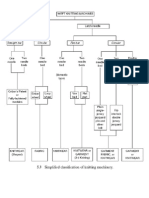

Automation on Ring Frame

2. Drive to Drafting Rollers Conventional System

Conventional System, all gear drive Many gears to be changed for changing the count / twist. Time consuming process. Multiple types of yarns can be produced but needs additional mechanisms attached. Increased need for regular maintenance & repairs. Inventory of parts.

Automation on Ring Frame

2. Drive to Drafting Rollers Alternative System Electrodraft System

Fr Roller(LH) Md Motor Bk Motor Fr Motor GE Md Roller(LH) Bk Roller(LH) Bk Roller(RH) Md Roller(RH) Fr Roller(RH) Fr Control Md Control Bk Control OE Md Motor

Automation on Ring Frame

2. Drive to Drafting Rollers Alternative System Electrodraft System Innovative proposed E-Drafting system

Display 330 ~ 480V AC, 3Ph, 50Hz +/-5%, THD (V) <5% DC 300V ~ 850V

= =

DC 24V

PLC (32 DI+16 RO / DO)

COMMUNICATION BUS 98KW

~ =

Pressure Transducer 0~2500 Pa (-ve)

Main Inverter

55/75KW

`

4~20mA

2.2KW

2.2KW

SVC

~ SVC

7.5KW

= ~

SVC

4KW

= ~

SVC

4KW

4 K KW

~ SVC

~ SVC

SVC

M1 55KW

M2 1.5KW

M3 1.5KW

M4 7.5KW

M5 1.5KW

M6 1.5KW

M7 1.5KW

M8 1.5KW

M8 M9 1.5KW

M10 1.5KW

Main Motor Doffing Motor LIFTING GEAR BOX-1 Position feedback

Pneuma Motor

Synchronise GEAR BOX-2 GEAR BOX-3 GEAR BOX-4

Synchronise GEAR BOX-5 GEAR BOX-6 BOX

Synch

GEAR BOX-7 Back Roller Drive

Front Roller Drive

Front Roller Drive

Mid. Roller Drive

Mid. Roller Drive

Back Roller Drive

Lifting Drive

During power failure synchronised stop for M1, M2, M4 ~ M10 required

To achieve synchronized stopping of lifting and drafting Motors along with Main Motor by using Kinetic Energy available in the machine.

Automation on Ring Frame

2. Drive to Drafting Rollers Alternative System Electrodraft System

All rollers driven by individual motors, controlled by individual drives. Possible to alter draft and twist from the key pad. Fine tuning of twist & draft adjustments possible. Possible to manufacture fashion yarn like multi twist , multi count , slub yarn. Interfacing & drive communication through Profibus and other types of protocols makes controls simple and very accurate.

Automation on Ring Frame

3. Pneumafil - Suction Pressure Monitoring System Present System : - Pneuma motor works at fixed rpm. - Suction values achieved is fixed and has no relation to the material or count being processed. Alternate System

Pneumafil motor is controlled by inverter. Suction pressure can be set in inverter. This is constantly monitored by pressure transducer. Suction pressure can be set in relation to spindleage of the machine, count, and raw material being processed. Reduces power consumption

Case Study : Saving of about 1.2 units per hour

3, 415V AC Motor

Inverter 7.5KW

Feedback (0~4.5V DC) Pressure Transducer

Exhaust Air Suction Pressure Monitoring Tube

Automation on Ring Frame

4. Automatic Doffer

Automatic Doffer system is now gaining customer acceptance. Reduced manpower requirement. Increase machine productivity. Reduce need for supervision. Increase life of components and accessories like spindle & bobbins.

Automation on Ring Frame

5. Link Coner System

Automatic Cop Transfer from Ring Frame to Winder. Possible to implement spin identification system. ( on line quality monitoring & identifying the spindle producing inferior quality yarn). No mix up of different counts. No deterioration of yarn quality due to manual handling.

Automation on Ring Frame

6. Automatic Roving Transfer

Automatic Transfer of Roving Bobbins from Roving Frame to Ring Frame. No deterioration in Roving quality due to storage and handling. Better yarn quality.

Automation on Ring Frame

7. Automatic Data Acquisition :

All machines are connected to a Central Computer. Two way communication between the Computer and Machine can be established. Possible to change the speed parameters from the Computer. On line monitoring of the machine status. Data acquired can be converted to production report. No need to manually record the production information from the machine.

Automation on Ring Frame

8. Automatic Breakage Control

Machine can be interfaced with the Ring Data System. Spindle speed can be automatically increased / reduced depending on the yarn breakage level

Automation on Ring Frame

9. Machine Brake

Brake is required on Ring Frame to prevent snarl formation while stopping the machine. Conventional system uses electro magnetic or mechanical brakes. Alternate system DC Injection brake from main inverter. Optimum braking time by varying the parameters. Elimination of all mechanical parts which require frequent resetting.

Automation on Ring Frame

Dream of all Machinery Manufacturers . AUTOMATIC YARN PIECING AT RING FRAMES

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Piccolo: Operating and Maintenance Instructions For The Deck OvenDocumento44 paginePiccolo: Operating and Maintenance Instructions For The Deck OvenAdam B100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Seamless Garment KnittingDocumento32 pagineSeamless Garment Knittingkathirvelus9408Nessuna valutazione finora

- The Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyDocumento6 pagineThe Danieli Danarc Plus M Furnace at Abs Meltshop: Aldo A. Fior Danieli C M - Process Engineer Buttrio, ItalyBrandon CoxNessuna valutazione finora

- Guide to Cross-Subject Area ReportsDocumento19 pagineGuide to Cross-Subject Area Reportssatyanarayana NVSNessuna valutazione finora

- Introspective Hypnosis Class - 052017 - Antonio Sangio (2745)Documento62 pagineIntrospective Hypnosis Class - 052017 - Antonio Sangio (2745)sandra100% (4)

- PreviewpdfDocumento50 paginePreviewpdfMarcosGouvea100% (1)

- Chapter 10 TestDocumento7 pagineChapter 10 Testapi-348969276Nessuna valutazione finora

- EiTEX- BAHIR DAR UNIVERSITY COSTING QUIZDocumento2 pagineEiTEX- BAHIR DAR UNIVERSITY COSTING QUIZKathirrveluSubramainanNessuna valutazione finora

- 2012 Bamboo Fibre Processing Insights Into Hemicellulase and Cellulase Substrate AccessibilityDocumento11 pagine2012 Bamboo Fibre Processing Insights Into Hemicellulase and Cellulase Substrate Accessibilitykathirvelus9408Nessuna valutazione finora

- TKFM-Quiz 1Documento1 paginaTKFM-Quiz 1kathirvelus9408Nessuna valutazione finora

- Eitex: Very ShortDocumento4 pagineEitex: Very Shortkathirvelus9408Nessuna valutazione finora

- Topic 2 Shedding MechanismsDocumento28 pagineTopic 2 Shedding Mechanismskathirvelus9408Nessuna valutazione finora

- Zaxet enDocumento12 pagineZaxet enkathirvelus9408Nessuna valutazione finora

- Weft Knitting: Prof - Dr.S.Kathirrvelu EitexDocumento17 pagineWeft Knitting: Prof - Dr.S.Kathirrvelu Eitexkathirvelus9408Nessuna valutazione finora

- Weft Knitting: Prof - Dr.S.Kathirrvelu EitexDocumento17 pagineWeft Knitting: Prof - Dr.S.Kathirrvelu Eitexkathirvelus9408Nessuna valutazione finora

- Production of Knitted Fabrics & Clothes ProfileDocumento16 pagineProduction of Knitted Fabrics & Clothes Profilekathirvelus9408Nessuna valutazione finora

- 01-Quality Parameters Analysis of Ring Spun Yarns - June2012Documento12 pagine01-Quality Parameters Analysis of Ring Spun Yarns - June2012Qasim Ahmad Mir100% (1)

- Ajtar DraftDocumento8 pagineAjtar Draftkathirvelus9408Nessuna valutazione finora

- Blowroom&CardingDocumento19 pagineBlowroom&Cardingkathirvelus9408100% (2)

- 02 ChellamaniDocumento5 pagine02 Chellamanikathirvelus9408Nessuna valutazione finora

- An Introducation To SilkDocumento5 pagineAn Introducation To Silkkathirvelus9408Nessuna valutazione finora

- 1 PBDocumento12 pagine1 PBkathirvelus9408Nessuna valutazione finora

- Automation in Ring Spinning Machines-KTTMDocumento24 pagineAutomation in Ring Spinning Machines-KTTMkathirvelus94080% (1)

- Weft KMDocumento2 pagineWeft KMkathirvelus9408Nessuna valutazione finora

- Automation in Ring Spinning Machines-KTTMDocumento24 pagineAutomation in Ring Spinning Machines-KTTMkathirvelus94080% (1)

- Knitting Elements 1Documento10 pagineKnitting Elements 1kathirvelus9408Nessuna valutazione finora

- 283 The Bamboo Industry in India Aniket Baksy1Documento48 pagine283 The Bamboo Industry in India Aniket Baksy1Mesquite IceNessuna valutazione finora

- WarpDocumento1 paginaWarpkathirvelus9408Nessuna valutazione finora

- Loops of Knitting: Dr.S.KathirrveluDocumento10 pagineLoops of Knitting: Dr.S.Kathirrvelukathirvelus9408Nessuna valutazione finora

- IND Textile Finishing Toolbox BrochureDocumento8 pagineIND Textile Finishing Toolbox Brochurekathirvelus9408Nessuna valutazione finora

- Automation SpinningDocumento12 pagineAutomation Spinningkathirvelus9408Nessuna valutazione finora

- Assignment Applications in TextilesDocumento1 paginaAssignment Applications in Textileskathirvelus9408Nessuna valutazione finora

- Assignment Applications in TextilesDocumento1 paginaAssignment Applications in Textileskathirvelus9408Nessuna valutazione finora

- The Knitting Compendium 3Documento22 pagineThe Knitting Compendium 3kathirvelus9408Nessuna valutazione finora

- Assignment Applications in TextilesDocumento1 paginaAssignment Applications in Textileskathirvelus9408Nessuna valutazione finora

- CASE ANALYSIS: DMX Manufacturing: Property of STIDocumento3 pagineCASE ANALYSIS: DMX Manufacturing: Property of STICarmela CaloNessuna valutazione finora

- Kamran Afzal ResumeDocumento2 pagineKamran Afzal ResumeChelsea ElizabethNessuna valutazione finora

- 5054 s09 QP 1Documento20 pagine5054 s09 QP 1Hany ElGezawyNessuna valutazione finora

- A 18-Page Statistics & Data Science Cheat SheetsDocumento18 pagineA 18-Page Statistics & Data Science Cheat SheetsAniket AggarwalNessuna valutazione finora

- Philips 170v7fbDocumento95 paginePhilips 170v7fbaposticaaNessuna valutazione finora

- Memory Slim CBLT PDFDocumento4 pagineMemory Slim CBLT PDFMichell ben ManikNessuna valutazione finora

- Operator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDocumento6 pagineOperator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDecoNessuna valutazione finora

- Positive Leadership and Adding Value - A Lifelong Journey: June 2017Documento7 paginePositive Leadership and Adding Value - A Lifelong Journey: June 2017CescSalinasNessuna valutazione finora

- Mathematics 10 Performance Task 1Documento2 pagineMathematics 10 Performance Task 1SnowNessuna valutazione finora

- Adruino LCD, Test CodeDocumento20 pagineAdruino LCD, Test CodeDaniel Evans100% (1)

- Flaechendicht k435 de 0216 0 Eng ScreenDocumento2 pagineFlaechendicht k435 de 0216 0 Eng ScreenAlexandru IonescuNessuna valutazione finora

- Writing and Reporting For The Media Workbook 12Th Edition Full ChapterDocumento32 pagineWriting and Reporting For The Media Workbook 12Th Edition Full Chapterdorothy.todd224100% (23)

- Course Material For Module 3Documento11 pagineCourse Material For Module 3Noble VargheseNessuna valutazione finora

- Air CasterDocumento25 pagineAir CasterPrabir Kumar Pati100% (1)

- VSP BrochureDocumento33 pagineVSP BrochuresudhakarrrrrrNessuna valutazione finora

- 2017 NEC Table of ContentsDocumento124 pagine2017 NEC Table of ContentsFaheem PP13Nessuna valutazione finora

- The Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, HopelessDocumento5 pagineThe Reference Frame - Nice Try But I Am Now 99% Confident That Atiyah's Proof of RH Is Wrong, Hopelesssurjit4123Nessuna valutazione finora

- Properties of Skeletal MuscleDocumento72 pagineProperties of Skeletal MuscleAakash GohilNessuna valutazione finora

- Earthquake Faults and Tectonic Plate Boundaries ExplainedDocumento21 pagineEarthquake Faults and Tectonic Plate Boundaries ExplainedAngelo RemeticadoNessuna valutazione finora

- QO™ Load Centers - QO124M200PDocumento4 pagineQO™ Load Centers - QO124M200PIsraelNessuna valutazione finora

- BS EN 50131-1998 Alarm Systems Intrusion Systems Part 6Documento30 pagineBS EN 50131-1998 Alarm Systems Intrusion Systems Part 6Michael Camit EsoNessuna valutazione finora

- The Art of Grooming - 230301 - 222106Documento61 pagineThe Art of Grooming - 230301 - 222106ConstantinNessuna valutazione finora

- DHP UM 015 IHP24 HART User ManualDocumento70 pagineDHP UM 015 IHP24 HART User Manualkumar ambujNessuna valutazione finora

- t640 - Parts CatalogDocumento69 paginet640 - Parts CatalogSattittecInfomáticaNessuna valutazione finora