Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

94% Process Audit Checklist

Caricato da

Ashutosh SinghDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

94% Process Audit Checklist

Caricato da

Ashutosh SinghCopyright:

Formati disponibili

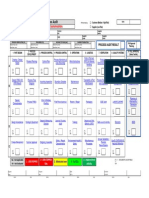

Process Audit Checklist

Process Audited: Process Owner:

Total Audit Points: Audit Summary: 101 Total Possible Points: 108

Date: Auditor: Audit Summary and Corrective Action

Percent: 94%

Overall result of the process audit for Grinding was good. In some places, improvement may be done while some parts required immediate attention and improvement. The document control section and the adherence of process to the control plan etc was the strongest portion of the audit whereas improvement is required quickly at some places.

Major / Minor NC, Objective Evidence & Corrective Action Required (if any):

1) Statement of Non Conformity: The Process of calibration was not effective in sampled case. 2) Objective Evidence: Calibration report of outside micrometer MC-198 was not evidenced in sample case.

GENERAL SCORING CRITERIA Rating Does Not Apply Does Not Comply 2 Needs Improvement 3 Score NA 1 Ability to meet requirement in question: Requirement is not applicable. Requirement is not met or partially met. There is no evidence of implementation or documentation, or major inconsistencies in implementation or documentation (major non-conformance). Requirement is met but there are minor inconsistencies in implementation or documentation, or is in the early phases and only preliminary evidence of implementation effectiveness exists. Requirement is met, effectively implemented, and fully documented. Corrective Action No action required Requires Corrective Action (CA)

Opportunity for Improvement.

Complies

No action required

Process Verification Audit Checklist

Part Number: Machine Number:

A.

Sr. No.

1 2 a 3 b 4 5

Document Control

Question

Is the part print to the current Revision Level? Are the Control Plan documents being used up-to-date? Do the process control documents adequately address all process parameters? Are the Process Key Characteristics known, visible, and is there a documented control plan to continuously monitor the process control and capability? Are the Process flow diagrams, PFMEAs, Control Plan are controlled and up-to-date? Are other pertinent process control documents up-to-date? (Examples: process sheets, inspection and test instructions, standard operating procedures) 3 3 3 3 3 3

Score

3 3 3 3 3 3

B.

a 6 b

Process Control

Is the Control Plan applied at each operation and being followed? Is the frequency of inspection being performed as described in the Control Plan? 3 2 2 3

6 c 7 8 Plan?

Process Audit Checklist

Are the inspection method and equipment being used as described in the Control Process Audited: Is inspection data retained and stored appropriately? Are operators properly trained to perform their operations?

Date: 3

3 2

3 3 2

C.

9 10 11 12 13

Tools/Gages

Is there an understanding of which tools/gages are needed for each operation, and are the needed tools/gages at the work station? Does the operator understand the proper use of the tools/gages and is he using them properly? Is equipment, including tooling, properly maintained? Are all the gages calibrated and records retained? Do Gage R&R studies have acceptable results? 3 3 2 3 3 3 3 3 1 3

D.

14 15

Corrective Action

Is the Reaction Plan listed on the Control Plan effective & being followed? Is there an adequate process for isolation & control of non-conforming material & is it being followed? 3 3 3 3

E.

Scoring Summary Total Points 108 Maximum Points Possible 51 94% 50 93%

Percent of Total Points Available (NA questions are excluded.)

Potrebbero piacerti anche

- Manufacturing Process Audit ChecklistDocumento4 pagineManufacturing Process Audit Checklistgksp100% (4)

- Manufacturing Process Audit Checklist: Reference DocumentsDocumento4 pagineManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Process Audit Check ListDocumento47 pagineProcess Audit Check ListAnas NazriNessuna valutazione finora

- Customer-focused quality processesDocumento8 pagineCustomer-focused quality processesSathyaprakash HsNessuna valutazione finora

- 03 (SQ) - Process Product Audit ReportDocumento2 pagine03 (SQ) - Process Product Audit ReportDEVENDERNessuna valutazione finora

- IATF 16949 Project Manager's GuideDocumento12 pagineIATF 16949 Project Manager's GuideJOECOOL67Nessuna valutazione finora

- Manufacturing Process Audit ScorecardDocumento1 paginaManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- Process Audit Check Sheet Cum ReportDocumento4 pagineProcess Audit Check Sheet Cum ReportLakshmanan Venkatesan100% (2)

- 4th Edition PPAPDocumento83 pagine4th Edition PPAPTerri Paleno Lebow100% (1)

- ISO IATF 16949 Gap Tool b70944Documento216 pagineISO IATF 16949 Gap Tool b70944SudhagarNessuna valutazione finora

- Process AuditDocumento15 pagineProcess Auditdesurkarb100% (2)

- Process Map - Unitwise Process LinkagesDocumento1 paginaProcess Map - Unitwise Process LinkagesSachin RamdurgNessuna valutazione finora

- Turtle Diagrams - IATF - 16949 - 2016Documento8 pagineTurtle Diagrams - IATF - 16949 - 2016Sathyaprakash Hs100% (1)

- Product Audit ReportDocumento2 pagineProduct Audit ReportManoharar R100% (2)

- Evidences To Be Maintained As Per APQP For PMDocumento3 pagineEvidences To Be Maintained As Per APQP For PMSachin RamdurgNessuna valutazione finora

- Turtle Diagram Rev'01Documento2 pagineTurtle Diagram Rev'01Ankur Parshav100% (6)

- Iatf 3year Internal Audit PlanDocumento6 pagineIatf 3year Internal Audit Planrajesh sharmaNessuna valutazione finora

- Master GM AuditDocumento37 pagineMaster GM AuditMichael Hicks100% (1)

- Annexure-1 Customer Specific Requirement MatrixDocumento5 pagineAnnexure-1 Customer Specific Requirement MatrixSunil Shrivastava50% (2)

- IATF 16949 - 2016 - List of Mandatory DocumentsDocumento3 pagineIATF 16949 - 2016 - List of Mandatory DocumentsSenthil_KNessuna valutazione finora

- Competence For Internal AuditorsDocumento2 pagineCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Layered AuditDocumento2 pagineLayered AuditJohn Hall100% (2)

- IATF Objective Data Analysis - Quality - ExampleDocumento1 paginaIATF Objective Data Analysis - Quality - ExampleSachin RamdurgNessuna valutazione finora

- APQP Timing Plan TemplateDocumento9 pagineAPQP Timing Plan TemplatemuthuselvanNessuna valutazione finora

- Internal Audit ChecklistDocumento37 pagineInternal Audit ChecklistSumeet Rathee100% (5)

- Auditor Training Content Files CombinedDocumento211 pagineAuditor Training Content Files CombinedSaemundrSigfussonNessuna valutazione finora

- Iatf ActivitiesDocumento6 pagineIatf ActivitiesWizard tube and Engineered componentNessuna valutazione finora

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDocumento1 pagina14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNessuna valutazione finora

- Internal Audit Maintenance ChecklistDocumento3 pagineInternal Audit Maintenance ChecklistRamdas Paithankar100% (1)

- Iatf 16949 Clause To Eqms ModuleDocumento8 pagineIatf 16949 Clause To Eqms Modulepodrao100% (3)

- TMT Procedure - Management ReviewP1Documento1 paginaTMT Procedure - Management ReviewP1sumanNessuna valutazione finora

- Apqp - DR SHFTDocumento60 pagineApqp - DR SHFTrajesh5000100% (2)

- Internal Audit Process ScheduleDocumento2 pagineInternal Audit Process Schedule25900solon50% (2)

- Supplier Quality Assurance Manual - Rev. 06Documento40 pagineSupplier Quality Assurance Manual - Rev. 06Sundaramoorthy ArumugamNessuna valutazione finora

- Turtle Diagram For AuditDocumento5 pagineTurtle Diagram For AuditSelvaraj Simiyon100% (3)

- IATF 16949 Mandatory DocumentsDocumento2 pagineIATF 16949 Mandatory DocumentsLuis AlejandroNessuna valutazione finora

- How To Use The Audit Program Manager: List The Processes/functional AreasDocumento25 pagineHow To Use The Audit Program Manager: List The Processes/functional AreasAliNessuna valutazione finora

- Layer Process AuditDocumento8 pagineLayer Process AuditR JNessuna valutazione finora

- TAFE Process Audit Check List - Revision 2Documento16 pagineTAFE Process Audit Check List - Revision 2Vijay OfficialNessuna valutazione finora

- Inputs Outputs: With Who? (Competence/skills/training) With What? (Materials and Equipment)Documento2 pagineInputs Outputs: With Who? (Competence/skills/training) With What? (Materials and Equipment)azire carlos100% (1)

- CS Customer - Plant Turtle Diagram 07Documento1 paginaCS Customer - Plant Turtle Diagram 07Alex100% (1)

- Process Audit Preparation GuideDocumento5 pagineProcess Audit Preparation GuideNumpetch Somsw100% (6)

- ISO 9001 Quality Procedure Context of the OrganizationDocumento1 paginaISO 9001 Quality Procedure Context of the OrganizationKarim HakimNessuna valutazione finora

- Internal Audit Check List MRDocumento3 pagineInternal Audit Check List MRGanesh Iyer100% (1)

- Aum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditDocumento24 pagineAum Prasad Casting PVT LTD: 1. Types of Audit 2. Objectives Overview 3. Introduction To Clauses. 4. Conducting AuditpraveenNessuna valutazione finora

- Process Map and Description Matrix: Edition No: Date of ReleaseDocumento22 pagineProcess Map and Description Matrix: Edition No: Date of Releasemuthuselvan100% (5)

- Internal audit checklist for hot shop operationsDocumento36 pagineInternal audit checklist for hot shop operationsDhinakaran100% (1)

- IATF 16949 mandatory documentsDocumento3 pagineIATF 16949 mandatory documentsOscar Solis MartirNessuna valutazione finora

- Layered Audit System VerificationDocumento13 pagineLayered Audit System VerificationcpsinasNessuna valutazione finora

- IATF Additional Requirement LocationsDocumento6 pagineIATF Additional Requirement LocationsSudhagar50% (2)

- IATF 16949 Transition Audit - Off Site Document Review WorksheetDocumento5 pagineIATF 16949 Transition Audit - Off Site Document Review WorksheetDuho ConsultoresNessuna valutazione finora

- PRODUCT AUDIT CHECKLIST (WO Schedule)Documento7 paginePRODUCT AUDIT CHECKLIST (WO Schedule)Ranjeet Dongre100% (1)

- IATF Road MapDocumento1 paginaIATF Road MapGANESH BORUDENessuna valutazione finora

- TurtlesDocumento15 pagineTurtlesshobhit2310100% (4)

- Department: HOT SHOP Auditee: AuditorDocumento52 pagineDepartment: HOT SHOP Auditee: AuditorSead ZejnilovicNessuna valutazione finora

- CSR Matrix (Example Only)Documento24 pagineCSR Matrix (Example Only)hmp90100% (1)

- APQP & PPAP Training ProgramDocumento1 paginaAPQP & PPAP Training Programbalakumar rajaram100% (1)

- Process Audit - Checklist - SCRIBDDocumento3 pagineProcess Audit - Checklist - SCRIBDcarryn1Nessuna valutazione finora

- Process Verification Audit ChecklistDocumento5 pagineProcess Verification Audit Checklistriki3xNessuna valutazione finora

- Progressive AuditDocumento40 pagineProgressive AuditMaye MtzNessuna valutazione finora

- IATF 16949 Transition Preparing for the TransitionDocumento34 pagineIATF 16949 Transition Preparing for the TransitionquycoctuNessuna valutazione finora

- Cahrc HR ManualDocumento15 pagineCahrc HR ManualAce Thor YaheeNessuna valutazione finora

- Lec16 PDFDocumento17 pagineLec16 PDFAshutosh SinghNessuna valutazione finora

- NSEZ Unit Details - 310516Documento45 pagineNSEZ Unit Details - 310516Anonymous 9AnxnHaW3D0% (1)

- 5480 2Documento40 pagine5480 2Ashutosh Singh80% (10)

- Cross Reference of Steel StandardsDocumento4 pagineCross Reference of Steel StandardsNugroho Adhi SaputroNessuna valutazione finora

- Coal India Sample Question Paper MT 2012Documento9 pagineCoal India Sample Question Paper MT 2012Ashutosh SinghNessuna valutazione finora

- Quality Manual PDFDocumento21 pagineQuality Manual PDFAshutosh SinghNessuna valutazione finora

- GATE AnalysisDocumento2 pagineGATE AnalysisAshutosh SinghNessuna valutazione finora

- Lear-75-GM Quality System Basics Audit FormDocumento12 pagineLear-75-GM Quality System Basics Audit FormalexrferreiraNessuna valutazione finora

- Is 2473-1975 - Norma Furos de CentroDocumento8 pagineIs 2473-1975 - Norma Furos de CentroEduardo Lopes100% (1)

- 10 0ProjectScorecard PDFDocumento6 pagine10 0ProjectScorecard PDFvesgacarlosNessuna valutazione finora

- Coal India Sample Question Paper MT 2011Documento10 pagineCoal India Sample Question Paper MT 2011Ashutosh SinghNessuna valutazione finora

- Hardness Conversion ChartDocumento10 pagineHardness Conversion ChartAshutosh SinghNessuna valutazione finora

- Gantt Chart Template STDFDocumento1 paginaGantt Chart Template STDFAshutosh SinghNessuna valutazione finora

- JisDocumento706 pagineJisHenry Poudel48% (25)

- OEEDocumento1 paginaOEEAshutosh SinghNessuna valutazione finora

- Excel Gantt v4Documento14 pagineExcel Gantt v4PMPNessuna valutazione finora

- The Digestive System: by Seth and RobinDocumento9 pagineThe Digestive System: by Seth and RobinAshutosh SinghNessuna valutazione finora

- Process AuditDocumento15 pagineProcess Auditdesurkarb100% (2)

- JD FormatDocumento4 pagineJD FormatAshutosh SinghNessuna valutazione finora

- Technical Skill Matrix EnggDocumento19 pagineTechnical Skill Matrix EnggAshutosh Singh100% (1)

- 10 0ProjectScorecard PDFDocumento6 pagine10 0ProjectScorecard PDFvesgacarlosNessuna valutazione finora

- Choosing an Induction Hardening InstallationDocumento9 pagineChoosing an Induction Hardening InstallationAshutosh SinghNessuna valutazione finora

- Types of Forging OperationsDocumento6 pagineTypes of Forging OperationsAshutosh SinghNessuna valutazione finora

- Spline Program Ver 1.1Documento6 pagineSpline Program Ver 1.1Ashutosh SinghNessuna valutazione finora

- To Date: 25.08.2014 HR Manager XXX: XXXXXXXXDocumento1 paginaTo Date: 25.08.2014 HR Manager XXX: XXXXXXXXAshutosh SinghNessuna valutazione finora

- Hardness Conversion ChartDocumento34 pagineHardness Conversion ChartAshutosh SinghNessuna valutazione finora

- JEE Advanced 2013 Analysis by ResonanceDocumento7 pagineJEE Advanced 2013 Analysis by ResonanceArpit JainNessuna valutazione finora

- Life ProcessesDocumento140 pagineLife ProcessesAshutosh SinghNessuna valutazione finora

- Unique Requirements Checklist-ISO/TS 16949Documento9 pagineUnique Requirements Checklist-ISO/TS 16949zubairsgcNessuna valutazione finora

- Bvqi Audit Report Main 1-7juvo0h 12112021150900 BvrbuqbupDocumento8 pagineBvqi Audit Report Main 1-7juvo0h 12112021150900 BvrbuqbupAuspice QatarNessuna valutazione finora

- Iosa Checklist Cab - Ism Ed 10 - 1 Sep 2016Documento104 pagineIosa Checklist Cab - Ism Ed 10 - 1 Sep 2016AndrewNessuna valutazione finora

- Yayat's CV Jun 2020Documento5 pagineYayat's CV Jun 2020Muchamad agung WicaksonoNessuna valutazione finora

- KMMG Supplier QDocumento32 pagineKMMG Supplier QClaudia PEÑANessuna valutazione finora

- Six Sigma TerminologiesDocumento92 pagineSix Sigma TerminologiesReshmi RajeshNessuna valutazione finora

- 2018 Qms Maturity Assessment ToolDocumento26 pagine2018 Qms Maturity Assessment ToolChi100% (2)

- Map ISO 55001 asset management requirements to Plant Wellness Way processesDocumento34 pagineMap ISO 55001 asset management requirements to Plant Wellness Way processesFrank SerranoNessuna valutazione finora

- Quality Control Manager JobDocumento2 pagineQuality Control Manager JobSarah ChaudharyNessuna valutazione finora

- Support Logs For HACCPDocumento51 pagineSupport Logs For HACCPjune dela cerna100% (1)

- Iso9001 Iqa EtaDocumento171 pagineIso9001 Iqa EtaKanan AgarwalNessuna valutazione finora

- ISO 9001:2015 PresentationDocumento61 pagineISO 9001:2015 PresentationC P ChandrasekaranNessuna valutazione finora

- QS9000 Check ListDocumento16 pagineQS9000 Check ListAngelo ZerellaNessuna valutazione finora

- Control of Non-Conforming Products ProcedureDocumento4 pagineControl of Non-Conforming Products ProcedureAlmario Sagun100% (1)

- Closed Loop Corrective ActionDocumento19 pagineClosed Loop Corrective ActionSajid MahammadNessuna valutazione finora

- FMEA Guide Failure ModesDocumento21 pagineFMEA Guide Failure ModesSusanoo12Nessuna valutazione finora

- Annual Report 19 20Documento28 pagineAnnual Report 19 20Australia IdeasNessuna valutazione finora

- Corrective and Preventive ActionDocumento4 pagineCorrective and Preventive Actionsudar1477Nessuna valutazione finora

- APQP ProcedureDocumento9 pagineAPQP ProcedurePk Nimiwal100% (4)

- Procedure For CapaDocumento6 pagineProcedure For CapachahiNessuna valutazione finora

- ISO 9001:2015 Documentation ToolkitDocumento2 pagineISO 9001:2015 Documentation ToolkitGaurav KansaraNessuna valutazione finora

- KepkDocumento58 pagineKepkasna watiNessuna valutazione finora

- Warning Letters - Philips Medical Systems (Cleveland) Inc 6-7-11Documento10 pagineWarning Letters - Philips Medical Systems (Cleveland) Inc 6-7-11FDwebredNessuna valutazione finora

- Roles & ResponsibilitiesDocumento2 pagineRoles & ResponsibilitiesPrasanna Kumar M100% (1)

- NewRCA CAPTemplateDocumento3 pagineNewRCA CAPTemplateWendo BijaksonoNessuna valutazione finora

- General Motors: Quality Systems Basics AuditDocumento12 pagineGeneral Motors: Quality Systems Basics AuditNaga ChaitanyaNessuna valutazione finora

- NCR Procedure - TemplateDocumento16 pagineNCR Procedure - TemplateHernandito Rahmat KusumaNessuna valutazione finora

- FSSC 22000 Templates IndexDocumento11 pagineFSSC 22000 Templates IndexMohammed Imran0% (1)

- Guidelines On A Major Accident Prevention PolicyDocumento17 pagineGuidelines On A Major Accident Prevention PolicyRemeras TartagalNessuna valutazione finora

- Company's EMS ManualDocumento18 pagineCompany's EMS ManualAldrinNessuna valutazione finora