Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ITD12420 WPB

Caricato da

Aditia C PurnomoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ITD12420 WPB

Caricato da

Aditia C PurnomoCopyright:

Formati disponibili

Halcrow Capability in tunnelling and ground engineering

1 WHY HALCROW?

analysis and damage assessment, temporary works, ground treatment and most importantly tunnel construction methods. We consider that any successful practitioner of tunnel design has to posses a combination of these core engineering skills. Halcrow is represented on the committee of the British Tunnelling Society and supports the technical committees of the International Tunnelling Association. We have representation on the Road Tunnel Safety Committee of PIARC and have experts recognised by such bodies as the United Nations and the International Society for Rock Mechanics.

With nearly 110 years of tunnelling experience Halcrow has developed a level of expertise in underground works that is sought after by clients worldwide. With such a long track record our tunnel engineers are able to deliver the skills that have been developed by successive generations of the worlds leading tunnel designers. We provide state-of-the-art tunnel expertise delivered from within a tunnelling ethos that has been established through over a century of understanding and managing the risks associated with the development of underground infrastructure.

TIMELINE

STAFF

Our tunnelling pedigree is summarised below by listing some of the landmark projects undertaken during more than a century of tunnel engineering: 1890-1900 ~Tunnels on the Port Talbot Railway, United Kingdom 1900-1910 ~ Proposals for the Charing Cross to Hammersmith Underground Railway, United Kingdom (not built) 1910-1920 ~ Kinlochleven Extension, United Kingdom. 1920-1930 ~ Waterloo Station Escalators Tunnels, United Kingdom & Lochaber Hydro Power, Ben Nevis Tunnel, United Kingdom.

Halcrow offers the services of recognised experts in tunnel design and associated disciplines. Including: Segmental linings for tunnels and shafts. Sprayed concrete & cast in situ linings. Cut and cover retaining structures and underground stations. Pipe jacking, micro trenchless technology. tunnelling and

Rocks tunnels, shafts and caverns. Urban soft ground tunnelling. Tunnel ventilation, fire/life safety engineering and computational fluid dynamics. Project and delivery management & Procurement strategies. Tunnel inspection and assessment, instrumentation monitoring services. tunnel and

1930-1940 ~ Piccadilly Line, Southgate Extension, United Kingdom. 1940-1950 ~ Home Office Shelters, United Kingdom. 1950-1960 ~ Woodhead Tunnel, United Kingdom. 1960-1970 ~ Orange Fish Tunnel, South Africa & Victoria Line, United Kingdom.

Masonry tunnels and immersed tubes.

Our tunnel engineers possess a broad range of knowledge including structural engineering, materials technology, geotechnical engineering, capability in ground movement, settlement

halcrow.com

Halcrow Capability in tunnelling and ground engineering

1970-1980 ~ Piccadilly Line, Heathrow Extension, United Kingdom. Cut and Cover Cut and cover techniques are frequently employed for rail and road tunnel developments. Halcrow has extensive experience in the design for cut and cover works including diaphragm walls, secant pile walls, contiguous pile walls and sheet piles.

1980-1990 ~ Channel Tunnel, United Kingdom/France 1990-2000 ~ Kuala Lumpur LRT II, Malaysia & Jubilee Line Extension, London, United Kingdom

Tunnel Boring Machines Experience with soft ground TBMs includes Earth Pressure Balance TBMs and Slurry TBMs as well as open face TBMs for use in more stable ground. Halcrows tunnel engineers appreciate that a full understanding of the operation of the TBM is one of the essential aspects of successful segmental lining design. Halcrows experience includes the EPBMs and slurry TBMs used for the Jubilee Line Extension, where Halcrows bolted precast concrete segmental lining was adopted for over 50% of the bored running tunnels. Other experience includes contributions to the specification for the TBMs for the Channel Tunnel Rail Link, where TBM manufacturers were prequalified before tenders for construction were invited. Incremental Support Methods Sometimes referred to as the New Austrian Tunnelling Method (NATM), this is a very flexible form of construction and ideally suited to the construction of complex tunnel arrangements such as metro stations. The use of incremental support methods is set to increase as demands are made to provide more complex arrangements of underground space in the most economical and efficient manner.

2000-Present ~ Channel Tunnel Rail Link, London, United Kingdom (commenced 1996) & DLR Woolwich Extension, United Kingdom

SOFT GROUND TUNNELS

We offer our clients expertise in the design of segmentally lined tunnels and shafts, and cut and cover tunnels. Our extensive experience includes tunnels driven by TBM, pipe jacked tunnels, tunnels advanced by incremental support methods and tunnels driven by pre-vaulting. Our expertise includes the design and specification of segmental linings including segment casting advice, segment mould specification and advice on lining erection. Construction Methods Halcrow has experience in a wide range of soft ground tunnelling construction techniques.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

Tunnel and Shaft Linings Segmental Tunnel Linings In the 1950s, Halcrow pioneered the use of expanded tunnel linings for use in water tunnels under London and that ability for innovation continues to be applied to all the work we carry out today. Halcrow are considered as one of the worlds leading segmental lining designers and our design approach for steel fibre reinforced concrete segmental linings is recognised in the industry as state-of-the-art. We have considerable experience in the design and construction supervision of tunnels using: grey cast iron and spheroidal graphite iron linings. grouted or expanded concrete linings. trapezoidal, planar segmentation. or hexagonal among the most important aspects of segmental lining design. We believe that these aspects can only be successfully incorporated where the necessary expertise and knowledge exists. Halcrows experience also caters for the design of openings and junctions in segmental linings and the design of the temporary works required for their execution. In situ Concrete Linings Halcrow offer a depth of experience in the design of reinforced and unreinforced in situ (monolithic) concrete tunnel linings for all types of tunnel. Advice is available on lining profiles, waterproofing details, lining construction sequences and fixings for tunnel services. Shaft Linings Halcrows experience in the design and construction supervision of shaft linings includes precast concrete segmental linings, diaphragm walls, secant piles and sheet piles.

curved bolts, straight bolts or dowel connectors. unreinforced concrete linings. reinforced concrete linings with conventional bar reinforcement or steel fibres. compression gaskets or gaskets for waterproofing. hydrophilic

through the segment or through the tail skin grouting systems.

Particular design aspects of shafts include: Overall stability/flotation in the permanent condition and during construction. Base stability during excavation. Requirements for openings permanent shaft lining. through

We consider that casting tolerances and details like bolt pocket configurations, caulking and gasket grooves, and lifting pockets etc. are

Settlement Analysis and Building Damage Assessments Halcrows experience in predicting settlement induced by tunnelling ranges from preliminary

halcrow.com

Halcrow Capability in tunnelling and ground engineering

studies prepared for project feasibility through risk assessments to detailed analysis of individual structures. Halcrow has developed a suite of settlement assessment models for predicting the surface settlement induced by tunnelling and for estimating building damage and damage to buried services. Soft Ground Tunnel Projects The following projects clearly illustrate Halcrows ability to combine its soft ground tunnelling skills with those of other disciplines to deliver successful projects. A more detailed list of Halcrows tunnelling experience is presented in Appendix A. Channel Tunnel Rail Link, United Kingdom Halcrow is a founding member of the consortium awarded the concession to design, build and operate the Channel Tunnel Rail Link (CTRL). CTRL is a $9bn, 68 mile long high speed rail line linking the Channel Tunnel to St Pancras Terminus in London. The majority of our input into this project arises from secondment of staff into Rail Link Engineering (RLE), a company which has been set up to provide project management, design, planning, procurement, costing, scheduling, construction supervision and commissioning expertise for the project. Major structures incorporated in the project include the following: 28 miles of tunnel, including a 2.2 mile long bored tunnel under the River Thames, 2 mile long NATM tunnel through the North Downs and 13 miles of 23.5ft I.D. TBM driven tunnel beneath urban London, lined with reinforced segmental lining. a fibre

A 0.6 mile long x 165ft wide x 70ft deep cut & cover station box at Stratford.

Halcrow employees seconded to RLE were responsible for the design of all tunnels, including geotechnical input such as the planning of site investigation programs and interpretation of the resulting data. They have also been instrumental in the design of the Stratford box, as well as a large number of ventilation and escape shafts, and other ancillary structures. Our engineers performed ground movement prediction analyses and building damage assessments for hundreds of structures in Central London, including the assessment of the crossing of the existing Central and Victoria Line subway tunnels, and the impact of the CTRL tunnels on the brick lined Thameslink tunnels at Kings Cross Station. The work also included development of mitigation and building protection measures, and specification of instrumentation and monitoring requirements. Deep Tunnel Sewerage System Contract T04, Singapore Halcrow acted as design consultant to Samsung Corporation for both the tender and detailed design of Contract T-04 of the Deep Tunnel Sewer System Project in Singapore. The project involved the design of the following structures: 4.6 miles of 156 ID precast concrete segmental tunnel lining in soft ground, with dowelled circumferential joints, bolted radial joints and a double gasket waterproofing system. The tunnel was driven using an EPB TBM. 141 ID corrosion protection lining consisting of a mass concrete ring poured within the segmental lining, with a 0.1 thick HDPE liner cast into the internal surface of the concrete to resist attack resulting from the potential buildup of acidic gases within the tunnel. A 526 ID slurry walled working shaft. 5 No. permanent access shafts ranging in diameter from 6 to 10 ID.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

A 2,625ft long NATM adit of 6 ID, connecting from a rectangular working shaft to the main bored tunnel, constructed through Granite and Old Alluvium. adits and passages associated with intervention shaft 230ft total length and up to 18 I.D. hand dug over-run tunnels

The twin running tunnels will be bored with an EPB TBM and pass under the River Thames. The tunnels will be lined with steel fibre reinforced segments and the tunnels will be excavated in chalk. Tottenham Court Road Station Upgrade, United Kingdom Halcrow led the Joint Venture awarded the upgrade of the existing Tottenham Court Road Station in London. The upgrade incorporated a new cut & cover ticket hall, elevators and escalators, and platform interchange passages. The JV consisted of architects, structural engineers and M&E engineers. Halcrow were responsible for coordinating all work undertaken by the JV, liaising with the Client and designing the tunnels and deep level concourses, shafts and interchange passages. Coordination of the design process was facilitated by the adoption of a single project model environment, which ensured that all JV members were using the same information. This was invaluable in managing the complex interfaces with the existing station structure (which was to remain operational throughout the upgrade works), and to achieve full coordination between each of the design disciplines.

In addition to the design work, Halcrow was also responsible for producing Construction Impact Reports, monitoring and instrumentation plans and a comprehensive Durability Report to demonstrate compliance with the required 100 year design life. We also provided construction support services during construction. Docklands Light Railway Extension to Woolwich, United Kingdom Halcrow are designer to the design and construct contractor for this 1.6 mile extension of the Docklands Light Railway in London. The project is currently under construction. Halcrow are responsible for the design of all the civil works including: diaphragm walled retained cut 800ft long and up to 40ft deep diaphragm walled cut and cover twin cell tunnel and launch chamber 672ft long and up to 60ft deep diaphragm walled station box 426ft long twin running tunnels 174I.D. and 5,900ft long intervention shaft 492I.D. and 130ft deep cross passages 112 I.D.

Halcrows design work included a new triple escalator tunnel, new connections between the Northern and Central Lines, subsurface lift shafts and emergency staircase shafts. The

halcrow.com

Halcrow Capability in tunnelling and ground engineering

tunnel designs utilized a range of segmental lining types, including concrete, spheroidal graphite iron, and steel. Due to the limited space available around the existing tunnels, innovative and complex designs and construction methods were required. For example, Halcrow designed 3 sets of new stairs leading down between the Northern Line platform tunnels. Due to the close proximity of the platform tunnels, the only way to construct the new stairs was to remove segments from the sides of both platform tunnels, replacing the support to the tunnels with steel box frames encased in concrete. The concrete encased steel frames formed the permanent stairwell. Halcrows other responsibilities included specification, procurement and supervision of the site investigation, interpretation of the geotechnical data and derivation of design parameters for use by the whole Joint Venture team. Halcrow also undertook extensive assessments of the effect of the construction works on the existing cast iron platform tunnels. Assessments were also made of the impact of the station box excavation on the adjacent 20+ storey Centrepoint building.

Our tunnel engineers are experienced in the practical and safety aspects of using explosives underground and have the appropriate technical capability in terms of blast design and techniques such as controlled perimeter blasting and vibration monitoring. Roadheaders In weaker rocks, the roadheader with a boom mounted cutter head can provide the advantage of flexibility of the cut profile whilst reducing rock disturbance and maintaining reasonable access to the face for installing rock support. In recent years, this type of machine has found particular application in conjunction with incremental support methods of tunnelling such as the New Austrian Tunnelling Method. Tunnel Boring Machines For over 30 years, Halcrow has been involved in the design development and use of a wide range of full-face tunnel boring machines (TBM) for soft ground and hard rock applications. Experience in weak rock includes the double-shielded TBMs on the Channel Tunnel and the earth pressure balance TBMs for Phase 2 of the Channel Tunnel Rail Link. In hard rock, full-face TBMs have been employed for the Rouna 4 Hydroelectric Project in Papua New Guinea and the Strategic Sewage Disposal Scheme in Hong Kong. Rock Support and Linings Typically, Halcrow will prepare rock support designs which are appropriate for the range of ground conditions expected along a tunnel

ROCK TUNNELS

Rock tunnels and caverns are often an integral part of a wide range of major infrastructure projects. Halcrow has engineered many large diameter tunnels and caverns in rock, from the first major hydroelectric developments in Scotland to the Channel Tunnel Rail Link, UK and Black Hill Tunnels, Hong Kong. Excavation Methods Halcrow's extensive rock tunnelling experience has created a valuable capability in the assessment of the most suitable and cost effective excavation methods for a particular project. Drill-and-Blast Techniques of drill-and-blast excavation in rock tunnels continue to develop and this method remains the most appropriate approach on many projects where, for example, variable rock conditions are anticipated, excavation layouts are complex or access for mechanised tunnelling plant is restricted.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

alignment or within an underground development. The requirement for rock support can be assessed using a range of analysis techniques in order to give maximum confidence in the design. These may include: defining the requirements for support through numerical analysis rock Rock Tunnel Projects The following projects illustrate Halcrows ability to combine its rock tunnelling skills with those of other disciplines to deliver successful projects. A more detailed list of Halcrows tunnelling experience is presented in Appendix A. A303 Stonehenge by-pass, United Kingdom Halcrow are the designer for the twin bore road tunnels required to carry the A303 under this World Heritage site. The works have been procured by the Highways Agency using a form of contract known as Early Contractor Involvement (ECI); a development of design and construct where the services of the contractor are secured at the concept design stage. Halcrow are responsible for the design of 1.3 miles of twin bore, 36 6 diameter, unidirectional road tunnels. Each bore is to carry a single carriageway, two lane highway. The tunnels have been designed for both NATM construction techniques and construction by tunnel boring machine with a precast concrete segmental lining. The tunnels are to be constructed in chalk below the ground water table. Halcrow are also responsible for the tunnel plant, roadside equipment and safety systems. The safety provision for the tunnels has been developed in accordance with the new European Union directive on road tunnel safety. Other structures associated with the road tunnels included a central service tunnel, cross passages between the traffic bores, approach cuttings, cut and cover portal structures incorporating buried tunnel plant rooms and the tunnel services buildings.

simplified rock-support interaction analyses based on engineering assumptions for rock parameters if prepared in the absence of site specific data. application of empirical rules based on established rock mass classification systems to determine rock support.

With the advances in shotcrete technology and quality control it is now common practice to include a contribution from the primary shotcrete lining in the load carrying capacity of the secondary lining. In fact, shotcrete technology has developed to the stage that it is now feasible to use shotcrete to construct both primary and permanent tunnel linings, with the potential to realise cost and time savings. By using good quality control, equipment and operators, a strong, low permeability, durable concrete can be produced which can be applied by spraying. This has the potential for use as both primary support and permanent tunnel lining and was an integral part of Halcrows design philosophy for the Wadi Muddiq road tunnel in the United Arab Emirates.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

Strood and Higham Tunnel Relining, United Kingdom Halcrow were designers for this design and construct contract to line the unlined sections of Strood and Higham rail tunnels in Kent, United Kingdom. The lining works were successfully completed during a 52 week blockade of one of the main commuter railways into central London. Strood and Higham Tunnels were originally designed and constructed as part of the Thames and Medway Canal. Tunnel construction was completed in 1824 and in 1846 the two tunnels were converted into twin-tracked railway tunnels by filling in the canal. The tunnels were originally excavated in chalk and were only partially lined with brick arches; where good quality chalk was encountered the tunnels were left unlined. There was approximately 4,600ft of unlined tunnel. Following a history of chalk falls the unlined chalk sections of both tunnels were lined during a 12 month blockade which commenced in January 2004. In developing the design the most crucial consideration was to limit the required intervention with the chalk; any intervention was believed to significantly increase the risk of chalk falls during construction. Wadi Muddiq to Gillay Road Tunnel, United Arab Emirates

The Wadi Muddiq-Gillay Road was a design project undertaken by Halcrow in Dubai for the Sharjah Municipality, United Arab Emirates (UAE). Halcrow undertook the preparation of preliminary design and detailed design for this 3,940ft long, single carriageway, bi-directional road tunnel. The Wadi Muddiq - Gillay Road Tunnel is located on the eastern side of the UAE in the Emirate of Sharjah. The single bore tunnel had an excavated face area of 1,012 ft2 and accommodates a single carriageway, two-lane road that has been constructed through the Hajar Mountains. This tunnel was completed in 2003 and is the first mined tunnel in the UAE. The tunnel was excavated in hard rock by drill and blast through gabbro; a coarse grained basic igneous rock. To provide an economical solution it was proposed that the permanent support to the tunnel was to be provided by sprayed concrete, grouted steel dowels and lattice girders. The tunnel was designed to have no secondary structural lining. Halcrow also prepared the performance specifications for the

The lining design consisted of steel arches at 6 centres supported off piled capping beams. The capping beam was supported by raked piles that were bored into the sidewalls of the old canal thereby avoiding the reliance on the unknown properties of the canal backfill material. The steel arches (with pattern rock bolts in the tunnel roof) provided immediate support to the unstable chalk. The permanent lining was provided by a cast in-situ plastic fibre reinforced concrete lining.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

tunnel mechanical and electrical services including the longitudinal ventilation system with bi-directional axial flow jet fans. Arrowhead Tunnel Project, North America The Arrowhead Tunnel Project involves the construction of nearly 8 miles of 16 ID water transfer tunnel in the San Bernadino Mountains in Southern California. The tunnel will be bored through mainly granitic rock, but with softer, weaker deposits at the portals. Halcrow were responsible for the detailed design of the precast concrete segmental lining. In addition to the ground loading, the design also had to take into account water pressures of over 1000 external head (a world record for a watertight segmental lining). The design of the gasket and gasket groove was therefore critical, as was the joint detail to prevent damage occurring due to the high load on the radial joints. Halcrow developed comprehensive specifications and a testing regime to demonstrate the adequacy of the gasket design (a 45 bar test pressure was satisfactorily met) and the ability of the radial joints to resist the prevailing loads. The joint testing program, undertaken at the University of Illinois, demonstrated that joint strength exceeded design expectations. This allowed for some reinforcing steel to be removed from the joints for a less congested and more economical segment design. Other tests undertaken included bolt pull-out tests, grout socket pull-out, water-tightness, and shear strength of the concrete under stiff gasket compression loads. Black Hill Tunnels, Hong Kong Halcrow was appointed as the detailed design consultant for a design and build contractor to undertake the design of over 5.5 miles of 19 8 diameter rock tunnels, associated shafts, adits, underground sidings, crossover tunnels and portals. The tunnels pass under Black Hill between Yau Tong and Tiu Keng Leng station and form part of the Tsuen Kwan O Extension Project for the Hong Kong Mass Transit Railway.

The concept for the design of the tunnels in rock was as follows: tunnel excavations supported with rock bolts and/or shotcrete and/or steel ribs, using support elements and materials considered unsuitable for incorporation in the permanent support design of the tunnel (i.e. "temporary" supports) permanent support of the tunnels provided by a concrete arch designed to support rock wedge and other ground and/or nominal hydrostatic loads permanent drainage of groundwater and waterproofing of the tunnels provided by a waterproofing membrane between the temporary support and permanent lining, in conjunction with a protective/drainage geotextile layer ground water pressure relief below the invert slab with a permanent drainage system.

The overall concept was to provide a physical waterproofing barrier which also relieved the ground water pressure on the cast in-situ tunnel arch. In addition to the use of rock mass classification systems finite and discrete element analyses were made using PHASES and UDEC software. FLAC was used for groundwater inflow

halcrow.com

Halcrow Capability in tunnelling and ground engineering

modelling and UNWEDGE was used for rock wedge support design. The permanent lining was designed using a non-linear methodology developed by Halcrow to allow the optimum use of mass concrete.

DESIGN CAPABILITY

At Halcrow we recognise the value of many of the currently available numerical design tools. The following section presents the comprehensive array of state-of-the-art design software currently used by our engineers. Software for Ground/Structure Interaction With the development of powerful ground/structure interaction design software it is becoming apparent that more and more designers are relying solely on the results of complex numerical analysis. In essence they consider it to be, in the absence credible tunnel design expertise, the panacea to all the challenges that tunnel design and construction presents. At Halcrow we consider our use of complex design software as a valuable design tool which allows our tunnel engineers to efficiently develop design options, run parametric studies and model complex forms of ground/structure interaction. However such forms of analysis are only employed by Halcrow to support and not to replace the decisions made by our tunnel designers. FLAC FLAC (Fast Lagrangian Analysis of Continua) is a powerful two-dimensional continuum code for modelling soil, rock and structural behaviour. Halcrow have wide experience of using FLAC to model soil structure interaction problems in two dimensions. Such problems often involve complex stratigraphy, complex construction sequences, groundwater modelling, and plastic behaviour of both ground and structures. Typical applications include: determining the development of loads in underground structures, including tunnel primary support systems and secondary linings for NATM type tunnel construction in both rock and clay; modelling settlement arising tunnels and deep excavations; from

analysing the effects of tunnel construction on adjacent underground structures; analysing changes in stress resulting form partial demolition of existing tunnel linings.

FLAC3D Halcrows capability in soil-structure interaction problems extends to 3 dimensional problems, for which FLAC3D is used. As well as the problem types described for FLAC above, the 3D capacity allows Halcrow engineers to determine the following: the effects of the construction sequence and long term behaviour of cross passage junctions, chambers or other changes in geometry; the effect of the separation and construction methods of headings in NATM type construction sequences; the build up of stresses in structural elements of complex 3D geometry, such as SGI hybrid opening sets for segmentally lined tunnels; the 3D effects of breaking out parts of existing structures.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

combinations of loading on a structure to be built up quickly and easily. SuperSTRESS has both 2D and 3D capabilities, and is commonly used for: multi-storey underground chambers; design of waling frames; design of steel arches for support to tunnel headings. design of tunnel linings.

FREW FREW (Flexible Retaining Walls) is part of the Oasys suite of software. Based on a 2D slice through an excavation, it allows the modelling of each stage of the installation of a retaining wall, including excavation, propping and changes in groundwater profile. Halcrow have wide experience in using FREW for the design of different types of retained excavation, including: retained cut structures, ventilation shafts, and cut and cover tunnels, including station boxes; propped and unpropped excavations; diaphragm wall, sheet piled and contiguous/secant piled constructions.

Software for Aerodynamics & Fire Safety Rail Tunnels Ensuring the safety of passengers in long rail tunnels is a key design element that must be considered from the concept stage right through to operation. Through careful consideration of the qualitative and quantitative risks, Halcrow can advise its clients on whether or not any emergency ventilation is required in case of fire or hazardous spillage. The safe design of rail tunnels requires an interdisciplinary approach between tunnel designers, rail engineers and ventilation experts to identify dangerous scenarios and to set in place appropriate operational, emergency and ventilation procedures.

SuperSTRESS Complex underground structures are often modelled in SuperSTRESS where there is no requirement for soil-structure interaction modelling. SuperSTRESS is a structural analysis package, and as such allows a number of

If emergency ventilation is required in a rail tunnel, we can advise on the most appropriate type e.g. longitudinal with jet-fans or Saccardo nozzles, single point supply and extract or distributed overhead extract within underground stations. Beyond concept design, we have a proven M&E detailed design capability to proceed to layout drawings, performance

halcrow.com

Halcrow Capability in tunnelling and ground engineering

specifications and detailed tender documentation. important bearing on the relevance of these standards, such as the presence of a particularly high proportion of high-emission diesel-powered vehicles or the danger of a particularly large potential fire load. Halcrow represents the United Kingdom in PIARCs Technical Committee 3.3, which sets international standards for road tunnel operations. Halcrows approach in designing road tunnels is genuinely interdisciplinary, putting experts in tunnel civil design together with ventilation, lighting, control and other M&E specialists to give clients the greatest possible benefits. These include low construction costs, minimum number and types of ventilation equipment, and low installed power requirements. The environmental impact of road tunnels on the environment can be considerable, and careful assessments may have to be made during the planning stage to ensure that the local air quality in the vicinity of the portals or ventilation stacks is kept within local or international guidelines. Within urban areas in particular, affected residents in many industrialised countries are increasingly demanding reassurance in terms of particulate matter (PM) emissions in addition to limits on gaseous contaminants including CO and NOx. Halcrow can provide environment impact assessments, and advise on the most effective means of satisfying local planning authority requirements, with solutions such as stack ventilation, tunnel short-circuiting and air filtration where appropriate. FLUENT Halcrow use Fluent as their in-house Computational Fluid Dynamics (CFD) software. Computational Fluid Dynamics (CFD) is a technique which enables the study of the dynamics of fluid flow. Using CFD, a computational model is built that represents a

In addition to safety considerations, we can advise on the means of achieving satisfactory comfort conditions for passengers and staff in railway tunnels, by ensuring appropriate air temperatures and air quality. All relevant parameters including initial ground temperature, tunnel lining characteristics, rail traffic schedules, traction supply arrangements and rolling stock thermal mass are taken into consideration in our tunnel climate simulations. Excessive train-induced draughts can compromise the comfort of passengers awaiting trains on underground platforms. Halcrow designs cost-effective draught relief systems through a combination of designing required civil works (cross-passages and draught relief shafts) and advising on appropriate train scheduling. Halcrow engineers have experience in designing high-speed railway systems while ensuring the comfort and safety of the passengers. Through aerodynamic simulations, we can advise on the effects of high-speed train movements within train cabins and on the tunnel structure. We can also recommend structural measures (e.g. pressure relief shafts) and improvements in rail operation to ameliorate any negative aerodynamic effects. Road Tunnels Halcrow provide expert advice on the most appropriate type of ventilation system for road tunnels under design, including natural, transverse, semi-transverse and longitudinal ventilation systems. This advice is based upon an intimate knowledge of the relevant international standards relating to road tunnel ventilation (e.g. NFPA, RABT and PIARC), in addition to being cognisant of local features that may have an

halcrow.com

Halcrow Capability in tunnelling and ground engineering

system or device for example a building or tunnel. Then, fluid flow physics is applied to this virtual prototype, and the software outputs a prediction of the fluid dynamics. Fluent is a general-purpose CFD package that enables Halcrow engineers to undertake: Smoke simulation studies for fire scenarios, including the production of videos of smoke spread in road or rail tunnels; Predictions of internal environments in underground and overground structures, including the estimation of temperature and humidity; Calculations of pressure pulses for vehicle movements in and out of tunnels; Designs of the ventilation and cooling systems required in utility tunnels (e.g. cable tunnels). applications of this programme in Halcrow include: the calculation and mitigation of pressure pulses experienced in trains and within rail tunnels due to train operation the simulation of smoke movement within rail tunnels during fire scenarios the design of ventilation equipment (including jet fans, impulse fans and dampers) for tunnels the design of draught relief systems within underground stations.

Maximum Repeated Difference Specified Limit 0.6 Recorded Pressure

0.8

Air Pressure (kPa)

0.4

0.2

0.0

-0.2

-0.4

-0.6

-0.8

-1.0 0 10 20 30 40 50 60 70 80

Time (Seconds)

SES SES (Subway Environmental Simulation) is a programme provided by the US Department of Transportation for the simulation of the environmental conditions within underground mass transit systems. In particular, heat sources due to power dissipated by rolling stock and station electrical loads, as well as heat sinks to the tunnel lining and surrounding ground, and convective heat flows, are considered in the calculation of air temperature and humidity. Typical applications for this program are: THERMOTUN ThermoTun is an aerodynamics solver for rail tunnel networks, developed by the University of Dundee for the prediction of the aerodynamic effects of high-speed rail operation in tunnels. The program solves the hyperbolic wave equations to accurately resolve the pressure waves within a tunnel system. The program also solves for air velocities and movement of scalars such as smoke within the tunnel. Typical the assessment of comfort conditions in underground subway systems the design of appropriate ventilation and cooling systems for stations and tunnels estimation of smoke spread in underground subway systems in case of fire.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

the design of smoke extract facilities to control the spread of smoke in fire scenarios.

PAXPORT Halcrow has considerable and long standing experience of escape and egress modelling. Since 1993, in the aftermath of the Kings Cross fire, Halcrow has developed PEDROUTE on behalf of London Underground Limited for the modelling of passenger movements and the prediction of escape times. These computer simulation techniques have been further developed into the PAXPORT code, to allow sophisticated modelling of passenger and occupant egress. Halcrow's evacuation and CFD modelling engineers are able to work collaboratively in order to provide a holistic and powerful modelling approach.

� selection of tunnel boring machine, � ground properties and parameters, � ground settlements due to tunnelling � hydro-geological effects due to tunnelling and � unforeseen poor ground and support failures

in rock tunnels. Geotechnical Engineering Halcrows geotechnical team has a wide range of experience in geotechnical engineering that including the feasibility study for foundations, design of retaining walls, design for deep excavations, design of sheet piles, concrete secant and contiguous piles, techniques of ground slope stabilisation, groundwater and dewatering assessments for constructability, value engineering and foundation design for buildings and structures. The geotechnical design also includes 3D finite difference models to predict ground movements after excavation. Seismic Design Halcrows expertise spans the whole process, from the identification of earthquake-related hazards to the design and analysis of structures to resist the effects of earthquakes. Our services include:

GEOTECHNICAL SERVICES

Apart from tunnelling experience, Halcrow is well recognise in the field of geotechnical engineering and currently provides excellence expertise consultancy in ground investigation, ground pressure analysis, soil structure interactions, ground treatment and design of foundations and underground structures in seismic zones. Ground Investigation Halcrows ground investigation experience includes site inspection, desk studies, soil investigation, geological and geotechnical interpretation, ground assessment identifying of mining hazards, potential surface instability and land slides zones. Halcrows geotechnical specialist also advises on � adequacy of site investigation,

� geological and seismotectonic studies to

characterise seismic sources, � deterministic & probabilistic seismic hazard analysis, � geotechnical and geophysical investigations, � derivation of seismic actions for dynamic analysis, � earthquake site response analyses, � dynamic soil-structure interaction, � liquefaction assessment and remediation, � earthquake resistant design and � independent review of third-party studies.

halcrow.com

Halcrow Capability in tunnelling and ground engineering APPENDIX A

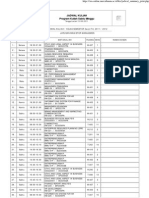

Tunnel Project Experience List (1998 to 2010)

2006-ongoing: U.K. Crossrail: Project Delivery Partnership (PDP)/Reference Design. Halcrow is helping to deliver a new world-class railway in conjunction with Bechtel and Systra form the PDP for the central London tunnel section of Crossrail. Crossrail which will link Maidenhead and Heathrow in the west with Shenfield and Abbey Wood in the east, providing better access to Londons West End, the City of London and Canary Wharf. As part of Crossrail Central, Halcrow are integral to all project delivery activities with particular emphasis on engineering assurance, contract administration and construction supervision, � liaison with external stakeholders, including LUL, � participation in Value Engineering, � preparation of tender documents and management of the tender process, � obtaining investment authority to make contract awards and � risk management, including liaison with insurers advisers. Halcrow carried out the reference design for southwest section of Crossrail route from Stepney Green to Abbey Wood including 6m ID tunnel through London Clay and Chalk below the Thames, access and ventilation shafts and stations. Responsible for Civil, M&E and Architectural works. Client: Cross London Rail Links 2008-ongoing: U.K. London Tideway Tunnels Thames Water commissioned CH2M Hill, in association with Halcrow, to programme manage the London Tideway Tunnels Scheme which will intercept, store and divert combined sewer overflows (CSO) discharges, currently overflowing into the Rivers Thames and Lee, for treatment at Beckton sewage treatment works (STW) to bring long-term benefits for the environment and people using the River Thames. The scheme comprises the Lee Tunnel, the Thames Tunnel, the connection of over 30 CSOs and a deep pumping station at Beckton STEW. Client: CH2M Hill UK Ltd for Thames Water 2009-ongoing: U.S.A.: Queens Bored Tunnels, East Side Access (Long Island Rail Road) Contract CQ031 Detailed design of precast concrete segmental linings for 5.94mID twin-bored tunnels, 3.2km long. Client: GTF Joint Venture for Metropolitan Transportation Authority 2009-ongoing: U.S.A.: University Link Project, Seattle, Contract U220 Detailed design of trapezoidal precast concrete segmental linings for twin bored tunnels of 5.74m ID. The ground cover above the 10.4km long route varied from 4.5m to 91m. Client: Traylor for Sound Transit. 2009-Ongoing: Panama, Panama Bay Wastewater Interceptor System. Detailed design of 8km long tunnelling in rock using segmental lining and prepared FEM modelling for analysis of tunnel and shaft segmental lining, settlement and structure damage analysis, tunnel alignment study and durability study of linings. Client: Odebrecht 2009-Ongoing: Argentina, Buebos Aires North Water Supply System. Detailed design of 14km long tunnelling in soft ground (mostly clay) using segmental lining and study of tunnel hydraulics, ground settlement and structure damage analysis, structural analysis for tunnels and shafts lining and site liaison with site contractors. Client: Odebrecht 2010-Ongoing: U.K, London Cable Replacement Tunnels Halcrow has been recently appointed by Costain Group Ltd as part of the Costain Tunnelling Partnership to commence the delivery of the detailed design for 3 new cable tunnels for National Grid. The cable tunnels stretch from Hackney in the East, Willesden in the west and a spur connects to Wimbledon in the south west of London. In total Halcrow are responsible for the design of 30km of 3 and 4m ID cable tunnel linings that includes a mixture of expanded and trapezoidal linings, 15 shafts or varying internal diameter of 15 to 5m and 14 operational head house structure. Halcrow with sub consultants Capita Symonds and Fereday Pollard began a challenging 18 month design delivery programme in Nov 2010 that is driven by the aspirations of National Grid to commence construction works in advance of the proposed Crossrail tunnelling contacts. Client: National Grid.

� management of engineering design, provision of

halcrow.com

Halcrow Capability in tunnelling and ground engineering

2010-Ongoing: U.K, Bond Street Station Upgrade. The Halcrow Atkins fully integrated JV partners have design responsibility for any single design discipline or area of the works. The scope of services includes detail design of all tunnelling works, buildings works, architectures works, mechanical, electrical and communication installation, fire systems, station controls systems, pedestrian modelling and fire engineering. Client: Costain, Laing O Rourke JV for LUL. 2010: Barzil, Rio Metro Line 4. A combined Tunnels and Geotechnical team of Halcrow provided engineering and construction planning inputs for a concept design of a 4km long extension to the existing metro. Client: FGV 2007-2010: U.K. Brighton and Hove Wastewater Treatment Works Tender design and detailed design of a new wastewater treatment works outside Peacehaven, along with related pipelines, 2.44m ID bored tunnels and three 17.5m ID pumping stations (up to 45metres deep) in an 11km long corridor along the coastline from Black Rock in Brighton in the west to Peacehaven Heights in the east. Client: 4D Joint venture (Costain Ltd) for Southern Water 2008-2010: U.K. West Ham Flood Alleviation Scheme A project intended to alleviate sewerage flooding for 400 properties and associated roads in West Ham in the London Borough of Newham. Involves the interception of effluent flows in the West Ham area and transporting them to the existing Abbey Mills Pumping Station for transport onto Beckton treatment works. Consisted of the enlargement of existing sewers and construction of 3km of new microtunnels connections, a new 2.87m ID transfer/storage tunnel and 23 shafts varying in size from 4.2m to 15m ID. Client: Costain for Thames Water 2008-ongoing: Republic of Ireland, Dublin Interconnector New twin-bore tunnel for a 20-train-per-hour rail link between the existing Connolly and Heuston rail stations in Dublin, to link, and provide interchange with, the existing Northern DART and Heuston Mainline lines. Provision of five new underground stations en route (with step-free access). Provision of interchange with existing suburban and intercity services from Heuston and Connolly Stations, the Luas local tram network, local buses, and a planned metro link to Dublin Airport. Client: Iarnrd ireann (Irish Rail) 2008-2010: Canada: Downtown Ottawa Transit Tunnel project Tunnel, fire and life safety engineering, carried out in support of Delcan in their preparation of a Planning and Environmental Assessment Study for this project. The passenger rail scheme comprises 4km of segmental twin bored tunnels and four underground stations, beneath the Canadian capital. Client: Delcan Corporation for City of Ottawa 2008: U.K. Cooling the Tube Programme Northern Line Package 10 Halcrow were appointed by London Underground Limited to prepare, to RIBA Stage D level, new mechanical, civil, electrical and fire design works associated with solutions to the problem of reducing the ambient temperatures in and around Elephant and Castle and Waterloo Stations on London Underground's Bakerloo and Northern Lines. This included tunnel design for new adits connecting into existing tunnels and shafts. Client: London Underground Limited 2008: Canada: Vancouver Evergreen LRT Definition of alignment constraints, and conceptual design of civil, structural and mechanical works, and evaluation of construction methods and logistics associated with a 2km long twin bore tunnel through glacial till. Preparation of performance specifications and other contract documentation associated with the procurement of a Public-Private-Partnership consortium to design, build and finance the project. Tunnel is part of a proposed 11km Advanced Light Rail Transit system in Vancouver. Client: Ministry of Transportation and Infrastructure 2008: U.K.: St John's Road Wandsworth Flood Alleviation Scheme Review of design options and develop a design for the construction of a new storm sewer and access shafts. Settlement analyses to identify buildings and services at risk of damage. Detailed analyses performed on buildings and services deemed particularly vulnerable. Client: Thames Water Utilities Ltd Framework 2008: U.K.: Hornsey WTW Bromate Project Detailed design of shaft, base slab and cover slab including floatation check for new sewer discharge shaft. Intended to transfer wastewater from new water treatment works to existing sewer. Client: Costain for Thames Water

halcrow.com

Halcrow Capability in tunnelling and ground engineering

2007-2009: U.K.: Airtrack Engineering Advice Preliminary engineering design and advice to support a Transport & Works Order application for a new rail connection from the SW train network at Staines to Heathrow Airport Terminal 5. The project will provide new rail infrastructure to support half-hourly services between Heathrow Terminal 5 and Reading, Guildford and Waterloo, using dedicated dual voltage rolling stock. Halcrow led the preliminary engineering and architectural design and produced Parliamentary Plans to support an application under the Transport and Works Act and applications for Planning Approval. The scheme incorporates twin bored and SCL tunnels, and cut and cover tunnels, totalling 1.6km. Above ground there includes a 1.2km piled slab, 1km concrete viaduct, 150m steel viaduct, a rebuilt station at Staines and rebuilt car park ramps, infrastructure and footbridges. At T5 the existing station will be extended to include two new platforms and connection to existing facilities. Client: BAA PLC mains, emergency escape/ intervention points, evacuation lighting, signage, electricity supplies to infrastructure in the tunnels, communications systems including CCTV, security and crime prevention measures, emergency OLE/3rd Rail isolation requirements, desk-top review of structural integrity of certain elements. Client: Network Rail 2007: U.K.: Coldharbour Lane Flood Alleviation Scheme Review of options for the construction of a new storm storage tunnelled sewer as part of a scheme to reduce the risk of flooding in Brixton, south London. Analyses to evaluate the predicted settlement caused and to identify buildings and buried utilities at risk of damage. Client: Thames Water Utilities Ltd Framework 2007: U.S.A.: North Shore Connector Tunnel Revised Segment Arrangement Design for a revised segment arrangement for the North Shore Connector Tunnel. Validation of design by design check based on the original lining arrangement using a computer programme developed in-house. Results compared with those obtained by the original designer Faber Maunsell. Client: North Shore Contractors Obayashi Trumbull JV 2007: Lake Mead Tender design for water intake system including inlet structure and shaft, 6.17m ID tunnel, and construction and access shaft. Construction through rock with water pressures up to 180m. Client: Traylor-Obayashi-Barnard 20072008: Northwest Interceptor Sewer, Sacramento Tender design and detail design for 5km long, 3.65m ID sewer tunnel through soft clays and loose sands. Client: Traylor-Shea JV 2007-2008: Avenue 45 to Arroyo Drive relief sewer, Los Angeles Tender design and detail design for 2km long, 2.38m ID steel fibre reinforced concrete sewer tunnel lining through weak to strong sandstone and siltstone, and alluvium. Client: Traylor-Shea JV 2007ongoing: Tottenham Court Road station Upgrade Detail design of revised congestion relief measures including new escalator tunnels and tunnels and adits

2007-2008: U.K.: Baldwyn Park Foul Water Flood Alleviation Scheme Feasibility study into the proposal of installing a new 600mm internal diameter microtunnel to upsize an existing surface water sewer. Research into construction methods, possible work sites, potential ground settlements and the risk of damage to surrounding buildings and utilities. Client: Thames Water Utilities Ltd Framework 2007-2008: U.K.: Park Farm Housing Development Water Main Pipejack Detailed design for two new auger-bored steel pipes under the Ashford to Hastings railway line and the A2070 main road in Kent, to provide a water supply and sewer connection to the new Park Farm housing development. Client: South East Water Ltd 2007-2008: U.K.: Network Rail Railway Estates N244 Inner Area Tunnel GRIP3 GRIP 3 & 4 study between Blackfriars and Kentish town/Belle Isle concerned with production of: Operational Concept Paper and associated Tunnel Emergency Plans, Fire Safety Strategy. Design options and solutions for Tunnels Systems including evacuation walkways, fire fighting water

halcrow.com

Halcrow Capability in tunnelling and ground engineering

for new stairs in segmental and Sprayed Concrete linings. New lifts for the mobility impaired and a major extension to the ticket hall. Client: London Underground Ltd. 2007: Bathurst to Langstaff and Avenue 19 to Leslie Street sewer Detail design of 2.74m ID reinforced concrete segmental lining for sewer north of Toronto. 8.8km and 4.2 km bored tunnel through tills, clays and sands. Client: McNally Construction Inc 20052008: DLR Extension to Woolwich Winning tender and Detail design for the extension to Docklands Light Railway including 1800m of twin 5.7m O.D running tunnels under the Thames, 350m of cut and cover tunnels and 140m long cut and cover station. Tunnels constructed in clay and chalk. Site supervision as part of the contractor's auditing team. Client: AMEC Capital Projects 2004-2005: UK, Vauxhall Station Enhancements and Accessibility Project In October 2004 Halcrow were appointed by Metronet Rail BCV Ltd to carry out the RIBA Stage B feasibility study associated with Vauxhall underground station. Halcrow were responsible for Pedroute studies and the presentation and appraisal of options for the enhancement of the station and the provision of MIP facilities. Client: Tube Lines Ltd 2005-2008: UK, Margate and Broadstairs Waste Water Transfer Scheme A design and construct scheme to construct two 800mm ID pipelines to transfer untreated sewage to a treatment works and then return treated effluent for disposal via a new sea outfall. The pipelines are to be located, in part, within a 2.87m ID transfer tunnel which is lined with a steel fibre reinforced precast concrete segmental lining. The tunnel is 2800m long and is to be constructed in variable quality chalk. In addition to the transfer tunnel there are three 9.00m ID access shafts between 12m and 29m deep and three 6.5m ID access shafts 12m deep. The scheme also includes four 1.2m ID pipe jacks beneath operational railway lines. The sea outfall is 1.8m ID and 600m long with a 12.5m ID, 25m deep storm storage shaft. Client: Costain Ltd 20052006: UK, Tube Lines Shaft Inspections Undertaking detailed inspections, dimensional surveys, intrusive investigations and structural assessments of existing shafts on the Northern, Jubilee and Piccadilly Lines for Infraco Tube Lines. Client: Tube Lines Ltd 2005-2008: San Vicente Pipeline to 2nd Aqueduct Tender design, detail design and specification for a 6.4m ID steel fibre reinforced segmental lining, to be used as primary support for over 13km of bored tunnel through sandstone and siltstone. Client: Traylor Brothers Inc 2005-2007: Australia, North South Bypass Tunnel Halcrow are undertaking the tender design for an 11m diameter segmental road tunnel lining. The twin highway tunnels are to be driven by hard rock TBMs with drive lengths of approx. 3500m going 60m under the Brisbane River in the centre of the city. Client: Theiss/John Holland/Hochtieff JV 2005-2007: Australia, MetroPitt Extensions Preparation of the concept engineering for an underground rail line below the Sydney CBD. The tunnels and station caverns are in sandstone. Present work includes modelling of tunnels below high rise buildings and proposed deep basements to protect easement. Client: Rail Corporation New South Wales 2005-2006: Australia, Heroes Avenue Sewer Project Design of 6m dia 25m deep shaft for pipe jack river crossing. Client: McConnell Dowell 2005-2007: New Zealand, Johnstones Hill tunnels Tunnel designers for the 340m long 12m wide twin road tunnels in sandstone/siltstone. Design includes bored and cut & cover sections. Client: URS New Zealand 2004-2006: Australia, Northern Diversion Sewer Pre-construction phase services. Temporary works designs for five shafts and TBM launch chambers varying form 13m to 6m diameter. Client: Gutteridge Haskins and Davey (GHD) 20042007: UK, Edinburgh Airport Link Preliminary engineering to develop an airport rail link with responsibility to take the proposals through the parliamentary process. Scheme includes 600m of cut and cover running tunnels, 250m long cut and cover station, 350m of retained cutting and 1km of 6.6m O.D. running tunnel. Client: Transport Initiatives Edinburgh 20042007: USA, Eastside LRT Design optimisation of 2.1km of twin segmentally lined tunnel including revised segmentation, design of sfrc option and specification and testing. The tunnels have an internal diameter 5.74m with a structural thickness

halcrow.com

Halcrow Capability in tunnelling and ground engineering

of 266mm, and are fully bolted and gasketed for construction behind a pressure balance TBM. Client: Traylor Brothers Inc. 2004-2005: USA, SR 91 MIS Supporting Jacobs Civil Engineering in undertaking this study to investigate tunnelled options for relieving the traffic congestion on the SR 91 between Riverside and Orange Counties in Los Angeles. Client: Orange County Transportation Authority 2004: USA, Elm Road Generating Station Intake Tunnel Tender design for a 24 internal diameter cooling water intake tunnel, 9000 long under Lake Michigan. Tunnel to be driven by TBM in Dolomite. Works also included lake bed intake, offshore riser shafts and onshore intake shafts. Client: Traylor/Jay Dee JV 2003: Bulgaria, Sofia Metro Extension Tender design for 1250m of twin 5.8m I.D. running tunnels and associated access shafts. Client: Nishimatsu Construction Corp 2003-2005: UK, Great Yarmouth CSO Improvements Detailed design and checking of contractor calculations for two diaphragm wall shafts and one secant piled wall shafts and base slab. A connecting pipe jack is also included in the scheme through sands and soft deposits. Client: Anglian Water Ltd 2003-2008: UK, Kessingland, Troopers Drive Sewage Scheme Detailed design and checking of contractor calculations for a caisson shaft and base slab in soft ground below water table. Client: Anglian Water Ltd 2003-ongoing: Brazil, Sao Paulo Metro Line 4 Detail design and specification of 10.2 km of 8.43m ID fibre reinforced concrete segmental tunnel through mixed ground including rock, weathered rock and soft sands/clays, all below the water table. Testing specifications also prepared. Client: Consortium Via Amarela 2003-ongoing: Iran, Tehran Sewerage Project Tender assessments and site supervision/contract administration assistance on Lot 3 and Lot 4. Traditional tunnelling techniques in stiff/firm sands. Client: Tehran Sewer Company 2003-ongoing: Yemen, Amran to Aden Highway Feasibility to detail design of civil, M&E and ventilation for tunnel options as part of a highway scheme. Feasibility study of 4 main tunnels with lengths between 2.5km and 7km, with an excavated area of 109m2. Client: Ministry of Public Works and Urban Development 2000-2007: Venezuela, Caracas Metro Lines 3 & 4 Detail design of both fibre reinforced and normally reinforced concrete options for bolted gasketed segmental tunnel lining, over 12km of twin tunnel. Internal tunnel diameter of 5.16m. Soft sands, clays and silts below the water table. Preparation of design methodology for fibre reinforced concrete and testing specifications to demonstrate use of sfrc. Client: Construtora Norberto Odebrecht 2003: UK, Clyde Tunnel Review of technical and cost proposals for ventilation upgrade and new fire rated secondary linings. Client: Glasgow City Council 2002-2003: Iran, Dez Ghomrud Water Tunnel Technical advice on rock tunnelling, TBM selection, tunnel lining design and precast concrete segment manufacture for 16km rock tunnel, 3.8m ID. Client: SAHEL Consulting Engineers 2003: Iran, Rudbar Lorestan Dam and Power Project Detail design of 400MW hydroelectric project with 150m high dam and approx 5kms of access tunnels, diversion tunnel and power tunnel in folded and faulted limestone. Client: Iran Water Power Corporation 20032004: Hong Kong, Route 9, Sha Tin Heights Highway Tunnel (Alternative Designs) Value engineered alternative designs for approx 2kms of twin 3-lane urban road tunnel through granite. Client: China State China Rail Joint Venture 2002: China, Chongxihe to Zunyi Expressway Project Tunnel Expert for ADB funded 130 kms long expressway project with 11 contracts including tunnel works, generally twin 2-lane tunnel drives in mountainous terrain. Geology includes karstic limestone with major cavities and coal bearing strata. Functions include review and advice on all aspects of tunnel construction, quality control and safety, with training of counterpart staff. Client: Guizhou Expressway Development Corporation.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

2003-2006: UK, Tunnel Management Strategies Formulation of tunnel examination and maintenance strategies for all 112 existing tunnels in Network Rail Southern Region, using a risk based approached. Client: Network Rail Southern Region 2003-2004: UK, Mill End to New Ground ALF (Taplow) Detailed design for 140m long pipe-jacked tunnel crossing beneath Great Western Mainline railway and A4 to carry 3 no 600mm water mains. The tunnel is to be constructed through gravels and chalk with high permeabilities. The commission is carried out under Framework Agreement 491 with Thames Water Utilities Ltd. Client: Thames Water Utilities Ltd. 2003-2004: UK, Horton Kirby Eynsford ALF Design advice for 1.2m ID pipe jacked tunnel beneath mainline railway and river as part of the Horton Kirby water main replacement scheme. The commission is carried out under Framework Agreement 491 with Thames Water Utilities Ltd. Client: Thames Water Utilities Ltd. 2003: UK, A47 Tunnel Crossing Technical advice regarding 1.2m ID pipe-jacked tunnel sewer beneath the A47 main road near Peterborough. Tunnel is constructed through stiff Oxford Clay using open faced TBM. Client: Anglian Water 2003-2004: UK, Barrow to Stonewall Trunk Main Technical advice regarding 1.2m ID pipe-jacked tunnel for replacement water main crossing beneath a main line railway. Client: Anglian Water 2003: UK, Heathrow Express Technical Consultancy Services Technical advice regarding the inspection and maintenance of the Heathrow Express tunnel as part of the framework agreement PA6581 Client: Heathrow Express 2003-2006: Romania, Braila Technical Assistance for the Management and Supervision of ISPA Contracts in Braila Specialist technical advice regarding tunnel element of a new sewerage scheme for the city of Braila in Romania. Tunnel is 3.5m ID and is constructed using compressed air methods through water bearing sands and silts. The project is funded by the European Union. Client: Government of Romania 20032006: Czech Republic, Extension of Ostrava Sewerage System Specialist technical advice concerning the construction of 1.4 km of service tunnel under the city of Ostrava. The tunnel construction method involves using extensive ground treatment by horizontal grout injection and lining using sprayed concrete techniques. Project is funded by the European Union Client: Statutory City of Ostrava 2003: UK, Network Rail Tunnel Feasibility Studies Historical and geotechnical desk studies, condition and dimensional surveys, intrusive tunnel site investigation and ground investigation supervision, remedial works and future monitoring strategy development for various national rail brick lined tunnel. Client: Network Rail 2003-2008: UK, Ross on Wye Inverted Siphon Tender and Detailed design of a flood alleviation scheme that consists of two shafts with inlets and outlets connected by a 1km length of bored tunnel through sandstone. Client: Herefordshire Council 2002-2003: UK, Thames Water Asset Management Plan Asset Management plan carried out for all Thames water potable tunnels. This plan recorded the level and costs of the inspections, repairs and maintenance required over the next 20 years, along with an assessment of the conditions of the tunnels at the present time. Client: Thames Water Utilities Ltd. 2003: Australia, New MetroRail City Project Tender design for new rail connection beneath the Central Business District, including two cut and cover underground stations, connecting tunnels and approaches. Client: Cityconnect JV. 2002-2007: UK, A303 Stonehenge Improvement Designer on early contractor involvement tunnelled road scheme through Chalk including review of tunnelling options, conceptual and preliminary design, preparation of draft orders for Public Inquiry and detail design. Client: Balfour Beatty/Costain 2002: UK, A3 Hindhead Road improvements Tender design for new twin dual carriageway road tunnels 1.7km long through lightly cemented sandstone and sand. Client: AMEC Capital Projects

halcrow.com

Halcrow Capability in tunnelling and ground engineering

2002-2006: UK, Higham Strood tunnel refurbishment Tender design for new permanent support to existing railway tunnel in Chalk. Client: Costain 2002: USA, Boston Harbour Outfall Tunnel Expert advice provided regarding tunnelling in wet conditions below Boston Harbour. Client: Kiewit-Atkinson-Kenny 2002-2004: USA, Arrowhead Tunnel Project Tender design and detail design of 4.88m ID segmentally lined tunnel through rock subject to maximum water head of 300m. Total tunnel length approx. 13km. Devise and report on gasket and segment joint testing programme. Client: Traylor Brothers Inc. 2002-2003: Portugal, Lisbon Metro Technical assistance Review of damaged section of constructed Metro lining (8.8m ID) and concept design for refurbishment works to reinstate structural integrity and durability. Development of design options in shotcrete and steel segmental lining construction. Review of liquefaction potential of As-Built ground conditions in alluviuals, clays and Sands/Silts. Client: ACE-Metro 2002: Spain, Barcelona Metro Detailed design and construction advice on tunnel segmentation and reinforcing the 9.5m ID tunnel segments. Client: Ferrovial - Agroman S.A. 2002: Spain / France, Pertus High Speed Rail Link Tender design for twin bore 8.1km segmental lined rail tunnel under the Pyrenees Mountains. Aerodynamic, fire safety and ventilation studies also carried out to determine optimum internal diameter of 9.2m ID for a design speed of 300km/h. Client: Ferrovial - Agroman S.A. 2001-2002: U.K., Thames Tideway Study Feasibility study for options to store combined sewer flows in storm conditions to minimise overflows into local river and water sources. Client: Thames Water 2001-2002: USA, Los Angeles Metro Expert Witness Expert advice provided regarding the precast concrete tunnel lining on one section of the LA Metro Red Line. Client: Obayashi 2001: Singapore, Kallang Expressway Tender design for a cut and cover dual carriageway road tunnel. Secant piled construction with drainage shafts and pipe jack tunnels. Client: Samsung 2001-2002: Australia, Parramatta Rail Link Sydney Tender design for the first stage of proposed 27km railway extension in western suburbs of Sydney. First stage includes approximately 15km of tunnel and 5 new underground stations. Client: Transfield Obayashi Joint Venture 2001: Hong Kong, CLP Cable Tunnels Tender designs for cable tunnels in rock, including a 2.9m ID segmentally lined tunnel, and a 5m span drill and blast tunnel with a permanent sprayed concrete support option. Client: Gammon/ Skanska 2001: Hong Kong, Strategic Sewers Disposal Scheme (TBM Tunnels) Technical advice and factual witness for major Arbitration Client: Maeda 2001: Australia, Cross City Tunnel Project Sydney Tender design for 1.5km of twin bore 2 lane road tunnels beneath the Sydney Central Business District. Includes cut & cover and bored tunnel. Client: Transfield Multiplex Joint Venture 2001: Australia, Eastern Freeway Extension Melbourne Tender design for 4km long freeway including 1.5km of twin bore 3 lane road tunnels in silurian mudstone. Client: McConnell Dowell/Clough Engineering 2001: Australia, Energy Australia Cable Project Sydney Detailed Design for a 1.9 km cable tunnel for the Sydney CBD and Inner Suburbs Electricity Supply Augmentation Project, including 4m by 3.6m tunnel excavated in Hawkesbury Sandstone, 4 access shafts and design of all cable support systems. Client: Downer Engineering 2000: Singapore, Cable Tunnels Tender designs for 5.2m I.D. segmental lining tunnels Client:Samsung, Downer & Nishimatsu 2000-2001: UK, Heathrow Airside Road Tunnel Cat III checks Design checks on the future Airside Rd Tunnel and associated structures 1km shallow cover 8.1m I.D.

halcrow.com

Halcrow Capability in tunnelling and ground engineering

bolted segmental tunnel lining and approach structures. Client: BAA 2000-2001: UK, Rotherhithe Tunnel Study Structural assessment of the capacity of the existing grey cast iron lining. Client: London Borough of Tower Hamlets 2000-2003: UK, Dock Street Relief Sewer Feasibility, tender, detailed design and site supervision for a 1 km 2.1 m ID sewer tunnel to be excavated through soft ground below water table. Client: North of Scotland Water Authority 2000-2004: UK, Thameslink 2000 Tunnels Detailed design of the connection between the existing Thameslink route with the new station to be constructed at St Pancras. The connection includes 2 No 6 m ID tunnels and a cut and cover section. The bored section will be excavated entirely through London Clay. The cut and cover section will account for environmental issues due to the extensive contaminative use of the land in this area. Client: Rail Link Engineering 2000: Indonesia, Besai Hydroelectric Power Project Failed Headrace Tunnel Investigation Investigation into failure on first filling of 4.3m dia reinforced concrete lined headrace tunnel on behalf of insurance loss adjuster. Client: P T Wiratman and Associates on behalf of McLarens Topliss/PT Asuransi Yasuda Indonesia. 2000: Korea, Soonchon Road Tunnel, Yosoo City Bypass Tender Design Advice on tunnel design and construction for 2 kms of twin 2-lane road tunnel in rock, with particular reference to internal tunnel finishes, tunnelling close to and through fault zones, and design for control of petrochemical spillage. Client: Hyundai Engineering and Construction Co Ltd. 2000: Korea, Blasting Impact Assessment for Wolmoon Rail Tunnel Tender Design Responsible for report on blasting impact, blast design, risk management strategy and protective measures for excavation of new twin-track rail tunnel in rock in close proximity to existing live rail tunnel. Client: Hyundai Engineering and Construction Co Ltd. 2000: Thailand, Khlong Tha Dan RCC Dam Temporary support design and proposals for permanent lining of drainage and grouting galleries in the abutments of a major RCC dam. Andesites and rhyolites. Client: CCVK Joint Venture. 2000: Singapore, MRTC (Singapore) Track bed and lining durability study for the MRTC in Singapore. Client: MRTC 2000: Australia, Inner Northern Busway Section 1 Brisbane Preliminary design of 650m of driven and cut & cover tunnel for a two lane road tunnel in Brisbane Central Business District. Client: Queensland Transport Alliance Project 1999-2002: Singapore, Deep Level Sewer Tunnel Scheme Tender and detail design for contract T04 of the sewer scheme including tunnels, access shafts monitoring of ground movements. Excavation through Old Alluvium. Client: Samsung 19992001: UK, Ashford Cut and Cover Box Detailed design of 1.6 km cut and cover tunnel through Ashford . The tunnel varies from 12.5 m wide to 32.5 m wide and has an internal height of up to 12 m to be constructed through Hythe Beds (sand/clay bands), Atherfield Clay and Weald Clay. Client: Channel Tunnel Rail Link 1999-2002: UK, Kings Cross/ St Pancras Thameslink Tunnel Cat III Checks Structural assessment of existing brickwork running tunnels north of St Pancras Station. Assessments associated with phase 2 CTRL works. Client: Rail Link Engineering 19992002: UK, LUL Public Private Partnership Technical advice (deep tube tunnels, drainage, earth structures, bridges and structures, environmental and M&E) provided to consortia Tube Lines and Surfacelines for the tender submissions for the LUL maintenance contracts for JNP and SSL Infracos. Consortium Tube Lines currently preferred bidder for JNP Infraco. Clients: Tubelines & Surfacelines Consortia. 1999-2001: Australia, Brisbane S1 Main Sewer Interceptor Detailed design of 5km of 3m diameter sewer tunnel through hard and soft ground requiring two types of TBM open face with rockbolt support and EPB with segmental lining. Project included 7 access shafts and internal uPVC tunnel lining. Client: Eroc/Obayashi 1999- 2000: Australia, Eastern Freeway Extension Melbourne Preliminary design and cost estimates of tunnelled options for a 4km freeway extension through region of

halcrow.com

Halcrow Capability in tunnelling and ground engineering

environmentally significance, in lieu of proposed surface alternative. Developed scheme was adopted by the client. Client: Department of Infrastructure, Victoria 1999-2000: Australia, South East Transit Project Brisbane Provision of specialist technical advice, construction supervision, and contract administration services for 410m long and 180m long two lane road tunnels excavated in rock and in-situ concrete lined. Client: Department of Main Roads/Queensland Transport 1999- 2001: UK, Portsmouth and Havant Water Treatment Works Detailed design of the high level pumping station constructed using a 12 m deep contiguous piled structure. 7 x 15 m. Client: AMEC Civil Engineering 19992000: UK, North Downs Tunnel Independent check for the secondary lining of an 11 m diameter tunnel excavated through chalk. The check is carried out using FLAC 2 and 3D and makes allowance for stresses due to long term creep. The tunnel is divided in 8 different zones according to the particular ground conditions to be found along the alignment. Client: Rail Link Engineering 1999-2000: Korea, Young Dong Railroad Relocation Project Multi-disciplinary international assistance and advice to a bid design team for 16.3 kms long single track mountain loop tunnel with crossover. Areas of assistance include rock tunnel design and methods, ventilation, risk control, site investigation, trackslab design, construction management and portal architecture. Turnkey contract. Client: Daewoo Corporation. 1999: UK, Bromborough Outfall Detail design of 2.85m diameter outfall tunnel and diffuser in soft sands of river estuary using precast concrete linings and epoxy-lined steel diffuser on design and build contract. Client: AMEC-PUREC JV 1999: China, Chongqing Expressway Project, Tunnel Construction Expert Advice Member of expert review team for ADB funded 80 km highway project with particular responsibility for twin three-lane rock tunnel design and construction in limestone and coal measures rocks. Client: Chongqing High-Grade Highway Construction Directorate. 1999: Ireland, Dublin Port Tunnel Risk assessment of a new development to be constructed above the tunnel alignment and subjected to potential settlements in order to support the planning application. Client: Ardmore Building Company Limited 1999: UK, Westwell Leacon Tunnel Detailed design of a 170 m long reinforced concrete buried box structure for high-speed trains to be constructed through Gault Clay and Folkestone Beds. Client: Rail Link Engineering 2000: UK, Ulverston Storage Tank Design of a 24m internal diameter diaphragm wall shaft 25m deep Client: AMEC Civil Engineering 2000: UK, Thames Tunnel Approaches Tender design of the 1300 m long approach structures to the Thames Tunnel, comprising piles cast-in-situ concrete troughs, propped diaphragm walls and cut-and-cover sections. The structures will be constructed through Alluvium, Terrace Gravels and Upper Chalk. Client: Rail Link Engineering 1998-2002: Hong Kong, Tseung Kwan O Black Hills Tunnels Detail design of design and build project for four 1750m long tunnels in volcanic and granite rock constructed by drill and blast technique. Includes central siding and two cross over caverns, ventilation shafts, cut and cover sections and tunnel portals. Client: Dumez/GTM/Chun Wo JV 1998-2002: UK, Tottenham Court Road Station Regeneration Detail design of congestion relief measures including new escalator tunnels and tunnels and adits for new stairs. New lifts for the mobility impaired and a major extension to the ticket hall. The work includes the project management of Architectural, civil engineering and M&E disciplines. Client: London Underground Ltd. 1998-2000: China, Chongqing Expressway Project Tunnel Construction Expert Review Assignments to expert review team for ADB funded 80 km highway project with particular responsibility for twin three-lane rock tunnel design and construction in karstic limestone and coal measures rocks. Client: Chongqing High-Grade Highway Construction Directorate.

halcrow.com

Halcrow Capability in tunnelling and ground engineering