Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TFT-LCD Modules " Improving Video Performance/ Reducing Cost

Caricato da

Anonymous O5WK6kiLiVDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TFT-LCD Modules " Improving Video Performance/ Reducing Cost

Caricato da

Anonymous O5WK6kiLiVCopyright:

Formati disponibili

TFT-LCD Modules " Improving Video Performance/ Reducing Cost

Michael Jennings, Director of Marketing, Intersil Corp., Milpitas, CA 1/3/2005 3:45 PM EST

The popularity of LCD displays has grown rapidly over the past 5 years. The technology which enabled the growth of the notebook market has now taken over the CRT in many desktop applications, where they offer very sharp text reproduction and large format displays in a form factor that doesn't take over the whole desk. Now, with the merging of the PC and the multimedia experience, video reproduction is becoming a key requirement for this technology. Some of the historical disadvantages of this technology have been weak color representation, the smearing of moving images and the inability to reproduce detail, especially in the very bright or very dark picture regions. In addition to the technological issues, the other historical drawback of the LCD display has been cost. If space is not a concern, the incumbent CRT provides a very cost effective solution. Panel prices have been dropping rapidly, especially over the later half of this year where supply has outstripped demand. This has led to many manufacturers dropping their price, although some have also cut back on production to bring the supply/demand curve back in line. In this article we will take a look at some of the new technologies which enable better video reproduction using TFT-LCDs, and how the pressure to move to lower cost contradicts this drive. LCD Module Components Figure 1: In addition to row and column drivers, the LCD display system also depends on gamma

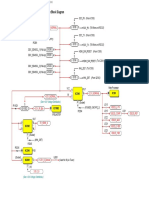

correction and multiple supply voltages. Click to Enlarge Figure 1 shows the typical circuitry of an LCD module. Whether the panel is designed for notebook, desktop

monitor or TV applications, all of these functions are required, but the performance of each product section does vary. The timing controller is a digital IC which sits at the heart of the panel. It is responsible for controlling the timing of the scanning mechanism used to control the writing of data in to the LCD display. This device resets the row and column drivers to start writing data in at the top of the display and scanning one row at a time to the bottom of the display. The row drivers are power drives used to select which row is having it's data written at a given time. The column driver converts the digital video data input to the display into an analog voltage to be stored across each individual pixel cell. Every LCD panel obviously requires a power supply. The panels carry 4 primary voltage supplies. The main supply (Avdd) provides a high voltage that is used to power many of the analog ICs within the LCD display, including the column drivers that are used to drive image content in to the display itself. Although many people think of TFT-LCD displays as a digital display, the brightness of each of the pixels is actually determined by an analog voltage level stored across that pixel. RGB filters in front of the pixels are used to enable color reproduction. Because of the analog nature of the display, the Avdd supply rail has to offer good load regulation and be capable of supplying enough current to charge and discharge all of the pixels within the display very quickly. Other supplies within the display include the logic supply for the digital IC products, as well as a high Von voltage and a negative VOFF voltage which are used to power the row drivers within the display. For high performance video displays, it is very important to use a high performance TFT-LCD regulator to reduce image distortion and smearing. Devices like the EL7585 (Figure 2, below) include all 4 of these supplies in a single IC, and also includes supply sequencing which is important to avoid damage to the LCD display Figure. 2. EL7585 generates four LCD power supply voltages.

Click to Enlarge The VCOM amplifier is used to supply a very stable reference voltage for all of the pixels within the display. This supply is typically about half the value of AVDD and the brightness at every pixel is determined by the difference between the voltage driven by the column drivers and this VCOM voltage. The relationship between the light emitted from a pixel and the voltage applied to it is a non-linear relationship.

This so called 'Gamma Curve' (Figure 3) is actually an S-curve in nature and can be either positive or negative referenced to VCOM. In fact, most panels switch alternating pixels between one polarity and the other. This gives an average DC voltage across the display of 0V, avoiding the burn in affect associated with such offsets. As each panel has a different gamma curve response, the column drivers need a reference curve so that they can drive the right voltage to each pixel to get the brightness required. These curves are typically supplied using the gamma buffers and a string of resistors which can be used to mimic the curve. Figure 3. The S-shaped 'Gamma Curve' shows a non-linear relationship between the light emitted

from a pixel and the voltage applied to it. Click to Enlarge The final device in our LCD block diagram is the backlight driver. Nearly all LCD panels today use a CCFL (Cold Cathode Fluorescent Lamp) backlight. These are required as the LCD panel itself does not emit light, but actually gates on or off the light from the light source behind it. These CCFL devices require a very high voltage AC waveform to drive them. Typical notebook and monitors can use just one CCFL controller per panel. However large panel, TV type displays require much brighter backlights, requiring more CCFLs and therefore more drivers. The light from each of these CCFLS also has to be matched, otherwise the image brightness will vary across the screen. Reducing Motion Blur One of the biggest issues with viewing video on LCD displays is motion blur. This effect comes from the very slow response of the liquid crystal within the display, leading to the appearance of a smear behind any moving image. Today's liquid crystal technologies are yield response times in the 12ms to 16ms range. Although much faster than the 20ms to 30ms of a couple of years ago, this still isn't fast enough to remove this artifact altogether. Of course, this has been a major area of focus for LCD development and there are now a number of technologies which can be used to eliminate the problem. The most obvious solution from the LCD panel front is to speed up the response of the liquid crystal material. The response of current materials can be increased by overdriving each pixel. However, this still does not produce the quick response that is required. Some companies though are now demonstrating new materials with response times of 5ms (gray to gray), and with gray to black times of around 1ms. The fast gray to black time also enables the very effective use of black insertion (See Figure 4). This technique inserts a black frame between each of the image frames. This creates a fast pulsing effect similar to a CRT. The human brain filters out this flickering and automatically creates the intermediate images. Demonstrations of this technique at recent

exhibitions has proved very effective. Figure 4. Black insertion puts a black frame between each of the image frames. This creates a fast pulsing effect similar to a CRT which the human brain integrates to effect motion.

Click to Enlarge If fast liquid crystal is not available, this effect can also be simulated by pulsing the backlight. This technique has also been demonstrated very effectively. By scanning the backlight from top to bottom, further motion artifacts can be removed resulting in very sharp moving images. Reducing Flicker Due to offset within the LCD panel, the required VCOM voltage can differ slightly from the ideal of one-half AVDD. This in turn can cause the appearance of flicker within the display. To eliminate this effect, the VCOM is usually adjusted on a panel-by-panel basis until the appearance of flicker is removed. This mechanical pot is now being replaced by digital potentiometers which enable automatic adjustment of these offsets, eliminating the possibility of offsets through human error. Figure 5a shows the Intersil ISL45041 driving an EL5111 high power VCOM amplifier in such an application. Figure 5. To eliminate flicker, the VCOM is usually adjusted on a panel-by-panel. The Intersil ISL45041 can drive an EL5111 high power VCOM amplifier in such an application (a). Newer panels use the actual VCOM value inside the panel is used to close a control loop (b).

Click to Enlarge

Click to Enlarge As each line is latched in to the LCD panel, charge injection in to the VCOM plane can also cause offsets which are seen as flicker. To eliminate this issue, newer panels are now using a technique where the actual VCOM value inside the panel is used to close a control loop which minimizes these offsets. This in turn reduces flickering artifacts. Figure 5b shows such a circuit. A third approach is to try to reduce the switching currents at the end of each line. A Von-slice circuit is used to

discharge the Von voltage at the end of each line, reducing the switching charge injection in to the VCOM line. This can be seen in Figure 6. Figure 6. To eliminate flicker, the VCOM can also be discharged by reducing the switching currents at

the end of each line. Click to Enlarge Removing Gamma Mismatch Due to variations in manufacturing and process parameters, each LCD that comes from a production line exhibits slightly different gamma response. Typically a single gamma curve is used for all panels which means that when we place multiple panels next to each other, each will have a slightly different color response. For many applications, this is extremely undesirable. To overcome this issue, the gamma curves ideally need to be set on a part by part basis as part of a closed loop system. Programmable gamma generators such as the EL5325 (Figure 7) from Intersil enable the gamma curve to be controlled via a micro-processor and therefore reprogrammed as part of the manufacturing process. Figure 7. Programmable gamma generators such as the EL5325 enable the gamma curve to be

controlled via a micro-processor. Click to Enlarge Improving Contrast for Dark and Bright Images Another issue with LCD displays is that they are not very good at distinguishing different contrast levels when producing very bright or very dark images. To overcome this issue, dynamic gamma can be used. This is where the gamma curve is adjusted on a frame by frame basis depending on the image content. This can be done in the digital domain as part of the scaling process, but limitation in bit depths of these devices leads to a number of undesirable artifacts. To overcome these artifacts, new systems will adjust the gamma reference curve using programmable gamma generators such as the EL5325 described above.

Improving Color Reproduction The use of CCFL technology as a backlight source seriously impacts the color spectrum we can produce in an LCD display. The typical CCFL backlight will enable an LCD display to reproduce <50% of the colors that can be transmitted using an NTSC signal. New high power LED technologies are now available as a backlight source to improve this coverage to >100% of the color spectrum of NTSC. In addition, these new LED backlights eliminate the mercury found in CCFL backlights, making them suitable for green applications. The LED backlight also has a number of other advantages. For larger panels, separate Red, Green and Blue LEDs are used. This enables the color temperature to easily be adjusted in a display. The fast response of these devices also makes them very suitable for strobing backlight applications. Although many manufacturers are working with these new technologies to improve image performance in their displays, they are also coming under intense pressure to reduce the cost of these devices to win market share. Without cost reduction, the growth of the market will be limited. This has led to many manufacturers removing functionality from the displays instead of improving the performance. It is very common now in mainstream monitors to not use gamma buffers. The curve is typically generated using a simple string of resistors and the performance degradation is accepted. As the fiercely competitive desktop monitor market continues to grow, we will see limited adoption of these new technologies for better video performance introduced in to these displays. Many of these desktop monitors are used in corporate environments where the emphasis is on text and graphics usage. But for the rapidly growing LCD-TV market, and for home PC multi-media stations, image quality is going to become a very important factor. Intersil has products targeted at both these market. For LCD-TV, Intersil is the only company to offer DC:DC, VCOM, DCP, Gamma and Backlight products. For the desktop market, high levels of integration enable a reduction in cost. Figure 8 shows the EL7642 which includes DC:DC, VCOM, gamma and Von-slicing functions in a single package. Figure 8. The EL7642 which includes DC-DC, VCOM, gamma and Von-slicing functions in a single

package. Click to Enlarge

Potrebbero piacerti anche

- 11th Generation Full High Definition Plasma DisplayDocumento103 pagine11th Generation Full High Definition Plasma Displaykeysi_2100% (6)

- Rainwater Harvesting - A Reliable Alternative in The San Juan IslandsDocumento103 pagineRainwater Harvesting - A Reliable Alternative in The San Juan IslandsGreen Action Sustainable Technology Group100% (1)

- T - Con Module Fault - Google SearchDocumento2 pagineT - Con Module Fault - Google SearchRaja Pathamuthu.G100% (1)

- Environmental SustainabilityDocumento3 pagineEnvironmental SustainabilityJoseph Michael Perez100% (1)

- Laptop Power Sequence Final by IntersotDocumento15 pagineLaptop Power Sequence Final by IntersotHas BiansyahNessuna valutazione finora

- SP 360 CmanualDocumento35 pagineSP 360 CmanualencontreelrepuestoNessuna valutazione finora

- Training LCD LG 42LG60 PDFDocumento87 pagineTraining LCD LG 42LG60 PDFparlentero100% (1)

- Service Manual: ChassisDocumento43 pagineService Manual: ChassisSokol Kadare50% (2)

- LCD TV Repair Guide Handbook 140211 v1Documento45 pagineLCD TV Repair Guide Handbook 140211 v1Jonatan Didier Sinkpon100% (1)

- 4 LCD+TV+Service+Guide+Handbook ENGDocumento61 pagine4 LCD+TV+Service+Guide+Handbook ENGJorge Fernando de TivantaNessuna valutazione finora

- LCD Troubleshooting Guide PDFDocumento35 pagineLCD Troubleshooting Guide PDFHamedKoneNessuna valutazione finora

- LCD Common Bad Phenomenon and Repair Methods (Figure)Documento14 pagineLCD Common Bad Phenomenon and Repair Methods (Figure)Minh NguyenNessuna valutazione finora

- Control IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ADocumento17 pagineControl IC For Single-Ended and Push-Pull Switched-Mode Power Supplies (SMPS) TDA 4718 ASledge HammerNessuna valutazione finora

- Ebook DecryptedDocumento278 pagineEbook DecryptededsonportosomNessuna valutazione finora

- v2 Led LCD Screen Panel Repair PDFDocumento73 paginev2 Led LCD Screen Panel Repair PDFRDWELN RDWELN100% (1)

- Ebook LCD Best OneDocumento125 pagineEbook LCD Best Oneananad addictNessuna valutazione finora

- Laptop SIO Power-UpDocumento2 pagineLaptop SIO Power-Upbong bernalbongNessuna valutazione finora

- LVDSDocumento2 pagineLVDSmarco giustiNessuna valutazione finora

- Design: IdeasDocumento6 pagineDesign: IdeasSamantha EwingNessuna valutazione finora

- Panel Volts LCD Led PDFDocumento3 paginePanel Volts LCD Led PDFRaj ChoudharyNessuna valutazione finora

- AC-DC LCD TV Poower Architecture and LED Backlight PDFDocumento53 pagineAC-DC LCD TV Poower Architecture and LED Backlight PDFRun Mouth100% (3)

- LCD Panel Repairing Book - Parte5Documento40 pagineLCD Panel Repairing Book - Parte5Ricardo Nicolau WerlangNessuna valutazione finora

- Training Material of RT49A-LA Chassis 20140612042844457Documento37 pagineTraining Material of RT49A-LA Chassis 20140612042844457بوند بوندNessuna valutazione finora

- LG 50PV450 Training Manual PDFDocumento160 pagineLG 50PV450 Training Manual PDFeliasNessuna valutazione finora

- Another 6 Pin SMD IC in LED & LCD TV/Monitor: Home Articles Download Page Recommend Contact UsDocumento10 pagineAnother 6 Pin SMD IC in LED & LCD TV/Monitor: Home Articles Download Page Recommend Contact UsyudelbysNessuna valutazione finora

- SONY T-CON - Training - Manual PDFDocumento12 pagineSONY T-CON - Training - Manual PDFJose Barroso GuerraNessuna valutazione finora

- Casalaptop Vip Booklist PDFDocumento4 pagineCasalaptop Vip Booklist PDFsajjadNessuna valutazione finora

- How To Bypass 4X LED Blinking Error For Sony KDL-55W900A Smart LED TVDocumento7 pagineHow To Bypass 4X LED Blinking Error For Sony KDL-55W900A Smart LED TVuzenNessuna valutazione finora

- LCD Panel VoltageDocumento10 pagineLCD Panel VoltageqwertNessuna valutazione finora

- LCD TV Repair Guide Handbook 140211 v1Documento45 pagineLCD TV Repair Guide Handbook 140211 v1devender kumar100% (2)

- Sony KDL-40R485A Chassis ITC2Documento70 pagineSony KDL-40R485A Chassis ITC2Nico50% (4)

- Sony - KDL 22 26 32ex420 - 22 26ex423 - 32 40 46ex520 - 32 40 46ex523 - CH - Az2gDocumento126 pagineSony - KDL 22 26 32ex420 - 22 26ex423 - 32 40 46ex520 - 32 40 46ex523 - CH - Az2gMalay K GhoshNessuna valutazione finora

- Manual Servico TV LCD Philips 42pfl3604Documento67 pagineManual Servico TV LCD Philips 42pfl3604abe_1962100% (1)

- TPM17.1E EuDocumento112 pagineTPM17.1E EuViktor SteinþórssonNessuna valutazione finora

- Manual de Service para TV LED PhilipsDocumento108 pagineManual de Service para TV LED Philipstavillo1980Nessuna valutazione finora

- Panasonic 10th Gen PDP TV Training ManualDocumento100 paginePanasonic 10th Gen PDP TV Training Manualenforcer2008Nessuna valutazione finora

- L.C.D L.E.D T.V Panels Connection and Voltages UnderstandingDocumento7 pagineL.C.D L.E.D T.V Panels Connection and Voltages UnderstandingSaidfa FaNessuna valutazione finora

- Asus P7H55 Desktop Motherboard Power On Sequence, Test Points and Voltages. - Laptop, Desktop, LCD, Led, TV, Printer, Smartphones, Repair TutorialsDocumento6 pagineAsus P7H55 Desktop Motherboard Power On Sequence, Test Points and Voltages. - Laptop, Desktop, LCD, Led, TV, Printer, Smartphones, Repair TutorialsDcs JohnNessuna valutazione finora

- Compal La-8951p r0.1 SchematicsDocumento55 pagineCompal La-8951p r0.1 SchematicsPaulo AmaralNessuna valutazione finora

- 10 True Repair Case Histories of LCD Monitors Volume IDocumento58 pagine10 True Repair Case Histories of LCD Monitors Volume IZerihun TadesseNessuna valutazione finora

- LCD-TV Repair ManualDocumento32 pagineLCD-TV Repair ManualrekhouNessuna valutazione finora

- Sony Smart LED PDFDocumento153 pagineSony Smart LED PDFAbimael Flores100% (1)

- Tecnica Guia Panasonic TH-42PZ700UDocumento77 pagineTecnica Guia Panasonic TH-42PZ700UAlberto Pernia100% (1)

- LCD Screens Don't Flicker - or Do They?Documento2 pagineLCD Screens Don't Flicker - or Do They?vikkix7Nessuna valutazione finora

- Adjusting Flicker On DisplayDocumento11 pagineAdjusting Flicker On Displaywaynecard71Nessuna valutazione finora

- Assignment 1 Computer Graphics NicoleDocumento5 pagineAssignment 1 Computer Graphics NicoleSimbarashe HlanyaNessuna valutazione finora

- Chapter - 12 Detailed Description About LCD Panels Thin-Film Transistor LCD Displays Introduction and OperationDocumento5 pagineChapter - 12 Detailed Description About LCD Panels Thin-Film Transistor LCD Displays Introduction and OperationAmar A V WNessuna valutazione finora

- TFT Driver - 040217Documento4 pagineTFT Driver - 040217looks_embNessuna valutazione finora

- AVR241: Direct Driving of LCD Display Using General IO 8-Bit Microcontrollers Application NoteDocumento11 pagineAVR241: Direct Driving of LCD Display Using General IO 8-Bit Microcontrollers Application NoteTilinschi LucianNessuna valutazione finora

- LED Backlighting WhitepaperDocumento6 pagineLED Backlighting WhitepaperAntonio DalioNessuna valutazione finora

- Sony PDP-01 Plasma TrainingDocumento91 pagineSony PDP-01 Plasma Trainingdann222Nessuna valutazione finora

- LCD Screen AdvantagesDocumento4 pagineLCD Screen AdvantagesOmprakash_janaNessuna valutazione finora

- LM201U04Documento26 pagineLM201U04bachettNessuna valutazione finora

- Lm170e01 G5Documento28 pagineLm170e01 G5iammiaNessuna valutazione finora

- Infineon-Component - Segment - LCD - (SegLCD) - V3.20-Software Module Datasheets-V03 - 04-ENDocumento35 pagineInfineon-Component - Segment - LCD - (SegLCD) - V3.20-Software Module Datasheets-V03 - 04-ENAlhassan Ahmed OmranNessuna valutazione finora

- Marvell Mobile Display TechnologiesDocumento12 pagineMarvell Mobile Display TechnologiesNguyễn Thanh HùngNessuna valutazione finora

- Samsung 2009 PDP Plasma Training Manual (ET)Documento74 pagineSamsung 2009 PDP Plasma Training Manual (ET)Tahir AliNessuna valutazione finora

- High Performance TFT LCD Driver Ics For Large-Size Displays: I Fast-Growing TV MarketDocumento9 pagineHigh Performance TFT LCD Driver Ics For Large-Size Displays: I Fast-Growing TV MarketDwi MandarisNessuna valutazione finora

- Infineon-Component - Segment - LCD - (SegLCD) - V2.10-Software Module Datasheets-V03 - 04-ENDocumento32 pagineInfineon-Component - Segment - LCD - (SegLCD) - V2.10-Software Module Datasheets-V03 - 04-ENCode-XNessuna valutazione finora

- SONY T CON Training ManualDocumento12 pagineSONY T CON Training ManualКрасимир Костадинов96% (26)

- North Museum Science & Engineering Fair 2015 WinnersDocumento9 pagineNorth Museum Science & Engineering Fair 2015 WinnersKarenShueyNessuna valutazione finora

- Definition of EbookDocumento14 pagineDefinition of EbookNurul IzzahNessuna valutazione finora

- Recruitment of Junior Associates (Customer Support & Sales) PDFDocumento2 pagineRecruitment of Junior Associates (Customer Support & Sales) PDFSingh ShivamNessuna valutazione finora

- SV50SP2RevB Released User DocumentsDocumento8 pagineSV50SP2RevB Released User DocumentsAhmed RamadanNessuna valutazione finora

- Transformer HandbookDocumento116 pagineTransformer HandbookAnder H. CaulfieldNessuna valutazione finora

- Digital Design Course FileDocumento191 pagineDigital Design Course FileCharan NethaNessuna valutazione finora

- CV hll3220cw Uke PSGDocumento17 pagineCV hll3220cw Uke PSGczarownikivanovNessuna valutazione finora

- Decline Curve AnalysisDocumento37 pagineDecline Curve AnalysisAshwin VelNessuna valutazione finora

- 7GCBC PohDocumento75 pagine7GCBC PohEyal Nevo100% (1)

- Centaour 50 Solar TurbineDocumento2 pagineCentaour 50 Solar TurbineTifano KhristiyantoNessuna valutazione finora

- ElinkDocumento36 pagineElinkjosemanuelarangoNessuna valutazione finora

- Competitive Products Cross-Reference GuideDocumento30 pagineCompetitive Products Cross-Reference GuideJeremias UtreraNessuna valutazione finora

- High Impact Presentation SkillsDocumento5 pagineHigh Impact Presentation SkillsMohd AqminNessuna valutazione finora

- Total Productive Maintenance WorksheetDocumento2 pagineTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- Section 02795 Porous Paving: Whole Building Design Guide Federal Green Construction Guide For SpecifiersDocumento6 pagineSection 02795 Porous Paving: Whole Building Design Guide Federal Green Construction Guide For SpecifiersAnonymous NMytbMiDNessuna valutazione finora

- GETDIL Annual Report 2016 17Documento172 pagineGETDIL Annual Report 2016 17kmnNessuna valutazione finora

- 08 PrimingDocumento6 pagine08 PrimingJose RojasNessuna valutazione finora

- DOE Cooling Catalogue 2017Documento164 pagineDOE Cooling Catalogue 2017Rashaad SheikNessuna valutazione finora

- Manual Instructions For Using Biometric DevicesDocumento6 pagineManual Instructions For Using Biometric DevicesramunagatiNessuna valutazione finora

- MailDocumento2 pagineMailSurya Ganesh SaitanaNessuna valutazione finora

- 797F Off-Highway Truck Transmission System: View A-ADocumento2 pagine797F Off-Highway Truck Transmission System: View A-AramiroNessuna valutazione finora

- Unit of Work Football Y9Documento5 pagineUnit of Work Football Y9api-282209830Nessuna valutazione finora

- TractionBatteries Technical WebDocumento20 pagineTractionBatteries Technical WebnarakribNessuna valutazione finora

- Teaching and Learning With Technology: An IntroductionDocumento4 pagineTeaching and Learning With Technology: An IntroductionAphril Joy LlorenteNessuna valutazione finora

- About Language UniversalsDocumento8 pagineAbout Language UniversalsImran MaqsoodNessuna valutazione finora

- Vsphere Esxi Vcenter Server 50 Monitoring Performance GuideDocumento86 pagineVsphere Esxi Vcenter Server 50 Monitoring Performance GuideZeno JegamNessuna valutazione finora

- The Organization & Structure of Banks & Their IndustryDocumento19 pagineThe Organization & Structure of Banks & Their Industryrachim04Nessuna valutazione finora

- Introducing Maf and Mef Frameworks: Exploring Managed Addin FrameworkDocumento9 pagineIntroducing Maf and Mef Frameworks: Exploring Managed Addin Frameworkkris2tmgNessuna valutazione finora