Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Wps Gtaw Monel b127 b164

Caricato da

Srinivasan MurugananthamDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Wps Gtaw Monel b127 b164

Caricato da

Srinivasan MurugananthamCopyright:

Formati disponibili

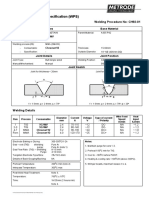

WELDING PROCEDURE SPECIFICATION (QW 482)

Applicable Codes: ASME SEC IX, Welding Process(es): JOINT DESIGN(QW-402): Single V Groove Single bevel Branch Socket Backing(Yes/No): NO Backing Material: Metal Nonfusing Metal Nonmetallic Other BASE METAL(QW-403): P.No. 42 OR Specification,type, and grade to Specification type, and grade OR Chemical Analysis,and Mechanical properties to Chemical Analysis,and Mechanical properties Thickness Range: Base Metal: PQR : Base Metal Range: Base metal Qualified: Others: Pipe Dia: . P.No. - 42 or ASTM B127, B164 or Equivalent 8mm THK Groove1.5 mm to 16mm Fillet All : NA : NA : ASTM B127, B 164 (UNS C04400) or Monel 400 or Equivalent : ASTM B127, B 164 (UNS C04400) or Monel 400 or Equivalent Summary: GTAW / 3G / B127 / B164 (Monel 400)

Type: Manual Automatic, Manual, or Semi Auto)

DOC. REF

Rev:00

Supporting PQR No:

Page No.:

GTAW

Joint Details:

30 5.

0

1.6mm0.8

2-3 mm

To

P.No.

42

FILLER METALS(QW-404): Root + Others Spec. No.(SFA) AWS No.(Class) F.No. A.No. Size of Filler Metals Weld Metal Thickness Groove Range Fillet Electrode Flux (Class) Flux Trade Name Consumable Insert Other: Filler wire Trade SFA 5.14 ER Nicu-7 34 NA 2/2.4 8 MM 16 MM ALL ------------.

PREPARED BY SIGN.

REVIEWED BY

APPROVED BY

Page 1 of 2

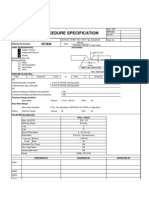

WELDING PROCEDURE SPECIFICATION (QW 482)

Applicable Codes: ASME SEC IX, POSITIONS(QW-405): Position of Groove 3G, 4G Welding Progression Position of Fillet Others All Uphill Summary: GTAW / 3G / B127 / B164 (Monel 400) Holding Temperature Range Holding Time Range Cooling Rate Others PREHEAT(QW-406): Preheat Temperature(Min.) -10 C Min Interpass Temperature(Max.) Preheat Maintenance Yes

0

DOC. REF

Rev:00

Supporting PQR No:

Page No.:

POST WELD HEAT TREATMENT(QW-407): Heating Rate NA NA NA NA

GAS(QW-408): Gas(es) Shielding 160 C

0

ARGON NA ARGON

percent composition %Comp. of Flow Rate mixture 99.995 % 8 to 18 LPM NA 99.995 % NA 8 to 18 LPM

Trailing Back Purging

ELECTRICAL CHARACTERISTICS(QW-409):

Current AC or DC - DC

Polarity -

Straight for GTAW (DCEN) 2.4 mm and 2% Thoriated NA NA

Ampere Range:

75 - 130 Amps

Voltage Range:

08 - 18 Volts

Tungeston Electrode Size and Type Mode of Metal transfer for GMAW Electrode/Wire feed speed range TECHNIQUE(QW-410): Stringe or Weave Bead Orifice or Gas Cup Size Method of Back Gouging Oscillation Contact Tube to Work Distance Multiple or Single Pass(per side): Multiple or Single Electrode Travel Speed Range Peening Others -

String bead for Root & String/Weave bead for other passes, Weaving shall not exceed 3 times of electrode dia.

6 -10 mm OD Grinding & Brushing NA NA NA Multiple Single 35- 60 mm/min NA Filler Metal Diameter Class mm

ER CuNi SFA 5.7 ER CuNi SFA 5.7 2.4 mm 2.4 mm

Initial and Interpass Cleaning(Brushing,Grinding,etc.) -

Weld Layer

Root+ Hot Filler/ Capping

Weld Process

GTAW GTAW

Current Type & Ampere Polarity Range

DCEN DCEN 75- 115 100 - 125

Voltage Range

08 - 12 10 - 15

Travel Speed Range

35 - 60 mm/min 35 - 60 mm/min

REMARK

PREPARED BY

REVIEWED BY

APPROVED BY

Page 2 of 2

Potrebbero piacerti anche

- WPS Resrvoire Sous Pression Smaw SawDocumento6 pagineWPS Resrvoire Sous Pression Smaw SawDanem HalasNessuna valutazione finora

- 1015 To Hastelloy VickoDocumento14 pagine1015 To Hastelloy Vickovgestantyo100% (1)

- Gtaw 106Documento2 pagineGtaw 106ganeshkumarg_1Nessuna valutazione finora

- Wps p91 - BhelDocumento2 pagineWps p91 - BhelAshish Gupta100% (4)

- Ami-001 WPSDocumento2 pagineAmi-001 WPSPramod Athiyarathu100% (1)

- WPS-Tube To Tube Sheet (SS-SS)Documento2 pagineWPS-Tube To Tube Sheet (SS-SS)suria qaqcNessuna valutazione finora

- Wps For Carbon Steel THK 7.11 GtawDocumento1 paginaWps For Carbon Steel THK 7.11 GtawAli MoosaviNessuna valutazione finora

- 19403955-WPS M.S. Is 2062Documento10 pagine19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPQ CS SmawDocumento1 paginaWPQ CS Smawniket0Nessuna valutazione finora

- Welding Procedure Specification "WPS": O O O ODocumento1 paginaWelding Procedure Specification "WPS": O O O OAli MoosaviNessuna valutazione finora

- 193 Gmaw Zug Asme (Andhika Rolando 3g) WPQDocumento1 pagina193 Gmaw Zug Asme (Andhika Rolando 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- 1035 03Documento2 pagine1035 03Anuj ShahiNessuna valutazione finora

- WPS 316 L PDFDocumento4 pagineWPS 316 L PDFIrinaNessuna valutazione finora

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Documento20 pagineWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Documento2 pagine(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- ASME 9 - CalculatorDocumento2 pagineASME 9 - CalculatorEmel Besir100% (1)

- Alu WpsDocumento4 pagineAlu WpsdselvakuuNessuna valutazione finora

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Documento12 paginePT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNessuna valutazione finora

- Metrode - P92 WPS PDFDocumento3 pagineMetrode - P92 WPS PDFXing ChenNessuna valutazione finora

- PQR 01 PDFDocumento2 paginePQR 01 PDFVijay BhaleraoNessuna valutazione finora

- 202 1sp 0 Saw Cs CsDocumento8 pagine202 1sp 0 Saw Cs CskrishimaNessuna valutazione finora

- Wps Gmaw SawDocumento2 pagineWps Gmaw Sawupedro26Nessuna valutazione finora

- ASME P Material NumbersDocumento1 paginaASME P Material Numbersmahi1437100% (1)

- API Welding Procedure Specification PDFDocumento3 pagineAPI Welding Procedure Specification PDFBob LeeNessuna valutazione finora

- For Fillet Weld Joint Project:Production ManifoldDocumento1 paginaFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- LBW WOPQ REV. 2010a Interactive FormDocumento1 paginaLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Documento8 pagineQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanNessuna valutazione finora

- WPS 2014-002 006 - 6G PipeDocumento3 pagineWPS 2014-002 006 - 6G PipejeswinNessuna valutazione finora

- Piping Inspection 22.01.2020Documento72 paginePiping Inspection 22.01.2020KarthikNessuna valutazione finora

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocumento4 pagine163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNessuna valutazione finora

- Aws d1.5 PQRDocumento2 pagineAws d1.5 PQRjacquesmayolNessuna valutazione finora

- WPSDocumento3 pagineWPSKhurram Burjees100% (1)

- Welding Procedure SpecificationDocumento27 pagineWelding Procedure SpecificationGopakumar K100% (2)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Documento2 pagineWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNessuna valutazione finora

- P 91 - Welding WPSDocumento2 pagineP 91 - Welding WPSSuhailshah123475% (4)

- WPS-PQR (Er309l Mo)Documento4 pagineWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS SampleDocumento182 pagineWPS Sampleaymenfr23Nessuna valutazione finora

- WPS & PQR (E Co Cr-E)Documento3 pagineWPS & PQR (E Co Cr-E)HossamSAshourNessuna valutazione finora

- SS WPSDocumento1 paginaSS WPSMOHAMEDABBASNessuna valutazione finora

- AWS D1.1 - Example PQR & WPS DocumentsDocumento4 pagineAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Electrodes ConsumablesDocumento2 pagineElectrodes Consumablesranjith_007100% (2)

- QW-483 BlankDocumento2 pagineQW-483 BlankCraftyBob100% (1)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Documento2 pagineWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNessuna valutazione finora

- Filler Metal Selection GuideDocumento2 pagineFiller Metal Selection GuideMehta Mehul100% (1)

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS)Documento2 pagineQw-482 Suggested Format For Welding Procedure Specifications (WPS)Ravelo Jeisson100% (2)

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Documento1 paginaQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)ventas ventasNessuna valutazione finora

- QW-451 Procedure Qualification Thickness Limits and Test SpecimensDocumento2 pagineQW-451 Procedure Qualification Thickness Limits and Test SpecimensmiteshNessuna valutazione finora

- WPS GTAW Stainless SteelDocumento7 pagineWPS GTAW Stainless SteelVarun MalhotraNessuna valutazione finora

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Documento2 pagineWelding Procedure Specification (WPS) : (Asme Sec. Ix)Emmanuel Loayza100% (1)

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Documento3 pagineAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNessuna valutazione finora

- WPQ Sample PrintoutDocumento1 paginaWPQ Sample PrintoutKannan VelNessuna valutazione finora

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Documento2 pagineWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNessuna valutazione finora

- Electrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsDocumento1 paginaElectrode Selection As Per Base Metal With Preheat, Postheat and Hardness DetailsJlkKumar100% (1)

- WPS GTAW Stainless SteelDocumento2 pagineWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS GTAW Stainless SteelDocumento4 pagineWPS GTAW Stainless SteelAnand NarayananNessuna valutazione finora

- Wps 316L SMAW+GTAW R00Documento2 pagineWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocumento6 pagineProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNessuna valutazione finora

- Welding Procedure Specification: Technip KT India LimitedDocumento5 pagineWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Wps For SS 304Documento3 pagineWps For SS 304MuraliKrishna87% (23)

- Wps Gtaw Monel b127 b164Documento2 pagineWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- Wps Gtaw Monel b127 b164Documento2 pagineWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- WPS GTAW Stainless SteelDocumento2 pagineWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS GTAW Stainless SteelDocumento2 pagineWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS GTAW Stainless SteelDocumento2 pagineWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Asme V Si UnitsDocumento3 pagineAsme V Si UnitsvidhisukhadiyaNessuna valutazione finora

- Research StatementDocumento5 pagineResearch StatementEmad AbdurasulNessuna valutazione finora

- Mathematical Model For LCL Filter With AFE ConverterDocumento4 pagineMathematical Model For LCL Filter With AFE ConverterSubash Chandar AdikesavanNessuna valutazione finora

- Analysis of Shear Walls For Multi-Storey Timber BuildingsDocumento54 pagineAnalysis of Shear Walls For Multi-Storey Timber BuildingsrahimmullaNessuna valutazione finora

- 05 PDFDocumento1 pagina05 PDFdruwid6Nessuna valutazione finora

- Kemira, Leonard Dan Bethel Acid FormicDocumento22 pagineKemira, Leonard Dan Bethel Acid FormicBen Yudha SatriaNessuna valutazione finora

- Astm C131Documento8 pagineAstm C131chatransito10% (1)

- Electricity and MagnetismDocumento84 pagineElectricity and Magnetismamalina rohaizanNessuna valutazione finora

- Coax Catalog - Times Microwave SystemDocumento80 pagineCoax Catalog - Times Microwave SystemweirdjNessuna valutazione finora

- Basf Processing Styrinic Polymers and CopolymersDocumento14 pagineBasf Processing Styrinic Polymers and CopolymersTejender SinghNessuna valutazione finora

- Manual On Experimental Stress AnalysisDocumento31 pagineManual On Experimental Stress AnalysisrmontandonNessuna valutazione finora

- AluminioDocumento14 pagineAluminiobrauliocoroNessuna valutazione finora

- Power Generation by Using Piezoelectric Transducer With Bending Mechanism SupportDocumento6 paginePower Generation by Using Piezoelectric Transducer With Bending Mechanism SupportIAES IJPEDSNessuna valutazione finora

- Conics 2Documento8 pagineConics 2Boy ShahNessuna valutazione finora

- Zhang 2007 J. Electrochem. Soc. 154 A910 PDFDocumento8 pagineZhang 2007 J. Electrochem. Soc. 154 A910 PDFPeterNessuna valutazione finora

- Fatigue Crack Growth Analysis of A FilletDocumento7 pagineFatigue Crack Growth Analysis of A FilletPhilip IannaNessuna valutazione finora

- Euler S Method and Runge-Kutta MethodDocumento12 pagineEuler S Method and Runge-Kutta MethodDalia Estefania Guerrero RodriguezNessuna valutazione finora

- Appendix 27 Alternative Requirements For Glass-Lined VesselsDocumento2 pagineAppendix 27 Alternative Requirements For Glass-Lined VesselsBinay K SrivastawaNessuna valutazione finora

- Sleipner A - North Sea Oil Platform CollapseDocumento28 pagineSleipner A - North Sea Oil Platform Collapsemacynthia26Nessuna valutazione finora

- Operating Instructions: Vegapuls 67Documento84 pagineOperating Instructions: Vegapuls 67SideparNessuna valutazione finora

- CHEM 212 - RecrystallizationDocumento16 pagineCHEM 212 - RecrystallizationkristaNessuna valutazione finora

- SSPC Pa 2Documento16 pagineSSPC Pa 2Rony Ruiz100% (5)

- Objective Method For Assessing The Audibility of Tones in Noise Joint Nordic MethodDocumento18 pagineObjective Method For Assessing The Audibility of Tones in Noise Joint Nordic MethodSheetaltwuNessuna valutazione finora

- Niosh Lift Push PullDocumento15 pagineNiosh Lift Push Pullahuan huanNessuna valutazione finora

- EE6501 Power System Analysis12Documento19 pagineEE6501 Power System Analysis12NAENWI YAABARINessuna valutazione finora

- FRAP 30mmDocumento97 pagineFRAP 30mmSkeevekillerNessuna valutazione finora

- Lutensol XP Surfactants Nonionic Surfactants For DetergentsDocumento11 pagineLutensol XP Surfactants Nonionic Surfactants For DetergentsKaran Kumar VermaNessuna valutazione finora

- Chapter 1 Smith and Van NessDocumento41 pagineChapter 1 Smith and Van NessJohn Raymart RaferNessuna valutazione finora

- SOPs For ChemicalsDocumento7 pagineSOPs For ChemicalselizasunderNessuna valutazione finora

- Construcion PiqueDocumento7 pagineConstrucion PiqueYery SantanderNessuna valutazione finora

- A Mini Project ReportDocumento37 pagineA Mini Project ReportChintuu Sai100% (2)