Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Valve Train Secrets Revealed

Caricato da

api-239528001Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Valve Train Secrets Revealed

Caricato da

api-239528001Copyright:

Formati disponibili

VALVETRAIN SECRETS REVEALED

Spin Control

EVER WONDER HOW ENGINES WITH HYDRAULIC LIFTERS ARE ABLE TO REV TO 8,000 RPM? YOU CAN SEE HOW IT WORKS ON THE SPINTRON

ver hear the saying ignorance is bliss? When it comes to the valvetrain on my Real Street pushrod engine, it might be true. For about a year, weve been looking for an opportunity to look at our valvetrain in a more technical manner. Over the course of several years, weve seen stock cam-and-lifter combinations being run well past 7,500 rpm. If you posted that on an Internet message board, youd be laughed off. Still, I see posts where guys cannot believe how high were able to rev our Real Street engines. Ive read many stories about camshaft companies that use the SpinTron to develop valvetrain components. Of the companies we talked with, most were in constant use for NASCAR applications. Surely, a Real Street combo would benefit from SpinTron testing. As fate would have it, I met Bob Fox at the PRI show in Orlando.While dining with friends from GM, I met Sue Christopherson and her husband, Steve, whowhen the conversation Text and Photos by Robin Lawrence

turned to my Real Street combination insisted I meet Bob Fox from Trend Performance. I had used Trend pushrods in my car with an improvement in stability.We eliminated some problems when I installed a set of Trend 38-inch, 0.135-wall pushrods. As it turns out, Bob invented and now owns the company that builds the SpinTron. He also owns Diamond Pistonsthis guy obviously knows a thing or two about a thing or two. When Bob offered the use of his in-house

demonstration unit, we jumped. As many of you know, Don West prepares my Trick Flow heads for the Real Street class. He has extensive experience with the Trick Flow Twisted Wedge and GT-40 heads I used in Factory Stock. Don has spent countless hours on the flow bench working on improving flow below the 0.480 total lift we see in those classes. In addition, he has the Stuska Dyno we use to test our improvements.To say Don was excited about a little time on the SpinTron

Horse Sense: The SpinTron is a machine thats powered by a 50hp electric motor and is used for testing valvetrain components. Once an engine block has been mounted to a fixture on a SpinTron, a mandrel is installed in place of the crankshaft, and a hole is cut into the side of the block where a laser is used to measure valve movement. With the electric motor spinning the engine to 12,000 rpm, information from the laser tracking is sent to the SpinTron software where it plots valve movement. Different rpm points can be set up to capture data and review it with the software at a later time. Every NASCAR and NHRA Pro Stock engine builder uses a SpinTron. Most are in the hands of cam manufacturers. Initially, Bob Fox built three machinesone for his company, Trend Performance, and two others to help offset costs. Hendrick Motorsports and Comp Cams bought those two units. To date, about 100 machines have been built.

150 5.0 AUGUST 2006

VALVETRAIN SECRETS REVEALED

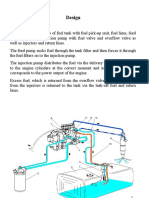

This is our 5.0 roller block as we arrived. As you can see, plugs are installed in each cylinder. We utilized the wet-sump oiling because thats what we run in our Real Street engine.

This is the hole that Leif (pronounced Life) Glasius at SpinTron cut in the side of the block. The laser will be positioned there to read the valve movement. Notice the block plug and aluminum cover where the lower portion of the block was cut away. Needless to say, this block is forever a test piece. Not to worryCar Shop [(309) 797-4188; www.carshopinc.com] fixed us up with a block that could not be bored any further. Now its being put to good use again.

would be an understatement. In the time Ive been involved in the Real Street class, 98 percent of our increases in power were directly related to the valvetrain. With the Paxton supercharger, more rpm meant more horsepower. In our quest for more rpm, we learned a lot, but sometimes at great expense. In 2004, I broke valves at Bradenton and at Atco. In both cases the damage was extensive. The Bradenton engine needed an overbore with a new set of pistons. We had the head welded, but after about 10 passes it had to be freshened. The Atco engine also needed an overbore, pistons, one rod, and a new set of heads. I had been spinning that engine past 8,400 rpm routinely with the Novi 2000. With the large blower pulley, the engine peaked at about 8,100 rpm on the engine dyno. Looking back, it probably peaked there because the valvetrain was out of control. After two engine failures, I chose to use the Paxton Novi 1200 for the 05 season. With that unit, our 307 had a horsepower peak at 7,400 rpm. Out came the 4.56 gears and in went the motive 4.29s.While experimenting on the dyno, we tested spring pressure as high as 500 pounds on the seat.Yes, you read that right: 500 pounds.When we lost control of the valves, several things happened. First, it beat the heck out of the seats, which I believe was due to the bounce of the valve as it was closing. And the keepers were difficult to remove, which was from the severe hammer effect that happens when you lose control of the valvetrain. For 2005, our effort was to stabilize the valvetrain.We found that anything over 380 pounds on the

152 5.0 AUGUST 2006

seat had no improvement.We did see considerable improvement with the new Trend 3 8-inch, 0.135-wall pushrods. There are people out there who will tell you the lifters will break at a certain spring pressure. In all of our testing, we have failed only three lifters.We use the OEM Eaton lifters that are available from Ford Racing Performance Parts.Weve looked at aftermarket replacements, but are staying with the FRPP pieces.The failures weve had were in instances where low spring pressure resulted in loss of valvetrain control.The hammer effect from the loss of control destroys lifters and valves. In all cases where we increased spring pressure, it reduced the loss of control. Since we mentioned the lifter, well also tell you about how we adjust the preload. At high rpm and high spring pressure, the lifter tends to collapse and lose effective lift.The rules in R/S state that we cannot run the lifters bottomed out, in effect running them solid.To determine if a lifter is bottomed out, spin the pushrod while the lifter is on the base circle of the cam. It should spin if it isnt bottomed out. Because of that, we run the lifter about 0.006 away from bottomed out. Once the engine warms and expands, we gain a little more. Setting the lifter this way ensures that you dont lose any effective lift and duration if the lifter starts to collapse. If you dont run a stock cam, you might think this doesnt apply to you. Most aftermarket cams for our applications were designed years ago, and therefore have not had the benefit of testing on a SpinTron. Most lobe designs are based on old masters that are more than 25 years old. Remember,

We began our testing with this setupthe Jesel MoHawk shaft rockers we ran for the past couple of years. NMRA has outlawed their use in Real Street. We wanted a baseline on what we ran in the past. You can see the titanium retainers and 38-inch pushrods that are also no longer legal. Im going to miss these parts.

Heres the engine ready to go. We used the same Trick Flow heads, valve cover, and intake we run on the car. The intake is there to keep the oil from spraying everywhere. As time went on, we only used the bolts for the valve cover and set the intake in place instead of bolting it down. That way, changes are much quicker.

If you look closely, you can see we have about 320 pounds on the seat. It had dropped considerably from where we had set it in 2005. These heads were pulled from the engine we ran last year. Don West brought along his LSM valvespring checking tool to measure the seat pressure, and were assuming this will be the method the NMRA uses to check the new valvespring rules.

NASCAR and NHRA Pro Stock are the first priorities for cam companies. Managing your valvetrain is just as critical, especially if youre running something much larger than the stock cam.

Testing 1, 2, 3

We looked at several things in our SpinTron test, one being our 04 combination.We wanted to see the kinds of forces we subjected our engine to that broke two valves. Next, we wanted to examine our 05 combination to discover what was responsible for its huge improvement in wear and tear. Finally, we looked at the new 06 combination. For 2006, the NMRA mandated sweeping changes in the valvetrain rules in Real Street. Pushrod cars are now limited to 160-pound spring pressure on the seat, steel retainers, no shaft rockers, and no larger than 5 16-inch pushrods. Other changes to the class include smaller 158-inch headers, 50 extra pounds and no bigger than a 3.73 gear ratio. This is NMRAs intent to attract more street-oriented racers to the class. Our first test was educational:We were losing control at about 7,800 rpm.While the bounce was there, I would learn later that it wasnt as bad as it could be.This combination used the Jesel Shaft Rocker, 320 pounds on the seat (down from where we had set them),Trend Products 38-inch, 0.135-wall pushrods, and Manley titanium retainers. I learned later this was a good point to reference all other tests.This test was at 8,000 rpm.While not optimum, it would live without beating up the valve seats (see 05 Setup Graph, p. 156). Next we removed the Trend Pushrods and installed a set of 516-inch, 0.080-wall pushrods we had run in 2004. The valvetrain was out of control at 7,000 rpm. Look at the graph to see what we were doing at 8,000 rpm. This was concrete evidence as to why I broke those valves. The pitch the

AUGUST 2006 5.0 153

VALVETRAIN SECRETS REVEALED

Try as I might, I could not get AskRobin.com on the SpinTron computer. Can you believe Gerry and Leif turned me loose on this thing? The software allows the user to set up predetermined rpm to sample. Click the mouse to start the process. It makes a lot more noise than you might think. At different rpm, the valvetrain makes different noises, and we could hear when the valvetrain lost control. We were a bit conservative and didnt want to continue when major float or bounce was detected. Don, on the other hand, wanted to see parts flying off the test engine.

This photo shows the laser installed in the side of the block. We painted the valves with a white paint so the laser would read the movement better. Each time we made a change, we had to realign the laser on the valve. SpinTron is currently working on a dual-pickup setup, which will be able to read an intake and exhaust valve at the same time. It will require holes on each side of the block to read from different cylinders.

engine made when it lost control of the valve was scary. I cant believe the valves held up as long as they did (see 04 Setup Graph, p. 156). That ended our first day, and I was depressed by what I learned. Knowing what the new rules in Real Street took away, I couldnt see how I was going to make any rpm and keep my parts from breaking. The next day, we removed all of last years components. Don worked on setting the valvesprings at their properly installed heights. He isnt used to working with these lame street-motortype parts.We didnt have enough height on some valves and would have to run without seat cups. All the time, Don was grumbling about the new rules, and we had several items to test. First we had two sets of valvesprings. One was the singleconical style, or beehive spring.These springs seem to be the latest rage, and theyve gotten a lot of ink because of their design.They are the same type of spring used on the Chevrolet LS engine series, and the advantages are myriad.They use an ovate string wound in a conical design.The small-diameter retainer is almost as light as titanium.The other set we tested were the Anderson Ford Motorsport Hi-Rev Series dual springs, which are more traditional springs. The guys at Trend whipped up a set of 6.700-inch-long, 518-inch-diameter, 0.105-wall pushrods to comply with the new rules. Remember when someone would tell you they have lightweight pushrods? If they do, smile and be proud that you have the heaviest ones you can find in your engine.They fill up with oil, so whatever weight you save on wall thickness will be filled with oil. Oil isnt

154 5.0 AUGUST 2006

know other Real Street racers use them successfully, but we saw only minimal gains on the dyno. Because of issues with keepers, we could not test the hollow stems with the conical springs. Back-to-back tests on the standard-stem valves showed the Anderson springs to be as good or slightly better than

Lief had split a stock timing cover before we arrived. This allowed us to change cams without having to remove the timing cover. After dropping the chain into the oil pan, we got smart and used an Allen wrench to hold the chain up out of the pan. We had no leakage on the timing cover during the testing.

nearly as rigid as chrome-moly.The NASCAR guys use huge 12- to 916-inch pushrods.They may be heavy, but they dont flex. During our tests, Bob Fox was hanging around answering all our questions.Generally, you will lose power when you get control of the valvetrain, he said. At first I scratched my head but later understood what he meant. We installed the guideplates and Trick Flow 1.7-ratio rocker arms. We used the 7 16-inch ARP rocker studs.Things werent nearly as dire as I thought (just dont tell the NMRAs James Lawrence or those pesky nitrous racers). I had hoped to see a stable valvetrain at 6,500 rpm.Things started to get out of control at 7,000, but nowhere near where it had been in 2004 (see 06 Setup at 7,000 Graph, p. 156). In addition to valvesprings, we tested some hollow-stem valves from Ferrea.We

SpinTron has plugs for the lifter bores that arent used. Several times, we blew out the plugs with the large volume of oil we had (I had sent Leif an old highvolume oil pump I had lying around). We had so much oil flow that we had to bypass some back to the pan. Next time Ill bring a used stock pump.

Don uses the most modern measuring equipment available. Here, hes using a combustion chamber burette to measure our installed heights. In the foreground you can see the beehive valvesprings along with the Anderson Ford Hi-Rev dual springs we tested. Don wants to keep me away from any measuring tools, as Ive broken two of his burettes.

This cam is now dedicated to SpinTron use. While testing recently, I broke one of the stock Ford horseshoe retainers. It allowed the lifter to turn and cause the damage you see here. It isnt the same cylinder we use on the SpinTron, so were good to go. An over-rev condition is usually what causes this to happen. Good valvetrain components should prevent this.

the standard stems.The hollow stems with the AFM springs were only slightly lower on the rpm range before they lost control.

More Questions

Jerry Pelkey of SpinTron told us we would leave with more questions than answersand boy was he right.We did learn where we would lose control with various parts.We also could see the benefit of lightweight parts such as hollow-stem valves and titanium retainers. Most of all, we saw how different thicknesses of pushrods, coupled with spring pressure, changed the characteristics of the valvetrain. We had heard about lofting a valve from the cam lobe. In essence this is free lift and duration. By utilizing certain components, its possible to have controlled loft so it can land the valve gently as it closes. Most of the

AUGUST 2006 5.0 155

VALVETRAIN SECRETS REVEALED

punishment of a valvetrain that has lost control is on the closing side of the camshaft. As you can see by the graphs, thats where the valve is literally bouncing off the seat (see Lofting the Valve Graph). OK, youre asking, What did you learn? If the Novi 2000 were still legal and they hadnt changed the rules, I would rule the class. I saw where we went wrong, and Im going to experiment with lofting the valve off the cam. Its like changing cams.The downside is, it can bite you in the butt. Missing a shift and over-revving the engine could result in the valve hitting the piston. Been there, done thatit isnt cheap. These are my recommendations for a hydraulic-roller cam engine. Set spring pressure between 150 to 200 on the seat.Those springs from Anderson Ford work well.The conical springs are also good, but they will cost a bit more.Titanium retainers are not just for race cars.They are stronger and lighter than steel. They cost a lot more, but youll appreciate it in the long run. Use only the lifters from Ford Racing Performance Parts, and check them regularly. Use the thickest-wall, largest-diameter pushrod you can. A 38-inch, 0.135-wall pushrod from Trend Performance works well.You may need to clearance the pushrod holes, but it will be worth it. Find a cam manufacturer that uses the newer cam-grinding machines. The technology has changed, but a lot of companies have not. The advancements in lobe design focus on controlling the valvetrain. Cams such as the Anderson Ford Motorsport Hi-Rev Series use this CNC technology. Upgrade to the

04 SETUP GRAPH This graph shows several things. The opening line for 8,000 rpm is spread a lot farther than the previous graph. This is the pushrod flexing. As the pushrod releases its energy, it lofts the valve higher than the baseline. After that, it crashes back into the lifter and bounces back off the cam profile. When the valve closes, it does so with a lot more force and bounces the valve off the seat. This is out of control.

7

16-inch studs if you use a stud-style rocker arm. The Trick Flow rockers we used worked well. If you plan to run the car on the street, adjust the preload as you would normally. When you go to the track, run the lifters as close as you can to bottomed-out.We use a dial indicator to find the optimum setting. Be careful not to run the valves so tight they are open, which can result in contact with the piston and a bent valve or two. Its amazing were able to see the numbers in these engines. Certainly no one except the NMRA will use stock cams.They arent designed for high rpm and our testing showed that. But with some good parts and a little testing, you can make a hydraulic-roller cam run high rpm. Racers in the NMRA Pure Street class, such as Rich Groh (now in Renegade) and Ron Anderson, run in the 9,000-plus range.

06 SETUP AT 7,000 GRAPH For a stock cam profile, this looks decent. Id guess the NMRA wanted to drop the rpm level between 1,500 and 2,000 rpm on the pushrod blower cars. This shows that we look fairly good at 7,000 rpm. Notice that there is little deflection as the cam opens the valve. Lower spring pressure helps this, as does a stiff pushrod. At full lift, the valve is close to the baseline trace. On the closing ramp, it follows the lobe well. After closing, the amount of bounce is minimal. Stock cam, stock lifters at 7,000 rpm.

This is our current 06 setup. We use the Trick Flow 7 16-inch studs and 1.7:1-ratio rocker arms. You can see the lightweight steel retainers and AFM springs on the exhaust valves. The intake springs in this photo were used on the dyno until our new keepers arrived.

This little baby, a friction dyno, was sitting next to the SpinTron we used. Its number two of two built, and uses a 250hp electric motor to spin a complete engine to whatever rpm youre brave enough to run. With it, you can measure gains in reducing friction. Imagine testing different ring packages, skirt designs, or frictionreducing coatings. The first unit was sold to a NASCAR team. Don and I offered to bring a couple of Real Street engines to test, but Bob has his Salt Flats speed-record engine way ahead of us. Oh well.

05 SETUP GRAPH If you compare the baseline (blue line) to 8,000 rpm (red line) you can see several things. First, the spread from the opening is minimal. Toward the top of the lobe, you can see the valve is lofted slightly and follows the closing ramp. The line is away from the baseline so it has lost control, but, as youll see later, it could be a lot worse. Notice the small blip at the bottom after the valve has closed. This indicates how much the valve is bouncing off the seat. In our car, this small amount wont tear things up. For 8,000 rpm, steel valves, and a stock cam, this isnt too bad.

LOFTING THE VALVE GRAPH OK, here it is. We tried a couple of combinations and this was the result. We had heard about engineered loft. Its possible to design in the ability to loft the cam, thus increasing effective lift. Were told the Cup guys run this type of setup. As you can see, the opening ramp is deflected so the pushrod has stored energy. Once it releases, the valve is tossed about 0.050 off the lobe. As it closes, it follows the closing ramp well. It does bounce the valve off the seat. I would bet a lot of racers are lofting their valves and dont know about it. Spring pressure must be maintained for all the conditions to be constant. If one cylinder has 20 more pounds of spring pressure, it wont have the same characteristics. Hmmm, I need to order a set of pistons with a lot of valve relief.

156 5.0 AUGUST 2006

OUT OF CONTROL GRAPH This graph is a lot like our setup from 2004. Its more dramatic in all areas. Notice the deflection at the opening followed by a rebound on the downside that actually is inverse of the baseline. The valve is slammed with such force that it bounces twice. After all the testing, we had to touch up the seats on our test heads. We could see the results of the pounding. Not everything we tried worked, and we even found a couple of things I had thought were good but werent. This is what you get when youve lost control: broken valves, snapped rocker studs, keepers pulled through retainers, or broken lifters. All these failures can cost huge dollars. Spend a little time on your valvetrain. Its worth it. 5.0

SOURCES

5.0

Anderson Ford Motorsport Dept. 5.0 1001 State Rte. 10 Clinton, IL 61727 (217) 935-3106 www.andersonfordmotorsport.com Jesel Dept. 5.0 1985 Cedar Bridge Ave. Lakewood, NJ 08701 (732) 901-1800 www.jeselonline.com Trend Performance (SpinTron) Dept. 5.0 23444 Schoenherr Warren, MI 48089 (586) 447-0400 www.trendperform.com Trick Flow Dept. 5.0 1248 Southeast Ave. Tallmadge, OH 44278 (330) 630-1555 www.trickflow.com West Racing Heads Dept. 5.0 8486 1800 N. Ave. Geneseo, IL 61254 (309) 944-4947 www.westracingheads.com

AUGUST 2006 5.0 157

Potrebbero piacerti anche

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesDa EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesValutazione: 5 su 5 stelle5/5 (1)

- Diesel Engine ImprovementDocumento12 pagineDiesel Engine Improvementkumail raza100% (1)

- PistonsDocumento6 paginePistonsapi-239528001Nessuna valutazione finora

- Turbo Tech 102 - Advanced: Understanding Air FlowDocumento10 pagineTurbo Tech 102 - Advanced: Understanding Air FlowrodrigoracingNessuna valutazione finora

- Project Street Rod: The Step-by-step Restoration of a Popular Vintage CarDa EverandProject Street Rod: The Step-by-step Restoration of a Popular Vintage CarNessuna valutazione finora

- DCC RetrofitDocumento32 pagineDCC RetrofitCarlosZavalaNessuna valutazione finora

- Paris Racing Engine Tuning Tech TipsDocumento6 pagineParis Racing Engine Tuning Tech Tipsvijendra_1893Nessuna valutazione finora

- Heavyduty OtcDocumento56 pagineHeavyduty OtcRod Jesusislord100% (1)

- Constant-Pressure Turbocharger Matching by Michael M. W. de SilvaDocumento32 pagineConstant-Pressure Turbocharger Matching by Michael M. W. de SilvaMichael M. W. de Silva100% (1)

- Using Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Documento20 pagineUsing Lock-N-Stitch Procedures For Casting Repair (0676, 0685) (SEBF8882)Chrisdian FaraniNessuna valutazione finora

- Efr Turbo Technical BriefDocumento126 pagineEfr Turbo Technical BriefTM125Nessuna valutazione finora

- Smallblockv 8 BalancingDocumento2 pagineSmallblockv 8 Balancingapi-239528001100% (1)

- Holley EFI Idle Tuning NotesDocumento7 pagineHolley EFI Idle Tuning NotesJam Bab100% (1)

- Holsetturbo Productionspecs PDFDocumento1 paginaHolsetturbo Productionspecs PDFJulio Eduardo Candia AmpueroNessuna valutazione finora

- Engine 3.0 v6Documento130 pagineEngine 3.0 v6Wlises GonzalezNessuna valutazione finora

- 1972 Ski DooDocumento243 pagine1972 Ski DooVincent RoyNessuna valutazione finora

- Camshaft Design For An Inlet Restricted FSAE EngineDocumento10 pagineCamshaft Design For An Inlet Restricted FSAE EngineAllan MachadoNessuna valutazione finora

- Cam Selection - Jim McFarland HRM March 1966Documento3 pagineCam Selection - Jim McFarland HRM March 1966garagepunkfanNessuna valutazione finora

- ABC Fuel InjectionDocumento15 pagineABC Fuel Injectionhasindu123Nessuna valutazione finora

- CI Engine CombustionDocumento14 pagineCI Engine CombustionRahul MeenaNessuna valutazione finora

- Engine BreathingDocumento18 pagineEngine BreathingNimalanNessuna valutazione finora

- 510-0245 Carb TuningDocumento2 pagine510-0245 Carb TuningChris KronzNessuna valutazione finora

- Valvetrain Feature ETM107 Mechadyne TechnologiesDocumento4 pagineValvetrain Feature ETM107 Mechadyne Technologiesseva0Nessuna valutazione finora

- Camshaft SelectionDocumento8 pagineCamshaft SelectionMichael Buff GNessuna valutazione finora

- Engine Math: About Mile Per Hour and Revolutions Per MinuteDocumento4 pagineEngine Math: About Mile Per Hour and Revolutions Per MinutexLibelleNessuna valutazione finora

- AEM Series 2 EMS Setup Notes - 02v02 Firmware UpdatesDocumento24 pagineAEM Series 2 EMS Setup Notes - 02v02 Firmware UpdatesAmaury RichardNessuna valutazione finora

- SE EFI Installation ManualDocumento85 pagineSE EFI Installation ManualTiến Minh100% (1)

- Chapter 1 - Engine Components and ClassificationDocumento42 pagineChapter 1 - Engine Components and ClassificationAdib MaharunNessuna valutazione finora

- HC PDFDocumento428 pagineHC PDFnetemma97Nessuna valutazione finora

- Trick Flow® Catalog-2019 (2021 - 01 - 27 20 - 16 - 46 UTC)Documento80 pagineTrick Flow® Catalog-2019 (2021 - 01 - 27 20 - 16 - 46 UTC)wade.hynesoutlook.comNessuna valutazione finora

- 2022 ARP CatalogDocumento180 pagine2022 ARP Catalogdonny rebornNessuna valutazione finora

- Cylinder Heads, Camshafts, and Valve Trains: Martin Restoule Algonquin CollegeDocumento41 pagineCylinder Heads, Camshafts, and Valve Trains: Martin Restoule Algonquin Collegelovedeep161Nessuna valutazione finora

- Tuning Manual Tuning Manual Tuning Manual Tuning ManualDocumento62 pagineTuning Manual Tuning Manual Tuning Manual Tuning ManualDavid BaylissNessuna valutazione finora

- Team Fast m-10 Universal Snowmobile SuspentionDocumento8 pagineTeam Fast m-10 Universal Snowmobile SuspentionnofearnemNessuna valutazione finora

- 2017 Catalog Compressed PDFDocumento140 pagine2017 Catalog Compressed PDFDaniel DonosoNessuna valutazione finora

- Air - Fuel Ratio Tuning - Rich Vs Lean - TurbobygarrettDocumento2 pagineAir - Fuel Ratio Tuning - Rich Vs Lean - TurbobygarrettDhirendra DubeyNessuna valutazione finora

- Catalogue ACDelco FuelPumpsDocumento45 pagineCatalogue ACDelco FuelPumpsAnonymous J1sELDp7Nessuna valutazione finora

- Engine - Blower Hardware - All 110101Documento58 pagineEngine - Blower Hardware - All 110101Didier Van Der LeeNessuna valutazione finora

- HEUI Injectors: HEUI Diesel Injection System OverviewDocumento5 pagineHEUI Injectors: HEUI Diesel Injection System OverviewFranco RHNessuna valutazione finora

- Diesel Engine Vs Petrol EngineDocumento5 pagineDiesel Engine Vs Petrol EngineAshutosh SinghNessuna valutazione finora

- 2010 Ginn Motor Company HHR Atlanta GADocumento8 pagine2010 Ginn Motor Company HHR Atlanta GAatlantachevroletNessuna valutazione finora

- Echo SRM210 Parts CatalogDocumento52 pagineEcho SRM210 Parts CatalogDude manNessuna valutazione finora

- 95 Egge KatlogDocumento196 pagine95 Egge KatlogMartin J.Nessuna valutazione finora

- Study Unit - Automotive Cooling SystemsDocumento104 pagineStudy Unit - Automotive Cooling SystemsWalter SarajevoNessuna valutazione finora

- Point of No Return - Returnless Fuel Injection SystemsDocumento5 paginePoint of No Return - Returnless Fuel Injection SystemsrxhughesNessuna valutazione finora

- CamsDocumento3 pagineCamsBilly Yargeau100% (1)

- Engine Induction SystemsDocumento9 pagineEngine Induction SystemsPM100% (1)

- Powerstroke ForumDocumento48 paginePowerstroke ForumRicardo AnusoNessuna valutazione finora

- High Volume LS Series Engine Oil Pump Kit: Parts List # DescriptionDocumento2 pagineHigh Volume LS Series Engine Oil Pump Kit: Parts List # DescriptionIgor MitrovićNessuna valutazione finora

- Development of High Speed Diesel EngineDocumento7 pagineDevelopment of High Speed Diesel EngineJaikirat SinghNessuna valutazione finora

- Dyno BlairDocumento10 pagineDyno BlairAntonino ScordatoNessuna valutazione finora

- Quarter Master 2016 CatalogDocumento76 pagineQuarter Master 2016 CatalogJohnny BrewerNessuna valutazione finora

- KTM - Technical Data PDFDocumento5 pagineKTM - Technical Data PDFrushiraj KadgeNessuna valutazione finora

- Dyno2000310 PDFDocumento114 pagineDyno2000310 PDFTony FoaleNessuna valutazione finora

- Camshaft and Valvetrain BasicsDocumento10 pagineCamshaft and Valvetrain BasicsRamesh RamasamyNessuna valutazione finora

- Electromagnetic Clutch System Full Seminar Report 4537Documento30 pagineElectromagnetic Clutch System Full Seminar Report 4537Lalit Tanan100% (1)

- Effect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsDocumento9 pagineEffect of Performance and Emissions On DI Diesel Engine Using Ethanol Diesel BlendsNgocTinhPhamNessuna valutazione finora

- Page 26 With LinksDocumento1 paginaPage 26 With Linksapi-239528001Nessuna valutazione finora

- Page 22 With LinksDocumento1 paginaPage 22 With Linksapi-239528001Nessuna valutazione finora

- Smallblockv 8 BalancingDocumento2 pagineSmallblockv 8 Balancingapi-239528001100% (1)

- Page 25 With LinksDocumento1 paginaPage 25 With Linksapi-239528001Nessuna valutazione finora

- Page 27 With LinksDocumento1 paginaPage 27 With Linksapi-239528001Nessuna valutazione finora

- Page 23 With LinksDocumento1 paginaPage 23 With Linksapi-239528001Nessuna valutazione finora

- Page 21 With LinksDocumento1 paginaPage 21 With Linksapi-239528001Nessuna valutazione finora

- Page 24 With LinksDocumento1 paginaPage 24 With Linksapi-239528001Nessuna valutazione finora

- Page 19 With LinksDocumento1 paginaPage 19 With Linksapi-239528001Nessuna valutazione finora

- Page 17 With LinksDocumento1 paginaPage 17 With Linksapi-239528001Nessuna valutazione finora

- Page 11 With LinksDocumento1 paginaPage 11 With Linksapi-239528001Nessuna valutazione finora

- Page 18 With LinksDocumento1 paginaPage 18 With Linksapi-239528001Nessuna valutazione finora

- Page 15 With LinksDocumento1 paginaPage 15 With Linksapi-239528001Nessuna valutazione finora

- Page 14 With LinksDocumento1 paginaPage 14 With Linksapi-239528001Nessuna valutazione finora

- Page 20 With LinksDocumento1 paginaPage 20 With Linksapi-239528001Nessuna valutazione finora

- Page 16 With LinksDocumento1 paginaPage 16 With Linksapi-239528001Nessuna valutazione finora

- Page 12 With LinksDocumento1 paginaPage 12 With Linksapi-239528001Nessuna valutazione finora

- Page 13 With LinksDocumento1 paginaPage 13 With Linksapi-239528001Nessuna valutazione finora

- Page 8 With LinksDocumento1 paginaPage 8 With Linksapi-239528001Nessuna valutazione finora

- Page 9 With LinksDocumento1 paginaPage 9 With Linksapi-239528001Nessuna valutazione finora

- Page 10 With LinksDocumento1 paginaPage 10 With Linksapi-239528001Nessuna valutazione finora

- Page 6 With LinksDocumento1 paginaPage 6 With Linksapi-239528001Nessuna valutazione finora

- Page 7 With LinksDocumento1 paginaPage 7 With Linksapi-239528001Nessuna valutazione finora

- Page 4 With LinksDocumento1 paginaPage 4 With Linksapi-239528001Nessuna valutazione finora

- Page 5 With LinksDocumento1 paginaPage 5 With Linksapi-239528001Nessuna valutazione finora

- Page 2 With LinksDocumento1 paginaPage 2 With Linksapi-239528001Nessuna valutazione finora

- Page 3 With LinksDocumento1 paginaPage 3 With Linksapi-239528001Nessuna valutazione finora

- Page 1 With Links No PreviousDocumento1 paginaPage 1 With Links No Previousapi-239528001Nessuna valutazione finora

- 2022 Acdelco Training Course CatalogDocumento81 pagine2022 Acdelco Training Course CatalogWilliam Orozco LópezNessuna valutazione finora

- Skandix Catalog Volvo s40 (-2004) v40Documento299 pagineSkandix Catalog Volvo s40 (-2004) v40gostafa100% (1)

- (Slides) - DESMODROMIC A Distinctiveness of The Ducati EnginesDocumento29 pagine(Slides) - DESMODROMIC A Distinctiveness of The Ducati EnginesFabio Guedes100% (1)

- Doosan D50SC 5 EngineMaintenanceManual SB4323E00 PDFDocumento366 pagineDoosan D50SC 5 EngineMaintenanceManual SB4323E00 PDFSami Enis Arıoğlu100% (2)

- Spare Parts General Overhaul VRUDocumento2 pagineSpare Parts General Overhaul VRUsubandiNessuna valutazione finora

- Complete Block Assembly EngineDocumento1 paginaComplete Block Assembly EngineCarlos PariNessuna valutazione finora

- Price List With MRP Wef 16 Sep 2021Documento259 paginePrice List With MRP Wef 16 Sep 2021Mihir Mehra100% (2)

- 16H Ats PDFDocumento37 pagine16H Ats PDFMiguel Marquez KongNessuna valutazione finora

- ST-117 Gear Train Inspection PDFDocumento6 pagineST-117 Gear Train Inspection PDFPopa MihaiNessuna valutazione finora

- MT-25 1rb04460e1 PDFDocumento70 pagineMT-25 1rb04460e1 PDFMochamad RizhalNessuna valutazione finora

- Perkins 4-154 Shop ManualDocumento108 paginePerkins 4-154 Shop ManualDoug Stuart75% (4)

- Fallas Camaro 2010 3.6 RsDocumento19 pagineFallas Camaro 2010 3.6 RsSebastian AnativiaNessuna valutazione finora

- Cadenas CadillacDocumento27 pagineCadenas CadillacAlfredo SalasNessuna valutazione finora

- ATUL - Gemini Petrol Premium Part Catalouge IndgnsDocumento71 pagineATUL - Gemini Petrol Premium Part Catalouge Indgnsvimal93rrNessuna valutazione finora

- View - Workshop Manual Group 21Documento114 pagineView - Workshop Manual Group 21Rachid Smaili100% (2)

- Fuso 6m60Documento20 pagineFuso 6m60Dowane Charles94% (31)

- Basic FuelDocumento30 pagineBasic FuelMulyadi Tarchani100% (1)

- CBR 600 FDocumento220 pagineCBR 600 FArmando EsparzaNessuna valutazione finora

- Parts Book Pc2000-8 - Lepbp2m800Documento1.898 pagineParts Book Pc2000-8 - Lepbp2m800Nugroho Prasetyo100% (1)

- Impreza Service ManualDocumento95 pagineImpreza Service ManualTaxiarhis ZoubosNessuna valutazione finora

- Katalog 920 PDFDocumento707 pagineKatalog 920 PDFbubulelaman100% (4)

- Overhaul Considerations: Operation and Maintenance ManualDocumento6 pagineOverhaul Considerations: Operation and Maintenance ManualCamilo Andres Cardozo FajardoNessuna valutazione finora

- Katalog Suku Cadang Honda ScoopyDocumento54 pagineKatalog Suku Cadang Honda Scoopymursid herialdiNessuna valutazione finora

- Members Section Common Rail and Camshaftless Engines The MAN B&W ME Engine Air Start SystemDocumento3 pagineMembers Section Common Rail and Camshaftless Engines The MAN B&W ME Engine Air Start SystemArun SNessuna valutazione finora

- JAC 4DA1 Series Diesel Engine PDFDocumento12 pagineJAC 4DA1 Series Diesel Engine PDFFerran Alfonso80% (5)

- Component Locator: Engine Covers and Component Assemblies (1 of 2)Documento24 pagineComponent Locator: Engine Covers and Component Assemblies (1 of 2)Wilmer HuangaNessuna valutazione finora

- Triumph Daytona 675 Race Kit ManualDocumento33 pagineTriumph Daytona 675 Race Kit ManualThunderbird3100% (2)

- M5HP85Documento610 pagineM5HP85GeigerpdfNessuna valutazione finora

- Procedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFDocumento12 pagineProcedimiento de Instalacion de La Culata Toyota 3sz-Ve PDFirvan hardiansyahNessuna valutazione finora

- The New Standard in Process Control.: Leitz Sirio SXDocumento14 pagineThe New Standard in Process Control.: Leitz Sirio SXtheflamebearerNessuna valutazione finora