Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Water Tank

Caricato da

Hari RamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Water Tank

Caricato da

Hari RamCopyright:

Formati disponibili

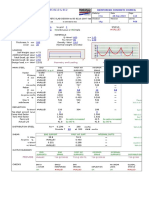

ABSTRACT: This paper deals with the design of underground water tanks, specifically with the comparison of the

codal provisions of the Indian and British Standards. The Indian Standard for the design of water tanks which has been split into four parts is IS 3370 and the corresponding British Standard is BS 8007. INPUT DATA REQUIRED: 1. 2. 3. 4. 5. 6. Dimensions of tank SBC of soil Surcharge Unit weight of soil Angle of internal friction Level of ground water

CRITICAL CONDITIONS: The two critical conditions for the design of walls are, 1. Tank full with water and no earth pressure outside 2. Tank empty with earth pressure outside The beneficial effects of soil pressure on the wall in tank full condition are to be ignored. In case of internal partition walls, they should be designed for liquid loading on each side separately. LOAD FACTORS: As per BS 8007:1987, the partial safety factors for the limit state of collapse as given in BS 8110-1:1997 can be used. The factors given are 1.4 for DL+IL/WL+ (Earth and Water Pressure) and 1.2 for DL+IL+WL+ (Earth and Water Pressure). IS 456:2000, does not mention explicitly partial safety factors for liquid and earth pressure, but as per IS 3370(Part 2):2009, the recommendations of IS 456:2000 can be used for the limit state of collapse. MATERIALS FOR CONSTRUCTION: Minimum grade of concrete for RC structures is M30 (for reinforced concrete structures) and M25 for tanks of small capacity as per Indian Standards. As per British standards, the minimum grade of concrete is C35A which has 28 day strength of 35 N/mm2. Lean concrete of grade M15 and of thickness 75mm to be placed over which the base slab is to be cast. As per BS the grade of concrete for PCC is C20. C25 grade to be used where aggressive soils are encountered.

LIMIT STATES OF SERVICEABILITY: Deflection: The Span/Effective depth ratio for limiting the defection as given by both the Indian and British codes is the same. Cracking: Maximum permissible crack width as per IS is 0.2mm. As per BS, the crack width permitted is 0.1mm for aesthetic appearance and 0.2mm for severe and very severe conditions. Floatation: When the tank is subjected to ground water pressure, it must be designed to counter the upward pressure by its self weight. The methods that can be adopted to counter flotation are 1. By thickening the base slab to increase the self weight. 2. By increasing the projection of the base slab beyond the perimeter of the wall so as to mobilize enough soil weight to resist ground water pressure. 3. Providing pressure release vessels discharging into the tank (when entry of ground water is permitted). BS 8007:1987 recommends a partial safety factor of 1.1 against flotation when the exact level of the ground water table is known. Whereas in the Indian Standards the factor against flotation is given as 1.2.

MINIMUM REINFORCEMENT: As per IS 3370(part 2):2009, the minimum steel required is 0.35 % for high strength deformed bars and 0.64% for mild steel bars on each surface zone. This percentage can further be reduced to 0.24% for deformed bars and 0.40% for mild steel bars when the tank dimensions do not exceed 15m. The bar spacing should not exceed 300mm or the thickness of the member, whichever is less. The British standard also specifies the same values with the addition of the maximum spacing for welded wire fabric to be 1.5 times the thickness of the section. PERMISSIBLE STRESSES: 1. Resistance to cracking in Concrete: The compliance with the permissible stress values as given in IS 3370(part 2):2009, ensures that the cracks developed are not excessive. 2. Resistance to cracking in steel: The tensile stress in steel is to be taken as the product of the modular ratio of steel and concrete and the corresponding tensile stress in concrete. Crack width may be deemed satisfactory if steel stress under service conditions is less than 115 MPa for MS bars and 130 MPa for HYSD bars.

FORCES IN WATER TANKS: The forces to be considered in design of water tanks are the triangular loading due to the water and soil on the walls, uniform loading on the base slab, surcharge weight and Internal vapor pressure (if any) for roof slabs. In addition to the vertical, horizontal moments and shear caused by these forces, the walls also experience tension due to the reaction from the orthogonal walls. The base slab also experiences tension because of the horizontal reaction from the walls. CALCULATION OF FORCES: For the calculation of shear and moment acting on the walls and base slab, IS 3370(Part 4):1967 can be used. These charts give coefficients on the panels at different points for different end conditions and different loadings on the wall. Similar to the Design Tables given by IS 3370 (Part 4):1967, Moodys Charts can also be used for obtaining the coefficients for the calculation of moments and shear.

REFERENCES: IS 3370(Part 1):2009 Concrete Structures for Storage of Liquids-General Requirements IS 3370(Part 2):2009 Concrete Structures for Storage of Liquids-Reinforced concrete Structures IS 3370(Part 4):1967 Concrete Structures for Storage of Liquids-Design Tables BS 8007:1987 Design of concrete structures for retaining aqueous liquids R.D.Anchor. Design of Liquid Retaining Concrete Structures

Potrebbero piacerti anche

- Slab Designer As Per IS 456-2000Documento7 pagineSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Design of overhead circular water tankDocumento30 pagineDesign of overhead circular water tankvishnumani3011100% (1)

- Biogas Generation From Rice Cooking WastewaterDocumento3 pagineBiogas Generation From Rice Cooking WastewaterProyectos Plantas De Tratamiento De AguaNessuna valutazione finora

- Checklist For Transformer Burnt Oil Tank Design & DrawingDocumento3 pagineChecklist For Transformer Burnt Oil Tank Design & DrawingRupesh KhandekarNessuna valutazione finora

- Seismic Design of Water TanksDocumento17 pagineSeismic Design of Water TanksJeevan ReddyNessuna valutazione finora

- CS5001 CourseworkDocumento9 pagineCS5001 CourseworkpeteligijusNessuna valutazione finora

- Qa & QC Manual - DraftDocumento15 pagineQa & QC Manual - DraftNayla Shafea Azzahra100% (1)

- Footing Design CalculationDocumento45 pagineFooting Design Calculationsam_antony20050% (1)

- Building Story Drift in ETABS PDFDocumento10 pagineBuilding Story Drift in ETABS PDFntirugiribambeNessuna valutazione finora

- Structural Analysis Report for Store Extension FlooringDocumento3 pagineStructural Analysis Report for Store Extension FlooringLandz GanzonNessuna valutazione finora

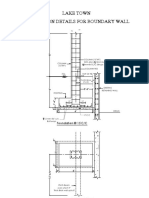

- Boundary wall foundation detailsDocumento1 paginaBoundary wall foundation detailsMohammed SumerNessuna valutazione finora

- Column Design BS8110Documento7 pagineColumn Design BS8110MinTzHo0% (1)

- Earthquake Resistant StructuresDocumento6 pagineEarthquake Resistant StructuresAmith KeshvtakarNessuna valutazione finora

- Delta Electronics Chennai Tender Compound Wall PlanDocumento1 paginaDelta Electronics Chennai Tender Compound Wall Plandox4useNessuna valutazione finora

- Building Collapse Oyenuga. 1373312119Documento11 pagineBuilding Collapse Oyenuga. 1373312119KosticNessuna valutazione finora

- Detailing To BS 8110Documento88 pagineDetailing To BS 8110Sudhakar KrishnamurthyNessuna valutazione finora

- Cantilever SlabDocumento5 pagineCantilever SlabMd Humayun Kabir100% (1)

- Basement Wall DesignDocumento2 pagineBasement Wall DesignArindam RoyNessuna valutazione finora

- Slab Design As Per IS 456Documento7 pagineSlab Design As Per IS 456RitaBiswas100% (1)

- Design of Water Retaining Structures-2003Documento35 pagineDesign of Water Retaining Structures-2003Mayank AgrawalNessuna valutazione finora

- Design and Analysis of Water TanksDocumento58 pagineDesign and Analysis of Water TanksNdoro BeiNessuna valutazione finora

- Member resistance under combined bi-axial bending and axial compressionDocumento12 pagineMember resistance under combined bi-axial bending and axial compressionrd radenNessuna valutazione finora

- Analysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCODocumento25 pagineAnalysis & Design of Multi Storeyed Buildings V.M.RAJAN, M.E. (Struct), FIE, Former CE/Civil/TANGEDCOV.m. RajanNessuna valutazione finora

- Sepakat Setia Perunding SDN BHD: Design InformationDocumento6 pagineSepakat Setia Perunding SDN BHD: Design InformationAfiq SyahmiNessuna valutazione finora

- Basic Concepts of ConcreteDocumento19 pagineBasic Concepts of ConcreteSathish SelvaNessuna valutazione finora

- Design of Intz TankDocumento14 pagineDesign of Intz TankSubbaReddyNessuna valutazione finora

- Design of two pile cap for 1072.8 KN column loadDocumento4 pagineDesign of two pile cap for 1072.8 KN column loadhemanth funny100% (1)

- Design of Underground Rectangular Concre PDFDocumento63 pagineDesign of Underground Rectangular Concre PDFNenadNessuna valutazione finora

- Design and Drawing of RC Structures: Dr. G.S.SureshDocumento40 pagineDesign and Drawing of RC Structures: Dr. G.S.SureshLeroy TuscanoNessuna valutazione finora

- Detail Design and Analysis of Earthquake PDFDocumento59 pagineDetail Design and Analysis of Earthquake PDFSabih Hashim Alzuhairy100% (1)

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Documento7 pagine1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNessuna valutazione finora

- Wind Load IS875Documento30 pagineWind Load IS875Pranjal Pareek100% (2)

- 2a - Design of Spread Footing-Usd MethodDocumento27 pagine2a - Design of Spread Footing-Usd MethodLouise LuyNessuna valutazione finora

- Design of Underground Water TankDocumento6 pagineDesign of Underground Water TankAlfred PatrickNessuna valutazione finora

- RC SHEAR WALL DESIGNDocumento7 pagineRC SHEAR WALL DESIGNAboalmaail AlaminNessuna valutazione finora

- Column Design - As Per BS CodeDocumento16 pagineColumn Design - As Per BS CodefatinamilinNessuna valutazione finora

- Footing Design According To BS8110 CodeDocumento4 pagineFooting Design According To BS8110 CodeMohit VatsNessuna valutazione finora

- Counterfort Retaining WallsDocumento1 paginaCounterfort Retaining WallsAzis Ali WibowoNessuna valutazione finora

- Wind Load Calculation (Based On CP3)Documento2 pagineWind Load Calculation (Based On CP3)Darshan ShahNessuna valutazione finora

- Structural Design ReportDocumento99 pagineStructural Design ReportCitizen Kwadwo AnsongNessuna valutazione finora

- Corn Cob FiltrationDocumento1 paginaCorn Cob FiltrationGwynneth A. OlifernesNessuna valutazione finora

- Compound Wall DesignDocumento1 paginaCompound Wall Designprozoam21Nessuna valutazione finora

- Prokon - Circular ColumnDocumento10 pagineProkon - Circular ColumnMasaba SolomonNessuna valutazione finora

- Circular Water TankDocumento7 pagineCircular Water Tanksimon maaaklaNessuna valutazione finora

- Daniel T. Li: Flagpole Footing Design Based On Chapter 18 Both IBC & UBC Input Data & Design SummaryDocumento1 paginaDaniel T. Li: Flagpole Footing Design Based On Chapter 18 Both IBC & UBC Input Data & Design SummaryJustinCharlesAmorNessuna valutazione finora

- RCC Circular Water TankDocumento23 pagineRCC Circular Water TankV.m. RajanNessuna valutazione finora

- DeckDocumento9 pagineDeckSamuel AntobamNessuna valutazione finora

- calc-SLABS CalculationsDocumento3 paginecalc-SLABS CalculationsHussen ShaikNessuna valutazione finora

- Design steel column axial loadsDocumento2 pagineDesign steel column axial loadsGihan Chathuranga100% (1)

- Structural Steel DesignDocumento32 pagineStructural Steel Designshaluka100% (1)

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Documento14 pagineSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqNessuna valutazione finora

- Column Wall DesignDocumento42 pagineColumn Wall DesignCivilax.comNessuna valutazione finora

- Seismic Analysis and Design of R.C.C Tall Building With Shear WallDocumento9 pagineSeismic Analysis and Design of R.C.C Tall Building With Shear WallNaveen JatavNessuna valutazione finora

- Ware House DesignDocumento8 pagineWare House DesignJay-Jay JapsNessuna valutazione finora

- Limit State DesignDocumento85 pagineLimit State Designkeshav1980Nessuna valutazione finora

- Design of Beams - BS 8110Documento3 pagineDesign of Beams - BS 8110thanigai veluNessuna valutazione finora

- Liquid Retaining StructuresDocumento25 pagineLiquid Retaining StructuresvijaygbordeNessuna valutazione finora

- Some Issues With IS 3370Documento5 pagineSome Issues With IS 3370A DubeyNessuna valutazione finora

- Water TankDocumento3 pagineWater Tankswe_maniNessuna valutazione finora

- ASTM specifications for concrete masonry unitsDocumento4 pagineASTM specifications for concrete masonry unitsHisham MohamedNessuna valutazione finora

- Lecture 2 Properties of ConcreteDocumento27 pagineLecture 2 Properties of ConcretemdaashuNessuna valutazione finora

- ADCSDocumento33 pagineADCSSHUBHAMNessuna valutazione finora

- Literature Study - Water TanksDocumento8 pagineLiterature Study - Water TanksHari RamNessuna valutazione finora

- Kharagpur - Staircase Design PDFDocumento38 pagineKharagpur - Staircase Design PDFjmusopole50% (2)

- Kharagpur - Staircase Design PDFDocumento38 pagineKharagpur - Staircase Design PDFjmusopole50% (2)

- Is 3370 - 1Documento27 pagineIs 3370 - 1mansidagaNessuna valutazione finora

- Phoenix Contact 3247055 enDocumento6 paginePhoenix Contact 3247055 enDGNessuna valutazione finora

- Tivizen Iplug Greek GuideDocumento13 pagineTivizen Iplug Greek GuideDenexoNessuna valutazione finora

- Making Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyDocumento2 pagineMaking Your Chain Run For Longer: Effective Chain Maintenance Advice From Renold JeffreyCương Phạm NgọcNessuna valutazione finora

- Cooling Tower PDFDocumento3 pagineCooling Tower PDFmaimslapNessuna valutazione finora

- SCT3030AL: 650V V R (Typ.) 30mDocumento14 pagineSCT3030AL: 650V V R (Typ.) 30mSas Pro EletronicaNessuna valutazione finora

- Especificaciones Discos de Embrague Transmision - Cat 140HDocumento6 pagineEspecificaciones Discos de Embrague Transmision - Cat 140HSergio StockmansNessuna valutazione finora

- Compressors & Compressed Gas Audit ChecklistDocumento3 pagineCompressors & Compressed Gas Audit ChecklistPerwez21100% (1)

- NHA 2430 Design Analysis Reporting FEADocumento7 pagineNHA 2430 Design Analysis Reporting FEAASIM RIAZNessuna valutazione finora

- MWD Log Quality & StandardsDocumento168 pagineMWD Log Quality & StandardsHamed Sadeghi100% (1)

- Slides - OOP With SmalltalkDocumento51 pagineSlides - OOP With Smalltalkapi-3728136Nessuna valutazione finora

- 03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1Documento352 pagine03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1sadh94Nessuna valutazione finora

- PM IS - 12818 June2021Documento10 paginePM IS - 12818 June2021Mahendra AhirwarNessuna valutazione finora

- Elsa CableDocumento2 pagineElsa CableJay WangNessuna valutazione finora

- University Institute of Information Technology: Ouick Learn - MCQDocumento53 pagineUniversity Institute of Information Technology: Ouick Learn - MCQvimalNessuna valutazione finora

- Fundamentals of Ship ConstructionDocumento18 pagineFundamentals of Ship ConstructionWAREKARNessuna valutazione finora

- J320 Maintenance Spare Parts ListDocumento1 paginaJ320 Maintenance Spare Parts ListKeith ChengNessuna valutazione finora

- Irc - 24-2010 PDFDocumento128 pagineIrc - 24-2010 PDFkiranNessuna valutazione finora

- Cloud Radio Access Network Architecture Towards 5G NetworkDocumento171 pagineCloud Radio Access Network Architecture Towards 5G NetworkwobblegobbleNessuna valutazione finora

- Catalogo Recordplus General ElectricDocumento12 pagineCatalogo Recordplus General ElectricDruen Delgado MirandaNessuna valutazione finora

- JIMCO Filter Catalog with Products and SpecificationsDocumento8 pagineJIMCO Filter Catalog with Products and SpecificationsDedy CjNessuna valutazione finora

- ECOSYS M6526cdn Fax SetupDocumento204 pagineECOSYS M6526cdn Fax SetupAnonymous gn8qxxNessuna valutazione finora

- RDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023Documento5 pagineRDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023sourish69Nessuna valutazione finora

- NUVE EN 032-055-120 Incubators BrochureDocumento2 pagineNUVE EN 032-055-120 Incubators BrochureDinhtrung TruongNessuna valutazione finora

- What Is Physical GeologyDocumento25 pagineWhat Is Physical GeologyMelanyNessuna valutazione finora

- Premiertrak 1100x650 Parts ENGDocumento276 paginePremiertrak 1100x650 Parts ENGarttv44100% (1)

- Davao October 2014 Criminologist Board Exam Room AssignmentsDocumento113 pagineDavao October 2014 Criminologist Board Exam Room AssignmentsPRC Board0% (1)

- Capitulos 10 y 11Documento34 pagineCapitulos 10 y 11mlpz188669Nessuna valutazione finora

- Electrical Power Transmission & DistributionDocumento18 pagineElectrical Power Transmission & DistributionMd Saif KhanNessuna valutazione finora