Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

400-Eng-9336-003 Rev 00 (Technical Specification For 220KV Switchyard) PDF

Caricato da

Sridhar Reddy GandraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

400-Eng-9336-003 Rev 00 (Technical Specification For 220KV Switchyard) PDF

Caricato da

Sridhar Reddy GandraCopyright:

Formati disponibili

PROJECT: 2 X 150 MW COAL BASED TPP, BHADRESHWAR, GUJARAT

DOCUMENT TITLE:

SPECIFICATION FOR 220kV GIS CUM AIS SWITCHYARD

Client Project Consultant Project No. Document No.

OPGS POWER GUJARAT PVT LTD.

Aquatherm Engineering Consultants (India) Pvt. Limited 9336 400-ENG-9336-003

PROJECT CONSULTANT:

Aquatherm Engineering Consultants (India) Pvt. Limited, 2nd Floor, St. Thomas Building, # 68, (Old No. 150), Luz Church Road, Mylapore, Chennai 600 004, India, Tel: (044) 24994032, 24660462, 24660464, Fax: (044) 24996085.

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

REVISION SUMMARY

Rev. No.

00

Date

24.12.2012

Prepared by

M.C.M

Checked By Approved by

T.S.S T.S.S

Revision Details

First Issue

Aquatherm Engineering Consultants India Pvt Ltd

Page 2 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

TABLE OF CONTENTS

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19.

INTRODUCTION ........................................................................................................... 4 SWITCHYARD CIRCUITS AND EQUIPMENT ............................................................. 4 BASIC INSULATION LEVEL ....................................................................................... 5 GAS INSULATION SWITCHYARD .............................................................................. 5 AIR INSULATION SUBSTATION ............................................................................... 29 220 KV SWITCHYARD LAYOUT REQUIREMENTS ................................................. 37 220 KV SWITCHYARD RELAY AND CONTROL PANELS....................................... 38 POWER LINE CARRIER COMMUNICATION (PLCC)............................................... 43 SCADA ....................................................................................................................... 44 ANNUNCIATORS ....................................................................................................... 50 LIGHTING SYSTEM ................................................................................................... 52 GALVANISED STEEL STRUCTURES....................................................................... 52 SWITCHYARD MARSHALLING BOXES ................................................................... 58 EARTHING SYSTEM .................................................................................................. 58 PRECOMMISSIONING WORKS ................................................................................ 58 DC SYSTEM ............................................................................................................... 58 SPECIFICATION FOR POWER AND CONTROL CABLES ...................................... 60 SPECIFICATION FOR TRAYS AND ACCESSORIES ............................................... 67 REFERENCE DRAWING ........................................................................................... 69

Aquatherm Engineering Consultants India Pvt Ltd

Page 3 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

1.

INTRODUCTION

This specification is intended to cover complete design, engineering, manufacture, assembly testing at manufacturer's works, supply, installation, commissioning and delivery, properly packed for transport to site of all equipment and accessories, Steel Structures & Structural work, complete and efficient erection, testing, commissioning & putting into successful commercial operation GIS cum AIS 220 kV switchyard of OPG power Gujarat PVT Ltd., Gujarat, India for 2x150 MW units. The bid for all items of equipment and system covered under this specification shall be complete in all respects and any item of equipment or accessory not specifically mentioned in this specification document but considered essential for efficient and satisfactory operation of individual equipment and system as a whole shall be included in the offer. The evacuation of generator power shall be through two nos of 220kV outgoing lines. The 220kV switchyard shall have Double Main Bus scheme with GIS as shown in the Drawings.

2.

SWITCHYARD CIRCUITS AND EQUIPMENT

The Design of the GIS Double main bus scheme shall have: 1. Generator transformer Feeder 2. Outgoing line bays 3. Station transformer Feeder 4. Bus coupler bay 2 no 2 no 1 no 1 no

The switchyard equipment shall be supplied and installed with all accessories to make the switchyard complete in all respects. The switchyard shall consist of, but not be limited to the following: 245 kV SF6 circuit breakers, isolators, current transformers and capacitor voltage transformers / EMVTs. 198 kV, 10kA lightning arrestors. Bus bar material & accessories, insulator, assemblies, clamps & connectors. Switchyard structures, supports. Switchyard control & relay panels such as outgoing line CRP, GT CRP, ST CRP, Bus Bar CRP, Bus Coupler CRP & unit transformer relay panel.

Aquatherm Engineering Consultants India Pvt Ltd Page 4 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

220kV GIS Bus duct from GIS to Transformer yard and its support materials SCADA & associated equipment. Power Line Carrier communication & associated equipment. Switchyard lighting & earthing materials. Power & control cables. 220V Battery & battery charger for switchyard 48V Batter & battery charger for PLCC ACDB & DCDB as required no.of outgoing feeders. 20% spare feeder should be provided by the contractor Design of switchyard civil works such as buildings for GIS & control room, isolator/CT/PT/LA foundation, tower & gantry foundation, bus duct support design & its footing design, fence & trenches.

3.

BASIC INSULATION LEVEL

Rated one minute Power Frequency Withstand Voltage kV (rms) Rated Lightning Impulse Withstand Voltage kV (peak) : 460 kV (RMS) : 1050 kV peak

4.

4.1.

GAS INSULATION SWITCHYARD

General The complete gas insulated switchgear shall be constructed in accordance with IEC 62271 - 203, unless otherwise stated in this Specification. It shall be fully tested in accordance with IEC 62271-100, 62271-102 and 60694. All type tests shall be either, carried out by independent testing laboratories not associated with the manufacturers, or, witnessed by independent observers. The Contractor shall supply suitable test equipment, interface transducers and connections to fully test the equipment offered. All Capacitive Couplers for Partial Discharge monitoring and site testing of GIS installations prior to energisation, shall be left in position for later use by the Client, to monitor periodically the levels of discharge. Only the analyzer shall be included in the list of spares.

Aquatherm Engineering Consultants India Pvt Ltd

Page 5 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

The signature records taken by the manufacturer prior to energisation shall be made available to the Client for future comparison purposes. Continuous partial discharge monitoring on the installation is not required. However, an optional cost for a continuous partial discharge monitoring system should be provided. 4.2. CODES & STANDARDS High voltage metal-enclosured switchgear High voltage AC Circuit Breaker Current Transformer Voltage Transformer AC Disconnectors & Earthing switches Cable connections for gas insulated metal enclosed switchgear Lightning Arrester All relevant IEC standards IEC 62271-209 IEC 60099-4 IEC 62271-203, 60694 IEC 62271-100 IEC 60044-1, 60044-6 IEC 60044-2 IEC 62271-102

4.3.

Gas Insulated Switchgear (GIS) Enclosures Enclosures shall be designed in accordance with the requirements of IEC 62271 - 203. The arrangement for bolting together and the method of ensuring electrical conductivity between enclosures shall be to approval of the Client. The live parts of the switchgear and busbars shall be supported on barriers of insulating material with proven long-term compatibility with SF6 gas and its arc degradation products. The insulating barriers shall be discharge free at all working voltages. The design of the enclosure shall be such as to keep loss of SF6 gas to a minimum. It is expected that replenishment of gas shall not be necessary for at least 10 years. Therefore, the gas leakage rate of any gas zone must not exceed 1 per cent of its volume per year. Gaskets and seals shall be designed for a life expectancy of at least 30 years and this shall be demonstrated by tests or otherwise. The switchgear gas enclosures must be sectionalised into gas zones with gas tight barriers between sections or compartments. The sections shall be arranged to minimize the extent of plant rendered inoperative when gas pressure is reduced, either by excessive leakage or for maintenance purposes, and to minimize the quantity of gas that

Aquatherm Engineering Consultants India Pvt Ltd

Page 6 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

has to be evacuated and then recharged before and after maintaining any item of equipment. In order to minimise the extent of equipment outage in the event of gas loss when gaining access inside equipment for maintenance or when an item of equipment needs to be removed, the overall equipment shall be divided into discrete gas zones isolated from each other by gas-tight bulkheads. Separate gas-zones shall be provided for busbars and isolators. The gas-tight support insulating barriers shall be capable of withstanding a pressure differential of a vacuum on one side and on the other a pressure equal to the design gas pressure or the maximum gas pressure under conditions of an internal fault if this is greater. The design of the enclosure assemblies shall be such that in the event of a fault, the damaged items can be replaced with minimum disturbance to the adjacent compartments. Each gas-tight zone shall be provided with a device to relieve any pressure rise developed during internal flashover. Overpressure created by arcing within an enclosure shall preferably be relieved by means of bursting discs venting into the atmosphere. The method of pressure release shall prevent permanent distortion of adjacent enclosures. Pressure relief by collapse of internal gas barriers is not acceptable. The arrangement of any pressure relief device shall be such that any expulsion of disc debris or gas will be directed in a manner that will not endanger any personnel and relief vents shall be provided with deflectors or vent pipes as appropriate to satisfy this requirement. The duration of the fault arc shall be determined by the operation of the main and back up protection equipment under all fault conditions as defined and specified in IEC 62271 - 203 and verified by relay setting calculations. During this fault period burn through of the enclosure by the fault arc is not permitted. 4.4. Gas Insulated Switchgear - Busbars and Connection Chambers The switchyard main buses of GIS shall be designed for 2000 A continuous current, 40kA short-circuit. The switchyard shall be designed for a fault level of 40 kA for 1sec and dynamic rating of 100 kA peak. To minimise the extent of dismantling necessary to remove a part of a main busbar, it is required that discrete lengths of busbar shall be able to be withdrawn without disturbing

Aquatherm Engineering Consultants India Pvt Ltd Page 7 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

adjacent busbar lengths; this may be achieved by the use of compressible bellows or other approved means. The equipment shall be arranged to avoid excessive dismantling in the event of a main busbar fault. Information shall be provided with the tender to indicate the facilities incorporated in the equipment to allow removal of busbars and the consequential maximum extent of dismantling that may be involved in the event of such a fault. All busbar connections and busbar chambers (where phase segregated busbars are employed) shall be colour coded to indicate the phase colour associated with the connection. All gas pipe work shall be colour coded and where more than one pipe follows a common route, each pipe shall be ring coded or labelled at regular intervals to identify the gas zone with which it is associated. 4.5. Enclosure Gas Zones The switchgear gas enclosures must be sectionalised into gas zones with gas tight barriers between sections or compartments. The sections shall be arranged to minimize the extent of plant rendered inoperative when gas pressure is reduced, either by excessive leakage or for maintenance purposes, and to minimize the quantity of gas that has to be evacuated and then recharged before and after maintaining any item of equipment. 4.6. Expansion Joints and Flexible Connections Expansion joints or flexible connections shall be provided in the busbars and metal enclosures to absorb the thermal expansion and contraction of the SF6 equipment. This shall include the switchgear supporting structures and shall accommodate differential settlement of the foundations and floors on which the equipment is mounted. The method of compensating for temperature variation and differential settlement as well as the number and position of the compensating devices shall be stated in the Schedules. 4.7. Future Extensions The design of the switchgear shall be such that it is possible to extend each end of the existing busbars without having to take more than one busbar out of service. Other circuits shall remain available for continuous uninterrupted service.

Aquatherm Engineering Consultants India Pvt Ltd

Page 8 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Where the distance between adjacent circuits is the width of a switchgear bay or greater, a removable straight through busbar section shall be included. It shall be possible to interchange this section with a future bay, if required, without having to take more than one bar out of service and without interruption of other connected circuits. 4.8. Gas Monitoring and Handling All gas zones shall be filled to the design pressure with pure SF6 gas (to IEC 60376/BS 5207) and shall be monitored individually by temperature compensated pressure switches and pressure gauges. A two-stage alarm system shall be provided for each gas section, including all relays, fascias, etc, these shall be accommodated adjacent to the switchgear. Additional repeat alarms to announce remotely each alarm stage for the group alarms of each switch bay shall be provided. The local control cubicle shall be adequately labelled to allow easy identification of signals from each gas section. The low pressure/density alarm switches shall be arranged to provide an instruction for the operation, either automatically or manually of the circuit breakers and disconnectors adjacent to a faulted gas zone and to subsequently inhibit their further operation until suitable remedial action has been taken. In view of the dependence of system security on the reliability of the gas density relays, and in view of the large number of relays involved in any regular relay checking procedure, the gas density relays shall have a high degree of reliability. Consideration shall be given in the design of the relay to allow easy checking of its proper operation. Provision shall be made to enable routine measurement of the gas density in each gaszone. The location of such measuring points shall be reasonably accessible. Each gas density device shall be connected to the gas compartment via a self-sealing valve to facilitate easy removal of the device for maintenance. The use of stop valves for this purpose is not acceptable. Facilities shall be provided to constantly monitor the gas density. A two-stage low gas pressure alarm and lock out system with local and remote indications shall be provided on each circuit breaker. 4.9. Local Control Cubicles Local control cubicles shall be separate, floor mounted cubicles, provided adjacent to each switchgear section which shall contain all facilities for control, indication,

Aquatherm Engineering Consultants India Pvt Ltd Page 9 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

local/remote control selection, protection and alarms associated with that switchgear section. A mimic diagram incorporating switches, contactors and relays necessary for local electrical control of circuit breakers, disconnectors and earth switches together with position indication shall be included. Any plug and socket cable connections between switchgear sections and their associated local control cubicles shall be provided with a secure means of locking the connection to prevent inadvertent disconnection. 4.10. Gas Insulated Bus Duct and Bushings SF6 insulated gas bus ducts and supporting structures and foundations shall be provided between circuits as required. The type of 245kV busduct ie isolated or non segregated, shall suit the arrangement of the main GIS switchgear to which the bus duct is connected. The SF6 enclosures shall be constructed from the same materials as the bus bar enclosures provided with the main GIS switchgear. The materials used shall prevent overheating at the specified rated currents. To reduce the effect of solar gain all SF6 insulated bus duct exposed to direct sunlight shall be covered with metallic sun shielding. The bus duct shall be complete with all components, enclosures, gas seals, gas monitors, gas compartments, gas filters, gas barrier and supporting insulators as defined in previous subsections. The bus ducts shall be terminated at one end direct on to the GIS switchgear and at the other end on to outdoor porcelain-clad, or approved composite-material-clad bushings for OHL feeders & Generator transformer/Station transformer feeders. The design of the bus ducts shall make full allowance of the thermal expansion associated with the switchgear, wall mounted bushings and any other equipments between which the bus ducts are connected. The Contractor shall fully co-ordinate the requirements of the SF6 insulated bus duct connections between the GIS switchgear feeders and the overhead line landing gantries & Generator/station transformer gantries, especially with regards to the differential settlement of the concrete floors of the switchgear room and the bus duct supporting structures. The design and installation of the bus ducts shall as such be fully co-ordinated with the manufacturers of the equipments to be connected and shall also be co-ordinated with the civil design and works in relation to the building height, wall openings, wall/roof embedment, structural, etc, apart from the foundation requirements described herein.

Aquatherm Engineering Consultants India Pvt Ltd

Page 10 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

The bus ducts and their supports shall be designed and tested for the specified rated normal and short time currents and for the maximum system voltage and specified test voltages. The ducts and their supports shall include any non-magnetic material or insulation necessary to prevent overheating or the induction of over-voltages in the secondary circuits. Provision shall be allowed for access and disconnection links for equipment HV testing as may be required at site. 4.11. 4.11.1. 245 kV GIS HV Circuit Breakers General SF6 gas insulated (GIS) circuit breakers shall be single-pressure puffer or Self-blast or Self- blast/Rotating Arc type, suitable for indoor installations. Circuit breakers shall be designed to IEC 62271 - 203 and fully tested in accordance with IEC 62271100, IEC 60694 and IEC 62771-110 and with the requirements of this Specification and shall be capable of carrying the specified rated current continuously under the Site conditions. All type tests shall be either carried out by independent testing laboratories or witnessed by independent observers. The design of the circuit breaker shall be such that inspection and replacement of contacts, nozzles and any worn or damaged component can be carried out quickly and easily. The circuit breaker shall be fitted with the open/closed position indicators easily visible from ground level. The inherent design of the circuit breakers shall be such that one set of contacts and nozzle (or nozzles as the case may be) shall be able to successfully interrupt at least twenty 100% fault currents without excessive erosion. When switching Capacitive (capacitor banks) and Inductive (including reactors) currents (IEC 62771-110), they produce very low over-voltages. The over-voltages produced on any switching duty must be considerably less (<<) than 2.5 pu. The sound pressure levels of the breaker during the mechanical operations shall comply with the local and national health and safety regulations. A suitably sized molecular sieve shall be used in the circuit breaker tank to absorb any moisture and contaminants for at least ten years in service.

Aquatherm Engineering Consultants India Pvt Ltd

Page 11 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

The circuit breakers shall be suitable for at least 10,000 satisfactory open and close mechanical operations in accordance with IEC 62271-100. A two-stage low gas pressure alarm and lockout system with local and remote indications shall be provided on each circuit breaker. The low pressure/density alarm switches shall instantly provide an instruction to the operator and subsequently inhibit their further operation until suitable remedial action has been taken. The circuit breaker shall be fitted with the necessary transducers to allow regular monitoring of circuit breaker travel characteristics and all routine and site test records shall be made available to the Client for ongoing comparison purposes. The provision of suitable test equipment for measurement of the circuit breaker timing cycle in included under this contract. 4.11.2. Spring Mechanisms Spring operated mechanisms are the preferred type Provision should be made for remote indication of 'Spring charged' and 'Spring charge fail' conditions. A spare normally open spring-drive limit switch shall be provided. It shall be possible to hand charge the operating springs with the circuit breaker in either the open or closed positions. In normal operation, recharging of the operating springs shall commence immediately and automatically upon completion of the closing operation and shall be completed within 30 seconds. Closure whilst a spring charging operation is in progress shall be prevented, and release of the springs shall not be possible until they are fully charged. The state of charge of the operating springs shall be indicated by a mechanical device which shows 'SPRING CHARGED' when operation is permissible and 'SPRING FREE' when operation is not possible. A local manual spring release device shall be provided and so arranged as to prevent inadvertent operations. Means shall be provided for hand charging the operating springs. 4.11.3. Hydraulic and Hydraulic/Spring Mechanisms Operating pressure shall be maintained automatically, a gauge being provided to give indication of the pressure. The pressure gauge shall be suitably damped to ensure that it is not subject to transient pressure oscillations either during pumping or during operation of the circuit breaker.

Aquatherm Engineering Consultants India Pvt Ltd

Page 12 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

A lockout device with provision for remote alarm indication shall be incorporated in each circuit breaker to prevent operation whenever the pressure of the operating medium is below that required for satisfactory subsequent operation at the specified rating. Such facilities shall be provided for the following conditions: Trip lockout pressure. Close lockout pressure. Auto reclose lockout pressure.

Alarm contacts shall be provided to indicate conditions a, b and c. If two trip systems are specified, then trip lockout shall apply to both systems. A sudden fall in pressure of the operating medium to a level below which a safe operation is not possible shall not result in slow opening or closing of the circuit breaker contacts. The mechanism shall be locked in position and electrical trip and close signals shall be isolated during this period. Facilities shall be provided to enable the available operating energy stored by the mechanism to be determined prior to operating the circuit beaker, together with an alarm in the event of the potential energy falling below a minimum rated level. Facility for hand charging of hydraulic systems shall be provided. Circuit breakers having independent operating mechanisms on each phase shall block tripping, closing, and auto-reclosing of all phases if the operating pressure is below a minimum rated level in one or more of the mechanisms. A pump running time meter shall be fitted and an alarm shall be provided to indicate excessive running time. 4.11.4. Mechanism Housings Where heaters are provided, these shall be permanently connected. Where two-stage heaters are provided, one stage shall be permanently connected and the other switched. Means for locking shall be provided for the doors of each mechanism housing. Mechanism housings for use outdoors shall have an IP rating of 55, those for indoor shall be IP 30.

Aquatherm Engineering Consultants India Pvt Ltd

Page 13 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

4.12.

GIS Disconnect Switches The GIS disconnect switches shall be constructed and fully tested in accordance with the requirements of IEC 62271-102, IEC60694, IEC61128, IEC62271 - 203, and IEC 60265 and this Specification. The design shall incorporate features, which shall reduce or eliminate very high frequency voltage transients during disconnect switch operation. The disconnecting function of disconnect switches shall still be effective when adjacent equipment components are dismantled. It is preferred that disconnect switch contacts are able to be maintained and replaced with the associated earthing switch closed. Disconnect switches shall be fitted with position indicators visible from ground level. Viewing windows for confirming the positions of disconnect switches and earth switch contacts shall be provided unless prior agreement is reached with the Client. The disconnect switches shall be provided with power and manually operated mechanisms. The power operation of the disconnect switches shall be capable of being controlled from a local or remote point. Each power-operated disconnect switch shall be complete with a lockable

LOCAL/REMOTE selector switch and OPEN/NEUTRAL/CLOSE control switch or push buttons. The function of all control and selector switches shall be clearly labelled. Power operating mechanisms shall be capable of being locked in the open or closed positions. The power operating mechanisms shall be suitable for the operation from voltages specified in the Schedules of this Specification. Operating motors shall be provided with thermal overload protection and in the case of 3 phase motors, phase unbalanced protection. The disconnect switches shall be suitable for slow closing operation. Manual operation of the disconnectors for maintenance purposes shall be provided. The number of normally open and normally closed auxiliary switches required shall be as dictated by the particular scheme of application. Where any particular scheme requires special timing of auxiliary contacts, these shall be provided. Electrical control circuits shall be so arranged that once initiated, an operation shall be completed unless prevented by loss of supply or operation of the motor protection. On restoration of supply the operation shall be completed.

Aquatherm Engineering Consultants India Pvt Ltd

Page 14 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Emergency hand operation shall be provided on power-operated disconnect switches and the power drive shall be mechanically disconnected during hand operation. It is required that the manual effort to operate the disconnectors or earth switches shall not be greater than 150 N. There shall be adequate access for the manual operation. In the case where the operating mechanism comprises an energy storage system followed by triggering for completion of the operation, the design shall exclude any possibility of operation by accidental triggering. Switch operation shall be effective only after full charging of the operating mechanism and after deliberate operator action. The operating handles for manual operation of power-operated mechanisms may be detachable, in which case only two handles of each type are required per substation. 4.13. 4.13.1. Earth Switches and Maintenance Earthing Devices GIS Earth Switches Earth switches shall comply with IEC 62271-102 IEC60694 and IEC 62271 - 203 and the requirements of this Specification. They shall be provided with power and manually operated mechanisms and shall be provided on one or both sides of the disconnect swiches dependent upon the locations. The electrical operation shall be performed from their control cubicles. The position indicators shall be clearly visible from the permanent working platform level. Each separate section of switchgear that can be disconnected shall have provision for earthing in accordance with the following requirements: (a) All incoming and outgoing supply circuits shall be earthed by a device having a

making current rating and short time rating equal to that of the associated circuit breaker. When specified, the earth switch shall be fully insulated and the connection to earth brought out through the enclosure by means of an insulating bushing in order that the earth switch may be used for various test purposes. A removable bolted link shall be provided for connecting the insulated earth switch connection to the actual earthing terminal. The earth switch and connection bushing shall be capable of withstanding an applied power frequency voltage of 10 kV. (b) Sections that can be established as having been disconnected shall be earthed by

a device having a short time rating equal to that of the circuit breaker.

Aquatherm Engineering Consultants India Pvt Ltd

Page 15 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

The earthing switch and the test injection point arrangement shall be suitable for a test current equal to the rated normal current of the connected busbars for a duration of 5 minutes minimum. Earth switches on line circuits shall be capable of closing onto an energised circuit and of interrupting the current induced in the line by a parallel fully loaded line. The interrupting duty required is as specified in the schedules. The earth switch operating mechanism shall be capable of being locked in the open or closed position. 4.13.2. Portable Maintenance Earthing Devices Where portable earthing is required, provision shall be made for applying fully rated portable maintenance earthing devices to the primary conductors of the equipment. The design of the device shall be such that the chamber in which the device is applied can be refilled with SF6 gas when the device is in the closed position. 4.14. GIS Current Transformers Gas insulated current transformers shall be of the bar primary type. The pressure of the gas at normal temperature and pressure shall be such that it remains in its gaseous state when operating at the lowest temperature stated in the Schedules. Facilities shall be provided for constant local monitoring of the current transformer gas pressure, and topping up or sampling the gas. For safety reasons, a bursting disc shall be fitted to the current transformer housing. Current Transformer Primary Injection Tests Facilities shall be provided which allow primary injection testing of the current transformers with the minimum disturbance to the switchgear. 4.15. GIS Voltage Transformers The inductive voltage transformer shall be housed in a metal tank, which complies with the internal arcing requirements of IEC 62271 - 203. The tank shall have a suitable lifting facility.

Aquatherm Engineering Consultants India Pvt Ltd

Page 16 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

The high voltage cast resin insulators (barriers) shall be suitable for withstanding the differential pressure i.e. the normal working pressure on one side and the vacuum on the other side. They shall be compatible with SF6 gas and its degradation products. The pressure of the gas at normal temperature and pressure shall be such that it remains in its gaseous state when operating at the lowest temperatures stated in the Schedules. Facilities shall be provided for constant local monitoring of the SF6 gas pressure inside the tank, topping up or sampling the gas. Facilities shall be provided for isolating the voltage transformer during the injection testing of GIS equipment. For safety reasons, a bursting disc shall be fitted to the transformer housing. 4.16. 4.16.1. Sulphur Hexafluoride Gas (SF6) General The sulphur hexafluoride SF6 gas shall comply with the requirements of IEC 60J7j and BS 5207. The SF6 gas shall be supplied in 45 kg cylinders. The dew point of the gas shall be lower than -45C. Sufficient quantity shall be provided to fill all SF6 equipment supplied under this contract plus an additional 20 per cent. The high-pressure cylinders in which the SF6 gas is transported to, and stored on site, shall comply with the requirements of local regulations and bye laws. Under normal conditions the SF6 gas of temperature and pressure is colourless, odourless and nontoxic. It is however five-times heavier than air and the arced gas and degradation products are toxic and harmful. It is therefore important that all personnel working on GIS equipment are kept fully informed of the potential risks and appropriate health and safety regulations. It is therefore the responsibility of the gis equipment supplier to provide: Adequate safety training to the Client's staff regarding gas detection, the disposal of arced products and storage. Sufficient number of facemasks, goggles, hand gloves and respirators, protective clothing and gloves.

Aquatherm Engineering Consultants India Pvt Ltd

Page 17 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

4.16.2.

First aid equipment including an eye wash bottle filled with distilled water.

Gas Handling Equipment A mobile gas handling plant for filling, evacuating, and processing the SF6 gas in the switchgear equipment, is to be supplied as part of the Contract to enable any maintenance work to be carried out. The plant shall include all the necessary gas cylinders for temporarily storing the evacuated SF6 gas as well as any other gases that may be used in the maintenance process. The capacity of the temporary storage facilities shall be at least sufficient for storing the maximum quantity of gas that could be removed when carrying out maintenance or repair work on the largest section of the switchgear and associated equipment. The plant provided shall be suitable for evacuating and treating the SF6 gas by the use of desiccants, driers, filters etc to remove impurities and degradation products from the gas. The capacity of the plant shall be such that the largest gas zone, with the exception of the circuit breaker, can be evacuated in less than one hour. The plant shall also be capable of reducing the gas pressure within the circuit breaker to a value, not exceeding 8 millibars, within a time not greater than two hours. It shall be capable of operating in the temperature range -27C to +50C.

4.16.3.

Pipes and Couplings for the Connection of SF6 Gas All the necessary pipes, couplings, flexible tubes and valves for coupling to the switchgear equipment for filling or evacuating all the gases to be used, with all necessary instructions for the storage of this equipment, shall be provided.

4.17. 4.17.1.

Overhead Travelling Crane General This contract includes the supply of all materials and works for a crane with all operating machinery, structural steel, control equipment including cables and all other parts and accessories required for proper and safe operation. The travelling crane shall be used for erection work as well as for normal maintenance, repair and overhaul purposes. The crane shall be complete, including, crab, hoisting machinery with motor and brakes, all lubricating devices, ropes, sheaves, hooks, flood lights, control apparatus

Aquatherm Engineering Consultants India Pvt Ltd

Page 18 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

including switchgear, runway rails, push-button controls, interlocks, limit switches, governors, protecting and alarm devices and all electric connections (cables and live rails including insulators) between all parts supplied. 4.17.2. Construction Features The design of the travelling crane has to guarantee fail-safe and satisfactory operation and has to be easy to access for service, inspection and repair. A safety factor of 1.5 times of the maximum load is to be taken into account for all stress calculations to allow shock loading. Adequate guards shall be provided to protect personnel from accidents caused by moving mechanism, live terminals, live conductors, etc. The guards shall be removable for inspection and maintenance without disturbing any other part of the plant. The Contractor shall supply suitable nameplates, giving details of the lifting capacity of the travelling crane. These nameplates shall be clearly visible to anyone who may use the cranes. The nameplates shall be inscribed in English Language. Operating machinery and other exposed parts shall be suitably housed so that the exterior of the travelling crane will consist of smooth surface and pleasing lines. 4.17.3. Structure The minimum plate thickness for the steel construction shall be 7 mm, unless otherwise demonstrated suitable by the Contractor. 4.17.4. Crane Rails Travelling crane rails shall be provided by the Contractor. Joints between rails on opposite runway girders for the cranes shall be staggered with respect to each other and to the wheelbase of the cranes. All joints of rails shall be welded. Rail joints shall not be located over the runway girder splices. Provision for rail expansion shall be made at the end stop locations only. Guiding of rails on the girders should be carried out with rail clamps to distance adjustment. Welded clips are not allowed. End stops shall be designed and located to limit the maximum crane travel. The end stops shall be capable of stopping the travelling crane fully loaded and travelling at the rated speed.

Aquatherm Engineering Consultants India Pvt Ltd Page 19 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

4.17.5.

Crane Bridge The travelling crane bridge shall consist of two girders rigidly attached to the end trucks. Gusset plates shall keep the crane in alignment. Welded joints shall be used for the main structure of the crane, bolted joints shall be avoided whenever possible. -In load bearing members, if a bolted joint is necessary, black bolts shall not be used. -The strength of welded joints or joints made by friction grip bolts in structural members shall not be less than the net strength of the member. Friction grip bolts shall comply with BS 3139 and shall be fitted in accordance with the recommendations of BS 3294. -The calculated strength of other bolted joints in structural members shall be not less than the net strength of the member plus 25 per cent. The calculated stress in screws, bolts and welds shall not exceed the appropriate permissible stress given in BS 2573. The travelling crane girders shall be welded in structural steel box sections, with wide flange beams, standard "I" beams or reinforced beams. Girders must be symmetrical and line-of-sight must be considered along with girder design, as well as suspended crane supports. Trellis girder shall be prohibited. The girders shall be designed to withstand all vertical loads and horizontal forces that may arise under service conditions. The vertical deflection of the girders, caused by the safe working load and the weight of the crab in the central position shall not exceed 1/1000 of the span. The larger of the following load combinations shall control the design of the girders: The sum of the maximum stresses due the dead load, the weight of the trolley, the rated load, and the impact allowance. The sum of the maximum stresses due to the dead load, the weight of the trolley, the rated load, and an allowance for the lateral load due to acceleration and deceleration of the travelling crane. The bridge girders shall be security braced to the end carriages to prevent cross racking. It must be impossible for the travelling crane to fall from the gantry in the

Aquatherm Engineering Consultants India Pvt Ltd

Page 20 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

event of derailment. The carriages shall be of the bogie type and shall be equipped on each end with spring buffers (bumpers). 4.17.6. Electrical Parts The travelling crane and hoists shall be so designed that adequate access for maintenance of the electrical control and operating gears is provided with suitable access facilities to enable removal of parts for maintenance and repair. The power supply shall be provided via adequately protected contact wires along the crane track and a suspended cable on the crane girders. The supply to the contact wires shall be via a manually operated load break isolating switch mounted at a convenient height above floor level, the switch being capable at being locked in the open position. Red indicating lights shall be arranged at collector level to show when the isolator is closed. Motors shall be provided with quick action brakes; controllers, resistors, magnetic contactors and overload protection switches. Heavy dust and splash-proof limit switches shall be provided to prevent over hoisting, over transversal and over travelling motions. 4.17.7. Motors All motors shall be totally enclosed, wound rotor type specifically designed and built for crane service. Motors shall be equipped with sealed antifriction, grease lubricated bearings, with provision for grease renewal. Motors shall have tapered shaft extension on the brake end for easy removal of the brake wheel. 4.17.8. Push Button Control Station The push button control station shall be suspended by means of flexible galvanised wire rope and connected to the crane control panel by means of flexible multicore cable. The arrangement shall permit movement of the control station along the entire length of the bridge at all levels of operation. The push button control station shall have a cast aluminium housing and shall have mechanical protection class of IP 44. The Control station shall contain besides all necessary individual push buttons for controlling operation of all crane motors, an emergency push button of the lockable type. This shall function as a master switch to

Aquatherm Engineering Consultants India Pvt Ltd

Page 21 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

cut off all power supply to the crane control panel, by switching off the master magnetic contactor. 4.17.9. Overload Relays Each motor shall be protected by overload relays adjustable for values between 50 and 150 per cent of the full load motor current. 4.17.10. Switchgear The power supply from the main collectors shall be controlled by means of a 3phase, manually operated circuit breaker, and a 3-pole master magnetic contactor provided with under-voltage and phase reversal protection. The operating coil of the contactor shall be wired in series with the auxiliary contacts of the adjustable, instantaneous relays in the circuit of each hoist and each travel motor, and in the circuits of all limit switches. The circuits shall be so arranged that, on the functioning of an overload relay or the tripping of the limit switch, the flow of power to the crane will be interrupted. 4.17.11. Circuit Breaker Cabinets The main circuit breaker, lighting supply circuit breaker, master contractor, relays and protective devices shall be enclosed in a suitable steel cabinet with hinged doors. The main circuit breaker shall be so arranged that it can be operated without opening the cabinet door and that it can be locked in the open position. 4.17.12. Limit Switches Limit switches shall be provided to control the upper limits of travel of all hoist motors and at each end of travel for the bridge and trolley. Switches shall be of the totally enclosed safety type operated by the hooks or hook blocks. 4.17.13. Tools One steel toolbox shall be provided containing complete set of ordinary and special tools needed for overhauling and repair of cranes furnished. General list of such tools shall be indicated in Tenderer's offer, and shall be detailed and submitted by the Contractor to the Client for checking and approval. 4.18. EARTHING SYSTEM FOR GIS GIS supplier should generally provide or be responsible for:

Aquatherm Engineering Consultants India Pvt Ltd

Page 22 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Providing the sub assembly to subassembly bonding to ensure safe voltage gradients between all intentionally grounded parts of the GIS assembly and between those parts and the main ground bus of GIS. Furnishing readily accessible connectors of sufficient mechanical strength to withstand electromagnetic forces and thermal abuse and that are capable of carrying the anticipated maximum fault current in that portion of the circuit without overheating. Providing ground pads or connector or both, allowing at least for two paths to ground from the main ground bus or from each metallic enclosure and auxiliary piece of GIS equipment designated for a connection to the stations ground if the main ground bus of GIS assembly does not actually exist. Recommending proper procedure for connections between dissimilar metals typically between a copper cable or a similar or (steel) ground conductor and aluminium enclosure. Grounding recommendation of GIS and interfacing with the overall switchyard grounding including limiting touch & step potentials. Providing EMI mitigation techniques caused by transients. 4.19. 4.19.1. Interlocking Equipment Extent of Supply The Contractor shall be responsible for the designing, supply and commissioning of all interlocking schemes to the satisfaction of the Client. Designs are to cover the 220 kV switchgear, ac station services, dc station services. 4.19.2. General All disconnecting switches and earthing devices shall be provided with interlocking features of the mechanical sequential locking type or electromechanical bolt type, and the scheme of interlocking shall be subject to approval and shall include the hand operation of apparatus which is normally electrically operated. All mechanical interlocks shall be applied at the point at which hand power is used, so that stress cannot be applied to parts remote from that point. Where key interlocking is employed, tripping of the circuit breaker shall not occur if any attempt is made to remove the trapped key from the mechanism. Any local

Aquatherm Engineering Consultants India Pvt Ltd

Page 23 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

emergency tripping device shall be kept separate and distinct from the key interlocking. All electrical interlocks shall so function as to interrupt the operating supply. Failure of supply or connections to any electrical interlock shall not produce or permit faulty operation. Electromechanical bolt interlocks shall be energized only when the operating handle of the mechanism is brought into the working position. Visible indication shall be provided to show whether the mechanism is locked or free. Means shall be provided whereby the bolt can be operated in the emergency of a failure of interlock supplies. Earthing switches are to be interlocked with the appropriate disconnect switches such that the earth switch cannot be closed unless the disconnect switches are open. Conversely, the disconnect switch cannot be closed unless the earth switch is open. When made of steel or malleable iron, operating boxes, handles, rods, tubes and other fittings for outdoor equipment shall be galvanized.

4.20.

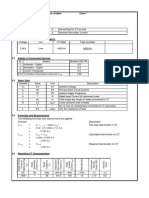

Technical Requirements OF 220kV GIS SWITCHYARD

General technical data Rated service voltage (kV rms) Rated maximum voltage (kV rms) Rated frequency (Hz) Rated continuous current Bus (arms) Terminal (arms) Rated short circuit current (kA rms) Short time current duration (s) Peak withstand current (close and latch) (kA rms) Withstand Voltage: Power frequency (kV rms) Full wave impulse (BIL)

User requirements 220 kV 245 kV 50 Hz 2000A

Supplier proposal

40 kA 1 sec

460 1050

Aquatherm Engineering Consultants India Pvt Ltd

Page 24 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Switching impulse (SIL), if required Maximum acceptable moisture level: Circuit breaker (PPMV)* Compartments where arcing is not expected (PPMV) Enclosure and conductor (for each rating) Inductance (H/m) Capacitance (pF/m) Resistance: Enclosure (/m) Conductor (/m) Surge impedance Weight of gas for largest gas zone (kg) Length of bus section (m) Bus enclosure data (for each rating) Type of material Outside diameter (mm) Wall thickness (mm) Internal SF6 GIS pressure at 20C (kPa) Circuit Breakers Voltage range factor Rated continuous current (A rms) Rated short circuit current (kA rms) Rated short time current duration (s) Rated peak withstand current (closing and latching) (kA rms) Rated interrupting time (ms) Rated reclosing time (ms) Rated permissible tripping delay (s) Rated capacitor switching current (a rms)

Aquatherm Engineering Consultants India Pvt Ltd Page 25 of 69

600 kPa

245 kV 2000 A 40 kA 3 sec 104 kA

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Rated operating duty cycle Type of operating mechanism Breaker operating time for rated control voltage and pressure Operating time from for rated energizing of trip coil to contact parting Closing resistors (if applicable) Ohmic value of closing resistors per phase Insertion time during closing (ms) Gas pressures Pressures at 20C Maximum foundation loading during operation: Horizontal (N) Vertical (N) Motor capacity Number and type Power of each (W) Voltage and number of phases (V) Current, start/run (A) Total heater power per three pole breaker (W) Control circuit Rated dc control voltage (V) Closing voltage range (V) Tripping voltage range (V) Maximum tripping current (A) Number of trip coils per breaker pole Number of operations before the breaker Must be removed from service for maintenance inspection No-load mechanical Full load non fault Rated short circuit current Expected number of hours required to perform a complete maintenance inspection of one breaker

O 0.3s CO 3 min CO Spring operated/ hydro mechanical with energy storage in springs

220 V DC 220 V DC 220 V DC

Two

40 kA

Aquatherm Engineering Consultants India Pvt Ltd

Page 26 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Number of breaker operations without recharging (dB) Number of full reclosing operations without overheating the closing resistors (specify the closing duty for the thermal rating) Disconnect Switches Rated full wave impulse withstand voltage Across the open gap (kV peak) Power frequency 1 withstand voltage: Across the open gap (kV rms) Number of switch operating mechanism operations before internal visual inspection or servicing Maximum operating current (A) Minimum closing current (A) Heater power per three pole switch (W) Main current carrying contact material Base material and specification Contact insert Plating material Control data for operating mechanism Operating time (s) Maximum charging current interrupting (A) Grounding Switches Rated Peak withstand current (close and latch) (kA rms) Number of the mechanical operations before internal visual inspection or servicing Number of closing operations into energized bus without damage Ground switch interrupting capacity, if specified and agreed (A) Voltages Transformers Name of the supplier Applied test voltage (kV rms) Power-frequency field test voltage with VT Connected (kV rms) 1050

460

2000

Aquatherm Engineering Consultants India Pvt Ltd

Page 27 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Ratio of high-voltage to low-voltage windings Thermal rating of each secondary winding (VA) Thermal rating of the primary winding (VA) accuracy classification List burdens for which the above accuracy classifications apply Current Transformers accuracy class Ratio in terms of primary and secondary current ratings Continuous thermal current rating factor Secondary winding insulation class Are all current transformers external to the GIS enclosures? (yes/no) Are CTs split-core type? (yes/no) Gas-to air-bushing Name of the supplier Type designation of the supplier Material Rated power frequency withstand Dry-1 min (kV rms) Wet-10s (kV rms) External strike distance; Phase-to-ground (mm) Phase-to-phase (mm) External creep distance (mm) Cantilever strength (N.m) Acceptable terminal load (N) Gas System Total quantity of SF6 gas required with the original equipment (kg) Total quantity of SF6 gas required per breaker (kg) Guaranteed maximum SF6 gas leakage rate from the complete GIS (Kg/year) Number of gas monitoring systems included with the equipment.

220 kV/3/110V/3 As per SLD

As per SLD

As per SLD As per SLD

31 mm/ kV

Aquatherm Engineering Consultants India Pvt Ltd

Page 28 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

* PPMV = Parts per Million per Volume

5.

AIR INSULATION SUBSTATION

5.1.

Clearances In line with the recommended insulation levels above, the following minimum clearances shall be adopted for 220 kV switchyard equipment & connections Phase to phase Phase to earth Sectional clearance Minimum Ground Clearance 2100 (min) mm 2100 (min) mm 4600 (min) mm 5500 (min) mm

5.2.

Creepage Distance Considering the location of the switchyard, minimum creepage distance of 31mm/kV shall be provided for the following equipment. For Generator Transformer and Station Transformer bushings creepage distance shall be 31mm/KV. Circuit breakers Bus post, isolators and lightning arresters Insulator strings Current and voltage transformers

5.3.

Bus Bars Bus bars shall be of stranded ACSR conductor (aluminium conductor steel reinforced) and tubular aluminium of suitable size according to standard metricised iron pipe size (IPS). The conductor size for bus shall also be based on maximum load current that the conductor can carry with allowable temperature rise within limits, short circuit conditions and permissible corona / voltage gradient. The final temperature of the conductor when carrying full load current shall not exceed 90 deg. C with a design ambient of 50 deg. C. reduce corona effect. The short time rating shall be 40 kA for 1sec. The tension in strung bus shall be such as to limit the sag within about 3% of the span. The tension for power conductor shall be 1000 kg/sub-conductor. The conductor size and spacing shall be checked to limit the voltage gradient to 17 kV/cm to

Aquatherm Engineering Consultants India Pvt Ltd

Page 29 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Voltage gradient criteria, which determine the minimum OD of the tube, shall be applicable for tubular buses as well. 5.4. Shield Wire The size of the shield wire shall be based on the lightning impulse current expected and time duration. Allowance shall be given to the final size of the earth wire to account for corrosion during service, at a rate of at least 0.03 mm per annum. However, the minimum size of the shield wire shall not be less than 70 mm2. Earth wire tension shall be 800 kg/conductor. 5.5. Insulators Tension and suspension insulator strings shall be fog type selected based on the voltage, insulation level, and pollution level and electro-mechanical strength. Creepage chosen shall be suitable for heavy pollution, i.e., 31mm / kV. Electromechanical strength shall be selected with factor of safety of 2.5. 5.6. Bus Post Insulators Bus post shall be solid core / post insulator type and shall be selected based on the system voltage, insulation level, and mechanical strength and pollution level requirements. Insulator hardware shall be corona free up to a falling power frequency visible discharge test voltage of 1.2 times the maximum system voltage. All steel components shall be double hot dip galvanized iron. 5.7. Lightning Protection of Switchyard The lightning protection of switchyard shall be by means of providing tower peaks. The zone of coverage shall be considered as 60 deg. between the two lightning conductors, inside the switchyard and 45 deg. on end conductors, outside the switchyard. The criteria for deciding phase to phase clearance in case of strung conductors shall take into account the conductor swing of one of the conductors (say R Phase) with maximum wind velocity and the adjacent conductor (say Y phase) with 80% of maximum wind velocity at maximum sag conditions. In the transformer yard, the power conductor termination shall not be tapped off directly to the generator transformer / station transformer from the strung bus between the TG building and the switchyard. The tap-off conductor shall be routed through a bus post insulator located near the transformer. For the layout proposed by the Contractor, the adequacy of the cantilever strength adopted shall be checked considering the following factors of safety:

Aquatherm Engineering Consultants India Pvt Ltd Page 30 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

Sum of all permanent normal loads (wind load on tubular bus + wind load on stack + dead weight of the tubes) = 2.5. Combination of all normal loads plus either short circuit or earth quake load, whichever is higher than 1. The switchyard shall be designed for the seismic coefficient and wind pressures as per the site data. 5.8. 220 kV ISOLATORS 220kV, 2000 Amps, 40 kA for 3 sec, double break, and center pole rotating type isolators shall be provided. A.C motor drive mechanism for main blade and manual operation mechanism for earth blade shall be provided. 5.8.1. Specific Requirements Isolators shall be electrically interlocked with the circuit breakers in accordance with the switchyard safety interlocking scheme. The required number of auxiliary contacts shall be provided for interlocks, DCS and panel indications. The flexible tinned copper connection between the rotating shaft of the earth switch and the frame shall have adequate cross-section to withstand short time current. 5.8.2. Technical Requirements The isolators shall comply with the requirements indicated in the following table: 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 2.0 2.1 2.2 2.3 2.4

RATING Application Quantity Nominal / Highest system voltage Frequency No. of phases Rated current Short time Current rating and duration Rated peak short circuit current Design Requirements Ambient temperature Insulation level Phase spacing Type of break 50 deg.C 1050 kV peak 3350mm (min) Horizontal double break(centre 100 kA (Peak) Switchyard As Required 220 / 245 kV 50 Hz 3 Phase 2000 A 40 kA for 3 sec.

Aquatherm Engineering Consultants India Pvt Ltd

Page 31 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

rotating) 2.5 2.6 Type of mounting Operating device (a) (b) 3.0 3.1 For isolator For earth switch Motor driven (Both local & remote) (Emergency Manual) Manual Insulation Data 1.2 / 50 micro sec. lightning impulse withstand (a) (b) To earth Across open disconnect lightning impulse 1200 kV peak. 31 mm/kV. 600 kg 460kV rms 530kV rms 1050 kV peak Horizontal upright

voltage applied to - One terminal 3.2 3.3 3.4 Minimum total creepage distance Minimum cantilever strength Power frequency withstand voltage (a) (b) 4.0 4.1 4.2 5.0 5.1 5.2 To earth Across terminals if open disconnect Miscellaneous Auxiliary supply Interlocks with circuit breakers Applicable standards Insulators Isolators IEC-296,BS:148 IEC 129,529,694,1128 & 1129 220 V DC for control and interlock; 230AC, 3 phase for motor drive electrical interlock

5.9.

220 KV CURRENT TRANSFORMERS 220 kV oil filled hermetically sealed single phase current transformers of the current ratios specified below shall be provided in the generator transformer bays, line bays and station transformer bays, as per Drg. Multi-ratio CT tappings shall be provided on the secondary side to obtain different ratios in order to permit different transformation ratios on each core, as desired.

5.9.1.

Specific Requirements The 220 kV current transformers shall comply with the requirements in the following table:

Aquatherm Engineering Consultants India Pvt Ltd

Page 32 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

1.0 2.0 3.0 4.0 5.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0 12.0

Type Nominal System Voltage Highest System Voltage No. of cores Primary current Secondary current Short time thermal rating Dynamic rating Class of Insulation Rated Burden Accuracy class - Core Maximum temp. rise of winding above ambient of 50 deg.C Cantilever strength of CT at the terminal (min) 1.2 / 50 sec. impulse positive & negative One minute power frequency withstand voltage Creepage distance (min) Partial discharge level Applicable standards Current transformers Bushings Large Hollow Porcelains Insulators Hot dip galvanising Insulating oil

: : : : : : : : : : : : : : :

Outdoor, oil filled, dead tank heremetically sealed. 220 kV, 50 Hz 245 kV As per Drg As per Drg 1A 40 kA for 3 sec. 100 kA (Peak) Oil immersed Class A. As per Drg As per Drg 40 deg.C 600 kg 1050kV (Peak) 460 kV

13.0 14.0 16.0 16.1 16.2 16.3 16.4 16.5 17.0

: : : : : : : :

31mm/kV <10 pico-coulomb IEC-185,IEC 60044,BS:3938, IEC-137,BS:223 IEC137, IEC233, IEC 273, IEC 815 IEC-296,BS:148 IS : 2633 & IS : 2629 IS : 335

5.10.

220 KV CAPACITIVE VOLTAGE TRANSFORMER Capacitor voltage transformers shall be provided for the 220 kV switchyard As per Drg.

5.10.1.

Specific Requirements Fuses / fast acting MCBs of adequate rating shall be provided in each secondary output leads of each VT to protect the VT secondary branch circuit from the abnormal voltage surges that may occur on the VT primary side. The secondary shall also include suitable number of links for each secondary as per the requirement of fuse failure detection relays. The burden of the CVTs shall be adequate for the loads connected.

5.10.2.

Technical Requirements

S.No

Particulars

Data

Aquatherm Engineering Consultants India Pvt Ltd

Page 33 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

S.No 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 13.

Particulars Quantity Application Nominal / Highest system voltage Power frequency System neutral earthing type Co-efficient of earthing Rated primary voltage Rated secondary voltage No. of secondary windings Application Rated burden Accuracy class - Core 1 - Core 2 - Core 3 Rated voltage factor Class of winding insulation Max. Winding temp. at 110% Excitation & rated burden Creepage distance (min) 1.2 / 50 micro sec. impulse voltage withstand One minute power frequency voltage withstand One minute power frequency test Withstand voltage between low - voltage terminal and earth terminal Withstand voltage for secondary winding Applicable Standards Voltage transformers Coupling capacitors and capacitor dividers Capacitor voltage transformer Bushings Large Hollow porcelains Insulators Hot dip galvanizing : : : : : : : : : : : : : : : : : : : :

Data As per Drg Outdoor 220 kV / 245 kV 50 Hz Effectively earthed 0.8 220 kV / 3V

110 / 3V / 110 / 3V / 110 / 3V

Three (3) Metering / protection As per Drg As per Drg As per Drg As per Drg 1.2 continuous & 1.5 for 30 seconds Oil immersed, Class A As per Table II of IEC 186 considering design ambient of 50 deg.C 31mm/kV 1050 kV (Peak) 460 kV (rms)

14. 15. 16. 17. 20. 21. 24.

: : : : : : : : :

4 kV (rms) 2 kV (rms) IEC 186,IEC 517,1EC60044 IS : 9348, IEC : 358 IS : 3156, Part IV, IEC : 186 IS : 2099 IEC 137, IEC 233,IEC 273, IEC 815 IEC 137, IEC 168, IEC 815 IS: 2629.

25. 25.1 25.2 25.3 25.4 25.5 25.6 25.7

5.11.

LIGHTNING ARRESTERS 198 kV, 10kA nominal discharge current, discharge Class - III, metal oxide gapless lightning arresters shall be provided. Three lightning arresters shall be used in each of the generator transformer, station transformer & line bays.

Aquatherm Engineering Consultants India Pvt Ltd

Page 34 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

5.11.1.

Specific Requirements Surge monitor comprising a digital type counter and leakage current detector shall be provided for each arrester and the same shall be mounted at eye level height to facilitate easy reading of the counter and leakage current detectors. The arrester shall be mounted on an insulating base. The surge monitor shall be inserted between the lightning arrester and earth. Insulated copper conductor of adequate size and length shall be used for connecting the discharge counter terminal and the lightning arrester earth terminal. Insulation level of the conductor shall not be less than 5 kV. Suitably sized bypass copper shunts shall be provided for bypassing the discharge counter for removal / maintenance of the counter.

5.11.2. S.No 1.0 1.1 1.2 1.3 1.4 1.5 2.0 2.1 2.2 2.3 3 4 4.1 4.2 4.3 5.0 5.1 5.2 5.3

Technical Requirements Particulars GENERAL Quantity Installation System Voltage (a) Nominal (b) Highest Type of earthing Type of arrester RATING Rated arrester voltage / maximum continuous operating voltage Rated frequency Nominal Discharge current of 8 / 20 micro second wave shape Minimum total creepage distance mm Additional requirements Minimum cantilever strength of arrester assembly Pressure relief class (As per IEC 99) Minimum prospective symmetrical fault current (as per IEC 99) Applicable Standards Lightning arrester For alternating current systems Insulators Large hollow porcelain insulators : : : : : : : : : : : : : : : Data As per Drg. Outdoor 220 kV 245 kV Effectively earthed Gapless 198 kV 50 Hz 10kA 31mm/kV 600 kg 40 kA 40 kA

: : : :

IEC-99-4, 99-3,99-1 and IEC 694 IEC 99 IEC 137, IEC 168 , IEC 815 IEC 137, IEC 233,IEC 273, IEC 815

Aquatherm Engineering Consultants India Pvt Ltd

Page 35 of 69

Project Client Document Title

: : :

2x150MW Coal Based TPP, Bhadreshwar, Gujarat OPGS Power Gujarat Pvt. Limited

Technical Specification for GIS Cum AIS 220kV Switchyard

Project Consultant

Document Number

:

:

Aquatherm Engineering Consultants (India) Pvt. Ltd.,

400-ENG-9336-003 Rev. No 00

5.12.

INSULATORS AND HARDWARE

Bus post insulators and insulator strings with fittings / hardware as required shall be provided for the entire switchyard. 5.12.1. Specific Requirements The hardware shall be corona free up to a falling power frequency visible discharge test voltage. All hardware components shall be smooth and as far as possible have round exposed surface. 5.12.2. Technical Requirements Sl. No. 1.0 1.1 1.2 1.3 1.4 1.5 1.6 2.0 2.1 2.2 2.3 2.4 3.0 3.1 3.2 3.3 3.4 Description Bus Post Insulator Type Voltage class Total creepage distance (min) Cantilever strength (min) Withstand voltages (a) 1 min. power freq. (b) 1.2/50 micro sec. Impulse Puncture voltage Disc Insulator Voltage class Type Creepage distance (min) Electromechanical strength Applicable Standards Post insulators Suspension Insulators Insulator fittings Hot dip galvanising process Unit Data Solid Core / Post type 245kV 31mm/kV 600 460 1050 1.3 times corresponding flash over voltage of the unit. 11 kV Anti Fog type 31mm/kV 8200 kg (min) IEC 137, IEC 168, IEC 815,IEC 273 IS : 731 IS : 2486 IS : 2629 & IS : 2633

kV mm kg kV kVp

mm

5.13. 5.13.1.

BUS CONDUCTORS, CLAMPS AND CONNECTORS Applicable Standards The conductors, clamps and connectors shall comply with the following standards: 1.0 1.1 1.2 1.3 1.4 AAC, ACSR conductors Copper conductors Galvanisation of steel wires Copper tubes Aluminium / Aluminium Alloys Bars, Rods, Tubes, Sections for Electrical Purposes : : : : : IS : 398 IS : 282 IS : 4826 BS : 159 IS : 5082

Aquatherm Engineering Consultants India Pvt Ltd

Page 36 of 69

Project Client Document Title

: : :