Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Katrol Tetap

Caricato da

sukmaweningDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Katrol Tetap

Caricato da

sukmaweningCopyright:

Formati disponibili

Fixed A fixed or class 1 pulley has a fixed axle. That is, the axle is "fixed" or anchored in aplace.

A fixed pulley is used to change the direction of the force on a rope (called a belt). A fixed pulley has a mechanical advantage of 1. A mechanical advantage of one means that the force is equal on both sides of the pulley and there is no multiplication of force.

How it works

Diagram 1 - A basic equation for a pulley: In equilibrium, the force F on the pulley axle is equal and opposite to the sum of the tensions in each line leaving the pulley, and these tensions are equal

Katrol tetap KM = 1 KM= Keuntungan Mekanik

1.) A fixed pulley is the only pulley that when used individually, uses more effort than the load to lift the load from the ground. The wheel does not move. Fixed pulleys change the direction of the effort force. It does not increase the size of the effort force. The advantage of the fixed pulley is that you do not have to pull or push the pulley up and down. The disadvantage is that you have to apply more effort than the load.

2.) A fixed pulley is the only pulley that when used individually, uses more effort than the load to lift the load from the ground.

3.) The fixed pulley when attached to an unmovable object e.g. a ceiling or wall, acts as a first class lever with the fulcrum being located at the axis but with a minor change, the bar becomes a rope. 4.) The advantage of the fixed pulley is that you do not have to pull or push the pulley up and down. 5.) The disadvantage is that you have to apply more effort than the load

WHAT DOES A PULLEY DO? A pulley changes the direction of the force, making it easier to lift things

This figure shows a single pulley with a weight on one end of the rope. The other end is held by a person who must apply a force to keep the weight hanging in the air (in equilibrium). There is a force (tension) on the rope that is equal to the weight of the object. This force or tension is the same all along the rope. In order for the weight and pulley (the system) to remain in equilibrium, the person holding the end of the rope must pull down with a force that is equal in magnitude to the tension in the rope. For this pulley system, the force is equal to the weight, as shown in the picture. The mechanical advantage of this system is 1!

The Parts of a Pulley

By Paul Dohrman, eHow Contributor updated: September 10, 2009 The three parts of a pulley are the hub (or boss), the arms (or spokes) and the rim. Cheeks (side plates) prevent lateral motion of the hub and catch the tackle (rope, string or chain) if

it disengages from the pulley rim. The hub may be mounted on a shaft using a key, splines or a set screw.

Rim

1. Bicycle Derailleur (Flickr/ragnar1984) The rim is concave on the arms side. This keeps the belt in the middle of the rim. When the belt is flat, the rim is flat, with flanges on the side to hold the belt in place. The rim may be V-shaped to accommodate a V-shaped belt. A rim can have teeth to catch the links of a chain, for example, as in the rear derailleur of a bicycle.

Arms

2. If the pulley wheel has arms or spokes, they are often cast curved. If the pulley is cast in one piece with the spokes at right angles to the rim, stresses during cooling can cause cracking. Curved arms absorb the stresses. Cast arms are typically elliptical in cross section, to reduce wind loss.

Hub

3. A pulley can be either fast or loose. This means the hub can be affixed to the shaft or allowed to move around it. A fast and a loose pulley on the same shaft can enable a belt to stop, even if the shaft has to keep rotating. By shifting a rotating belt from the fixed pulley over to the loose pulley, the shaft can continue rotating while the belt stops. In short, a fast and loose pulley system can therefore be used to interrupt the transmission of motion in machinery. A loose hub can be made to turn more freely with bushings (cylinder or sleeve) or ball bearings inserted between hub and axle. Pulleys can be made interchangeable by swapping in bushings that match the radius of the shaft.

Block

4. Block and Tackle Hoists and Their Mechanical Advantage If the cheeks hold multiple pulleys, they form what is called a block. Multiple blocks can be used to gain mechanical advantage. If one of the blocks has to move along with a load, then for the distance it is hoisted, the rope (tackle) stretched between separate blocks must each shorten the same distance. If there are three stretches of rope between two blocks, the mechanical advantage would be 3:1, because the rope would need to be pulled three times what the load is lifted. It is analogous to using a lever to reduce the force required to lift a heavy load by increasing the distance over which the input force must be applied. This type of system is called block and tackle.

Differential Pulley

5. A variation of block and tackle is a differential pulley. The pulleys in a block are of different radius. The rims have engaging sprockets to prevent slip. The chain makes a complete loop so that it is unending. The merit of the system is that it affords great mechanical advantage without requiring the tackle/chain to be tied down or in need of a brake to keep the load from dropping. Keeping the radii (R and r) close, friction is enough to keep the pulley from turning when under load.

Potrebbero piacerti anche

- 507 Mechanical Movements: Mechanisms and DevicesDa Everand507 Mechanical Movements: Mechanisms and DevicesValutazione: 4 su 5 stelle4/5 (28)

- System of Pulleys AND Gear TrainDocumento22 pagineSystem of Pulleys AND Gear TrainMohammad TahaNessuna valutazione finora

- The Book of Basic Machines: The U.S. Navy Training ManualDa EverandThe Book of Basic Machines: The U.S. Navy Training ManualValutazione: 4 su 5 stelle4/5 (4)

- 2.pulleys KinesiologyDocumento13 pagine2.pulleys KinesiologyNimra TariqNessuna valutazione finora

- Kinesiology (LEC-5) : Dr. Iqra Karamat PTDocumento13 pagineKinesiology (LEC-5) : Dr. Iqra Karamat PTNimra Tariq100% (1)

- Kinesiology Lecture on Mechanical Principles and Pulley TypesDocumento13 pagineKinesiology Lecture on Mechanical Principles and Pulley TypesNimra TariqNessuna valutazione finora

- The Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesDa EverandThe Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesNessuna valutazione finora

- Pulley SystemDocumento9 paginePulley Systemvaithsr0% (1)

- Heavy Load Lifting MachineDocumento41 pagineHeavy Load Lifting MachineAlmubeenNessuna valutazione finora

- Pulleys 200417152522Documento17 paginePulleys 200417152522Gg GookuNessuna valutazione finora

- Belt DrivesDocumento10 pagineBelt DrivesJyoti ChoudharyNessuna valutazione finora

- PulleysDocumento12 paginePulleysRiya Sachan100% (2)

- Dme Short Answer QuestionsDocumento16 pagineDme Short Answer QuestionsAbinandh VNessuna valutazione finora

- 1 Body PulleysDocumento12 pagine1 Body PulleysNeha Bhasin75% (4)

- PulleyDocumento6 paginePulleySanthosh PothulaNessuna valutazione finora

- Rotational Motion Transmission SystemsDocumento21 pagineRotational Motion Transmission Systemslolu pandey100% (2)

- Dr. Kanwal Khan Assistant Professor SciptrDocumento12 pagineDr. Kanwal Khan Assistant Professor SciptrKanwal KhanNessuna valutazione finora

- Ars (AutoRecovered) 5Documento11 pagineArs (AutoRecovered) 5christinachikafaNessuna valutazione finora

- Belt DrivesDocumento11 pagineBelt Drivesabduallah rabahNessuna valutazione finora

- Everything You Need to Know About PulleysDocumento7 pagineEverything You Need to Know About PulleysMohan ChetriNessuna valutazione finora

- Slides 16-27Documento12 pagineSlides 16-27api-189616674Nessuna valutazione finora

- See Figures 1 Thru 7: Suspension SystemDocumento28 pagineSee Figures 1 Thru 7: Suspension SystembalajigandhirajanNessuna valutazione finora

- Automotive Suspension SystemDocumento8 pagineAutomotive Suspension SystemAsraNessuna valutazione finora

- AT - 3 and 4Documento14 pagineAT - 3 and 4vandanaharikumarNessuna valutazione finora

- MHE Abduljebar AssDocumento21 pagineMHE Abduljebar AssAbduljebar SemuNessuna valutazione finora

- PulleysDocumento28 paginePulleysNayela AkramNessuna valutazione finora

- Lecture 4 PulleysDocumento26 pagineLecture 4 PulleysAmjad AshrafiNessuna valutazione finora

- Belt and Pulley SystemsDocumento5 pagineBelt and Pulley SystemsNBRellos50% (2)

- The Wheel and AxleDocumento7 pagineThe Wheel and AxleKathryn Bianca AcanceNessuna valutazione finora

- Metal Cutting M/C: Plasma CuttersDocumento25 pagineMetal Cutting M/C: Plasma CuttersN Dhanunjaya Rao BorraNessuna valutazione finora

- Pulley: By: Melissa Hale and Melinda MillerDocumento17 paginePulley: By: Melissa Hale and Melinda MillerDhanar Tri AtmajaNessuna valutazione finora

- Belt Drives: Power Transmission DevicesDocumento16 pagineBelt Drives: Power Transmission Devicesniaz kilamNessuna valutazione finora

- The 6 Simple Machines: Wedge Screw Inclined PlaneDocumento27 pagineThe 6 Simple Machines: Wedge Screw Inclined Planefiey_ra100% (3)

- Compasison Leaf Spring - Plastic SpringDocumento21 pagineCompasison Leaf Spring - Plastic Springpippo233Nessuna valutazione finora

- Simple MachinesDocumento26 pagineSimple MachinesPaulNessuna valutazione finora

- Pulleys: Dr. Zahra Batool CashtDocumento29 paginePulleys: Dr. Zahra Batool CashtMaryam AdeelNessuna valutazione finora

- Physics 3rd Edition Giambattisata Solutions ManualDocumento38 paginePhysics 3rd Edition Giambattisata Solutions Manualloganyjl9th100% (14)

- Physics 3rd Edition Giambattisata Solutions ManualDocumento38 paginePhysics 3rd Edition Giambattisata Solutions Manualcharles90br100% (15)

- Physics 3Rd Edition Giambattisata Solutions Manual Full Chapter PDFDocumento65 paginePhysics 3Rd Edition Giambattisata Solutions Manual Full Chapter PDFjonathanwelchjrcizmsdty100% (8)

- Experiment 2Documento6 pagineExperiment 2Parvesh DahiyaNessuna valutazione finora

- Block and Tackle - Wikipedia, The Free EncyclopediaDocumento3 pagineBlock and Tackle - Wikipedia, The Free Encyclopediadonodoni0008Nessuna valutazione finora

- Unit 2-At6402 Automotive ChassisDocumento20 pagineUnit 2-At6402 Automotive ChassisSathis KumarNessuna valutazione finora

- Suspension SystemDocumento11 pagineSuspension SystemARUNSFRHNessuna valutazione finora

- Grade 4 WheelsleversDocumento16 pagineGrade 4 Wheelsleversapi-253059746100% (1)

- Unit 3 Notes - Engineering Level 3 CtechDocumento11 pagineUnit 3 Notes - Engineering Level 3 CtechHadley PeckNessuna valutazione finora

- 2 - Power TransmissionDocumento30 pagine2 - Power TransmissionAmarjeet Singh (Assistant Professor- Mechanical Engineer)Nessuna valutazione finora

- Belt DrivesDocumento35 pagineBelt DrivesKelvin Kindice MapurisaNessuna valutazione finora

- Sistem PuliDocumento31 pagineSistem Pulimega rahayuNessuna valutazione finora

- Pulley System: Aarav, Parth, Pushti, Shreya and VirajDocumento14 paginePulley System: Aarav, Parth, Pushti, Shreya and VirajParth YadavNessuna valutazione finora

- Unit 4Documento36 pagineUnit 4hisuresh196Nessuna valutazione finora

- Suspension SubsystemDocumento29 pagineSuspension SubsystemAkhilesh KatdareNessuna valutazione finora

- Levers Pulleys Human BodyDocumento41 pagineLevers Pulleys Human BodyAzfar Khurshid MalghaniNessuna valutazione finora

- Belt DriveDocumento34 pagineBelt DriveGaurav Kumar GuptaNessuna valutazione finora

- AUTO 201 Steering and Suspension SystemDocumento6 pagineAUTO 201 Steering and Suspension Systempig123Nessuna valutazione finora

- Chapter8suspension 1Documento12 pagineChapter8suspension 1Muhammad AbbasNessuna valutazione finora

- Different Types of Simple Machines - Science 6Documento13 pagineDifferent Types of Simple Machines - Science 6ilagan.haqqi0321Nessuna valutazione finora

- Suspension System and Transmission SystemDocumento121 pagineSuspension System and Transmission SystemVghNessuna valutazione finora

- UntitledDocumento23 pagineUntitledAnaLizaD.SebastianNessuna valutazione finora

- Presentation Assignment STEIDocumento1 paginaPresentation Assignment STEIsukmaweningNessuna valutazione finora

- 25+ Apps To Make Your Everyday Life Easier: TED StaffDocumento7 pagine25+ Apps To Make Your Everyday Life Easier: TED StaffsukmaweningNessuna valutazione finora

- Bundel Soal STI Semester 3 2016-2017 PDFDocumento91 pagineBundel Soal STI Semester 3 2016-2017 PDFsukmaweningNessuna valutazione finora

- Apps To Make Your Everyday LifeDocumento18 pagineApps To Make Your Everyday LifesukmaweningNessuna valutazione finora

- Project Charter TemplateDocumento1 paginaProject Charter TemplateAlok ChitnisNessuna valutazione finora

- SoalDocumento4 pagineSoalsukmaweningNessuna valutazione finora

- Deforestation in Indonesia Is A Big Problem in Indonesia 3Documento1 paginaDeforestation in Indonesia Is A Big Problem in Indonesia 3sukmaweningNessuna valutazione finora

- Deforestation in Indonesia Is A Big Problem in IndonesiaDocumento1 paginaDeforestation in Indonesia Is A Big Problem in IndonesiasukmaweningNessuna valutazione finora

- Katrol TetapDocumento4 pagineKatrol TetapsukmaweningNessuna valutazione finora

- Flutek Swing MotorDocumento2 pagineFlutek Swing Motorsunil0081Nessuna valutazione finora

- XI-Opt. Syllabus (2023-24)Documento29 pagineXI-Opt. Syllabus (2023-24)INDERDEEPNessuna valutazione finora

- DS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1Documento52 pagineDS White-Papers Getting Started With Business Logic 3DEXPERIENCE R2017x V1AlexandreNessuna valutazione finora

- Maintenance Recommendations: Operation and Maintenance ManualDocumento10 pagineMaintenance Recommendations: Operation and Maintenance ManualAmy Nur SNessuna valutazione finora

- Oracle® Fusion Middleware: Administrator's Guide For Oracle Business Intelligence Applications 11g Release 1 (11.1.1.7)Documento76 pagineOracle® Fusion Middleware: Administrator's Guide For Oracle Business Intelligence Applications 11g Release 1 (11.1.1.7)Nicholas JohnNessuna valutazione finora

- AdvancesDocumento328 pagineAdvanceshanumsj123Nessuna valutazione finora

- Effect of Temperature on Chemical ReactionDocumento8 pagineEffect of Temperature on Chemical ReactionnajihahNessuna valutazione finora

- Proportional Chopper Amplifier VB-3A: Min MaxDocumento5 pagineProportional Chopper Amplifier VB-3A: Min MaxryujoniNessuna valutazione finora

- Test 2Documento16 pagineTest 2edwardNessuna valutazione finora

- p-4500 Technical InformationDocumento13 paginep-4500 Technical InformationElhoiNessuna valutazione finora

- Ukur KadasterDocumento21 pagineUkur KadasterMuhammad NajmiNessuna valutazione finora

- Daikin RXS-K - Technical DataDocumento21 pagineDaikin RXS-K - Technical DataPrestoneKNessuna valutazione finora

- NTSE 2015 Stage I Official Result Karnataka PDFDocumento10 pagineNTSE 2015 Stage I Official Result Karnataka PDFAnnu NaikNessuna valutazione finora

- Ef TechnologyDocumento2 pagineEf TechnologyAdarsha SarpangalaNessuna valutazione finora

- SPCU3C14Documento20 pagineSPCU3C14ming tsaoNessuna valutazione finora

- Battery Testing, Test Methods and ProceduresDocumento8 pagineBattery Testing, Test Methods and ProceduresMuraliKrishnaNessuna valutazione finora

- Prepare and Interpret Technical DrawingDocumento5 paginePrepare and Interpret Technical DrawingDwin Rosco75% (4)

- HP ALM FeaturesDocumento51 pagineHP ALM FeaturesSuresh ManthaNessuna valutazione finora

- Wi Cswip 3.1 Part 13Documento7 pagineWi Cswip 3.1 Part 13Ramakrishnan AmbiSubbiahNessuna valutazione finora

- Biology Notes HSCDocumento107 pagineBiology Notes HSCGouri DasNessuna valutazione finora

- Chapter 3 Step Wise An Approach To Planning Software Projects 976242065Documento31 pagineChapter 3 Step Wise An Approach To Planning Software Projects 976242065RiajiminNessuna valutazione finora

- 478 - Phs 242 NotesDocumento61 pagine478 - Phs 242 NotesSovan ChakrabortyNessuna valutazione finora

- Tutorial - Lecture 3 SolutionsDocumento10 pagineTutorial - Lecture 3 SolutionsBastián Olfos MárquezNessuna valutazione finora

- FT 539G Eng 01Documento4 pagineFT 539G Eng 01lmw_arunNessuna valutazione finora

- LsApi PDFDocumento347 pagineLsApi PDFEduardo Martin Vega100% (2)

- Influence of Ring-Stiffeners On Buckling Behavior of Pipelines UnderDocumento16 pagineInfluence of Ring-Stiffeners On Buckling Behavior of Pipelines UnderSUBHASHNessuna valutazione finora

- BHEL Turbine ManualDocumento58 pagineBHEL Turbine Manualnivasssv75% (4)

- Fiziks: Basic Properties and Tools of ThermodynamicsDocumento28 pagineFiziks: Basic Properties and Tools of ThermodynamicsSURAJ PRATAP SINGHNessuna valutazione finora

- Debre Tabor University: Network and System AdministrationDocumento33 pagineDebre Tabor University: Network and System AdministrationBethelhem YetwaleNessuna valutazione finora

- Solution to Tutorials 1-4: Shock Absorber, Crane, SDOF Vibration, Landing GearDocumento19 pagineSolution to Tutorials 1-4: Shock Absorber, Crane, SDOF Vibration, Landing GearPearlyn Tiko TeoNessuna valutazione finora

- The Inner Runner: Running to a More Successful, Creative, and Confident YouDa EverandThe Inner Runner: Running to a More Successful, Creative, and Confident YouValutazione: 4.5 su 5 stelle4.5/5 (60)

- Depression Hates a Moving Target: How Running With My Dog Brought Me Back From the BrinkDa EverandDepression Hates a Moving Target: How Running With My Dog Brought Me Back From the BrinkValutazione: 4 su 5 stelle4/5 (35)

- The Pants Of Perspective: One woman's 3,000 kilometre running adventure through the wilds of New ZealandDa EverandThe Pants Of Perspective: One woman's 3,000 kilometre running adventure through the wilds of New ZealandValutazione: 4.5 su 5 stelle4.5/5 (82)

- Triathlon Training Bible: A Triathletes Book Covering The Sports Diet/Food, Techniques, Gears, Ironman Exercises & More...Da EverandTriathlon Training Bible: A Triathletes Book Covering The Sports Diet/Food, Techniques, Gears, Ironman Exercises & More...Nessuna valutazione finora

- How to Run a Marathon: The Go-to Guide for Anyone and EveryoneDa EverandHow to Run a Marathon: The Go-to Guide for Anyone and EveryoneValutazione: 5 su 5 stelle5/5 (17)

- Can't Nothing Bring Me Down: Chasing Myself in the Race Against TimeDa EverandCan't Nothing Bring Me Down: Chasing Myself in the Race Against TimeValutazione: 4 su 5 stelle4/5 (1)

- Showing Up: Get Comfortable Being UncomfortableDa EverandShowing Up: Get Comfortable Being UncomfortableValutazione: 5 su 5 stelle5/5 (2)

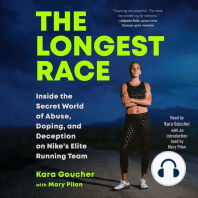

- The Longest Race: Inside the Secret World of Abuse, Doping, and Deception on Nike's Elite Running TeamDa EverandThe Longest Race: Inside the Secret World of Abuse, Doping, and Deception on Nike's Elite Running TeamValutazione: 5 su 5 stelle5/5 (58)

- Endure: Mind, Body, and the Curiously Elastic Limits of Human PerformanceDa EverandEndure: Mind, Body, and the Curiously Elastic Limits of Human PerformanceValutazione: 4.5 su 5 stelle4.5/5 (237)

- In the Spell of the Barkley: Unravelling the Mystery of the World's Toughest UltramarathonDa EverandIn the Spell of the Barkley: Unravelling the Mystery of the World's Toughest UltramarathonNessuna valutazione finora

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- Mind Gym: An Athlete's Guide to Inner ExcellenceDa EverandMind Gym: An Athlete's Guide to Inner ExcellenceValutazione: 3.5 su 5 stelle3.5/5 (18)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for Implementing Process Safety ManagementDa EverandGuidelines for Implementing Process Safety ManagementNessuna valutazione finora

- Whole Body Barefoot: Transitioning Well To Minimal FootwearDa EverandWhole Body Barefoot: Transitioning Well To Minimal FootwearValutazione: 4.5 su 5 stelle4.5/5 (33)

- The Beginning Runner's Handbook: The Proven 13-Week RunWalk ProgramDa EverandThe Beginning Runner's Handbook: The Proven 13-Week RunWalk ProgramValutazione: 3.5 su 5 stelle3.5/5 (3)

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- 80/20 Running: Run Stronger and Race Faster by Training SlowerDa Everand80/20 Running: Run Stronger and Race Faster by Training SlowerValutazione: 4.5 su 5 stelle4.5/5 (97)

- Guidelines for Auditing Process Safety Management SystemsDa EverandGuidelines for Auditing Process Safety Management SystemsNessuna valutazione finora

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeDa EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNessuna valutazione finora

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationDa EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNessuna valutazione finora

- No Meat Athlete: A Plant-Based Nutrition and Training Guide for Every Fitness Level—Beginner to BeyondDa EverandNo Meat Athlete: A Plant-Based Nutrition and Training Guide for Every Fitness Level—Beginner to BeyondValutazione: 4 su 5 stelle4/5 (4)

- The Perfect Medicine: How Running Makes Us Healthier and HappierDa EverandThe Perfect Medicine: How Running Makes Us Healthier and HappierValutazione: 4.5 su 5 stelle4.5/5 (14)

- Marathon Training: The Underground Plan To Run Your Fastest Marathon Ever : A Week by Week Guide With Marathon Diet & Nutrition PlanDa EverandMarathon Training: The Underground Plan To Run Your Fastest Marathon Ever : A Week by Week Guide With Marathon Diet & Nutrition PlanNessuna valutazione finora

- Strength Training For Runners : The Best Forms of Weight Training for RunnersDa EverandStrength Training For Runners : The Best Forms of Weight Training for RunnersValutazione: 2 su 5 stelle2/5 (5)

- Not Your Average Runner: Why You're Not Too Fat to Run and the Skinny on How to Start TodayDa EverandNot Your Average Runner: Why You're Not Too Fat to Run and the Skinny on How to Start TodayValutazione: 5 su 5 stelle5/5 (1)

- Sick to Fit: 3 Simple Techniques that Got Me from 420 Pounds to the Cover of Runner's World, Good Morning America, and The Today ShowDa EverandSick to Fit: 3 Simple Techniques that Got Me from 420 Pounds to the Cover of Runner's World, Good Morning America, and The Today ShowValutazione: 4.5 su 5 stelle4.5/5 (6)