Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Koomey S&s Manual

Caricato da

borregocrTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Koomey S&s Manual

Caricato da

borregocrCopyright:

Formati disponibili

CONVENTIONAL

BOP CONTROL SYSTEM

WITH

AIR REMOTE CONTROL

STEWART & STEVENSON MODEL SSC-400-3S11

SERIAL NUMBER: 8135

FOR

CROSCO

INTEGRATED DRILLING & WELL SERVICES Co., Ltd.

THIS PAGE INTENTIONALLY LEFT BLANK

TABLE OF CONTENTS

1 SYSTEM DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 ACCUMULATOR UNIT ASSEMBLY 1

1.2 AIR PUMP ASSEMBLY 1

1.3 ELECTRIC PUMP ASSEMBLY 1

1.4 HYDRAULIC CONTROL MANIFOLD ASSEMBLY 1

1.5 AIR REMOTE CONTROL PANEL(S) 2

1.6 AIR REMOTE CONTROL INTERFACE ASSEMBLY 2

1.7 INTERCONNECT CABLE ASSEMBLY 2

1.8 SIZING RECOMMENDATIONS - Normal Pressure and/or Standard Service 3

1.9 SIZING RECOMMENDATIONS - High Pressure And/or H

2

S Environment 6

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 INSTALLATION INTRODUCTION 9

2.2 ACCUMULATOR UNIT 10

2.3 AIR PANEL INSTALLATION 14

2.4 DRILL AHEAD 15

2.5 INSTALLATION DATA SHEET 16

3 TYPICAL SYSTEM DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 TYPICAL INSTALLATION PICTORIAL 17

3.2 TYPICAL ACCUMULATOR UNIT ASSEMBLY 18

3.3 TYPICAL INTERCONNECT SCHEMATIC 19

3.4 HYDRAULIC SCHEMATIC TYPICAL CONTROL FLUID CIRCUIT 20

3.5 HYDRAULIC SCHEMATIC TYPICAL CONTROL MANIFOLD CIRCUIT 21

3.6 STARTER CONTROL SCHEMATIC PUMP ELECTRIC MOTOR 22

4 OPERATION INSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1 ACCUMULATORS AND RESERVOIR 24

4.2 AIR PUMP ASSEMBLY 24

4.3 ELECTRIC PUMP ASSEMBLY 25

4.4 CONTROL MANIFOLD ASSEMBLY 26

4.5 AIR REMOTE CONTROL PANEL ASSEMBLY 31

4.6 AIR REMOTE CONTROL INTERFACE ASSEMBLY 34

4.7 INTERCONNECT CABLE ASSEMBLY 34

4.8 ACCESSORIES 34

5 MAINTENANCE INSTRUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 INTRODUCTION 37

5.2 SPECIFIC TOOLS LIST 38

5.3 NITROGEN PRECHARGE INSTRUCTIONS - BLADDER TYPE ACCUMULATORS 39

5.4 NITROGEN PRECHARGE INSTRUCTIONS - 80 GALLON SPHERICAL TYPE ACCUMULATORS 41

5.5 ACCUMULATOR UNIT 42

5.6 AIR OPERATED PUMPS 42

5.7 ELECTRIC PUMPS 43

5.8 CONTROL MANIFOLD 45

5.9 AIR PANELS 46

5.10 AIR JUNCTION BOXES 47

6 ACCUMULATOR UNIT TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.1 ACCUMULATOR PROBLEMS 49

6.2 AIR SUPPLY PROBLEMS 51

6.3 PUMP PROBLEMS 52

6.4 ELECTRIC MOTOR PROBLEMS 57

6.5 FOUR-WAY VALVE PROBLEMS 58

6.6 GAUGE PROBLEMS 59

6.7 REGULATOR PROBLEMS 61

6.8 AIR REMOTE CONTROL PANEL PROBLEMS 63

7 STORAGE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.1 INTRODUCTION 64

7.2 INITIAL PREPARATION 64

7.3 FINAL PREPARATION 65

7.4 CHECKOUT AND RECONDITIONING 67

8 REFERENCE MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.1 HYDRAULIC & PNEUMATIC SYMBOLS 68

8.2 ELECTRICAL SYMBOLS 69

8.3 ABBREVIATIONS 70

8.4 GLOSSARY OF TERMS 71

8.5 CONVERSION FACTORS 77

9 SYSTEM SPECIFIC DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

9.1 SYSTEM DRAWINGS 81

9.1.1 Assy. BOP CONTROL SYSTEM, MODEL SSC400-3S11 Dwg. No.: 00000050 82

9.1.2 INSTALLATION SPECIFICATION BOP CONTROL SYSTEM, Dwg. No.: 00000064 83

9.1.3 Assy. BOP ACCUMULATOR WITH 8-FUNCTIONS AND 1 AIR REMOTE PANEL, Dwg. No.: 00000051 Pg. 1 84

9.1.4 Assy. BOP ACCUMULATOR WITH 8-FUNCTIONS AND 1 AIR REMOTE PANEL, Dwg. No.: 00000051 Pg. 2 85

9.1.5 SCHEMATIC Assy. BOP ACCUMULATOR, Dwg. No.: 00000063 Pg. 1 86

9.1.6 SCHEMATIC Assy. BOP ACCUMULATOR, Dwg. No.: 00000063 Pg. 2 87

9.1.7 Assy. DRILLER'S AIR REMOTE PANEL, Dwg. No.: 00000052 88

9.1.8 Assy. AIR HOSE BUNDLE FOR DRILLER'S REMOTE PANEL, Dwg. No.: 00000053 89

9.1.9 Assy. HYDRAULIC HOSE, BOP TYPE 1" SIZE X 50 FT. LONG, Dwg. No.: 00000054 90

SALES AND SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 1 of 91

1 SYSTEM DESCRIPTION

A Blowout Preventer (BOP) Control System is a high pressure hydraulic power unit fitted with directional control valves to safely

control kicks and prevent blowouts during drilling operations. We offer a wide variety of equipment to meet the customer's specific

operational and economic criteria. A typical BOP Control System consists of the following equipment:

1.1 Accumulator Unit Assembly

1.2 Air Pump Assembly

1.3 Electric Pump Assembly

1.4 Hydraulic Control Manifold Assembly

1.5 Air Remote Control Panel(s)

1.6 Remote Control Interface Assembly(ies)

1.7 Interconnect Cable Assembly(ies)

1.1 ACCUMULATOR UNIT ASSEMBLY

The primary function of the Accumulator Unit is to provide the atmospheric fluid supply for the pumps and storage of the high

pressure operating fluid for control of the BOP stack. It includes accumulators, reservoir, accumulator piping and a master

skid for mounting of the air operated pump, electric motor driven pumps and the Hydraulic Control Manifold.

1.1.1 Accumulators

Accumulators are ASME coded pressure vessels for storage of high pressure fluid. These accumulators are

available in a variety of sizes, types, capacities and pressure ratings. The two (2) basic types are bladder and float

which are available in cylindrical or ball styles. The accumulators can either be bottom or top loading. Top loading

means the bladder or float can be removed from the top while it is still mounted on the Accumulator Unit. Bottom

loading accumulators must be removed from the Accumulator unit to be serviced. Bladder and buoyant float type

accumulators can be repaired in the field without destroying their stamp of approval.

1.1.2 Reservoir

A rectangular reservoir is provided for storage of the atmospheric fluid supply for the high pressure pumps. It

contains baffles, fill and drain ports and troubleshooting inspection ports. For filling and cleaning procedures see

the Maintenance Section.

1.1.3 Accumulator Piping

This piping connects the high pressure discharge lines of the pumps to the accumulators and the hydraulic

manifold. It is comprised of 1" or 1-1/2" Schedule 80 or 160 pipe, isolator valves and a 3500 psi relief valve to

protect the accumulators form being over-pressured. Cylindrical type accumulators are mounted on machined

headers to minimize line restrictions and leaks.

1.2 AIR PUMP ASSEMBLY

The air pump assembly consists of one (1) or more air operated hydraulic pumps connected in parallel to the accumulator

piping to provide a source of high pressure operating fluid for the BOP control system. These pumps are available in a variety

of sizes and ratios. For proper sizing of the air pump assembly see Pump Sizing Recommendations

1.3 ELECTRIC PUMP ASSEMBLY

The electric pump assembly consists of a duplex or triplex reciprocating plunger type pump driven by an explosion-proof

electric motor. It is connected to the accumulator piping to provide a source of high pressure operating fluid for the BOP

control system. It is available in a variety of horsepower and voltage ranges. For proper sizing of the electric pump assembly

see Pump sizing Recommendations.

1.4 HYDRAULIC CONTROL MANIFOLD ASSEMBLY

The hydraulic control manifold consists of hydraulic regulators and directional control valves to direct the flow of high pressure

operating fluid to control the BOP stack. Two (2) regulators are usually provided, one (1) for the annular preventer and one

(1) for the remainder of the BOP stack functions which is called the manifold regulator. These regulators reduce the 3000

psi accumulator pressure to a pressure compatible with the operating limits of the preventers. The directional control valves

are usually 1" with an 1-1/2" size available for annular preventers requiring large volumes of control fluid. The manifold also

contains gauges for monitoring the control system's operating pressures, a 10,000 psi bleeder valve and a 3500 psi relief

valve.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 2 of 91

1.5 AIR REMOTE CONTROL PANEL(S)

Air remote control panels provide partial or complete control and pressure monitoring of the BOP control system.

This enables the accumulator unit and hydraulic control manifold to be placed in a safe area so that it can remain operational

in emergency conditions. Multiple air remote control panels can be added to a control system with minimal additional cost

to enhance the safety of drilling operations. Air remote control panels can be provided in a wide variety of mixes, styles and

configurations to meet specific space and operational criteria. All air remote control panels contain a master control valve

which must be operated simultaneously with the selected function to initiate operation. They all contain four-way spring

centered air control valves and require a customer furnished air supply, air remote control interface assembly and

interconnect cable assembly.

1.6 AIR REMOTE CONTROL INTERFACE ASSEMBLY

Air remote control interface assemblies are required when an air remote control panel included with the BOP control system.

These assemblies contain all the components that must be added to the hydraulic control manifold for air remote operation.

These components include air cylinders, fixed plate half of an air junction box and all necessary stainless steel tubing and

fittings. For panels with remote regulation and pressure monitoring, these components also include an air regulator, selector

valve and a pressure transmitter assembly. When two (2) air remote panels are included on one BOP control system the

interface assembly also includes an additional fixed plate half of an air junction box and air shuttle valves.

1.7 INTERCONNECT CABLE ASSEMBLY

Air interconnect cables are used to carry signals from the air operated remote control panels to the air interface assemblies

on the accumulator unit. They include a customer specified length of a flame resistant multi-conduct air cable. The air cable

consists of a spirally wound 3/8" OD polyethylene air tubing in a polyvinyl chloride (PVC) sheath. The junction boxes consist

of a hose and half of an air junction box on each end which mate to the fixed plate halves mounted on the air panels and on

the air interface assemblies.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 3 of 91

1.8 SIZING RECOMMENDATIONS - Normal Pressure and/or Standard Service

The approach to correctly sizing accumulator units is to provide ample accumulator capacity (fluid stored under pressure)

to immediately control the preventers during an emergency. The pumps are designed to charge these accumulators within

a reasonable time period, and to maintain this charge, as pressure is used to control the preventers. The following steps for

sizing the BOP control system and selecting the appropriate Mendel numbers have been prepared to assist you in correctly

selecting a safe and reliable BOP control system.

1.8.1 Sizing Accumulator Volume

The total accumulator volume for a 3000 psi BOP control system should be sized to fully close the annular and

all ram preventers with pumps out of service while maintaining a minimum of 1200 psi operating pressure (20 psi

above precharge). An additional 50% safety factor is required to compensate for any fluid loss in the control

system or preventers.

1. Determine the total gallons to close preventers.

EXAMPLE:

Preventer Type Mfg. By Mfg. Type Stack Size Work Press Gal. to Close

Annular Hydril GK 13-5/8" 5,000 PSI 17.98

Pipe Ram Cameron U 13-5/8" 10,000 PSI 5.54

Blind Ram Cameron U 13-5/8" 10,000 PSI 6.78

Pipe Ram Cameron U 13-5/8" 10,000 PSI 5.54

TOTAL 35.84

The total system accumulator capacity should meet or exceed the following requirements:

Total Gallons to Close 35.84

50% Safety Factor + 17.92

Total Gallons of Usable Fluid Required (VR) 53.76 Gallons

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 4 of 91

2. Calculate the total accumulator volume (nitrogen and fluid) required (derived form Boyle's Law, P

1

, V

1

= P

2

V

2

):

P

1

= Maximum pressure of accumulator when completely charged (3000 PSI)

P

2

= Minimum operating pressure of accumulator (1200 PSI)

P

3

= Nitrogen precharged pressure (1000 PSI)

V

1

= Volume of nitrogen at maximum pressure

V

2

= Volume of nitrogen at minimum pressure

V

3

= Total accumulator volume of (nitrogen and fluid)

V

R

= Total usable fluid required including safety factor

R

3

3 3

2 1

V 53.76

V = = = 107.52 110 Ga.

P P 1000 1000

P P 1200 3000

3. Determine the number of accumulators required by deriving the total accumulator volume (nitrogen and fluid)

by the nominal accumulator capacity. The nominal accumulator capacity is the accumulator size in gallons,

less 1 gallon to allow for bladder/float displacement.

EXAMPLE (USING 11 GALLON ACCUMULATORS)

(A) Total accumulator volume 107.52

(B) Nominal accumulator capacity (11 - 1 = 10) 10.00

(C) Number of Eleven Gallon Accumulators [AB] 10.75 . 11

TOTAL ACCUMULATOR VOLUME 110 Gallons

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 5 of 91

1.8.2 Sizing Air and Electric Pump

Each pump source for a 3000 PSI conventional BOP control system should be capable of charging the entire

system accumulator capacity from 0 to 300 PSI in fifteen minutes or less. The control system should include two

independently powered pump sources.

1. Determine the required pump GPM by multiplying the total accumulator volume (obtained in step 2 of 1.09.01)

by 0.67 (the actual fluid capacity) and divide by 15 minutes:

Total Accumulator Volume (step 2) 110.00 Gallons

Actual Fluid Capacity Factor X 0.67 Gallons

Total Actual Fluid Capacity 73.70 Gallons

Divided by 15 Minutes 15 Minutes = 4.9 GPM

TOTAL REQUIRED (EACH PUMP) 4.9 GPM

2. Select the pump model numbers each with a pump output greater than the total GPM required above. See Air

Pumps and Electric Pumps for additional specification.

EXAMPLE

Model No. Description Total GPM

A197-602 Air Pump Assy. 7.20*

TPE06-15460 Electric Triplex Pump Assy. 6.40

* NOTE: Air pump output is based on 125 PSI air input to the air motor and the

output at 2000 PSI (2000 PSI is the average rate between the 1000 PSI

precharge and the 3000 PSI operating pressure).

It is not recommend air pump ratios less than 50:1. Rig air pressure may drop as low as 60 PSI under normal

operating conditions which would not allow lower ratio pumps to attain the required 3000 PSI output.

EXAMPLE

Pump Ratio Air Supply Pressure Stall Pressure

60:1 60 PSI 3600 PSI

50:1 60 PSI 3000 PSI

40:1 60 PSI 2400 PSI

35:1 60 PSI 2100 PSI

It is not recommend air operated pumps with 10 inch or larger air motors. Each of these motors require 300 SCFM

or more air supply to maintain 3000 PSI operating pressure. The combined air demand of two or three of these

pumps would often exceed the available air supply of many floating drilling rigs.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 6 of 91

1.9 SIZING RECOMMENDATIONS - High Pressure And/or H

2

S Environment

1.9.1 Sizing Accumulator Volume

The total accumulator volume for a 3000 PSI BOP control system operating in a high pressure and/or H2S

environment should be sized to fully close, open and close the annular and all ram preventers. This must be done

with the pumps out of service while maintaining a minimum 1200 PSI operating pressure (200 PSI above

precharge).

1. Determine the total gallons to close, open and close preventers.

EXAMPLE

Preventer Type Mfg. By

Mfg.

Type

Stack Size Work Press

Gal. to

Close

Gal. to Open

Annular Hydril GK 11" 10,000 PSI 25.10 18.07

Pipe Ram Cameron U 11" 10,000 PSI 3.31 3.16

Blind Ram Cameron U 11" 10,000 PSI 4.23 4.03

Pipe Ram Cameron U 11" 10,000 PSI 3.31 3.16

TOTAL 35.95 28.42

The total system accumulator capacity should meet or exceed the following requirements:

Gallons to close all preventers 35.95

Gallons to open all preventers 28.42

Gallons to close all preventers +35.95

Total Gallons of Usable Fluid Required (V

R

) 100.32

2. Calculate the total accumulator volume (nitrogen and fluid) required (derived from Boyle's Law, P

1

V

1

= P

2

V

2

):

R

3

3 3

2 1

V 100.32

V = = = 200.64 200 Ga.

P P 1000 1000

P P 1200 3000

Quick Calculation:

Multiply gallons to close-open-close by 2. 100.32 X 2 = 200.64

3. Determine the number of accumulators required by dividing the total accumulator volume (nitrogen and fluid)

by the nominal accumulator capacity. The nominal accumulator capacity is the accumulator size in gallons,

less 1 gallon to allow for bladder/float displacement.

EXAMPLE - (USING 11 GALLON ACCUMULATORS)

Total Accumulator Volume 200.64

Nominal Accumulator Capacity [11 - 1 = 10] 20.00

Number of Eleven Gallon Accumulators 20.06 . 20

Total Accumulator Volume 200 Gallons

Model Number For Accumulator Unit - SSBA-200-3S11

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 7 of 91

1.9.2 Sizing Air And Electric Pumps

Each pump source for a 3000 PSI conventional BOP control system operating in a high pressure and/or H2S

environment should be capable of closing the annular and opening a hydraulically operated choke line valve in

two minutes or less. This must be done with the accumulator out of service while maintaining a minimum 1200

PSI operating pressure (200 PSI above precharge).

1. Determine the number of gallons to close the annular and open the hydraulic choke valve. Refer to the quick

reference tables for the annular and use 1 gallon (maximum) for the choke valve. Divide the combined gallons

by 2 minutes to arrive at the GPM required from each pump source.

Gallons to Close Annular 25.10

Gallons to Open Choke Valve (est.) + 1.00

Combined Gallons 26.10

Divide by 2 Minutes 2

TOTAL REQUIRED (EACH PUMP) 13.05 GPM

2. Select the pump model numbers each with a pump output greater than the total GPM required above. See Air

Pumps and Electric Pumps for additional specifications..

EXAMPLE

Model No. Description Total GPM

A1985-603 Air Pump Assy. 15.00

TPE12-30460 Electric Triplex Pump Assy. 14.20

1.9.3 Sizing the Nitrogen Backup System

The nitrogen backup system is sized to close the annular and one (1) choke line valve plus 50% safety factor;

however, any of the functions may be operated until the nitrogen pressure has be exhausted.

1. Determine the gallons to close the annular. Use 1 gallon (maximum) to open the choke line valve.

Preventer Type Mfg. By Mfg. Type Stack Size Work Press Gal. to Close

Annular Hydril GK 13-5/8" 5,000 PSI 17.98

Choke Valve - - - - 1.00

TOTAL 18.98

a. Multiply the total gallons to close by 1.5 to arrive at the total gallons required including the safety factor.

EXAMPLE.

Total Gallons Required 18.98

50% Safety Factor + 9.49

Total Volume Required (V

3

) 28.47 Gallons

The nitrogen bottle has been calculated to equate to 6.23 equivalent usable fluid gallons. To determine

the number of nitrogen bottles required, divide the total volume, including safety factor, by the

equivalent

usable fluid gallons per bottle.

TOTAL VOLUME 28.47

Divide by Usable Gallons 6.23

Number of Nitrogen Bottles 4.56 . 5

Model Number NBS-0605 Nitrogen Backup Unit

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 8 of 91

Air Pump Assembly Specifications

Model No. Air Motor Dia (in.) No. Of Pumps Approx. GPM @ 125 Psi Air Pressure

1200 PSI 2000 PSI 3000 PSI

A197-601 7-3/8" 1 3.90 3.60 3.20

A197-602 7-3/8" 2 7.80 7.20 6.40

A197-603 7-3/8" 3 11.70 10.80 9.60

A9875-601 8-1/2" 1 6.00 5.00 3.90

A9875-602 8-1/2" 2 12.00 10.00 7.80

A9875-603 8-1/2" 3 18.00 15.00 11.70

Electric Pump Assembly Specifications

Model No. HP Plunger Size Volts Approx. Flow @ 3000 PSI Ph Hz

DPE21-03460 3 5/8" 460 1.14 GPM 3 60

DPE21-05460 5 3/4" 460 2.19 GPM 3 60

DPE21-07460 7 3/4" 460 2.50 GPM 3 60

TPE06-10460 10 3/4" 460 4.55 GPM 3 60

TPE06-15460 15 3/4" 460 6.40 GPM 3 60

TPE06-20460 20 7/8" 460 8.70 GPM 3 60

TPE21-25460 25 1" 460 11.40 GPM 3 60

TPE21-30460 30 1-1/4" 460 14.20 GPM 3 60

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 9 of 91

2 INSTALLATION

2.1 INSTALLATION INTRODUCTION

The following Installation Instructions explain how to hookup and checkout a standard Manual/Air Remote BOP Control

System. These guidelines will ensure that all the equipment is operational so that drilling operations may begin safely.

The Installation Instructions are divided into two (2) main topics, the Accumulator Unit and the Air Remote Control Panels.

At the end of the instructions are Installation Data Sheets containing specifications for customer supplied power requirements.

Located in the Equipment Section of this manual are drawings containing information which is necessary to properly install

the equipment. These drawings are:

Typical Installation Pictorial Figure 3-1

Typical Accumulator Unit Assembly Figure 3-2

Typical Interconnect Schematic Figure 3-3

Hydraulic Schematic Typical Control Fluid Circuit Figure 3-4

Hydraulic Schematic Typical Control Manifold Circuit Figure 3-5

Starter Control Schematic Pump Electric Motor Figure 3-6

The Typical Installation Pictorial shows the typical installation placement of the BOP Control System. The Interconnect

Diagram shows the typical pipe and air cable connections and the Electric Motor Wiring Diagram specifies wire size and

terminal connections.

To identify specific component parts referenced in the text, it may be necessary to review the assembly drawings and material

lists located in the Equipment Section.

There are a couple of major steps that must be performed during all phases of equipment use. Wherever the following

instructions are given, refer to these steps.

Stop Pumps

(1) Close air supply valves.

(2) Turn triplex pump motor starter to OFF position.

Start Pumps

(1) Open air supply valves.

(2) Turn triplex pump motor starter to AUTO position.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 10 of 91

2.2 ACCUMULATOR UNIT

2.2.1 Set up Location

1. The distance recommended to provide maximum protection of the accumulator unit during a blowout of other

emergencies is approximately 100 to 150 feet from the well bore.

2. Location placement should consider maintenance and service:

a. Accessibility

b. Illumination

c. Ventilation

3. Accumulator Unit SHOULD NOT BE:

a. Placed near oxygen storage.

b. Where there would be high heating effects from surrounding equipment.

4. After initial installation the following steps are recommended.

2.2.2 Inspect Reservoir

1. Open the 4" inspection/fill ports on the sides of the fluid reservoir and make sure the tank is free of any debris

that could contaminate the system. A clean reservoir reduces maintenance costs. For reservoir cleaning

procedures see Maintenance Section.

2. Make sure all reservoir connections are tightly secured

2.2.3 Fill Reservoir

1. Fill with a high quality SAE 10 Hydraulic Oil to 8" from the top of the reservoir.

2.2.4 Check Accumulator Precharge (See Nitrogen Precharge Instructions in the Maintenance Section)

1. Open the manifold bleeder valve.

2. Open the accumulator bank isolation valves.

3. Remove the guard from the valve stem of the accumulator and attach a Charging and Gauging Assembly.

4. Screw on gauge and screw down T-handle.

5. Gauge pressure reading should be 1000 PSI 100 PSI.

a. Low precharge reading:

(1) Attach the precharge line from the nitrogen bottle to the Charging and Gauging Assembly (DO NOT

USE OXYGEN)

(2) Slowly open the nitrogen bottle valve and verify that the gauge reading is still 1000 PSI.

b. High precharge reading:

(1) Open the Charging and Gauging Assembly bleeder valve until the precharge drops to 1000 PSI.

(2) Close the bleeder valve and verify that the gauge reading is still 1000 PSI.

KEEP A CHARGING AND GAUGING ASSEMBLY ACCESSIBLE TO THE ACCUMULATOR UNIT

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 11 of 91

2.2.5 Check Air Pumps

1. Check that the air lubricator is full of SAE 10W lubricating oil.

2. Close the air supply valve(s).

3. Close the air pressure switch bypass valve.

4. Purge a 1" air line from the main rig air supply line and connect it to the customer air supply connection on

the Accumulator Unit. For Air Supply Requirements see the Installation Data Sheet.

2.2.6 Check Electric Pumps

1. Turn off the electrical power at the Main Generator Panel.

2. Turn the Triplex pump motor starter switch to the OFF position.

3. Ensure that the Accumulator Unit is grounded.

4. Check the resistance, voltage, and current of the power lines to be connected. For Electrical Power

Requirements see the Installation Data Sheet.

5. Connect the electrical power lines to the three-phase terminal connections in the triplex pump motor starter

(see Starter Wiring Diagram). Similar metal conductors (copper) should be used. Ensure that a good ground

connection is made.

6. Check that the triplex pump crankcase is full of oil (weight will vary with the ambient temperature). For Chain

Guard Oil Specifications see Maintenance Section.

7. Turn on the electrical power at the main generator panel.

8. Check the rotation of the motor by turning the triplex pump motor starter switch to AUTO and then OFF. If the

rotation is backwards from arrow indication on chain guard, swap any two-phase terminal connections to

reverse the motor rotation.

9. Use a sealing compound with a melting point of at least 2000 Deg. F and pour the electrical conduit seal. Seal

should be at least 5/8" thick.

2.2.7 Interconnect Piping

1. Lay interconnect piping and sufficient size and pressure rating from the Accumulator Unit to the connections

on the Blowout Preventer Stack.

2. Connect swivel-joint assemblies to the 1" function outlets on the back of the Accumulator Unit. DO NOT

CONNECT TO BOP STACK.

2.2.8 Check Valve Positions

1. Place all four-way control valves on the hydraulic manifold in the CENTER position.

2. Place the manifold regulator bypass valve in the LOW pressure (handle left) position.

3. Open the manifold bleeder valve.

4. Open the suction Valves of all pumps.

5. Check that the air pressure switch bypass valve is closed.

6. Check that the accumulator bank isolation valves are open.

7. Check that the accumulator bank bleeder valves are closed.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 12 of 91

2.2.9 Verify Gauges

1. All gauges on the hydraulic manifold should read 0 PSI.

2. Air supply gauge should read 125 PSI.

2.2.10 Start Pumps

1. With the manifold bleeder valve in the OPEN position, alternately open the air supply valve to each pump to

ensure that each pump operates smoothly and without leaks.

2. Close the air supply valve to each pump.

3. With the main generator power ON, place the triplex pump motor starter switch to the AUTO position. Check

that the pump runs smoothly and without leaks.

4. Close the manifold bleeder valve.

5. Open all air supply valves.

6. Set air lubricator to 6 drops per minute.

7. Pumps should continue running until accumulator pressure reaches 3000 PSI. If problems occur during initial

start-up, consult the Troubleshooting Section.

2.2.11 Check Pressure Switches

1. After the system pressure has reached 3000 PSI and the pumps have stopped, open the manifold bleeder

valve.

2. Pumps should automatically start when accumulator pressure in 2500 - 2700 PSI. If lower, the pressure

switches need adjustment (See Maintenance Section).

3. Close manifold bleeder valve and recharge the system to 3000 PSI.

2.2.12 Check Gauge Readings

1. All accumulator pressure gauges should read 3000 PSI.

2. Manifold pressure gauge should read 1500 PSI, the pressure setting of the manifold regulator. To adjust the

manifold regulator setting see Maintenance Section.

a. Alternately decrease and increase the settings of the manifold regulator and verify the correct response

on the manifold pressure gauge.

b. Move the manifold bypass valve into the HIGH pressure (handle right) position, and verify that the

manifold pressure gauge increases to 3000 PSI.

3. Annular pressure gauge should indicate the pressure setting recommendations of the annular preventer

manufacturer to adjust the annular regulator see Maintenance Section.

a. Place annular unit/remote selector valve located in the gauge housing on the hydraulic manifold to the

UNIT position.

b. Adjust annular regulator through various operating pressures and check for correct response on the

annular pressure gauge.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 13 of 91

2.2.13 Connect to BOP Stack

1. Move the manifold bypass valve into the LOW pressure (handle left) position.

2. Stop pumps.

3. Open Manifold bleeder valve and relieve system pressure.

4. Make sure swivel-joint and hammer union connections on function outlets are tight and secure.

5. Start pumps.

CAUTION: DO NOT FLUSH WITH HIGH PRESSURE

6. OPEN each four-way control valve to flush the OPEN function line.

7. CLOSE each four-way control valve to flush the CLOSE function line.

8. Return the control valves to the CENTER position.

9. Open the 4" inspection/fill ports and check the control valves for leaks.

10. Connect but do not tighten each swivel-joint assembly to its correct inlet on the BOP stack.

11. Operate each function to ensure correct function operation and to purge BOP stack. Make sure a joint of

drill pipe is in the hole to prevent damage to rubber element of the annular preventer.

12. Return control valves to the CENTER position.

13. Securely tighten the swivel-joint assemblies and hammer union connections at the BOP stack.

14. Stop pumps.

15. Open the manifold bleeder valve and relieve all system pressure.

2.2.14 Refill Reservoir

1. Check the fluid level of the reservoir after line flushing.

2. Refill the reservoir to 8" from the top.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 14 of 91

2.3 AIR PANEL INSTALLATION

2.3.1 Set up Location

1. Install air panels securely on firm foundation, taking into consideration the following factors.

a. Operation and service accessibility.

b. Illuminated areas.

c. Unobstructed ventilation.

d. Minimal heating effects from surrounding equipment.

2. Driller's panel should be installed on the drill floor at or near the Driller's position.

2.3.2 Panel Preparation

1. Fill the lubricator with SAE 10 lubricating oil.

2. Connect a 1" ID, 125 PSI air supply line to air supply inlet of the panel.

2.3.3 Air Cable Connection

1. The air interconnect cable assembly connects the air remote control panel to the Accumulator Unit. It should be

installed in a manner to avoid damage and stress at the termination fittings, normal traffic flow and other mechanical

equipment. Do not hang over sharp edges or bend around sharp corners.

2. At the panel, inspect the junction boxes and gasket for damage and/or debris.

3. Connect junction box on the air cable to the mating junction box on the panel using the alignment pin as a guide and

evenly tighten the mounting bolts.

4. Before connecting the remaining end of the junction box, hold down panel master air valve and open and close each

function. This will purge the air tubing of any debris. Then repeat steps 2 and 3 for Accumulator Unit end of the air

interconnect cable assembly.

2.3.4 Panel Checkout

1. With Accumulator Unit pumps turned off and accumulator pressure at 0 PSI, hold down panel air master valve

and operate (open and close) each function.

2. Verify that the panel valve operates the corresponding valve on the hydraulic manifold correctly.

3. Check the air panel, air cable, junction boxes and air cylinders on hydraulic manifold for leaks. Repair if

necessary.

4. At the Accumulator Unit:

a. Make sure the accumulator bleeder valves are closed.

b. Make sure the manifold bleeder valve is open.

c. Make sure pump suction valves are open.

d. Center all four-way control valves.

e. Place the unit/remote selector valve in the REMOTE position.

f. Start pumps.

g. Close the manifold bleeder valve.

5. When accumulator pressure has reached 3000 PSI, Driller's Panel gauges and gauges on hydraulic manifold

should match. Gauges on the Driller's panel should read:

a. Accumulator pressure - 3000 PSI.

b. Manifold pressure - 15000 PSI.

c. Annular pressure - Operating pressure recommendations of the annular preventer manufacturer.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 15 of 91

6. Using Driller's Panel Annular air regulator, adjust operating pressure of annular to various pressure settings. Verify

that Driller's Panel annular gauge and hydraulic manifold gauge correspond throughout the various pressure

settings.

7. From the panel hold down the air master valve and operate each function (open and close) several times. Check

that the control valves on the hydraulic manifold are not inter-flowing. Return flow to the reservoir can be detected

by viewing through the inspection/fill ports on the reservoir.

8. See Drill Ahead.

CAUTION:

MAKE SURE THAT DRILL PIPE IS IN THE HOLE WHEN OPERATING THE ANNULAR PREVENTER SO AS NOT

TO DAMAGE THE RUBBER ELEMENT.

2.4 DRILL AHEAD

The following list identifies the normal operating position of the shutoff valves and control valves of the BOP control system.

2.4.1 Shutoff Valves

1. Air pump supply valves - OPEN

2. Air and electric pump suction valves - OPEN

3. Accumulator bank isolator valves - OPEN

4. Accumulator bank bleeder valves - CLOSED

5. Manifold bleeder valve - CLOSED

6. Air pressure switch bypass valve - CLOSED

2.4.2 Control Valves

1. Annular - OPEN

2. Pipe rams - OPEN

3. Choke and kill Valves - CLOSE

4. Manifold regulator bypass valve - LOW PRESSURE (handle left)

5. Annular Unit/Remote selector valve - REMOTE

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 16 of 91

2.5 INSTALLATION DATA SHEET

2.5.1 Electric Pump Assembly

Model No. HP

Starter

Connection

Volts

Full Load

Current (Amps)

Ph Hz

TPE06 -10230 10 1-1/2" FPT 230 26 3 60

TPE06 -10460 10 1-1/2" FPT 460 13 3 60

TPE06-15230 15 1-1/2" FPT 230 42 3 60

TPE06-15460 15 1-1/2" FPT 460 21 3 60

TPE06-20230 20 2" FPT 230 48.70 3 60

TPE06-20460 20 2" FPT 460 24.40 3 60

TPE21-25230 25 2" FPT 230 64.90 3 60

TPE21-25460 25 2" FPT 460 32.45 3 60

1. Customer to furnish wiring to meet applicable codes and standards for installation.

2. Maximum allowable voltage variation is 10%.

3. Maximum allowable frequency variation is 5%.

4. Combined voltage and frequency variation is 10% (with no more than 5% frequency variation).

5. Similar metal conductors (copper) should be used.

2.5.2 Air Pump Assembly

Model No. Air Motor Dia. (in.) No. of Pumps CFM GPM @ 3000 PSI

A197-601 7-3/8" 1 76 1.98

A197-602 7-3/8" 2 160 3.96

A197-603 7-3/8" 3 236 5.94

A1985-601 8-1/2" 1 112 3.20

A1985-602 8-1/2" 2 235 6.40

A1985-602 8-1/2" 3 347 9.60

1. Flow capacities approximate based upon minimum air supply pressure of 90 PSI.

2. Connection - Size 1" FPT.

3. Customer should ensure that the air supply is clean and dry. Excessive moisture and other contaminants can

cause operational problems.

2.5.3 Air Remote Control Panel Assembly(ies)

1. Connection Size - 1" FPT

2. Minimum Air Supply Pressure - 100 PSI

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 17 of 91

3 TYPICAL SYSTEM DRAWINGS

3.1 TYPICAL INSTALLATION PICTORIAL

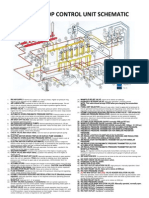

FIGURE 3-1

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 18 of 91

3.2 TYPICAL ACCUMULATOR UNIT ASSEMBLY

FIGURE 3-2

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 19 of 91

3.3 TYPICAL INTERCONNECT SCHEMATIC

FIGURE 3-3

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 20 of 91

3.4 HYDRAULIC SCHEMATIC TYPICAL CONTROL FLUID CIRCUIT

FIGURE 3-4

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 21 of 91

3.5 HYDRAULIC SCHEMATIC TYPICAL CONTROL MANIFOLD CIRCUIT

FIGURE 3-5

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 22 of 91

3.6 STARTER CONTROL SCHEMATIC PUMP ELECTRIC MOTOR

FIGURE 3-6

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 23 of 91

4 OPERATION INSTRUCTION

The BOP Control System is a hydraulic power unit with controls necessary to operate the Blowout Preventers during drilling

operations. These units can be packaged in a variety of sizes and configurations to meet the specific requirements dictated by size,

quantity and working pressure of the preventers, the drilling location itself, as well as by the specifications generated by various

regulatory agencies. The operation of all of these units is essentially the same, and understanding the proper operation is very

important to save lives and property in emergency situations.

The hydraulic control manifold directs the flow of the high pressure fluid to operate the preventers. Air remote control panel

assemblies can be included with the BOP control system to enhance the safety in drilling operation. Operational accessory safety

features can also be added to the system to provide additional operational capabilities. To better understand the function and

operation of each assembly, operation of the BOP control system has been divided into the following sections:

4.1 Accumulators and Reservoirs

4.2 Air Pump Assembly

4.3 Electric Pump Assembly

4.4 Control Manifold Assembly

4.5 Air Remote Control Panel Assembly

4.6 Air Remote Control Interface Assembly

4.7 Interconnect Cable Assembly

4.8 Accessories

The following operation descriptions include item numbers which refer to the illustrations following the text.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 24 of 91

4.1 ACCUMULATORS AND RESERVOIR

The master skid assembly of heavy duty steel consists of: (1) accumulators (separator or guided float types), (2) reservoir,

and (3) accumulator piping which includes isolator and relief valves.

4.1.1 Accumulators (Item 24 Fig. 4-1)

The accumulators are ASME coded vessels of 3000 PSI working pressure that are precharged to 1000 PSI 100

PSI of nitrogen at our plant. When there is demand to operate a preventer, the high pressure fluid contained in

the accumulator is forced out by the nitrogen. The accumulators are charged to 3000 PSI by the high pressure

pumps. Each accumulator should be periodically checked since loss of precharge causes loss of available

operational fluid. NEVER USE OXYGEN FOR PRECHARGING. Always keep a charging and gauging assembly

readily accessible. If adjustments are required see Maintenance Section.

1. The separator type accumulators house bladders to contain the nitrogen precharge, and come in 5, 10 and

11 gallon capacities. A poppet valve keeps the bladder- from extruding through the port. For applications where

bladder type accumulators will be continually subjected to temperatures below 0 Deg. F or for intermittent

temperatures below -20 Deg. F, special low temperature bladders should be used. these bladders will provide

longer service in the cold weather application.

The guided float accumulators are of 80 gallon capacity. the poppet valve contained in the discharge port of

the accumulators keeps the nitrogen precharge from escaping with the operational fluid. For proper operation

the precharge pressure must be maintained at 1000 PSI ( 100 PSI). Loss of precharge can be caused by

aeration of the fluid with the nitrogen. Aeration and float damage can also occur if the accumulators are

subjected to tilting movements.

4.1.2 Reservoir (Item 7 Fig. 4-1)

The reservoir is used to sore the fluid supply for operation of the pumps. The BOP control system is a closed-loop

system where all vented fluid is returned to the reservoir. Therefore, it is very important to inspect the reservoir

periodically for contaminants that may enter form the preventers. Debris can clog pump suction filters and make

the control system inoperative, for procedures to clean the reservoir or change the fluid see Maintenance Section.

4.1.3 Accumulator Module Piping

Accumulators are mounted in banks and can be isolated with the isolator valves (Item 23 Fig. 4-1). These valves

should remain open at all times during normal operation. If it is known an accumulator is faulty, that bank may

be isolated until it can be serviced. NEVER TRY TO SERVICE AN ACCUMULATOR UNIT IS PRESSURIZED

(see Maintenance Section). Since the accumulators are 3000 PSI working pressure, the accumulator piping

includes a 3500 PSI relief valve (Item 21 Fig. 4-1) to protect them against higher pressures. This valve should

never be removed. If the valve is faulty, it should be repaired and replaced or a new valve should be installed.

4.2 AIR PUMP ASSEMBLY

This is one of the high pressure power sources used to pressurize BOP control system. This module normally produces a

maximum pressure of 3000 PSI but most are capable of much higher pressures, it is therefore important to know how to

operate this assembly, along with when and how to control the use of the higher pressure outputs. These pumps require a

customer furnished air supply of sufficient pressure and volume to operate them (see Installation Data Sheet). The air pump

assembly consists of: (1) air supply manifold, (2) fluid suction manifold, (3) air pumps, and (4) air pressure switch.

4.2.1 Air Supply Manifold

The customer furnished air supply should be connected to the air supply manifold as indicated in the Installation

Section. Included in the air supply manifold is:

1. Air filter (Item 1 Fig. 4-1) - which filters the air and removes contaminants that may damage the air pumps.

This filter must be cleaned periodically to maintain maximum air flow (see Maintenance Section).

2. Air lubricator (Item 2 Fig. 4-1) - which impregnates the air with oil to lubricate the pumps during operation. This

lubricator should also be serviced periodically to replenish the oil (see Maintenance Section).

3. Air supply gauge (Item 3 Fig. 4-1) - 0-300 PSI, mounted in the air supply manifold for monitoring of the

customer furnished air supply pressure.

4. Air supply valve - one for each pump to enable independent operation. Under normal operation these valves

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 25 of 91

should remain in the open position at all times. The air pumps can be stopped by rotating the valve handles

clockwise to the closed position.

4.2.2 Fluid Suction Manifold

The fluid suction manifold is used to connect the high pressure pumps to the reservoir which contains the

operating fluid. The manifold includes:

1. Suction valve (Item 11 Fig. 4-1) - that is used to isolate the pump during servicing. In normal operation.

2. Suction strainer (Item 10 Fig. 4-1) - to remove impurities in the fluid. Impurities can enter the system through

the preventers and return to the reservoir with the vented fluid. This strainer should be serviced periodically

to prevent clogging which could damage the pumps by running them dry (see Maintenance Section).

4.2.3 Air Pumps (Item 8 Fig. 4-1)

Air pump are used to convert lower air pressure into higher hydraulic fluid pressures. They consist of two (2) main

components: the air motor and the fluid end. They are sized by the fluid ratio of the piston area in the air motor

to the area of the piston in the fluid end. The standard double acting pumps are 60:1 ratio. This means there is

60 times the piston area in the air motor as in the fluid end. Therefore, 1 PSI of air will produce 60 PSI of hydraulic

fluid pressure. The pumps have self adjusting packing glands and therefore should require no adjustment in

normal operation. The pumps are double acting so air is exhausted on each up stroke and downstroke of the

pump. As the pumps exhaust the lubricated air, it is normal to find oil on surrounding equipment, and for the

moisture in the exhausted air to cause an ice formation on the air pump. Excessive freezing may cause

operational problems (see Troubleshooting Section). Before servicing the pump, bleed off the system pressure.

The pump discharge line is fitted with a check valve (Item 9 Fig. 4-1) to allow the system to be repressurized while

the pump is being serviced.

4.2.4 Air Pressure Switch (Item 6 Fig. 4-1)

Since the air pumps are capable of producing pressures in excess of 3000 PSI, it is necessary to automatically

stop the pumps when the discharge pressure reaches 3000 PSI. The air pressure switch senses the discharge

pressure and blocks the air supply to the pumps when the set pressure is reached. Normally, the pressure switch

is set for 3000 PSI for accumulator units with air pumps only, and 2900 PSI on accumulator units with both air

and electric pumps. When the system pressure drops to 2700 PSI, the pressure switch automatically allows the

air to flow to start the pumps. To adjust the pressure switch setting see Maintenance Section.

The line to the air pressure switch is fitted with a bypass valve to allow the pumps to produce higher fluid

pressures. In normal operation this valve should be closed. If pressures in excess of 3000 PSI are required, such

as during testing:

1. Close the electric pump isolator valve.

2. Move the manifold regulator bypass valve (Item 26 Fig. 4-1) to the HIGH pressure position.

3. Open the air pressure switch bypass valve.

4. This will produce pressures up to 5500 PSI, which is the setting of the manifold relief valve.

4.3 ELECTRIC PUMP ASSEMBLY

The electric pump assembly is a primary, or additional, high pressure pump source. This assembly requires a customer

furnished power source, usually 220 or 440 volt, 60 cycles, 3-phase power. The amount of current required depends on the

horsepower of the electric motor (see Installation Data Sheet). The pump output remains constant up to the maximum

pressure of 3000 PSI, independent of the system back pressure. The electric pump assembly consists of: (1) fluid suction

manifold, (2) duplex or triplex pump, (3) electric motor, and (4) drive assembly which includes chain, sprocket, chain guard,

motor starter and pressure switch.

4.3.1 Fluid Suction Manifold

The fluid suction manifold connects the high pressure pump to the reservoir which contains the operational fluid.

This manifold includes:

1. Suction valve (Item 16 Fig. 4-1) - which remains open at all times in normal operation, but is closed to isolate

the pump during servicing.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 26 of 91

2. Suction strainer (Item 15 Fig. 4-1) - which removes impurities that may have entered the system with the

vented fluid from the preventers. Strainer should be serviced periodically (see Maintenance Section) to prevent

clogging and damage to the pump by running it dry.

4.3.2 Duplex or Triplex Pump

This pumps (Item 14 Fig. 4-1) derive their name from the number of plungers in the pump, duplex - two and triplex

three. Duplex pumps are used with 3, 5, and 7-1/2 HP electric motors. Triplex pumps can use motors from 10 to

60 HP. Plunger sizes can be varied to meet the specifications of the particular BOP control system. In normal

operation the pumps operate automatically, however; the plunger, packing and crankcase should be inspected

periodically, for adjustments (see Maintenance Section). The pump discharge line is fitted with a check valve (Item

18 Fig. 4-1) and an isolator valve. The isolator valve remains open at all times in normal operation but is closed

to isolate pumps either for servicing or to bypass the accumulators so pressure higher than 3000 PSI can be

reached.

4.3.3 Electric Motor

All electric motors (Item 12 Fig. 4-1) used in the pump assemblies are of the explosion-proof design. These

motors are either 50 or 6 0 cycle turning at speeds of 1500 and 1800 RPM respectively. Because most pumps

cannot turn at these speeds, reducing drive assemblies are used.

4.3.4 Drive Assembly

1. Sprockets - reduce the speed of the motor to the operating limits of the pump.

2. Chain complete with oil bath chain guard - used in place of belts to eliminate slippage and prolong service life.

Oil level in the chain guard oil specifications see Maintenance Section.

3. Motor starter (Item 17 Fig. 4-1) - controls the power to the electric motor and is housed in an explosion-proof

enclosure. The starter control switch should always be in the AUTO position during normal operation.

4. Electric pressure switch (Item 13 Fig. 4-1) - stops the electric motor when discharge pressure reaches 3000

PSI and automatically restarts the motor when discharge pressure drops to 2700 PSI. This protects the pump

from over pressuring which can damage the packing or the power frame. Pressure switch settings have a

tendency to drift and require periodic calibration. This is especially true when the equipment has been moved

to a different location. To adjust the pressure switch setting see Maintenance Section.

4.4 CONTROL MANIFOLD ASSEMBLY

The control manifold is connected directly to the BOP stack, and operational mistakes can be costly in terns of lives and

property. The manifold directs the flow of the high pressure fluid stored in the accumulators to operate the preventers and

gate valves on the blowout preventer (BOP) stack. Most preventers operate at a maximum of 1500 PSI. However, the

accumulator pressure is 3000 PSI; therefore, regulators are required to reduce the operating pressure from 3000 PSI to 1500

PSI maximum. Annular (bag type) preventers require different operating pressures from the other functions on the BOP stack,

so all control manifold use the double manifold design. The control manifold consists of; (1) control valves, (2) regulators,

(3) gauges, and (4) manifold piping which includes a supply header, high pressure strainer, relief valve and bleeder valve.

4.4.1 Control Valves

The control valves (Item 28 Fig. 4-1) are 1" four-way, three-position shear seal selector type valves. They have

90' handle rotation with 45 Deg. detents, there is one for each preventer and gate valve, complete with an

aluminum nameplate stating function name with OPEN and CLOSE positions marked in relation to handle

position. The control valves should always be in either the OPEN or CLOSE position. Never leave the valves in

the center position as this blocks both function ports of the control valve. To operate the valve from CLOSE to

OPEN or from OPEN to CLOSE, move the handle in one swift motion. Pausing will cause the valve to inter-flow,

thus venting some of the supply fluid and delaying function operation. The center position should be used to block

further pressure drop of the system if a regulator malfunctions while operating a preventer. The control valves

should be serviced periodically to ensure proper operation (see Maintenance Section).

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 27 of 91

4.4.2 Regulators

The double manifold, designed to accommodate variable pressure requirements, consists of a manifold regulator

assembly, bypass valve assembly and an annular regulator assembly.

1. Manifold regulator assembly - the manifold regulator (Item 25 Fig. 4-1) reduces the 3000 PSI fluid pressure

from the accumulator to a maximum of 1500 PSI. This regulated pressure is the supply to operate the ram

type preventers and gate valves; pressures greater than 1500 PSI cannot be regulated. The pressure setting

of this regulator must be manually adjusted; to do this:

a. Loosen the locknut on the adjustment handle and hold with one hand.

b. Rotate the regulator adjustment handle with other hand.

(1) To increase pressure, rotate clockwise.

(2) To decrease pressure, rotate counterclockwise.

c. Read manifold pressure gauge (Item 35 Fig. 4-1) for pressure setting of the regulator. Set at desired

pressure.

d. Tighten the locknut of the adjustment handle.

2. Bypass valve assembly - to operate with pressures up to 3000 PSI, the manifold regulator assembly is fitted

with a quick-opening bypass valve (Item 26 Fig. 4-1) that can shut off supply through the manifold regulator

to supply direct accumulator fluid pressure to the ram preventers and gate valves. In normal operation this

valve should be in the regulated LOW pressure position, for pressures up to 3000 PSI, the valve must be in

the HIGH pressure position.

3. Annular Regulator Assembly - The Annular Regulator (Item 34 Fig. 4-1) reduces the accumulator fluid pressure

from 3000 PSI to a maximum of 1500 PSI for the operation of the annular preventer. The annular preventer

is used for stripping operations along with well control. Therefore, it is necessary to consult the annular

preventer manufacturer's recommendation for maximum operating pressure so as to ensure and prolong the

life of the element. The manually operated annular regulator is adjusted in the same manner as the manifold

regulator described above. Read the annular pressure gauge (Item 38 Fig. 4-1) when adjusting pressure

setting of the annular regulator.

The regulation of the annular operating pressure is often needed at an accessible control panel on the drill

floor. This remote operation requires fitting an air regulator on the control manifold to regulate pilot pressure

to the Air Operate Annular Regulator (Item 34 Fig. 4-1).

To remotely regulate the annular operating pressure the unit/remote selector valve (Item 32 Fig. 4-1) must be

in the REMOTE position. To adjust the annular operating pressure from the unit, it must be in the UNIT

position. An air filter is mounted in the 1/4" O.D. tubing supply line of the annular regulator assembly. This filter

must be serviced periodically (see Maintenance Section).

4.4.3 Gauges

The gauges are either 6 inch panel mounted or mud pump style. The panel mounted gauges are connected to the

pressure pickup points by stainless steel tubing. The mud pump style gauges mount directly into the manifold for

pickup points on the annular and manifold pressure. The accumulator gauge pickup point is connected by

stainless steel tubing. Gauges provided on the control manifold are to monitor:

1. Accumulator pressure 0-6000 PSI (Item 38 Fig. 4-1).

2. Manifold pressure, 0-10,000 PSI (Item 35 Fig. 4-1).

3. Annular pressure, 0-3000 PSI (Item 37 Fig. 4-1).

4.4.4 Manifold Piping

Consists of a manifold header, high pressure strainer, bleeder valve and relief valve.

1. Manifold Header (Item 27 Fig. 4-1) - for the control valves; made of 2 inch Schedule 160 pipe and welded so

as to eliminate possible leaks.

2. High Pressure Strainer - to remove debris from the fluid that could damage the regulators and control valves.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 28 of 91

The strainer must be serviced periodically to ensure proper operation (see Maintenance Section).

3. Manifold Bleeder Valve - which is in the closed position during normal operation and is opened to bleed

pressure off the BOP control system before servicing.

4. Manifold Relief Valve (Item 30 Fig. 4-1) - protects the control manifold from pressures in excess of 3300 PSI

that may cause component and system failure or damage.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 29 of 91

TYPICAL ACCUMULATOR UNIT ASSEMBLY

FIGURE 4-1

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 30 of 91

LEGEND - TYPICAL ACCUMULATOR UNIT ASSEMBLY

TABLE 4-1

Item # Customer Locations

A Customer Air Supply Connection

B Customer Motor Starter Power Connection

C 4" Fill/Inspection Port

Item # Description Item # Description

1 Air Filter 24 Accumulator

2 Air Lubricator 25 Manifold Regulator

3 Air Supply Pressure Gauge 26 Manifold By-Pass Valve

4 Air Pressure Switch Bypass Valve (Not Shown) 27 Manifold Supply Header

5 Air Supply Valve (Not Shown) 28 4-Way Control Valve

6 Air Pressure Switch 29 Air Cylinders

7 Reservoir 30 Manifold Relief Valve

8 Air Operated Hydraulic Pump 31 Reserved

9 Air Pump Discharge Check Valve 32 Unit/Remote Selector Valve

10 Air Pump Suction Strainer 33 Regulator Air Filter (Not Shown)

11 Air Pump Suction Valve 34 Annular Air Regulator

12 Electric Motor 35 Manifold Pressure Gauge

13 Electric Pressure Switch 36 Manifold Bleeder Valve (Not Shown)

14

Reciprocating Hydraulic Pump (Duplex or Triplex

Pump)

37 Annular Pressure Gauge

15 Electric Pump Suction Strainer 38 Accumulator Pressure Gauge

16 Electric Pump Suction Valve 39 Transmitter-Annular Pressure

17 Electric Motor Starter 40 Transmitter-Accumulator Pressure

18 Electric Pump Discharge Check Valve 41 Transmitter-Manifold Pressure

19 Electric Pump Isolator Valve (Not Shown) 42 Transmitter Air Regulator (Not Shown)

20 High Pressure Strainer (Not Shown) 43 Fixed Plate Half-Air Junction Box

21 Accumulator Relief Valve

22 Accumulator Supply Header

23 Accumulator Bank Isolator Valve

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 31 of 91

4.5 AIR REMOTE CONTROL PANEL ASSEMBLY

Air operated remote control panels are used for remote control of the hydraulic control manifold and monitoring of the

operating pressures of the BOP control system. These panels are divided into two (2) basic types: Driller's Panel and Auxiliary

Panels. The Driller's control panel should be located on the drill floor and provides complete remote control and operating

pressure monitoring. The auxiliary panel should be placed in a safe area. This way if the driller's panel is inoperative and the

hydraulic control manifold cannot be reached, the well can be controlled from this panel. Since it is used only in emergency

situations, it does not contain monitoring of the operating pressures of the control system required during normal operation.

Both remote control panels require a customer furnished, 125 PSI air supply. Major components of these panels include: (1)

air supply manifold, (2) master control valve, (3) Air control valves, (4) bypass valve, (5) nameplates, (6) gauges, and (7)

annular air regulator.

4.5.1 Air Supply Manifold

The customer furnished air supply should be connected to the air supply manifold as indicated in the Installation

Section. Included in the air supply manifold is a filter (Item 17 Fig. 4-2) and a lubricator (Item 19 Fig. 4-2). The

filter is used to remove contaminants in the air supply that can damage air valves. The lubricator is used to

lubricate the valves during operation. The filter and lubricator should be serviced periodically to ensure proper

operation of the air remote control panel (see Maintenance Section).

4.5.2 Master Air Control Valve (Item 4 Fig. 4-2)

This valve is a 1/4", three-way, spring centered valve which must be operated to provide the necessary air supply

pressure to the remaining air valves on the remote panel. This valve must be held open to allow the air supply

to flow through it while operating the other valves. When the handle is released, it will automatically spring center,

shutting off the air supply and venting all of the downstream air pressure. This helps to prevent accidental

operation of a BOP function.

4.5.3 Air Control Valves (Item 2 and 3 Fig. 4-2)

These valves are 1/4", four-way, spring centered valves to remotely operate the hydraulic control valves on the

hydraulic manifold. Operation of these air control valves actuates the air cylinders attached to the hydraulic valves

on the manifold. This actuation positions the hydraulic valve to the corresponding operation of the air control valve

on the panel. High pressure hydraulic fluid is then directed to operate the selected function. When the air centers,

venting the air pressure on the air cylinder thus allowing the hydraulic control valve on the manifold to be manually

operated.

4.5.4 Bypass Valve (Item1 6 Fig. 4-2)

This 1/4", four-way, spring centered valve remotely operates the manifold regulator bypass valve. When moved

to the "Low Pressure" position, regulated pressure is supplied to them.

4.5.5 Nameplates (Items 10 thru 14 Fig. 4-2)

The air control valves are arranged on the panel to represent the actual stack configuration. The nameplates for

these control valves are also shaped to graphically illustrate each preventer or gate valve function. This helps the

operator to quickly an accurately operate the required function.

4.5.6 Gauges

Gauges are provided on the control panel to remotely monitor the operating pressures of the control system. Four

(4) 4-1/2" face gauges are provided on the driller's panel for:

1. Air Supply Pressure, 0-300 PSI (Item 6 Fig. 4-2)

2. Accumulator Pressure, 0-6000 PSI - Receiver type gauge (Item 8 Fig. 4-2)

3. Manifold Pressure, 0-6,000 PSI - Receiver type gauge (Item 7 Fig. 4-2)

4. Annular Pressure, 0-3000 PSI - Receiver type gauge (Item 9 Fig. 4-2)

4.5.7 Annular Air Regulator (Item 5 Fig. 4-2)

The driller's control panel contains an air regulator for adjusting the operating pressure of the annular preventer.

To operate this regulator, the Unit/Remote selector (Item 32 Fig. 4-1) valve on the hydraulic manifold must be

placed in the REMOTE position. The operating pressure of the annular can than be adjusted by rotating the air

regulator handle clockwise to increase the pressure or counterclockwise to decrease the pressure. Always check

the annular pressure gauge when adjusting the air regulator.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 32 of 91

TYPICAL AIR REMOTE CONTROL PANEL

FIGURE 4-2

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 33 of 91

LEGEND - AIR REMOTE CONTROL PANEL

TABLE 4-2

Item Description

1 Remote Air Control Panel Assembly

2 Air Remote Control Valve - Preventers

3 Air Remote Control Valve - Wing Valves

4 Air Remote Control Valve - Master Air Valve

5 Air Regulator - Annular Pressure

6 Gauge - Air Pressure

7 Receiver Gauge - Manifold Pressure

8 Receiver Gauge - Accumulator Pressure

9 Receiver Gauge - Annular Pressure

10 Graphic Nameplate

11 Graphic Nameplate

12 Graphic Nameplate

13 Graphic Nameplate

14 Graphic Nameplate

15 Reserved

16 Air Remote Control Valve - Manifold Bypass

17 Air Filter

18 Fixed Plate Half - Air Junction Box (Rectangular J-Box shown, Round J-Box is STANDARD)

19 Air Lubricator

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 34 of 91

4.6 AIR REMOTE CONTROL INTERFACE ASSEMBLY

Air remote control interface assemblies include additional components necessary on the Accumulator Unit to enable the BOP

control system to be remotely controlled and/or monitored from an air panel.

4.6.1 Cylinders (Item 29 Fig. 4-1)

Air cylinders are mounted on each hydraulic four-way control valve on the hydraulic manifold that requires remote

operation. The cylinder piston rod is connected to the handle of the control valve. An air pressure signal from the

air valve on the air panel causes the cylinder piston rod to extend or retract. This movement causes the handle

to rotate thus operating the function. The cylinders should be serviced periodically to ensure proper operation (see

Maintenance Section).

4.6.2 Air Junction Boxes (Item 43 Fig. 4-1)

All of the signal lines included in the interface assembly terminate at a fixed-plate half of an air junction box which

mates to the hose-end half attached to the interconnect cable assembly. This junction box facilitates handling of

the BOP control system equipment during rig moves or when relocating equipment.

4.7 INTERCONNECT CABLE ASSEMBLY

The interconnect cable assembly connect the air remote control panel to the accumulator unit. It consists of a multi-tube

bundle with a hose-end half of an air junction box on each end. These junction boxes should be attached to the mating

junction boxes on the interface assembly and the air remote control panel. One interconnect cable assembly is required for

each air remote control panel. The cable consists of 3/8" OD, 175 PSI working pressure polyethylene tubes spirally wound

and encased in 3/16" thick polyvinyl chloride (PVC) outer jacket. Two (2) tubes are required for each function and one (1)

each for the pressure regulating and monitoring signals.

4.8 ACCESSORIES

There are optional items that can be added to the BOP control system to increase the functional capability. Accessories

include: (1) nitrogen backup system, (2) rig test outlet, (3) rig skid outlet and (4) alarms. The following will provide functional

descriptions and operation instructions:

4.8.1 Nitrogen Backup System

The nitrogen backup system - This system connects to the control manifold to provide an emergency pressure

power source to close the ram type preventers and gate valves. This system should be used only as the last

possible means of control.

1. The nitrogen backup system consists of:

a. Nitrogen bottles - charged to 2200 PSI. The nitrogen bottles connect to the manifold on the high pressure

supply side of the manifold regulator bypass valve. This direct the nitrogen pressure to flow through the

control valve(s) to operate the preventers even though hydraulic pressure is not available. The bottle

valves are in full open position during normal operation.

b. Shut-off valves - which are closed during normal operation, and must be manually opened to begin

nitrogen flow. This valve location should be familiar to operator personnel to enable quick and correct use.

c. Check valves - which direct nitrogen toward control valves only and do not allow back-flow to fill up the

accumulators.

d. Nitrogen pressure gauge - 0-5000 PSI. This gauge reading should be observed daily. Nitrogen pressure

should be maintained at 2200 PSI.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 35 of 91

2. To operate the nitrogen backup system during emergency situations.

a. Move the Manifold Regulator Bypass Valve (Item 26 Fig. 4-1) to HIGH pressure position. Perform this

operation from point of quickest access. If possible operate from the remote panel before power supplies

are shut down.

b. Open the nitrogen system shutoff valve. This operation must be done manually at the unit.

c. Operate the desired ram preventers or gate valves. Do not attempt to operate the annular. Nitrogen flow

is not directed through this function and will only waste time and pressure.

4.8.2 Rig Test Outlet

This assembly provides a 6000 PSI working pressure test outlet from the accumulator unit.

1. The test outlet consists of:

a. Rig test isolator valve - is open during normal operation.

b. Rig test pressure gauge - 0-10,000 PSI.

c. Rig test relief valve - 6500 PSI.

d. Rig test shut-off valve - is closed during normal operation.

e. Rig test check valve.

2. To operate the rig test outlet:

a. Connect a 6000 PSI line fitted with 6000 PSI bleeder valve (supplied by customer) from rig test outlet to

equipment to be tested and a return line to the reservoir for vented fluid.

b. Close rig test isolator valve.

c. Open rig test shut-off valve.

d. Check that Air Pump Suction Valve (Item 11 Fig. 4-1) is open and customer furnished bleeder valve is

closed.

e. Open the air supply valve for the air pump connected to the rig test outlet and then shut it when test

pressure is reached.

f. Slowly open customer furnished bleeder valve and vent fluid back to reservoir.

4.8.3 Rig Skid Outlet

This assembly provides a 3000 PSI outlet for connection to the rig skid control manifold for operation of rig skid

cylinders.

1. The skid outlet consists of:

a. Rig skid isolator valve - is open during normal operation.

b. Rig skid pressure gauge - 0-6000 PSI.

c. Rig skid shut-off valve - is closed during normal operation.

d. Rig skid relief valve - 3500 PSI.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 36 of 91

2. To operate the rig skid outlet to the rig skid outlet:

a. Connect 3000 PSI line from the rig skid outlet to the rig skid control manifold and a return line to the

reservoir from the rig skid control manifold.

b. Close the rig skid isolator valve.

c. Open the rig skid shut-off valve.

d. Operate the control valves of the rig skid manifold several times to purge the system of air.

4.8.4 Alarms

Alarm Systems of audio (horn) and visual (flashing red light) signal can be added to the BOP control system.

These alarms require a customer supplied 120 volt AC power supply hookup at installation with cable connection

of 0.375" to 0.500" diameter. The alarms include use of the lamp test/acknowledge button which deactivates the

horn alarm. The flashing red light signals until the system is restored to normal operating conditions. The alarms

are activated by pressure switches.

1. The low accumulator pressure alarm pressure switch is activated when the system pressure drops to 2200

PSI.

2. The low fluid level alarm pressure switch is activated by a float switch in the reservoir. When fluid level is low,

the float switch vents the air supply to the pressure switch.

3. The low air pressure alarm pressure switch is activated when the rig air supply pressure drops to 35-50 PSI.

OPERATOR'S MANUAL

BOP CONTROL SYSTEM WITH AIR REMOTE CONTROL

Produced By: Entrada International, Inc. 2002 Page 37 of 91

5 MAINTENANCE INSTRUCTION

5.1 INTRODUCTION

A regularly scheduled maintenance Program must be developed to sufficiently maintain the BOP Control System. The

operator must develop an appropriate program based on the operating, testing and drilling programs, The entire control

system should be tested a minimum of once a week, This may simply involve operating alt functions (remotely as well as

from the unit) and noting gauge and meter readings. A good maintenance program must be developed whether the operator

chooses a very simple or a very thorough test program.

Installation, maintenance repairs and adjustments around high pressure and electrical equipment must be done with careful

concentration and caution to ensure the safety of all personnel. Pay particular attention to all notes, cautions, and bold type

words as these are to ensure safety during all phases of equipment use.

PAY PARTICULAR ATTENTION WHEN WORKING AROUND AREAS WITH:

A. Exposed electrical terminals.

B. Remotely operated equipment.

C. High pressure hydraulic lines.

a. Remove all pressure from lines before disconnecting Fittings or splicing. Verify line pressure is released

before attempting to disconnect.