Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SKF Bearing Designations

Caricato da

Patrick BaridonTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SKF Bearing Designations

Caricato da

Patrick BaridonCopyright:

Formati disponibili

Supplementary designations

Head Ofce: Acorn Industrial Services Ltd, Midland Road, Rotherham, South Yorkshire, S61 1TE, ENGLAND

How to contact your authorised distributor

Distribution Centres Regional Branches

Divisions

0845 602 9946

01709 789 988

sales@acorn-ind.co.uk

www.acorn-ind.co.uk

T

F

E

W

Rotherham CDC

0845 602 3568

01229 833 510

northwest@acorn-ind.co.uk

www.acorn-ind.co.uk/northwest

T

F

E

W

North West Branch

0121 521 5999

0121 521 5888

midlands@acorn-ind.co.uk

www.acorn-ind.co.uk/midlands

T

F

E

W

Midlands RDC

01506 476 199

01506 462 655

scotland@acorn-ind.co.uk

www.acorn-ind.co.uk/scotland

T

F

E

W

Scotland Branch

01179 820 414

01179 823 222

southwest@acorn-ind.co.uk

www.acorn-ind.co.uk/southwest

T

F

E

W

South West RDC

01709 789 949

linear@acorn-ind.co.uk

www.acorn-ind.co.uk/linear

T

E

W

Linear Division

0191 417 8899

0191 419 0001

northeast@acorn-ind.co.uk

www.acorn-ind.co.uk/northeast

T

F

E

W

North East RDC

+44 1709 789 933

+44 1709 789 966

export@acorn-ind.co.uk

www.acorn-ind.co.uk/export

T

F

E

W

Export Division

Supplementary designations

Supplementary designations

Prefixes

Prefixes are used to identify components of a

bearing and are usually then followed by the

designation of the complete bearing, or to

avoid confusion with other bearing designa

tions.

For example they are used in front of desig

nations for taper roller bearings according to

a system described in ANSI/ ABMA Standard

9 for (predominantly) inch bearings.

GS Housing washer of a cylindrical

roller thrust bearing

K Cylindrical roller and cage thrust

assembly

K- Inner ring with roller and cage assem

bly (cone) or outer ring (cup) of inch

taper roller bearing belonging to an

ABMA standard series

L Separate inner or outer ring of a separ

able bearing

R Inner or outer ring with roller (and

cage) assembly of a separable bearing

W Stainless steel deep groove ball bearing

WS Shaft washer of a cylindrical roller

thrust bearing

ZE Bearing with SensorMount

feature

Suffixes

Suffixes are used to identify designs or vari

ants which differ in some way from the origi

nal design, or which differ from the current

standard design. The suffixes are divided into

groups and when more than one special fea

ture is to be identified; suffixes are provided in

the order shown in the scheme in diagram 1.

The most commonly used suffixes are listed

below. Note that not all variants are available.

A Deviating or modified internal design

with the same boundary dimensions.

As a rule the significance of the letter

is bound to the particular bearing or

bearing series. Examples:

40 A: Double row deep groove ball

bearing without filling slots

30 A: Double row angular contact

ball bearing without filling slots

AC Single row angular contact ball bear

ing with a 5 contact angle

ADA Modified snap ring grooves in the

outer ring; a twopiece inner ring

held together by a retaining ring

B Deviating or modified internal design

with the same boundary dimensions.

As a rule the significance of the letter

is bound to the particular bearing

series.

Examples:

74 B: Single row angular contact

ball bearing with a 40 contact angle

30 B: Steep contact angle taper

roller bearing

Bxx(x) B combined with a two or threefig

ure number identifies variants of the

standard design that cannot be iden

tified by generally applicable suffixes.

Example:

B0: Reduced width tolerance

C Deviating or modified internal design

with the same boundary dimensions.

As a rule the significance of the letter

is bound to the particular bearing

series. Example:

306 C: Spherical roller bearing

with a flangeless inner ring, symmet

rical rollers, loose guide ring and a

pressed windowtype steel cage

CA . Spherical roller bearing of C design,

but with retaining flanges on the

inner ring and a machined cage

. Single row angular contact ball

bearing for universal matching.

Two bearings arranged backto

back or facetoface will have an

axial internal clearance smaller

than Normal (CB) before mounting

CAC Spherical roller bearing of the CA design

but with enhanced roller guidance

CB . Single row angular contact ball

bearing for universal matching.

Two bearings arranged backto

back or facetoface will have a

Normal axial internal clearance

before mounting

. Controlled axial clearance of a

double row angular contact ball

bearing

CC . Spherical roller bearing of C design

but with enhanced roller guidance

. Single row angular contact ball

bearing for universal matching.

Two bearings arranged backto

back or facetoface will have an

axial internal clearance larger than

Normal (CB) before mounting

CLN Taper roller bearing with tolerances

corresponding to ISO tolerance class

6X

CL0 Inch taper roller bearing with toler

ances to class 0 according to

ANSI/ABMA Standard 9.:994

CL00 Inch taper roller bearing with toler

ances to class 00 according to

ANSI/ABMA Standard 9.:994

CL3 Inch taper roller bearing with toler

ances to class 3 according to

ANSI/ABMA Standard 9.:994

CL7C Taper roller bearing with special fric

tional behaviour and heightened run

ning accuracy

Supplementary designations

3

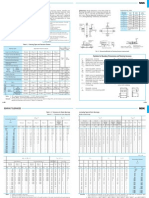

Diagram 1

Designation system for suffixes

Designation example

605RSNRTN9/P63LT0CVB3

3064 CCK/HA3C084SW33

Basic designation

Space

Suffixes

Group : Internal design

Group : External design (seals, snap ring groove etc.)

Group 3: Cage design

Oblique stroke

Group 4: Variants

Group 4.: Materials, heat treatment

Group 4.: Accuracy, clearance, quiet running

Group 4.3: Bearing sets, paired bearings

Group 4.4: Stabilization

Group 4.5: Lubrication

Group 4.6: Other variants

6205 -RS1NR TN9 / P63 LT20C VB123

23064 CC K / HA3 C084 S2 W33

4.1 4.2 4.3 4.4 4.5 4.6

1 2 3 / 4

Group Group Group Group

3

Supplementary designations

4

CN Normal internal clearance, normally

only used together with an additional

letter that identifies a reduced or dis

placed clearance range. Examples:

CNH Upper half of the Normal

clearance range

CNL Lower half of the Normal

clearance range

CNM Two middle quarters of the

Normal clearance range

CNP Upper half of the Normal and

lower half of C3 clearance

The above letters H, L, M and P are

also used together with the clearance

classes C, C3, C4 and C5

CV Full complement cylindrical roller

bearing with modified internal design

CS Sheet steel reinforced contact seal of

acrylonitrilebutadiene rubber (NBR)

on one side of the bearing

CS CS contact seal on both sides of the

bearing

CS Sheet steel reinforced contact seal

of fluoro rubber (FKM) on one side

of the bearing

CS CS contact seal on both sides of the

bearing

CS5 Sheet steel reinforced contact seal of

hydrogenated acrylonitrilebutadiene

rubber (HNBR) on one side of the

bearing

CS5 CS5 contact seal on both sides of

the bearing

C1 Bearing internal clearance smaller

than C

C Bearing internal clearance smaller

than Normal (CN)

C3 Bearing internal clearance greater

than Normal (CN)

C4 Bearing internal clearance greater

than C3

C5 Bearing internal clearance greater

than C4

C0 Extra reduced tolerance for running

accuracy of inner ring of assembled

bearing

C04 Extra reduced tolerance for running

accuracy of outer ring of assembled

bearing

C08 C0 + C04

C083 C0 + C04 + C3

C10 Reduced tolerance for the bore and

outside diameters

D Deviating or modified internal design

with the same boundary dimensions;

as a rule the significance of the letter is

bound to the particular bearing series.

Example:

330 D: Double row angular contact

ball bearing with a twopiece inner ring

DA Modified snap ring grooves in the

outer ring; twopiece inner ring held

together by a retaining ring

DB Two single row deep groove ball bear

ings (), single row angular contact

ball bearings () or single row taper

roller bearings matched for mounting

in a backtoback arrangement. The

letter(s) following the DB indicate the

magnitude of the axial internal clear

ance or preload in the bearing pair

before mounting.

A Light preload ()

B Moderate preload ()

C Heavy preload ()

CA Axial internal clearance smaller

than Normal (CB) (, )

CB Normal axial internal clearance

(, )

CC Axial internal clearance larger

than Normal (CB) (, )

C Special axial internal clearance in

mm

GA Light preload ()

GB Moderate preload ()

G Special preload in daN

For paired taper roller bearings the

design and arrangement of the inter

mediate rings between the inner and

outer rings are identified by a two

figure number which is placed between

DB and the above mentioned letters.

DF Two single row deep groove ball

bearings, single row angular contact

ball bearings or single row taper roller

bearings matched for mounting in a

facetoface arrangement. The letter(s)

following the DF are explained under

DB

DT Two single row deep groove ball

bearings, single row angular contact

ball bearings or single row taper roller

bearings matched for mounting in a

tandem arrangement; for paired

taper roller bearings the design and

arrangement of the intermediate

rings between the inner and/or outer

rings are identified by a twofigure

number which follows immediately

after DT

E Deviating or modified internal design

with the same boundary dimensions;

as a rule the significance of the letter

is bound to the particular bearing

series; usually indicates reinforced

rolling element complement.

Example:

7 BE: Single row angular contact

ball bearing with a 40 contact angle

and optimized internal design

EC Single row cylindrical roller bearing

with an optimized internal design and

with modified roller end/flange contact

ECA Spherical roller bearing of CA design

but with reinforced rolling element

complement

ECAC Spherical roller bearing of CAC design

but with reinforced rolling element

complement

F Machined steel or special cast iron

cage, rolling element centred; differ

ent designs or material grades are

identified by a figure following the F,

e.g. F

FA Machined steel or special cast iron

cage; outer ring centred

FB Machined steel or special cast iron

cage; inner ring centred

G Single row angular contact ball bear

ing for universal matching. Two bear

ings arranged backtoback or face

toface will have a certain axial

clearance before mounting

G.. Grease filling. A second letter indi

cates the temperature range of the

grease and a third letter identifies the

actual grease. The significance of the

second letter is as follows:

E Extreme pressure grease

F Food compatible grease

H, J High temperature grease,

e.g. 0 to +30 C

L Low temperature grease,

e.g. 50 to +80 C

M Medium temperature grease,

e.g. 30 to +0 C

W, X Low/high temperature grease,

e.g. 40 to +40 C

A figure following the threeletter

grease code indicates that the filling

degree deviates from the standard:

Figures , and 3 indicate smaller

than standard, 4 up to 9 a larger fill.

Examples:

GEA: Extreme pressure grease,

standard fill

GLB: Low temperature grease,

5 to 5 % fill

GA Single row angular contact ball bear

ing for universal matching. Two bear

ings arranged backtoback or face

toface will have a light preload

before mounting

GB Single row angular contact ball bear

ing for universal matching. Two bear

ings arranged backtoback or face

toface will have a moderate preload

before mounting

4

Supplementary designations

5

GC Single row angular contact ball bear

ing for universal matching. Two bear

ings arranged backtoback or face

toface will have a heavy preload

before mounting

GJN Grease with a polyurea thickener of

consistency to the NLGI Scale for a

temperature range 30 to +50 C

(normal fill grade)

GXN Grease with a polyurea thickener of

consistency to the NLGI Scale for a

temperature range 40 to +50 C

(normal fill grade)

H Pressed snaptype steel cage, hard

ened

HA Casehardened bearing or bearing

components. For closer identification

HA is followed by one of the following

figures:

0 Complete bearing

Outer and inner rings

Outer ring

3 Inner ring

4 Outer ring, inner ring and rolling

elements

5 Rolling elements

6 Outer ring and rolling elements

7 Inner ring and rolling elements

HB Bainitehardened bearing or bearing

components. For closer identification

HB is followed by one of the figures

explained under HA

HC Bearing or bearing components of

ceramic material. For closer identifi

cation HC is followed by one of the

figures explained under HA

HE Bearing or bearing components of

vacuum remelted steel. For closer

identification HE is followed by one of

the figures explained under HA

HM Martensitehardened bearing or

bearing components. For closer iden

tification HM is followed by one of the

figures explained under HA

HN Special surface heattreated bearing

or bearing components. For closer

identification HN is followed by one

of the figures explained under HA

HT Grease fill for high temperatures (e.g.

0 to +30 C). HT or a twofigure

number following HT identifies the

actual grease. Filling degrees other

than standard are identified by a letter

or letter/figure combination following

HTxx:

A Filling degree less than standard

B Filling degree greater than standard

C Filling degree greater than 70 %

F Filling degree less than standard

F7 Filling degree greater than standard

F9 Filling degree greater than 70 %

Examples: HTB, HT or HT4B

HV Bearing or bearing components of

hardenable stainless steel. For closer

identification HV is followed by one

of the figures explained under HA

J Pressed steel cage, rolling element

centred, unhardened; different designs

are identified by a figure, e.g. J

JR Cage comprising of two flat washers

of unhardened steel, riveted together

K Tapered bore, taper :

K30 Tapered bore, taper :30

LHT Grease fill for low and high tempera

tures (e.g. 40 to +40 C). A two

figure number following LHT identi

fies the actual grease. An additional

letter or letter/figure combination as

mentioned under HT identifies fill

ing degrees other than standard.

Examples: LHT3, LHT3C or

LHT3F7

LS Contact seal of acrylonitrilebutadiene

rubber (NBR) or polyurethane (AU)

with or without sheet steel reinforce

ment, on one side of the bearing

LS LS contact seal on both sides of the

bearing

LT Grease fill for low temperatures (e.g.

50 to +80 C). LT or a twofigure

number following LT identifies the

actual grease. An additional letter or

letter/figure combination as men

tioned under HT identifies filling

degrees other than standard.

Examples: LT, LT0 or LTF

L4B Bearing rings and rolling elements

with special surface coating

L5B Rolling elements with special

surface coating

L5DA NoWear

bearing with coated rolling

elements

L7DA NoWear bearing with coated rolling

elements and inner ring raceway(s)

M Machined brass cage, rolling element

centred; different designs or material

grades are identified by a figure or

a letter , e.g. M, MC

MA Machined brass cage, outer ring cen

tred

MB Machined brass cage, inner ring cen

tred

ML Machined onepiece windowtype

brass cage, inner or outer ring cen

tred

MP Machined onepiece windowtype

brass cage, with punched or reamed

pockets, inner or outer ring centred

MR Machined onepiece windowtype

brass cage, rolling element centred

MT Grease fill for medium temperatures

(e.g. 30 to +0 C). A twofigure

number following MT identifies the

actual grease. An additional letter or

letter/figure combination as men

tioned under HT identifies filling

degrees other than standard.

Examples: MT33, MT37F9 or MT47

N Snap ring groove in the outer ring

NR Snap ring groove in the outer ring

with appropriate snap ring

N1 One locating slot (notch) in one outer

ring side face or housing washer

N Two locating slots (notches) 80

apart in one outer ring side face or

housing washer

P Injection moulded cage of glass fibre

reinforced polyamide 6,6, rolling

element centred

PH Injection moulded cage of polyether

etherketone (PEEK), rolling element

centred

PHA Injection moulded cage of polyether

etherketone (PEEK), outer ring centred

PHAS Injection moulded cage of polyether

etherketone (PEEK), outer ring cen

tred, lubrication grooves in the guiding

surfaces

P4 Dimensional and running accuracy to

ISO tolerance class 4

P5 Dimensional and running accuracy to

ISO tolerance class 5

P6 Dimensional and running accuracy to

ISO tolerance class 6

P6 P6 + C

P63 P6 + C3

Q Optimized internal geometry and

surface finish (taper roller bearing)

R . Integral external outer ring flange

. Crowned runner surface (track

runner bearing)

RS Contact seal of acrylonitrilebutadiene

rubber (NBR) with or without sheet

steel reinforcement on one side of

the bearing

RS RS contact seal on both sides of the

bearing

RS1 Sheet steel reinforced contact seal of

acrylonitrilebutadiene rubber (NBR)

on one side of the bearing

RS1 RS contact seal on both sides of the

bearing

RS1Z Sheet steel reinforced contact seal of

acrylonitrilebutadiene rubber (NBR)

on one side and one shield on the

other side of the bearing

RS Sheet steel reinforced contact seal of

fluoro rubber (FKM) on one side of

the bearing

5

Supplementary designations

6

RS RS contact seal on both sides of the

bearing

RSH Sheet steel reinforced contact seal of

acrylonitrilebutadiene rubber (NBR)

on one side of the bearing

RSH RSH contact seal on both sides of the

bearing

RSL Sheet steel reinforced lowfriction

contact seal of acrylonitrilebutadiene

rubber (NBR) on one side of the

bearing

RSL RSL lowfriction contact seal on both

sides of the bearing

RZ Sheet steel reinforced lowfriction

seal of acrylonitrilebutadiene rubber

(NBR) on one side of the bearing

RZ RZ lowfriction seal on both sides of

the bearing

S0 Bearing rings or washers dimension

ally stabilized for use at operating

temperatures up to +50 C

S1 Bearing rings or washers dimension

ally stabilized for use at operating

temperatures up to +00 C

S Bearing rings or washers dimension

ally stabilized for use at operating

temperatures up to +50 C

S3 Bearing rings or washers dimension

ally stabilized for use at operating

temperatures up to +300 C

S4 Bearing rings or washers dimension

ally stabilized for use at operating

temperatures up to +350 C

T Windowtype cage of fabric reinforced

phenolic resin, rolling element centred

TB Windowtype cage of fabric reinforced

phenolic resin, inner ring centred

TH Snaptype cage of fabric reinforced

phenolic resin, rolling element centred

TN Injection moulded cage of polyamide

6,6, rolling element centred

TNH Injection moulded cage of polyether

etherketone (PEEK), rolling element

centred

TNHA Injection moulded cage of polyether

etherketone (PEEK), outer ring centred

TN9 Injection moulded cage of glass fibre

reinforced polyamide 6,6, rolling ele

ment centred

U U combined with a onefigure number

identifies a taper roller bearing, cone

or cup, with reduced width tolerance.

Examples:

U: Width tolerance +0,05/0 mm

U4: Width tolerance +0,0/0 mm

V Full complement bearing (without

cage)

V V combined with a second letter,

identifies a variant group, and fol

lowed by a three or fourfigure

number denotes variants not covered

by standard designation suffixes.

Examples:

VA Application oriented variants

VB Boundary dimension deviations

VE External or internal deviations

VL Coatings

VQ Quality and tolerances other

than standard

VS Clearance and preload

VT Lubrication

VU Miscellaneous applications

VA01 Bearing for hightemperature

applications (e.g. kiln trucks)

VA08 Bearing for hightemperature

applications

VA16 Bearing for hightemperature

applications

VA8 Bearing for hightemperature

applications

VA301 Bearing for traction motors

VA305 Bearing for traction motors

+ special inspection routines

VA3091 Bearing for traction motors with

aluminium oxide coated outside

surface of outer ring for electrical

resistance up to 000 V DC

VA30 Bearing for railway axleboxes

according to EN 080:998

VA350 Bearing for railway axleboxes

VA405 Bearing for vibratory applications

VA406 Bearing for vibratory applications

with special PTFE bore coating

VC05 Bearing with specially debrisheat

treated components for applications

in heavily contaminated environ

ments

VE40 CARB

bearing modified for greater

axial displacement

VE447 Shaft washer with three equally

spaced threaded holes in one side

face to accommodate hoisting tackle

VE55 Outer ring with three equally spaced

threaded holes in one side face to

accommodate hoisting tackle

VE553 Outer ring with three equally spaced

threaded holes in both side faces to

accommodate hoisting tackle

VE63 Housing washer with three equally

spaced threaded holes in one side

face to accommodate hoisting tackle

VG114 Surfacehardened pressed steel

cage

VH Full complement cylindrical roller

bearing with selfretaining roller set

VL041 Aluminium oxide coated outside

surface of outer ring for electrical

resistance up to 000 V DC

VL071 Aluminium oxide coated outside

surface of inner ring for electrical

resistance up to 000 V DC

VQ015 Inner ring with crowned raceway

for increased permissible misalign

ment

VQ44 Running accuracy better than C08

VT143 Extreme pressure grease with a

lithium thickener of consistency to

the NLGI Scale for a temperature

range 0 to +0 C (normal fill

grade)

VT378 Food grade grease with an aluminium

thickener of consistency to the

NLGI Scale for a temperature range

5 to +0 C (normal fill grade)

W Without annular groove and lubri

cation holes in outer ring

WT Grease fill for low as well as high

temperatures ( e.g. 40 to +60 C).

WT or a twofigure number follow

ing WT identifies the actual grease.

An additional letter or letter/figure

combination as mentioned under

HT identifies filling degrees other

than standard. Examples: WT or

WTF

W0 Three lubrication holes in the outer

ring

W6 Six lubrication holes in the inner

ring

W33 Annular groove and three lubrica

tion holes in the outer ring

W33X Annular groove and six lubrication

holes in the outer ring

W513 Six lubrication holes in the inner

ring and annular groove and three

lubrication holes in the outer ring

W64 Solid Oil filling

W77 Plugged W33 lubrication holes

X . Boundary dimensions altered to

conform to ISO standards

. Cylindrical runner surface (track

runner bearing)

Y Pressed brass cage, rolling element

centred; different designs or mate

rial grades are identified by a figure

following the Y, e.g. Y

Z Shield of pressed sheet steel on one

side of the bearing

Z Zshield on both sides of the bearing

6

www.skf.com

SKF, CARB, NoWear and

SensorMount are registered

trademarks of the SKF Group.

SKF 005

The contents of this publication

are the copyright of the publisher

and may not be reproduced (even

extracts) unless permission is gran

ted. Every care has been taken to

ensure the accuracy of the infor

mation contained in this publica

tion but no liability can be accep

ted for any loss or damage whether

direct, indirect or consequential

arising out of the use of the infor

mation contained herein.

0009 EN 1 june 006 JA

Printed in Sweden.

Potrebbero piacerti anche

- What Is Not Said: Metaphor and The Deflationary Account: Chris GenovesiDocumento13 pagineWhat Is Not Said: Metaphor and The Deflationary Account: Chris GenovesimiprofesorjaviNessuna valutazione finora

- Maintenance Guidelines: 8. 1 Centrifugal Pumps Fits and Clearance Checklist. Basic Data No: Measurement ToleranceDocumento2 pagineMaintenance Guidelines: 8. 1 Centrifugal Pumps Fits and Clearance Checklist. Basic Data No: Measurement Tolerancedave381dNessuna valutazione finora

- Fallas en CojinetesDocumento2 pagineFallas en CojinetesAlfredo OrellanaNessuna valutazione finora

- Continuous Thread Stud Double End Stud ADocumento11 pagineContinuous Thread Stud Double End Stud AMarius Mihai Buzduga0% (1)

- ME0403 Ch2 Gear MeasurementDocumento42 pagineME0403 Ch2 Gear MeasurementMANOJ M100% (1)

- NPD1 Training - PTPL - Smart Modular Gearbox - Apr 2020 PDFDocumento20 pagineNPD1 Training - PTPL - Smart Modular Gearbox - Apr 2020 PDFShyam J Vyas0% (1)

- Day 2 - S3 S4 - Introduction To Jbase Database1Documento48 pagineDay 2 - S3 S4 - Introduction To Jbase Database1alasad parvezNessuna valutazione finora

- Bearing BasicsDocumento69 pagineBearing BasicsHashem Mohamed HashemNessuna valutazione finora

- Pressure Dam Bearings USEFULDocumento16 paginePressure Dam Bearings USEFULAmna Chaudary100% (1)

- Bearing Main Prefix and Suffix System PDFDocumento9 pagineBearing Main Prefix and Suffix System PDFNandu ThulasidharanNessuna valutazione finora

- SKF - NoWear Presentation at 07-12-06Documento27 pagineSKF - NoWear Presentation at 07-12-06Patrick Baridon100% (1)

- Gear CouplingsDocumento62 pagineGear CouplingsKhurram Rehman100% (2)

- Exciter Field - Cat GeneratorDocumento5 pagineExciter Field - Cat Generatorwagner_guimarães_10% (1)

- New ZKL General CatalogueDocumento644 pagineNew ZKL General Catalogueerayrelmo100% (1)

- Oracle Ebs InstallationDocumento22 pagineOracle Ebs InstallationMr. JalilNessuna valutazione finora

- EleconDocumento72 pagineEleconPranit BangeraNessuna valutazione finora

- Gear Coupling FGCDocumento4 pagineGear Coupling FGCMandar PundeNessuna valutazione finora

- Journal Bearings Practice PDFDocumento20 pagineJournal Bearings Practice PDFPrabhath KumaraNessuna valutazione finora

- Increasing The Kiln SpeedDocumento1 paginaIncreasing The Kiln SpeedsreeganeshrNessuna valutazione finora

- Gear Assembly Maintenance Techniques TurbogearsDocumento12 pagineGear Assembly Maintenance Techniques Turbogearshumayun121Nessuna valutazione finora

- Series H - Industrial Gearbox: Installation & MaintenanceDocumento24 pagineSeries H - Industrial Gearbox: Installation & MaintenanceManisankar IrukuvajjalaNessuna valutazione finora

- Basic of GearsDocumento35 pagineBasic of Gearskcshieh100% (1)

- Bearing Designation Numbers, SuffexDocumento12 pagineBearing Designation Numbers, SuffexWajahat Ali KhanNessuna valutazione finora

- SKF NameDocumento26 pagineSKF NameIslam Fawzy100% (1)

- Bearing TerminologiDocumento9 pagineBearing Terminologihengki wibowoNessuna valutazione finora

- SEW MC Series Gear UnitsDocumento104 pagineSEW MC Series Gear UnitsPaolo100% (1)

- Bearing Number CodesDocumento3 pagineBearing Number CodesgksamyNessuna valutazione finora

- Suffix of BearingDocumento14 pagineSuffix of BearingPirnandoTariganNessuna valutazione finora

- Elecon Gear Box O&M ManualDocumento38 pagineElecon Gear Box O&M ManualSrinivasa Rao PallelaNessuna valutazione finora

- DHB5A MS Range PDFDocumento32 pagineDHB5A MS Range PDFAshutosh PandeyNessuna valutazione finora

- Loctite Industrial Gearbox Service ManualDocumento13 pagineLoctite Industrial Gearbox Service ManualDumitrescuNessuna valutazione finora

- Gear Coupling 2014Documento4 pagineGear Coupling 2014Dado Maja ArseninNessuna valutazione finora

- Tpi 169 de enDocumento16 pagineTpi 169 de enPatrick BaridonNessuna valutazione finora

- Catalog KingcoleDocumento33 pagineCatalog Kingcoleg_casalinuovo19812344Nessuna valutazione finora

- Prefixes Suffixes SKFDocumento9 paginePrefixes Suffixes SKFPatrick Baridon100% (1)

- Tilting Pad TroubleshootingDocumento7 pagineTilting Pad Troubleshootinghamedia83Nessuna valutazione finora

- KPAV125Documento183 pagineKPAV125Hana TruongNessuna valutazione finora

- Cardan Shaft AlignmentDocumento26 pagineCardan Shaft AlignmentconstantinNessuna valutazione finora

- Approved LubricationDocumento16 pagineApproved LubricationAhmed El-ShafeiNessuna valutazione finora

- Kumera Girth Gear Technical ManualDocumento12 pagineKumera Girth Gear Technical ManualBhaskar Reddy100% (1)

- 7300en PDFDocumento9 pagine7300en PDFWaris La Joi WakatobiNessuna valutazione finora

- Prefixes and Suffixes SKF BearingDocumento15 paginePrefixes and Suffixes SKF BearingcoupercouperNessuna valutazione finora

- SEW Compact Constant Speed Reducer MC SeriesDocumento195 pagineSEW Compact Constant Speed Reducer MC SeriesDênis DáyolNessuna valutazione finora

- High Speed Gear: Quality Driven High Speed Gears For The WorldDocumento5 pagineHigh Speed Gear: Quality Driven High Speed Gears For The WorldNur YantoNessuna valutazione finora

- Cojinetes de Generador Renk Manual de AplicacionesDocumento39 pagineCojinetes de Generador Renk Manual de AplicacionesMiguel Angel PonceNessuna valutazione finora

- Binocular Vision Development, Depth Perception and DisordersDocumento275 pagineBinocular Vision Development, Depth Perception and DisordersJuliana ToméNessuna valutazione finora

- Bearing Data GeneralDocumento17 pagineBearing Data GeneralpdmserviceNessuna valutazione finora

- NKE SuffixesDocumento5 pagineNKE SuffixesNaeemSiddiquiNessuna valutazione finora

- Bearing Fits PDFDocumento9 pagineBearing Fits PDFMujahidin AhmadNessuna valutazione finora

- Steps To Check SKF BearingsDocumento1 paginaSteps To Check SKF BearingsSanjoy Kr. DeyNessuna valutazione finora

- NPD1 Training - PTPL - Cooling Tower - PCX-Series - Apr 2020Documento38 pagineNPD1 Training - PTPL - Cooling Tower - PCX-Series - Apr 2020Shyam J VyasNessuna valutazione finora

- Alignment Shaft Thermal GrowthDocumento6 pagineAlignment Shaft Thermal Growthmmcsw6624Nessuna valutazione finora

- GM I & S PDFDocumento178 pagineGM I & S PDFsanjibkrjanaNessuna valutazione finora

- Bearing CatalogueDocumento12 pagineBearing CatalogueSandeep MatetiNessuna valutazione finora

- Pulverizers 101 - Part IDocumento9 paginePulverizers 101 - Part Iabo1510Nessuna valutazione finora

- Installation Procedure - RFN 7012Documento3 pagineInstallation Procedure - RFN 7012Barry ChungNessuna valutazione finora

- Angular Contact Bearing SKFDocumento26 pagineAngular Contact Bearing SKFjayendrakashyap010% (1)

- B106 Taper Roller Brgs.Documento37 pagineB106 Taper Roller Brgs.prasanna2210Nessuna valutazione finora

- 1, RKB Roller Bearing CatalogueDocumento356 pagine1, RKB Roller Bearing CatalogueCristian OrtizNessuna valutazione finora

- SKF Thrust BearingsDocumento20 pagineSKF Thrust BearingsBùi Văn HợpNessuna valutazione finora

- Metric Design Tapered Roller BearingsDocumento36 pagineMetric Design Tapered Roller BearingsMohan RajNessuna valutazione finora

- SKF Cylindircal Roller BearingsDocumento36 pagineSKF Cylindircal Roller Bearingskvramanan_1100% (1)

- 1 141227035156 Conversion Gate02 PDFDocumento52 pagine1 141227035156 Conversion Gate02 PDFPhasin ChitutsahaNessuna valutazione finora

- Eaton-Airflex - Type CB Tech SpecsDocumento40 pagineEaton-Airflex - Type CB Tech SpecsEdwin HernandezNessuna valutazione finora

- SNH Europe GMBH PDFDocumento9 pagineSNH Europe GMBH PDFalaine1114Nessuna valutazione finora

- NSK - Drawn Cup Needle Roller ClutchesDocumento11 pagineNSK - Drawn Cup Needle Roller ClutchesWillian MoreiraNessuna valutazione finora

- B1031e-3 Precision BearingDocumento28 pagineB1031e-3 Precision Bearingmbahe_azisNessuna valutazione finora

- Filter Screen With Stainless BushingDocumento2 pagineFilter Screen With Stainless BushingPatrick BaridonNessuna valutazione finora

- Corrosion Prevention: 1 ScopeDocumento2 pagineCorrosion Prevention: 1 ScopePatrick BaridonNessuna valutazione finora

- UK06t Omp Omr MetricDocumento1 paginaUK06t Omp Omr MetricPatrick BaridonNessuna valutazione finora

- Series: ARC-8 Type: MFHN Outer-Ø / Size: 255-8: Info@atec-Weiss - deDocumento1 paginaSeries: ARC-8 Type: MFHN Outer-Ø / Size: 255-8: Info@atec-Weiss - dePatrick BaridonNessuna valutazione finora

- Normafix Rsgu enDocumento8 pagineNormafix Rsgu enPatrick BaridonNessuna valutazione finora

- Eriks - RX Spiralex-FstDocumento1 paginaEriks - RX Spiralex-FstPatrick BaridonNessuna valutazione finora

- Eriks - RX SpiralexDocumento1 paginaEriks - RX SpiralexPatrick BaridonNessuna valutazione finora

- Koyo Bearings PRDocumento2 pagineKoyo Bearings PRPatrick BaridonNessuna valutazione finora

- NSK Innovativeproduct IP E 2023Documento1 paginaNSK Innovativeproduct IP E 2023Patrick BaridonNessuna valutazione finora

- Rotary Seals VringsDocumento25 pagineRotary Seals VringsPatrick BaridonNessuna valutazione finora

- Maintenance Arpex enDocumento39 pagineMaintenance Arpex enPatrick BaridonNessuna valutazione finora

- Ball and Roller Bearings: Designed For Optimum PerformanceDocumento2 pagineBall and Roller Bearings: Designed For Optimum PerformancePatrick BaridonNessuna valutazione finora

- Cle Frappe TMFNDocumento1 paginaCle Frappe TMFNPatrick BaridonNessuna valutazione finora

- July 2006 @ptitude Exchange News Vol. 5, Ed. 7: in This NewsletterDocumento4 pagineJuly 2006 @ptitude Exchange News Vol. 5, Ed. 7: in This NewsletterPatrick BaridonNessuna valutazione finora

- Strength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyDocumento3 pagineStrength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyVasanth KumarNessuna valutazione finora

- Sr. Grand Test Key and HintsDocumento7 pagineSr. Grand Test Key and HintsM JEEVARATHNAM NAIDUNessuna valutazione finora

- BBBBBDocumento11 pagineBBBBBAlfredo ErguetaNessuna valutazione finora

- 05 - A Statistical Analysis of Body Measurements of Filipino WomenDocumento15 pagine05 - A Statistical Analysis of Body Measurements of Filipino WomenJenberrose G TrelinskiNessuna valutazione finora

- 2 EesyllDocumento77 pagine2 EesyllDileepNessuna valutazione finora

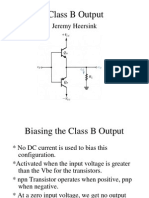

- Class B Output: Jeremy HeersinkDocumento10 pagineClass B Output: Jeremy Heersinkdummy1957jNessuna valutazione finora

- ACT Geometry - PolygonsDocumento8 pagineACT Geometry - PolygonsaftabNessuna valutazione finora

- Seizmic Design of RE WallsDocumento49 pagineSeizmic Design of RE Wallsljubomirjocic@yahoo.com100% (1)

- Chapter 11 - SkullDocumento10 pagineChapter 11 - Skullwamaithamargaret257Nessuna valutazione finora

- Dam From: Safety Valve For A DamDocumento28 pagineDam From: Safety Valve For A DamRashmi SahooNessuna valutazione finora

- Fuels and Combustion (Unit-Viii) 1. (A) Explain How Fuels Are Classified With Suitable ExamplesDocumento15 pagineFuels and Combustion (Unit-Viii) 1. (A) Explain How Fuels Are Classified With Suitable ExamplesengineeringchemistryNessuna valutazione finora

- Leica Disto d410 Manual EngDocumento24 pagineLeica Disto d410 Manual EngcsudhaNessuna valutazione finora

- 03 - Random Effect ModelDocumento10 pagine03 - Random Effect ModelAdji Pelangi SaputriNessuna valutazione finora

- Revised Draft Ammendment To IRS T29 MAR13Documento11 pagineRevised Draft Ammendment To IRS T29 MAR13Shipra MishraNessuna valutazione finora

- MPM2D CPT: Knights of The Night Station: Include All Your Work For Each Part On Their Own .PDF File orDocumento5 pagineMPM2D CPT: Knights of The Night Station: Include All Your Work For Each Part On Their Own .PDF File orKavya Pandya100% (2)

- Design Data (No Longer Current But Cited in The Building Regulations)Documento290 pagineDesign Data (No Longer Current But Cited in The Building Regulations)ferdinand bataraNessuna valutazione finora

- NCERT Solutions For Class 12 Physics Chapter 12 AtomsDocumento14 pagineNCERT Solutions For Class 12 Physics Chapter 12 AtomsKritika MishraNessuna valutazione finora

- Fairwell TestDocumento16 pagineFairwell TestSsekyanzi CalvinNessuna valutazione finora

- Rangkaian Om Telolet OmDocumento5 pagineRangkaian Om Telolet Omwalid suwalidNessuna valutazione finora

- Leaf Spring - Final DocumentationDocumento64 pagineLeaf Spring - Final DocumentationSushmitha VaditheNessuna valutazione finora

- Ak98 Preset ListDocumento21 pagineAk98 Preset ListHichem NaghmouchiNessuna valutazione finora

- Significant FiguresDocumento24 pagineSignificant Figurestatroclaire88Nessuna valutazione finora

- CONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Documento4 pagineCONTEXT PLUS - HFC227ea Systems - SALES BROCHURE - 01-17Ronny HasanNessuna valutazione finora

- Reviewer MathDocumento6 pagineReviewer MathLuna Ronquillo100% (1)

- Bio Sem2 EssayDocumento2 pagineBio Sem2 EssayEileen WongNessuna valutazione finora