Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asme Ix Wps PQR Checklist

Caricato da

aghussr0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

321 visualizzazioni0 pagineTitolo originale

Asme Ix Wps Pqr Checklist

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

321 visualizzazioni0 pagineAsme Ix Wps PQR Checklist

Caricato da

aghussrCopyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 0

ASME Sect.

IX WPS & PQR Check List

www.weldassistant.com

PARAGRAPH

1 in groove design N N N N N N S

2 Backing N

3 Backing Composition N

4 - of backing in single sided weld N N N

5 + backing ( and chemical composition ) N N

10 Root spacing N N N N N N N

11 Retainers N N N N E N

1 P-Number E E

2 Max. T qualified E

4 Group Number S

5 in group number QW-422 S S S S S

6 T Limits impact S S S S S

8 T Qualified E E E E E

9 t pass > 1/2 in (13 mm) E E E E

10 T Limits Qualified (Short Circuit Arc) E

11 P-N Qualified E E E E

12 P-Number/melt-in E

3 Size N N N

4 F-N E E E E E E E

5 A-N E E E E E E E

6 Diameter N N N N

7 Diameter > in (6 mm) S

9 Flux/Wire Classification E

10 Alloy flux E

12 AWS classification S S S E S S

14 Filler E E

17 Flux Type or composition E

18 Wire to plate E

19 Consum guide E

22 Consumable insert N N

23 Filler metal product form

(Solid/metal or flux-cored)

E E E

24 Supplemental Filler Metal E E

27 Alloy elements E E E

29 Flux designation N

30 t E E E E E

32 t Limits (Short Circuit Arc) E

33 AWS Classification N N N N N N

34 Flux Type E

35 Flux/Wire Classification S N

36 Recrushed Slag E

50 Flux N

1 + Position N N N N N N

2 Position S S S S

3 Vercal Welding N N N N

PAW

PAW ESW

ESW

QW-404 Filler Metals

SMAW

ESW

QW-403 BASE METAL

SMAW SAW

GMAW /

FCAW

GTAW

GTAW PAW

ESW

OFW

PAW

OFW

QW-402 JOINTS

SMAW SAW

GMAW /

FCAW

GTAW

SAW

GMAW /

FCAW

SAW

GMAW /

FCAW

GTAW

OFW

! ! ! Cannot replace the use of Section IX ! ! !

OFW

QW-405 Positions

SMAW

copyright 2012 hsk-welding solutions info@h-s-k.org www.weldassistant.com

ASME Sect. IX WPS & PQR Check List

www.weldassistant.com

PARAGRAPH

! ! ! Cannot replace the use of Section IX ! ! !

1 Decrease > 100F (55C) E E E E N E

2 Preheat maintenance N N N

3 Increase > 100F (55C) (IP) S S S S S

1 PWHT E E E E E E E

2 PWHT ( Time & Temperature Range) S S S S S S

4 T Limits E E E E E E

1 Trailing or composition N N N

2 Single, mixture or % E E

3 Flow rate N N

4 Composition E

5 Backing flow N N N

7 Type fuel gas E

9 - Backing or composition E E E

10 Shielding or trailing E E E

21 Flow rate N

1 > Heat input S S S S S

2 Transfer Mode E

3 Pulsing I N

4 Current or Polarity S N S N S N S N S N

5 15% I & E range E

8 I & E Range N N N N N

12 Tungsten electrode N N

1 String/Weave N N N N N N

2 Flame characteristics N

3 Orifice cup, or nozzle size N N N

4 Technique N

5 Method of cleaning N N N N N N N

6 Method of back gouge N N N N N

7 Oscillation N N N E N

8 Tube to Work distance N N

9 Multi to single pass per side N S N S N S N S N

10 Single to multi electrodes S N S N S N E S N

11 Closed to out of chamber welding E E

12 Melt-in to keyhole S

15 Electrode spacing N N N N N

25 Manual or Automatic N N N N

26 Peening N N N N N N N

64 Use of thermal process E E E E E E E

> Increase / greater than + Addition Uphill Forehand Change

< Decrease / less than - Deletion Downhill Backhand

N = Nonessential variables must be indicated on the WPS but when changed do not require requalification of WPS

NOTE: WPSs are to indicate all Essential, Nonessential and Supplementary Essential variables.

LEGEND

PAW ESW

QW-407 PWHT

SMAW SAW

GMAW /

FCAW

GTAW

SAW

QW-406 Preheat

SMAW

PAW

QW-408 GAS

SMAW SAW

GMAW /

FCAW

GTAW

OFW

GMAW /

FCAW

SAW

GMAW /

FCAW

GTAW PAW

ESW

PAW

GTAW

PAW ESW

GTAW

E = Essential Variables which must be indicated on both the WPS and recorded on the PQR .

Any changes to these variables require requalification of WPS

S = Supplementary Essential Variables must be indicated on the WPS and Recorded on the PQR when Impact Testing is required Changes to these variables

when Impact testing is performed require requalification of WPS

Do not indicate variables which are not used as NA,

they are applicable and should be entered on the WPS as None or Not used

OFW

OFW

OFW

OFW ESW

QW-410 Technique

SMAW

ESW

QW-409 Electrical Characteristics

SMAW SAW

GMAW /

FCAW

copyright 2012 hsk-welding solutions info@h-s-k.org www.weldassistant.com

Potrebbero piacerti anche

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Da EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Nessuna valutazione finora

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Documento2 pagineWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Asme Sec Ix-WpqDocumento47 pagineAsme Sec Ix-WpqKaushal Sojitra100% (1)

- Painting Inspector: Passbooks Study GuideDa EverandPainting Inspector: Passbooks Study GuideNessuna valutazione finora

- API Welding Procedure Specification PDFDocumento3 pagineAPI Welding Procedure Specification PDFBob LeeNessuna valutazione finora

- A Quick Guide to Welding and Weld InspectionDa EverandA Quick Guide to Welding and Weld InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)

- WPS Steps of MakingDocumento51 pagineWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- WPQ CS SmawDocumento1 paginaWPQ CS Smawniket0Nessuna valutazione finora

- WPS-PQR Road MapDocumento1 paginaWPS-PQR Road MapBaraa AzebNessuna valutazione finora

- 2019 ASME Section IX SynopsisDocumento31 pagine2019 ASME Section IX SynopsisFaiez GhrabNessuna valutazione finora

- HT Chart For ASME Material-B31.3Documento1 paginaHT Chart For ASME Material-B31.3MurugananthamParamasivamNessuna valutazione finora

- WPS& WQRDocumento132 pagineWPS& WQRAby Jacob Mathews100% (3)

- Weld Fit Up Inspection Employee TrainingDocumento10 pagineWeld Fit Up Inspection Employee TrainingMohammad RizwanNessuna valutazione finora

- WPS, PQR & WPQTDocumento14 pagineWPS, PQR & WPQTSky RNessuna valutazione finora

- Ilcs-Smaw-D1.3-Deck (G) WPSDocumento3 pagineIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Miller RMDDocumento4 pagineMiller RMDRony Lesbt100% (1)

- General Repair ProcedureDocumento3 pagineGeneral Repair ProcedurevenkateshNessuna valutazione finora

- Welding Procedures and Welders QualificationDocumento41 pagineWelding Procedures and Welders QualificationHamid MansouriNessuna valutazione finora

- Welding Inspection VT Course-New PDFDocumento82 pagineWelding Inspection VT Course-New PDF7okaz100% (2)

- ASME 9 - CalculatorDocumento2 pagineASME 9 - CalculatorEmel Besir100% (1)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocumento1 paginaWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- Techniques of Visual InspectionDocumento80 pagineTechniques of Visual InspectiontranngNessuna valutazione finora

- Transformer-WPS OfficeDocumento19 pagineTransformer-WPS OfficeVinaya kumar BGNessuna valutazione finora

- Note-8 WQT-Material, Position and Acceptance CriteriaDocumento19 pagineNote-8 WQT-Material, Position and Acceptance Criteriamrbart_88Nessuna valutazione finora

- FCAWDocumento6 pagineFCAWshravan.office11Nessuna valutazione finora

- ATF - WelderTestPackage - v2 Welder and Welding Operator Perfomance Qualification RecordDocumento5 pagineATF - WelderTestPackage - v2 Welder and Welding Operator Perfomance Qualification Recordfallalovaldes61Nessuna valutazione finora

- Flux Cored and MIG Pipe WeldingDocumento59 pagineFlux Cored and MIG Pipe Weldingcentaury2013Nessuna valutazione finora

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocumento5 pagineHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNessuna valutazione finora

- Dss 2205 Wps PQR WPQDocumento8 pagineDss 2205 Wps PQR WPQAnand KesarkarNessuna valutazione finora

- Preheat PDFDocumento4 paginePreheat PDFKamal UddinNessuna valutazione finora

- AWS D1.2 GuidesDocumento3 pagineAWS D1.2 GuidesTuan DangNessuna valutazione finora

- Log Sheet For Baking ElectrodesDocumento1 paginaLog Sheet For Baking ElectrodesAbu Huraira100% (1)

- ASME Weld Number Tables (P, F, A)Documento19 pagineASME Weld Number Tables (P, F, A)Osman GoneNessuna valutazione finora

- WPS PQR Check List Table 2017Documento5 pagineWPS PQR Check List Table 2017TuTuy An89% (19)

- Weld Inspection and RepairDocumento10 pagineWeld Inspection and RepairDeepak Kumar Kant KesriNessuna valutazione finora

- Welding GaugeDocumento11 pagineWelding GaugeDevesh ChauhanNessuna valutazione finora

- Ab-094 Welding Examiner SyllabusDocumento8 pagineAb-094 Welding Examiner SyllabusSiva Sankara Narayanan SubramanianNessuna valutazione finora

- WeldassistantDocumento3 pagineWeldassistantjangdiniNessuna valutazione finora

- Quick Guide To Welding Procedure Qualification (WPS & PQR)Documento5 pagineQuick Guide To Welding Procedure Qualification (WPS & PQR)Annamalai Ram JGCNessuna valutazione finora

- TES-WELD-API - Welding of Pipelines and Facilities SpecificationDocumento37 pagineTES-WELD-API - Welding of Pipelines and Facilities SpecificationFederico QuintanaNessuna valutazione finora

- Module 1Documento30 pagineModule 1mahmoud aliNessuna valutazione finora

- Welding Inspection CSWIP PDFDocumento683 pagineWelding Inspection CSWIP PDFmohdrafeek83Nessuna valutazione finora

- Golden WeldDocumento4 pagineGolden Weldenels77Nessuna valutazione finora

- WPS PqrchecklistDocumento1 paginaWPS PqrchecklistrodofgodNessuna valutazione finora

- WPS and PQR ChecklistDocumento2 pagineWPS and PQR Checklistshabbir626Nessuna valutazione finora

- WPS-PQR Review Checklist 2007Documento2 pagineWPS-PQR Review Checklist 2007sajeed76740Nessuna valutazione finora

- WPS Variables Asme IX 2019Documento2 pagineWPS Variables Asme IX 2019RedzuanNessuna valutazione finora

- Mil-C-22992 RTIDocumento16 pagineMil-C-22992 RTIchak1729Nessuna valutazione finora

- WPS & PQR Review Check List: Asme Sec. Ix Ed.2007Documento2 pagineWPS & PQR Review Check List: Asme Sec. Ix Ed.2007KyNessuna valutazione finora

- Data Collection For Shrinkage2Documento97 pagineData Collection For Shrinkage2SagarNessuna valutazione finora

- EatonDocumento8 pagineEatongulamkasim mominNessuna valutazione finora

- Mueller Equivalent Lengths PDFDocumento1 paginaMueller Equivalent Lengths PDFkuchaitanyaNessuna valutazione finora

- WPS PQR Review Checiklist - FreDocumento2 pagineWPS PQR Review Checiklist - FreFreddyNessuna valutazione finora

- JVC Av-N29302 SchemDocumento7 pagineJVC Av-N29302 SchemJoe BravoNessuna valutazione finora

- Wps & PQR Check ListDocumento2 pagineWps & PQR Check ListDimaz ragaNessuna valutazione finora

- Wps & PQR Check List: Qw-402 Joints Smaw SAW GM/FC GtawDocumento2 pagineWps & PQR Check List: Qw-402 Joints Smaw SAW GM/FC GtawBS AhnNessuna valutazione finora

- TGN-M-04 Weld Procedure Comparison Struc SteelDocumento5 pagineTGN-M-04 Weld Procedure Comparison Struc Steelmanoj983@gmail.comNessuna valutazione finora

- Ev DG05Documento14 pagineEv DG05mtbecerrapNessuna valutazione finora

- Data Sheet Thermal Wax Actuator TWA: ApplicationDocumento4 pagineData Sheet Thermal Wax Actuator TWA: ApplicationMostafa AliNessuna valutazione finora

- TDS 010 Structural BoltsDocumento4 pagineTDS 010 Structural BoltsAnonymous 4CnOgVNessuna valutazione finora

- Torque Guide BoltDocumento1 paginaTorque Guide BoltaghussrNessuna valutazione finora

- Brochure DemagDocumento16 pagineBrochure DemagaghussrNessuna valutazione finora

- Mechanical Properties Bolt For Steel Structure: A. Astm 1. ASTM A 325Documento3 pagineMechanical Properties Bolt For Steel Structure: A. Astm 1. ASTM A 325aghussrNessuna valutazione finora

- A - Piping Joint HandbookDocumento161 pagineA - Piping Joint HandbookCharles Tauk100% (30)

- TLPE ResumeDocumento3 pagineTLPE ResumeaghussrNessuna valutazione finora

- AWS Welding Performance Qualification StandardDocumento12 pagineAWS Welding Performance Qualification Standardnarutothunderjet216Nessuna valutazione finora

- ANSI EMMA - 557-09 Standards For Expanded MetalDocumento16 pagineANSI EMMA - 557-09 Standards For Expanded MetalaghussrNessuna valutazione finora

- ANSI AMP - 555-92 Code of Standard Practice For The Architectural Metal IndustryDocumento40 pagineANSI AMP - 555-92 Code of Standard Practice For The Architectural Metal IndustryaghussrNessuna valutazione finora

- Coating HVLP TrainingDocumento30 pagineCoating HVLP Trainingaghussr100% (1)

- False Set and Flash Set and CEMENTDocumento31 pagineFalse Set and Flash Set and CEMENTk_981966368Nessuna valutazione finora

- Hysteresis Loop Tracer.: TitleDocumento7 pagineHysteresis Loop Tracer.: TitleSubhrajit SamantaNessuna valutazione finora

- July 2017: Understanding The Basics of Hand Taps and Carbide TapsDocumento24 pagineJuly 2017: Understanding The Basics of Hand Taps and Carbide TapswinasharNessuna valutazione finora

- Foundry LabDocumento24 pagineFoundry LabthodatisampathNessuna valutazione finora

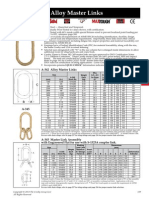

- Master Link CatalogueDocumento1 paginaMaster Link CatalogueHafizi HZnumismatic50% (2)

- Instrument Air Design GuideDocumento39 pagineInstrument Air Design Guidesapu11jagat5855Nessuna valutazione finora

- Radiographic Testing of Welds BSEN 1435Documento37 pagineRadiographic Testing of Welds BSEN 1435thanhhai66100% (1)

- Classification of Zinc Die Casting DefectsDocumento20 pagineClassification of Zinc Die Casting DefectsAnshuman RoyNessuna valutazione finora

- B 232 - B 232m - 01 - Qjizmi9cmjmytqDocumento16 pagineB 232 - B 232m - 01 - Qjizmi9cmjmytqYayan RnsNessuna valutazione finora

- Bilder Architektur BauDocumento27 pagineBilder Architektur BauChristina ChristovaNessuna valutazione finora

- Pin Brazing ManualDocumento24 paginePin Brazing ManualXiaohua ChenNessuna valutazione finora

- Accessories: Aluminium Products WindguardsDocumento1 paginaAccessories: Aluminium Products WindguardsBoy AlfredoNessuna valutazione finora

- ECmDocumento32 pagineECmAmit BedareNessuna valutazione finora

- MonelDocumento3 pagineMonelnurarifiantoNessuna valutazione finora

- Comparison of BS and BSEN For Steel Simplified VersionDocumento19 pagineComparison of BS and BSEN For Steel Simplified VersionSadashiva sahooNessuna valutazione finora

- En 9Documento2 pagineEn 9Swaran SinghNessuna valutazione finora

- Asme Sec 9 - ADocumento144 pagineAsme Sec 9 - Aروشان فاطمة روشانNessuna valutazione finora

- Mil I 17563CDocumento18 pagineMil I 17563Cchitti409Nessuna valutazione finora

- 3 0 Visual Weld InspectorDocumento74 pagine3 0 Visual Weld InspectorVincent Sofia RaphaelNessuna valutazione finora

- Reaction Kinetics of Ammonia & Nitric AcidDocumento116 pagineReaction Kinetics of Ammonia & Nitric AcidMonica Garcia100% (1)

- Izbeljivanje DrvetaDocumento9 pagineIzbeljivanje DrvetaMarko GolubovicNessuna valutazione finora

- Socket Screw Tech Manual PDFDocumento84 pagineSocket Screw Tech Manual PDFrcktechNessuna valutazione finora

- Grundfosliterature 1654 PDFDocumento64 pagineGrundfosliterature 1654 PDFkiranNessuna valutazione finora

- Use of Waste Copper Slag, A Sustainable MaterialDocumento15 pagineUse of Waste Copper Slag, A Sustainable MaterialDaniel VegaNessuna valutazione finora

- Effect of Postweld Heat Treatment On Microstructures and Hardness of TIG Weldment Between P22 and P91 Steels With Inconel 625 Filler MetalDocumento7 pagineEffect of Postweld Heat Treatment On Microstructures and Hardness of TIG Weldment Between P22 and P91 Steels With Inconel 625 Filler MetalParmodSharmaNessuna valutazione finora

- 50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveDocumento2 pagine50B-4KG1 Globe 2050B-4KG1 Angle: Fire Protection Pressure Relief ValveAlbeiro LeivaNessuna valutazione finora

- CH 10Documento9 pagineCH 1000gp1200r100% (1)

- Etals Nternational Imited: Significant Welding Variables Brazing ReferencesDocumento2 pagineEtals Nternational Imited: Significant Welding Variables Brazing ReferencesSSMNessuna valutazione finora

- Tecnicas de SoldaduraDocumento96 pagineTecnicas de SoldaduraRodolfoMarínNessuna valutazione finora