Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

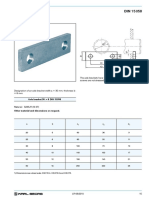

Din 17671

Caricato da

Niculescu MarianDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Din 17671

Caricato da

Niculescu MarianCopyright:

Formati disponibili

Global Marketing for Tube & Pipe www.TubeSolution.

com

DI N 17671 Part 1 WROUGHT COPPER AND COPPER ALLOY TUBES Properties

1.Field of application

In conjunction with the technical delivery conditions specified in DIN 17671 Part 2, this standard specifies the properties of wrought copper and copper alloy tubes for the

dimensional ranges of wall thickness and for outside diameters up to 350mm, as listed in the tables.

The properties of tubes with dimensions outside the dimensional ranges specified shall be agreed at the time of ordering.

Table 1. Copper (composition in accordance with DIN 1787)

Material

Designation Number

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

SF-Cu 2.0090

p .08

zh .20

To be agreed. No strength values specified.

F20 .10 over 3 200 to 260 max. 110 40 55

F22 .10 up to 3 220 to 270 max. 140 40 55

F25 .26 0.5 to 10 250 to 300 min. 150 20 80

F29 .30 up to 5 min. 290 min. 250 6 95

F36

.32 up to 3 min. 360 min 320 - 110

Table 2. Copper-zinc alloys without further alloying elements (Brass) (composition in accordance with DIN 17660)

Material

Designation Number 1)

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

CuZn5 2.0220

Global Marketing for Tube & Pipe www.TubeSolution.com

P .08 To be agreed. No strength values specified.

F22 .10 up to 10 220 to 260 max.130 40 60

F26 .26 up to 10 260 to 320 min. 190 19 85

F32

.30 up to 5 min. 320 min. 260 8 110

CuZn15 2.0240

P .08 To be agreed. No strength values specified.

F26 .10 up to 10 260 to 310 max.150 45 65

F31 .26 up to 10 310 to 370 min. 200 23 95

F37

.30 up to 5 min. 370 min. 290 11 120

CuZn20 2.0250

P .08 To be agreed. No strength values specified.

F27 .10 up to 10 270 to 320 max.160 47 65

F32 .26 up to 10 320 to 390 min. 200 25 100

F39

.30 up to 5 min. 390 min. 300 13 25

CuZn30 2.0265

P .08 To be agreed. No strength values specified.

F28 .10 up to 10 280 to 350 max.180 50 70

F35 .26 up to 10 250 to 420 min. 200 28 110

F42

.30 up to 5 min. 420 min. 320 13 130

CuZn36

CuZn37

2.0335

2.0321

P .08

zh .20

To be agreed. No strength values specified.

F29 .10 up to 10 290 to 370 max.180 50 70

F37

.26 up to 10 370 to 440 min. 200 27 110

Global Marketing for Tube & Pipe www.TubeSolution.com

F44 .30 up to 5 440 to 540 min. 340 12 135

F54

.32 up to 2 370 to 440 min. 470 6 160

CuZn40 2.0360

P .08 To be agreed. No strength values specified.

F34 .10 up to 10 min. 340 max.220 35 80

F41 .26 up to 10 min. 410 min. 220 20 115

F47

.30 up to 5 min. 470 min. 350 11 140

1) The appended numbers.26, 30 and 32 do not apply for the non-stress relieved condition. No values have been specified for strain-hardened stress relieved conditions.

Table 3. Leaded copper-zinc alloys (composition in accordance with DIN 17660)

Table 4. Copper-zinc alloys with further alloying elements (special brass) (composition in accordance with DIN 17660)

Material

Designation Number

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

CuZn20 Al2 2.0460

P .08 To be agreed. No strength values specified.

F22

.10 up to 10 330 120 35 85

CuZn23Al6Mn4Fe3 F78 2.0500.88 up to 20 780 540 8 190

CuZn31Si 1

(CuZn31Si)

2.0490

P .08 To be agreed. No strength values specified.

F44 .27 1 to 8 440 200 30 120

F49

.31 1 to 8 490 290 15 160

CuZn35Ni2

(CuZn35Ni)

2.0540

Global Marketing for Tube & Pipe www.TubeSolution.com

P .08 To be agreed. No strength values specified.

F49 .27 3 to12 490 290 18 130

F54

.31 3 to 8 540 390 14 150

CuZn40 Al1 2.0561

P .08 To be agreed. No strength values specified.

F39 .09 3 to12 390 150 25 110

F44 .27 3 to 8 440 200 20 120

F59

.31 3 to 8 490 260 15 140

CuZn40 Al2 2.0550

P .08 To be agreed. No strength values specified.

F44 .27 4 to 12 540 230 15 150

F49

.31 4 to10 590 250 10 160

CuZn40Mn

(CuZn40Mn)

2.0572

P .08 To be agreed. No strength values specified.

F44 .27 3 to12 440 180 20 125

F49

.31 3 to 8 490 270 18 140

CuZn40Mn 1Pb

(CuZn40MnPb)

2.0580

P .08 To be agreed. No strength values specified.

F39 .09 3 to12 390 150 22 110

F44 .27 3 to 8 440 180 18 125

F49

.31 2 to 5 490 290 15 140

1) Some designations have been amended in accordance with DIN 17660. The previous designations are given in brackets for the purposes of information.

Table 5. Copper-tin alloys (tin bronze) (composition in accordance with DI N 17662)

Global Marketing for Tube & Pipe www.TubeSolution.com

Material

Designation Number

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

CuSn6 2.1020

P .08 To be agreed. No strength values specified.

F34 .10 up to 5 340 to 400 max.260 55 85

F40 .26 up to 5 400 to 490 min. 220 30 135

F49 .30 up to 2 490 to 610 min. 390 12 155

F61

.32 up to 2 min. 610 min. 510 7 185

CuSn8 2.1030

P .08 To be agreed. No strength values specified.

F34 .10 up to 5 390 to 450 max.290 60 90

F40 .26 up to 5 450 to 540 min. 250 28 145

F46

.30 up to 2 min. 540 min. 460 10 170

Table 6. Copper-nickel-zinc alloys (nickel siver) (composition in accordance with DIN 17663)

Material

Designation Number

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

CuNi12Zn20 2.1020

P .08 To be agreed. No strength values specified.

F34 .10 up to 3 340 to 420 max.290 45 85

F42 .26 up to 3 420 to 490 min. 240 28 125

F49

.30 up to 2 min. 490 min. 390 12 150

CuNi18Zn20 2.1030

P .08 To be agreed. No strength values specified.

F37

.10 up to 3 370 to 440 max.290 40 95

Global Marketing for Tube & Pipe www.TubeSolution.com

F44 .26 up to 3 440 to 540 min. 290 20 135

F54

.30 up to 2 min. 540 min. 470 6 150

Table 7. Copper-nickel alloys (composition in accordance with DIN 17 664)

Material

Designation *) Number

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

CuNi10Fe1Mn

(CuNi10Fe)

2.0872

P .08 To be agreed. No strength values specified.

F34

.10 up to 5 min. 290 min. 90 30 80

CuNi30Mn1Fe

(CuNi30Fe)

2.0882

P .08 To be agreed. No strength values specified.

F36

.10 up to 5 360 to 490 min. 120 30 100

*) Some designations have been amended in accordance with DIN 17 664. The previous designations are given in brackets for the purposes of information.

Table 8. Copper-aluminum alloys (aluminum bronze) (composition in accordance with DIN 17665)

Material

Designation *) Number 1)

Wall thickness

mm

Tensile

strength

Rm

N/

0.2%proof

stress

Rp 0.2

N/

min

Elongation

after fracture

A5 %

min

Brinell

hardness

HB

CuAl8 2.0920

P .08 To be agreed. No strength values specified.

F37 .10 2 to10 370 to 450 130 35 90

F49

.30 2 to 8 min. 490 270 15 130

Global Marketing for Tube & Pipe www.TubeSolution.com

CuAl8Fe

(CuAl8Fe)

2.0932

P .08 To be agreed. No strength values specified.

F39 .10 4 to12 390 to 490 150 30 110

F54

.30 4 to 8 min. 540 270 12 145

CuAl10FeMn2

(CuAl10Fe)

2.0936

P .08 To be agreed. No strength values specified.

F64

.98 4 to 8 min. 640 290 10 165

CuAl9Mn2

(CuAl9Mn)

2.0960

P .08 To be agreed. No strength values specified.

F44 .27 3 to12 440 180 20 125

F49

.31 3 to 8 490 270 18 140

CuZn40Mn 1Pb

(CuZn40MnPb)

2.0580

P .08 To be agreed. No strength values specified.

F64 .97 4 to 12 min. 640 340 10 180

CuAl11Ni6Fe5

(CuAl11Ni)

2.0978

P .08 To be agreed. No strength values specified.

F69

.97 2 to 5 490 290 15 140

*) Some designations have been amended in accordance with DIN 17665. The previous designations are given in brackets for the purposes of information.

1) The appended number. 30 does not apply for the non-stress relived condition. If, subject to a particular agreement, the tubes are to be supplied in the stress relived in

the stress relieved condition, the appended number is to be changed into 3.1.

Potrebbero piacerti anche

- Asme B1.20.1 (NPT)Documento2 pagineAsme B1.20.1 (NPT)Victor Castellanos AlegriaNessuna valutazione finora

- SC-2103681-ME1a - Manual 660.YTC. (1x6.5kW) .6 M1546-51G K460-4522-12FO-FC-R M9PG-OT-WP-LCBT + DG90-DB120 + 2xDG45 4xM1Documento61 pagineSC-2103681-ME1a - Manual 660.YTC. (1x6.5kW) .6 M1546-51G K460-4522-12FO-FC-R M9PG-OT-WP-LCBT + DG90-DB120 + 2xDG45 4xM1kiên phạm trungNessuna valutazione finora

- Chaveta para Ejes DIN 15 058Documento1 paginaChaveta para Ejes DIN 15 058JDGM01Nessuna valutazione finora

- Astm A24 (2001) PDFDocumento4 pagineAstm A24 (2001) PDFJim FrostNessuna valutazione finora

- Metal matrix composites: Processing and InterfacesDa EverandMetal matrix composites: Processing and InterfacesR EverettNessuna valutazione finora

- Ansi-Isa 67.04.01 2006Documento23 pagineAnsi-Isa 67.04.01 2006HumbertoRalphOrtizAbacheNessuna valutazione finora

- Korea Herald 20090512Documento1 paginaKorea Herald 20090512raiseyNessuna valutazione finora

- 3 Phase Electrical Wiring InstallationDocumento3 pagine3 Phase Electrical Wiring Installationsofyan_shah100% (2)

- Super Duplex Stainless Steel: Excellent Engineering SolutionsDocumento4 pagineSuper Duplex Stainless Steel: Excellent Engineering SolutionsTXUSNessuna valutazione finora

- ASTM A356 A356M - 07 Steel CastingsDocumento6 pagineASTM A356 A356M - 07 Steel CastingsMacario LeyvaNessuna valutazione finora

- PreviewpdfDocumento58 paginePreviewpdfDavid SuryamanNessuna valutazione finora

- Carbon Steel Tee Rails: Standard Specification ForDocumento7 pagineCarbon Steel Tee Rails: Standard Specification ForAAYNessuna valutazione finora

- Kiln Shell Laser Manual 1Documento24 pagineKiln Shell Laser Manual 1uddinsalahNessuna valutazione finora

- Simmerrings PDFDocumento152 pagineSimmerrings PDFGogyNessuna valutazione finora

- DIN 1683-1-General Toleranve and Maching Allowance of Steel CastingDocumento4 pagineDIN 1683-1-General Toleranve and Maching Allowance of Steel Castingrajksharma100% (1)

- Crushing and Screening Handbook Edition7 23022023 2Documento109 pagineCrushing and Screening Handbook Edition7 23022023 2Gilberto Garnica MurilloNessuna valutazione finora

- Astm A 27 PDFDocumento4 pagineAstm A 27 PDFRyan LasacaNessuna valutazione finora

- Backstop p5c4 VulkanDocumento32 pagineBackstop p5c4 VulkanrodrigoNessuna valutazione finora

- Fajas TransportadorasDocumento11 pagineFajas TransportadorasAnibal Aldava Crispin100% (1)

- Molycop Tech Sheet Small Size BallsDocumento3 pagineMolycop Tech Sheet Small Size BallsLuis Miguel La TorreNessuna valutazione finora

- New Coldbox BinderDocumento8 pagineNew Coldbox BinderAnudatt A. Gowda100% (1)

- Bokela Dyno FilterDocumento12 pagineBokela Dyno FilterAlanNessuna valutazione finora

- Pulp and PaperDocumento8 paginePulp and PaperDevanshGoenkaNessuna valutazione finora

- KE Masterflex RubberDocumento4 pagineKE Masterflex RubberBenjamin StricklandNessuna valutazione finora

- National Fire Code of Canada (PDFDrive)Documento56 pagineNational Fire Code of Canada (PDFDrive)Shabin Shabi100% (1)

- CEMA Technical Report 2014 01 Design Considerations For High Temperature Screw Conveyor Applications Mz30smDocumento9 pagineCEMA Technical Report 2014 01 Design Considerations For High Temperature Screw Conveyor Applications Mz30smLeonardo LimaNessuna valutazione finora

- Design Requirements of Precoat Filters For Water FiltrationDocumento445 pagineDesign Requirements of Precoat Filters For Water FiltrationYesi CeballosNessuna valutazione finora

- Building Technologies: HVAC ProductsDocumento7 pagineBuilding Technologies: HVAC Productsshivv230Nessuna valutazione finora

- Bucket Elevator ConveyorDocumento7 pagineBucket Elevator ConveyorJuan Carlos RNessuna valutazione finora

- Shallow, Rounded Buckets Din 15232: FoldedDocumento1 paginaShallow, Rounded Buckets Din 15232: Foldedmkiani2Nessuna valutazione finora

- A Simplified Model To Calculate The Power Draw For Material Movement in Industrial Rotary KilnsDocumento5 pagineA Simplified Model To Calculate The Power Draw For Material Movement in Industrial Rotary KilnsAnonymous NxpnI6jCNessuna valutazione finora

- Elevators Shallow Buckets DIN 15231Documento1 paginaElevators Shallow Buckets DIN 15231Bob AntunesNessuna valutazione finora

- MUNSCH NPC with-Mechanical-SealDocumento11 pagineMUNSCH NPC with-Mechanical-SealAlfa Pumps0% (1)

- Bubble Cap FucntionDocumento4 pagineBubble Cap FucntionPujo PurwantoNessuna valutazione finora

- Of The Nuclear Safety Standards Commission (KTA)Documento123 pagineOf The Nuclear Safety Standards Commission (KTA)smallik3Nessuna valutazione finora

- Watson Marlow Bredal SPX PumpsDocumento12 pagineWatson Marlow Bredal SPX PumpsCesar Armando Hernandez ViteNessuna valutazione finora

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocumento2 pagine1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFrabmusukeNessuna valutazione finora

- Knelson Concentrator - New Gravity Equipment at The Boliden ConcentratorDocumento12 pagineKnelson Concentrator - New Gravity Equipment at The Boliden ConcentratorAlexCSP11Nessuna valutazione finora

- B Boehler X 70-IG de en 5Documento1 paginaB Boehler X 70-IG de en 5Jorge RushNessuna valutazione finora

- 34g KSBDocumento1 pagina34g KSBGut BeerliNessuna valutazione finora

- Conveyor Chain Installation, Maintenance, & Best Practices - 001Documento19 pagineConveyor Chain Installation, Maintenance, & Best Practices - 001num fistismNessuna valutazione finora

- ABON Sizers BrochureDocumento8 pagineABON Sizers BrochureIgnacio León IbarraNessuna valutazione finora

- Datasheet Sandvik 6r35 enDocumento7 pagineDatasheet Sandvik 6r35 enSimone FerronNessuna valutazione finora

- Specifications For Design of Hot Metal Ladles AISE Standard No PDFDocumento17 pagineSpecifications For Design of Hot Metal Ladles AISE Standard No PDFBuda PesteNessuna valutazione finora

- SULZER CastMaterials - E00510Documento5 pagineSULZER CastMaterials - E00510nhirpara1Nessuna valutazione finora

- ISO 3302-2 - 1998 - Tolerancia Dimensional BorrachasDocumento6 pagineISO 3302-2 - 1998 - Tolerancia Dimensional BorrachasEngineerMecNessuna valutazione finora

- FEECO Complete OfferingsDocumento8 pagineFEECO Complete OfferingsawfahNessuna valutazione finora

- Dimensional Tolerance & Physical Defects of Refractory Bricks-350T TLC-N...Documento5 pagineDimensional Tolerance & Physical Defects of Refractory Bricks-350T TLC-N...Bholanath BeraNessuna valutazione finora

- UHMW-PE (Ultra High Molecular Weight - Polyethylene)Documento2 pagineUHMW-PE (Ultra High Molecular Weight - Polyethylene)Gaurav PatilNessuna valutazione finora

- Track DrillDocumento28 pagineTrack DrillMarco Antonio Aquino AquinoNessuna valutazione finora

- SC470-P Four Inch STUB Cyclone 2016Documento2 pagineSC470-P Four Inch STUB Cyclone 2016Tobias De Somer100% (1)

- SEW Compact Constant Speed Reducer MC SeriesDocumento195 pagineSEW Compact Constant Speed Reducer MC SeriesDênis DáyolNessuna valutazione finora

- AGMA Fatores de ServiçoDocumento4 pagineAGMA Fatores de Serviçochu42Nessuna valutazione finora

- Manual IOM Molino VerticalDocumento137 pagineManual IOM Molino Verticalrodrigo espinoza100% (1)

- Material Comparison F316L Vs F321Documento1 paginaMaterial Comparison F316L Vs F321Vivi OktaviantiNessuna valutazione finora

- HE Crushing Solutions Engineeing and MN OverviewDocumento48 pagineHE Crushing Solutions Engineeing and MN OverviewJorge VillalobosNessuna valutazione finora

- LCC M150 500 3 LCCPump Metal PDFDocumento8 pagineLCC M150 500 3 LCCPump Metal PDFFrancisco Loyola CarrascoNessuna valutazione finora

- Catalogos de Motores Electricos Eberle - DelcrosaDocumento1 paginaCatalogos de Motores Electricos Eberle - DelcrosaMiguel Guillermo Zelaya DamianNessuna valutazione finora

- PBL Series K CatalougeDocumento117 paginePBL Series K CatalougeankitkanujiyaNessuna valutazione finora

- Sepction - 3Documento3 pagineSepction - 3k koradiaNessuna valutazione finora

- Vulcan Industrial Engineering Co. Pvt. LTDDocumento3 pagineVulcan Industrial Engineering Co. Pvt. LTDk koradiaNessuna valutazione finora

- En 10028 P355GHDocumento2 pagineEn 10028 P355GHEvriMert RüzgArdaNessuna valutazione finora

- Boliya Ji (Electric Lay Out)Documento11 pagineBoliya Ji (Electric Lay Out)alive computerNessuna valutazione finora

- Math Formula Chapter 07trigonometryDocumento4 pagineMath Formula Chapter 07trigonometryTanvirul IslamNessuna valutazione finora

- KrishnaDocumento9 pagineKrishnaKrishna KashyapNessuna valutazione finora

- BAHASA INGGRIS 3 MA Ganjil 2016-2017Documento5 pagineBAHASA INGGRIS 3 MA Ganjil 2016-2017Rofial Mubarok100% (1)

- Is-5382-1998 Specification-for-Rubber-Sealing-Rings-for-Gas-Mains-Water-Mains-and-Sewage PDFDocumento23 pagineIs-5382-1998 Specification-for-Rubber-Sealing-Rings-for-Gas-Mains-Water-Mains-and-Sewage PDFDeven Patle0% (1)

- Optimization For Engineering Systems1Documento290 pagineOptimization For Engineering Systems1Tarun SisodiaNessuna valutazione finora

- C 14Documento26 pagineC 14pfylNessuna valutazione finora

- Aestiva MRIDocumento18 pagineAestiva MRImalamandeaceroNessuna valutazione finora

- Structure of The AtomDocumento24 pagineStructure of The AtomKunalNessuna valutazione finora

- Maths Grade 9 Ujian SekoahDocumento10 pagineMaths Grade 9 Ujian SekoahKopi LuwakNessuna valutazione finora

- Backer Rod Brochures - 2pagesDocumento2 pagineBacker Rod Brochures - 2pageszultrsb689Nessuna valutazione finora

- Amini, H., Lee, W. & Di Carlo, D. Inertial Microfluidic Physics. Lab Chip 14, 2739-2761 (2014)Documento23 pagineAmini, H., Lee, W. & Di Carlo, D. Inertial Microfluidic Physics. Lab Chip 14, 2739-2761 (2014)문진식Nessuna valutazione finora

- STANDARD TEST METHOD: Thermostable Alpha-AmylasesDocumento5 pagineSTANDARD TEST METHOD: Thermostable Alpha-Amylasesamithg33Nessuna valutazione finora

- UBD Physics Unit 2 - Energy and The EnviornmentDocumento5 pagineUBD Physics Unit 2 - Energy and The EnviornmentAlfred Melvin SolivaNessuna valutazione finora

- (Guedes - Soares-Joško - Parunov) - Advanced Ship Design For Pollution Prevention-2010Documento303 pagine(Guedes - Soares-Joško - Parunov) - Advanced Ship Design For Pollution Prevention-2010Wee WeeNessuna valutazione finora

- Autonomous VehiclesDocumento20 pagineAutonomous VehiclesKiran KumarNessuna valutazione finora

- Servo Solenoid ValvesDocumento204 pagineServo Solenoid Valveschandushar1604100% (1)

- Energy TypesDocumento3 pagineEnergy TypesSuki TsangNessuna valutazione finora

- Organic Chemistry Lab Formal Report FormatDocumento2 pagineOrganic Chemistry Lab Formal Report FormatJohn Kenneth PranadaNessuna valutazione finora

- Chapter 4 - Drains and SwalesDocumento23 pagineChapter 4 - Drains and SwalesFadhlullah Abu Bakar100% (1)

- Black SmokerDocumento25 pagineBlack SmokergilangNessuna valutazione finora

- One-Factor Short-Rate Models: 4.1. Vasicek ModelDocumento8 pagineOne-Factor Short-Rate Models: 4.1. Vasicek ModelbobmezzNessuna valutazione finora

- Robotics Question Bank IIDocumento2 pagineRobotics Question Bank IIsai sudeepNessuna valutazione finora

- Answers & Solutions: JEE (Advanced) - 2019Documento40 pagineAnswers & Solutions: JEE (Advanced) - 2019Amogh VaishnavNessuna valutazione finora

- Summative Atomic StructureDocumento3 pagineSummative Atomic StructureNovie Mae ReambonanzaNessuna valutazione finora

- Urea BrochureDocumento0 pagineUrea BrochureiosiiosiNessuna valutazione finora

- Okjop, E9Uweeiowuweuhjqwhjwqhhwqjdhjwjkxjasljxlassj A Short-Circuit Design Forces in Power Lines and SubstationsDocumento28 pagineOkjop, E9Uweeiowuweuhjqwhjwqhhwqjdhjwjkxjasljxlassj A Short-Circuit Design Forces in Power Lines and Substationsamit77999Nessuna valutazione finora

- Near-Infrared Spectroscopy NIRS-based Digit Skin TDocumento5 pagineNear-Infrared Spectroscopy NIRS-based Digit Skin TRussell AngelesNessuna valutazione finora