Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tubesheet HE-20 (ASME) Con Spiral Wound PDF

Caricato da

Milena Lemus FonsecaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tubesheet HE-20 (ASME) Con Spiral Wound PDF

Caricato da

Milena Lemus FonsecaCopyright:

Formati disponibili

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 1

Printed: 24/10/2013 at 11:57:33 a.m.

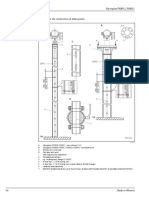

Code Details - Tubesheets/Expansion Joints

Component: Front Tubesheet Rules for the Design of Fixed Tubesheets

ASME VIII-1 2011a UHX-13 Fig.UHX-13.1(b) Controlling Case: UHX-13.4(a)(7)

*** Tubesheet material:

Tubesheet temperature T

TubSh allowable stress S

TubSh mod.elasticity

E

Poisson's rat. tubSh

v

=

=

=

=

SA-516 K02700 Grd 70 Plate

300 F

TubSh metal tmp at rim T'= 300 F

20000 psi

*TubSh th.ex.coe. alpha = 6.9

28100000 psi *TubSh th.ex.coe. alpha' = 6.9

0.3

*(th.exp.coef * 10**6)

*** Shell material:

Design temp. shell

Shell allowable str.

Shell mod.elasticity

Poisson's ratio shell

Ts

Ss

Es

vs

=

=

=

=

SA-516 K02700 Grd 70 Plate

230 F

Shell metal tmp/TubS T's

20000 psi

*Shell th.ex.coe.alpha's

28450000 psi Shell mean metal tmp Tsm

0.3

*Shell th.ex.coe.alphasm

*** Tube material:

Design temp. tubes

Tt

Tube allow.Str. at Tt St

Tube mod.elas. at Tt Et

Poisson's rat. tubes vt

Tube yield stress

Syt

=

=

=

=

=

SA-214 K01807 Wld. tube

300 F

Tubes mean metal tmp Ttm

13412 psi

Tube allow.Str. at T Stt

28100000 psi Tube mod.elas. at T Ett

0.3

*Tube th.ex.coe.alphatm

23000 psi

*(th.exp.coef * 10**6)

*** Channel material:

Design temp. channel

Channel all. stress

Channel mod.elast.

Poisson's rat.channel

=

=

=

=

SA-516 K02700 Grd 70 Plate

300 F

Channel metal tmp TS T'c = 300 F

20000 psi

*Chan.th.ex.coe.alpha'c = 6.9

28100000 psi

*(th.exp.coef * 10**6)

0.3

Tc

Sc

Ec

vc

*** Adjacent shell matl:

Adj Shell all. str. Ss,1 = -

Tubesheet thickness

=

=

=

=

230 F

6.76

230 F

6.76

=

=

=

=

300 F

13412 psi

28100000 psi

6.9

*Shell th.ex.coe.alpha's1= 0.0

*Shell th.ex.coe.alpha'sm1=0.0

h = 2.625 in

Actual tubesheet thk

ha = 2.625 in

Shell side corr allow c = 0.125 in

SS TubSh corr allow

cs = 0.125 in

Tube side cor.allow.

TS TubSh corr allow

c = 0.0625 in

ct = 0.125 in

Shell diameter, Ds

Channel diameter, Dc

Shell thickness, ts

Adjacent shell thk ts,1

Channel thickness, tc

Corroded case

48.25 in

48.125 in

0.375 in

0.0 in

0.4375 in

Minimum TubSh thk, hmin

Thickness h used

Tubesheet OD

2.0645 in

2.375 in

A = 61.75 in

Uncorroded case

48.0 in

48.0 in

0.5 in

0.0 in

0.5 in

2.0779 in

2.625 in

Bolt circle diam.

C = 58.25 in

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Shell gasket diam.

Gs

Gasket reaction diam. G

Number of tubes

Nt

Pass partition groove hg

Tube outside diam.

dt

Tube pitch

p

Tube projection

tpr

Tube length L

L

Tube expanded depth ltx

Tube buckling factor

k

Outermost tube rad.

ro

Shell radius

as

Exp.joint spring rate kj

=

=

=

=

=

=

=

=

=

=

=

=

=

55.5 in

1874

0.1875 in

0.75 in

1.0 in

0.125 in

354.5 in

2.5 in

1

23.375 in

24.0 in

-

Page 2

Printed: 24/10/2013 at 11:57:33 a.m.

Channel gasket diam. Gc

Gasket reaction diam. G1

Flange load

W*

Eff.tube side groove h'g

Tube thickness

tt

Center-to-center dis UL

Tube corrosion allow. c

Tube length Lt

Lt

Tube exp.depth ratio rho

Unsupported tube span l

Unsupp.length lt=k*l lt

Channel radius

ac

EJ diameter

Dj

=

=

=

=

=

=

=

=

=

=

=

=

=

55.5 in

55.5 in

1356078 lbf

0.0 in

0.083 in

1.5 in

359.75 in

0.952

30.0 in

30.0 in

27.75 in

-

Pressure cases:

Shell pressure, Ps = 130 psi

Shell vacuum pr.Psv= -

Tubes pressure, Pt = 120 psi

Tubes vacuum pr.Ptv= -

Controlling tubesheet thickness case:

Shell pressure, Ps = 130 psi

UHX-13.5.1 Step 1.

Tubes pressure, Pt = 120 psi

Determine Do, Mu, Mu* and h'g from UHX-11.5.1.

Do = 2 * ro + dt

Do

mu = (p - dt) / p

mu

d* = MAX(dt-2*tt*(Ett/E)*(Stt/S)*Rho),(dt-2*tt))

d*

Pass lane area limit

4*Do*p

Actual pass lane area, AL

AL

Effective pitch = p/SQRT(1-(4*MIN[AL,4*Do*p]/Pi*Do**2))

p*

mu* = (p* - d*) / p*

mu*

h'g = MAX[(hg-ct),(0)]

h'g

=

=

=

=

=

=

=

=

47.5 in

0.25

0.644 in

190 in2

71.25 in2

1.0207 in

0.3691

0.0 in

=

=

=

=

=

23.75 in

1.0105

1.1684

0.5328

0.7167

Calculate ao, rhos, rhoc, xs and xt

ao =

rhos

rhoc

xs =

xt =

radius of the perforated region = Do / 2

= as/ao

= ac/ao

1 - Nt*(dt/(2*ao))**2

1 - Nt*((dt-2*tt)/(2*ao))**2

ao

rhos

rhoc

xs

xt

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 3

Printed: 24/10/2013 at 11:57:33 a.m.

UHX-13.5.2 Step 2. Calculate the shell axial stiffness Ks, tube axial

stiffness Kt, and stiffness factors Ks,t and J

Shell axial stiffness, Ks = PI*ts(Ds+ts)*Es/L

Ks =

Ks* = PI*(Ds+ts)/((L-2*l1)/(Es*ts)+(2*l1/(Es,1*ts,1)) Ks* =

Tube axial stiffness, Kt = PI*tt(dt-tt)*Et/L

Kt =

Factor Ks,t = Ks/(Nt*Kt) or Ks*/(Nt*Kt)

Ks,t =

J = 1 / (1 + (Ks/Kj))

J =

6114031 lbf/in

13786 lbf/in

0.2367

1.0

Calculate shell coefficients betas, ks, lambdas and deltas

betas = (12*(1-vs**2))**0.25 / ((Ds+ts)*ts)**0.5

betas =

ks = betas*(Es*ts**3)/(6*(1-vs**2))

ks =

lambdas=(6*Ds/h**3)*ks*(1+h*betas+(h**2*betas**2)/2) lambdas =

deltas = (Ds**2/(4*Es*ts))*(1-vs/2)

deltas =

0.3691

240436

9335281

0.0000344

Calculate channel coefficients betac, kc, lambdac and deltac

betac = (12*(1-vc**2))**0.25 / ((Dc+tc)*tc)**0.5

betac =

kc = betac*(Ec*tc**3)/(6*(1-vc**2)

kc =

lambdac=(6*Dc/h**3)*kc*(1+h*betac+(h**2*betac**2)/2) lambdac =

deltac = (Dc**2/(4*Ec*tc))*(1-vc/2)

deltac =

0

0

0

0

NOTE: If the effect of plasticity used, Es or Ec will be Es* or Ec*

UHX-13.5.3 Step 3. Calculate h/p. If rho changes, recalculate d* and mu*

from UHX-11.5.1. Determine E*/E and v* relative to h/p from UHX-11.5.2

Layout: Triangular

Tubesheet thickness

From fig. UHX-11.2 or UHX-11.3 - E*/E = 0.3725

h/p = 2.625

Effective Tubsheet Mod.Elasticity E* = 10467052 psi

Parameter Xa = (24*(1-(v*)**2)*Nt*(Et*tt*(dt-tt)*

ao**2)/((E*)*L*h**3))**0.25

h = 2.625 in

v* = 0.3193

mu* = 0.3691

Xa = 4.794

UHX-13.5.4 Step 4. Calculate diameter ratio K and coefficient F.

K = A / Do

F = ((1-v*)/E*)*(lambdas+lambdac+E*Ln(K))

K = 1.300

F = 1.086

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 4

Printed: 24/10/2013 at 11:57:33 a.m.

Parameters Zd, Zv, Zw and Zm from Table UHX-13.1

Psi1(Xa)=bei(Xa)+(1-v*)/Xa*ber'(Xa)

Psi2(Xa)=ber(Xa)-(1-v*)/Xa*bei'(Xa)

Za

Zd

Zv

Zw

Zm

=

=

=

=

=

Psi1(Xa) = 0.3509

Psi2(Xa) = -4.9581

bei'(Xa)*Psi2(Xa)-ber'(Xa)*Psi1(Xa)

(ber(Xa)*Psi2(Xa)+ bei(Xa)*Psi1(Xa))/(Xa**3*Za)

(ber'(Xa)*Psi2(Xa)+ bei'(Xa)*Psi1(Xa))/(Xa**2*Za)

(ber'(Xa)*ber(Xa)+ bei'(Xa)*bei(Xa))/(Xa**2*Za)

(ber'(Xa)**2+bei'(Xa)**2)/(Xa*Za)

Za

Zd

Zv

Zw

Zm

=

=

=

=

=

17.7908

0.0139

0.0445

0.0445

0.307

Phi

Q1

Qz1

Qz2

U

=

=

=

=

=

1.4334

-0.0369

3.2352

8.7434

17.4868

Calculate Q1, Qz1, Qz2 and U

Phi = (1+v*) * F

Q1 = (rhos-1-Phi*Zv)/(1+Phi*Zm)

Qz1 = ((Zd+Q1*Zw)*Xa**4)/2

Qz2 = ((Zv+Q1*Zm)*Xa**4)/2

U = ((Zw+(rhos-1)*Zm)*Xa**4)/(1+Phi*Zm)

UHX-13.5.5 Step 5.

UHX-13.5.5(a) Calculate gamma (shown is max value for all cases)

gamma = (alphatm*(Ttm-Tamb)-alphasm*(Tsm-Tamb))*L

(= 0 used for load cases 1, 2, 3)

gamma = 0.1792 in

UHX-13.5.5(b) Calculate omegas, omegas*, omegac, omegac*

omegas = rhos*ks*betas*deltas*(1+h*betas)

omegas* = ao**2*((rhos**2-1)*(rhos-1))/4-omegas

omegac = rhoc*kc*betac*deltac*(1+h*betac)

omegac* = ao**2*(((rhoc**2+1)*(rhoc-1))/4(rhos-1)/2)-omegac

omegas = 6.0783

omegas* = -6.0469

omegac = 0.0

omegac* = 53.2049

UHX-13.5.5(c) Calculate gammab

gammab = (Gc-C)/Do

gammab = -0.0579

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Fig.UHX-13.1(b)

Page 5

Printed: 24/10/2013 at 11:57:33 a.m.

Controlling Case: UHX-13.4(a)(7)

UHX-13.5.6 Step 6. For each loading case calculate Ps', Pt', Pgamma, Pw,

Prim, and effective pressure Pe.

Ps' = (xs+2*(1-xs)*vt+(2/Kst)*(Ds/Do)**2*vs(Rhos**2-1)/(J*Kst)-((1-J)/(2*J*Kst))*

(DJ**2-Ds**2)/Do**2 ) * Ps

Ps' = 430.65 psi

Pt' = (xt+2*(1-xt)*vt+1/(J*Kst))*Pt

Pt' = 613.47 psi

Pgamma

= (Nt*Kt/(Pi*ao**2))*gamma

Pgamma = 2612.09 psi

PW

= -(U/ao**2)(gammab/(2*Pi))*W*

Prim

= -(U/ao**2)*((omegas*)(Ps)-(omegac*)(Pt))

PW = 387.37 psi

Prim = 222.3 psi

Effective pressure, Pe

Pe =

J*Kst/(1+J*Kst(Qz1+(rhos-1)Qz2))

* (Ps'-Pt'+Pgamma+PW+Prim)

Pe = 402.36 psi

UHX-13.5.7 Step 7. For each loading case calculate Q2 and Q3.

Q2 = ((omegas*)*Ps-(omegac*)*Pt)((omegas*(Ps*)-omegac*(Pc*))+

(gammab/(2*Pi))*(W*)/(1+Phi*Zm)

Q3 = Q1 + 2*Q2 / (Pe*ao**2)

Q2 = -13656.3809

Q3 = -0.1573

Using Xa and Q3, determine coefficient Fm for each loading case from

either Table UHX-13.1 or Figs. UHX-13.3.-1 and UHX-13.3.-2.

Controlling x for Fm, x = 4.794

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 6

Printed: 24/10/2013 at 11:57:33 a.m.

Fm(x) = (Qv(x) + Q3 * Qm(x)) / 2

Fm = MAX|Fm(x)|

Fm(x) = -0.0786

Fm = 0.0786

For each loading case, calculate the bending stress in the tubesheet

sigma = (1.5*Fm/mu*)*(2*ao/(h-h'g))**2 * Pe

sigma = 42107 psi

|sigma| <= 2*Sy

42107 psi <= 67200 psi

UHX-13.5.8 Step 8. For each loading case, calculate the maximum shear

stress in the tubesheet across the tubesheet diameter

Area enclosed by perimeter

Perimeter of the tube layout

Shear diameter, Dia = DL or Do

|Pe| = 402.36

3.2*S*mu*h/Do = 884.21

Ligament efficiency, mu

DL = 4*AP/CP

AP

CP

DL

Do

Dia

=

=

=

=

=

1604.74 in2

154.7128 in

41.4896 in

47.5 in

47.5 in

mu = (p-dt)/p = 0.25

Controlling x for FQ, x = 4.794

FQ(x) = (Qb(x) + Q3 * Qa(x))

FQ = MAX|FQ(x)|

FQ(x) = 1.0

FQ = 1.0

Shear stress at periphery,

tau = ( 1/(4*mu))*(Dia/h)*Pe tau = 7281 psi

Max shear across diameter,

tau = (FQ/(4*mu))*(Dia/h)*Pe tau = 7281 psi

|tau| <= 0.8*S

7281 psi <= 16000 psi

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

UHX-13.5.9 Step 9.

Page 7

Printed: 24/10/2013 at 11:57:33 a.m.

Perform this step for each loading case.

UHX-13.5.9(a) Check the axial tube stress.

UHX-13.5.9(a)(1) For each loading case determine coefficient Ft,min

and Ft,max from Table UHX-13.2 and calculate the two extreme values

of sigmat,1 and sigmat,2. These values may be positive or negative

Ft(x) = [Zd(x)+Q3*Zw(x)]*(Xa**4/2)

for 0 <= x <= Xa

Ft,min = MIN[[Zd(x)+Q3*Zw(x)]*(Xa**4/2)]

Ft,max = MAX[[Zd(x)+Q3*Zw(x)]*(Xa**4/2)]

Ft,min = -0.2709

Ft,max = 1.8349

UHX-13.5.9(a)(1)(a) When Pe <> 0:

sigmat,1 = ((Ps*xs-Pt*xt)-Pe*Ft,min)/(xt-xs)

sigmat,2 = ((Ps*xs-Pt*xt)-Pe*Ft,max)/(xt-xs)

sigmat,1 = 502 psi

sigmat,2 = -4105 psi

UHX-13.5.9(a)(2) Determine sigmat,max

sigmat,max = MAX(|sigmat,1|,|sigmat,2|)

Allowable tube stress in tension

sigmat,max = 4105 psi

St = 26824 psi

UHX-13.5.9(b) Check the tube-to-tubesheet joint

UHX-13.5.9(b)(1) Calculate the tube-to-tubesheet joint load, Wt

Wt = sigmat,max*Pi*(dt-tt)*tt

Wt = 714 lbf

UHX-13.5.9(b)(2) Determine the maximum allowable load for the

tube-to-tubesheet joint design Lmax

UW-18(d) max

UW-20

max

App.A max No

App.A max

load

=

load

=

test load =

test load =

2333 lbf

2799 lbf

Lmax = 2333 lbf

UHX-13.5.9(c) Check the tubes for buckling.

UHX-13.5.9(c)(1) Calculate largest buckling length lt

Tube buckling factor

Unsupported tube span

k = 1

l = 30.0 in

lt = largest unsupported buckling length = k*l

lt = 30.0 in

UHX-13.5.9(c)(2) Calculate rt, Ft and Ct

rt = SQRT(dt**2+(dt-2*tt)**2)/4

Ft = lt/rt

Ct = SQRT(2*PI**2*(Et/Syt))

UHX-13.5.9(c)(3) Determine the factor of safety Fs

Fsc = (3.25-0.25*(Zd+Q3*Zw)*Xa**4) = 2.3387

rt = 0.2376 in

Ft = 126.242

Ct = 155.2938

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Fs = MAX((1.25, Fsc)

Page 8

Printed: 24/10/2013 at 11:57:33 a.m.

(Fs need not be > 2)

Fs = 2.0

UHX-13.5.9(c)(4) Determine the buckling stress limit Stb

For Ct <= Ft

For Ct > Ft

Stb = MIN[(1/Fs)*(PI**2*Et/(Ft**2),St]

Stb = MIN[(Syt/Fs)*(1-Ft/(2*Ct)) ,St]

Stb = Stb = 6826 psi

UHX-13.5.9(c)(5) Determine sigmat,min

sigmat,min = MIN(sigmat,1 , sigmat,2)

sigmat,min = -4105 psi

|sigmat,min| <= Stb

4105 psi <= 6826 psi

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 9

Printed: 24/10/2013 at 11:57:33 a.m.

UHX-13.5.10 Step 10. For each loading case, calculate the stresses in the

shell and /or channel integral with the tubesheet.

Calculate the axial membrane stress sigmasm, axial bending stress sigmasb

and total axial stress sigmas in the shell at its junction to the tubesheet

sigmasm = ao**2/[ts*(2*as+ts)]*[Pe+(rhos**2-1)

*(Ps-Pt)]+as**2/[ts*(2*as+ts)]*Pt

sigmasm = 12214 psi

sb1 = (6/ts**2)*ks

sb2 = betas*deltas*Ps

sb3 = 6*(1-(v*)**2)/(E*)*(ao**3/h**3)*(1+(h*betas/2))

sb4 = Pe*(Zv+Zm*Q1)+(2/ao**2)*Zm*Q2

sigmasb = sb1*(sb2+sb3*sb4)

sigmasb = 4499 psi

sigmas = |sigmasm| + |sigmasb|

sigmas = 16714 psi

sigmas <= 2*Sy

16714 psi <= 68880 psi

ASME VIII-1 2011a UHX-13 - Rules for the Design of Fixed Tubesheets

ASME Fig.UHX-13.1(b)

All Load Cases

Controlling case:

Load case:

Tubeside press, Pt

Shellside press, Ps

Axial diff.Th.Exp

120

0

0.0

0

130

0.0

120

130

0.0

***

7

0

0

0.1792

120

0

0.1792

0

130

0.1792

120

130

0.1792

TubSh Bending stress

Max TubSh Bending st

Min TubSh thk

-16258

30000

1.9489

2905

30000

0.8599

17795

30000

2.0361

30232

67200

1.7607

39339

67200

2.0084

33000

67200

1.8395

42107

67200

2.0779

TubSh Shear stress

Max TubSh Shear str

Min TubSh thk

-1079

16000

0.1902

1090

16000

0.2414

1163

16000

0.1136

7186

16000

1.179

6191

16000

1.0156

8276

16000

1.3578

7281

16000

1.1945

Tubesheet thickness

2.625

2.625

2.625

2.625

2.625

2.625

2.625

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 10

Printed: 24/10/2013 at 11:57:33 a.m.

Component: Front Tubesheet

ASME Fig.UHX-13.1(b)

All Load Cases

Load case:

Tubes controlling:

Tubes stress st,1

Tubes stress st,2

Max Tubes tens.str

Max Tubes comp.str

-1035

1752

13412

10921

538

-560

13412

7497

1192

-645

13412

6826

819

-5022

26824

6826

-37

-3636

26824

6826

***

1357

-5582

26824

6826

502

-4105

26824

6826

Shell controlling:

Total shell stress

Max shell stress

Max shell stress EP

29419

30000

68880

15572

30000

68880

16778

30000

68880

21342

68880

20356

68880

***

36914

68880

16714

68880

Channel controlling:

Total channel stress

Max channel stress

Max channel str. EP

EP factor - Facts(*)

EP factor - Factc(*)

1.0

1.0

1.0

1.0

1.0

1.0

(*) <= 1 used in calculations

Tube stress across the tubesheet diameter (0 <= x <= Xa)

Load case:

Ft,min

Ft,max

-2.425

9.487

-0.494

2.858

sigmat,1

Location x

-1035

2.013

538

0.096

1192

4.794

sigmat,2

Location x

1752

4.794

-560

4.794

Maximum stress

Max buckling stress

13412

10921

13412

7497

-13.702 -0.379

5.92

2.326

-0.232

1.703

-0.394

2.396

-0.271

1.835

819

0.096

-37

0.096

1357

0.096

502

0.096

-645

2.589

-5022

4.794

-3636

4.506

-5582

4.794

-4105

4.698

13412

6826

26824

6826

26824

6826

26824

6826

26824

6826

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Shell axial membrane stress, sigmasm

Load case:

|sigmasm|

Allowable stress

(JE*S) JE = 0.85

Compression:

sigmasm

Allowable stress

ASME VIII-1 2011a

1791

17000

1465

17000

3256

17000

9237

40000

10749

40000

10703

40000

12214

40000

UHX-13 - Fixed Tubesheets - All Cases

Ps

psi

Pt

psi

Gamma

in

0

130

130

0

0

130

130

120

0

120

0

120

0

120

0

0

0

0.1792

0.1792

0.1792

0.1792

Load case

1

2

3

4

5

6

7

Printed: 24/10/2013 at 11:57:33 a.m.

Units: psi

Load case

1

2

3

4

5

6

7

Page 11

P's

psi

P't

psi

0

430.7

430.7

0

0

430.7

430.7

613.5

0

613.5

0

613.5

0

613.5

Pgamma

psi

0

0

0

2612.1

2612.1

2612.1

2612.1

Pomega

psi

0

0

0

0

0

0

0

Ps*

psi

Pc*

psi

W*

lbf

0

0

0

0

0

0

0

0

0

0

0

0

0

0

317150

0

317150

1356078

1356078

1356078

1356078

Pw

psi

90.6

0

90.6

387.4

387.4

387.4

387.4

Prim

psi

197.9

24.4

222.3

0

197.9

24.4

222.3

Pe

psi

-43

60.2

17.2

397.1

342.1

457.4

402.4

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Load case

1

2

3

4

5

6

7

Q2

Q3

-6462.9

-545.9

-7008.8

-8676.9

-13110.5

-9222.8

-13656.4

0.4957

-0.0691

-1.4799

-0.1144

-0.1728

-0.1084

-0.1573

Fm

Sigma

psi

0.2706

0.0345

0.74

0.0572

0.0864

0.0542

0.0786

Printed: 24/10/2013 at 11:57:33 a.m.

Sigma All

psi

-16258

2905

17795

30232

39339

33000

42107

30000

30000

30000

67200

67200

67200

67200

Page 12

FQ

1.3865

1

3.7318

1

1

1

1

Tau

psi

Tau All

psi

-1079

1090

1163

7186

6191

8276

7281

16000

16000

16000

16000

16000

16000

16000

ASME VIII-1 2011a UHX-13 - Fixed Tubesheets - All Cases

Load case

1

2

3

4

5

6

7

Fs

1.25

1.8209

2

2

2

2

2

Ft,min

-2.425

-0.494

-13.702

-0.379

-0.232

-0.394

-0.271

Load case

Sigsm

psi

Sigsb

psi

1791

1465

3256

9237

10749

10703

12214

-27629

14106

-13522

12105

-9607

26211

4499

1

2

3

4

5

6

7

Ft,max

Sigt,1

psi

Sigt,2

psi

9.487

2.858

5.92

2.326

1.703

2.396

1.835

-1035

538

1192

819

-37

1357

502

1752

-560

-645

-5022

-3636

-5582

-4105

|Sigs| Sigsall

psi

psi

29419

15572

16778

21342

20356

36914

16714

30000

30000

30000

68880

68880

68880

68880

Sigcm

psi

Sigcb

psi

Sigt,All

psi

13412

13412

13412

26824

26824

26824

26824

|Sigc|

psi

-

Stb

psi

10921

7497

6826

6826

6826

6826

6826

Sigcall

psi

-

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 13

Printed: 24/10/2013 at 11:57:33 a.m.

Type of tube-to-TS joint: 'k' - Expanded with no grooves

Load case:

Wt tube-TS Load, lbf

Allowable no-test

Allowable test

Factor k

Max load K*At*Sa

1

305

1166

1400

1

2333

2

97

1166

1400

1

2333

3

207

1166

1400

1

2333

4

873

2333

2799

2

4665

5

632

2333

2799

2

4665

6

971

2333

2799

2

4665

7

714

2333

2799

2

4665

Allowable Loads per ASME Section VIII Div.1 2011a Appendix A

No Test

Type

Joint description

fr

Lmax

fr

a

Welded only a >= 1.4t

0.8

3732

1

b

Welded only t <= a < 1.4t

0.55

1283

0.7

b-1 Welded only a <= t

0

0 *

0.7

e

Welded a >= 1.4t and expanded

0.8

3732

1

f

Welded a < 1.4t exp.with 2 grooves 0.75

3499

0.95

g

Welded a < 1.4t exp.with 1 groove

0.65

3032

0.85

h

Welded a < 1.4t exp.with no grooves 0.5

2333

0.7

i

Expanded with 2 grooves

0.7

3266

0.9

j

Expanded with 1 groove

0.65

3032

0.8

k

Expanded with no grooves

0.5

2333

0.6

* = Load calculated exceeds code allowable for this joint type.

For joints types a,b,b-1,c,d,e :

Lmax = At*Sa*fr

For joints types f,g,h,

:

Lmax = At*Sa*fe*fr*fy

For joints types i,j,k

:

Lmax = At*Sa*fe*fr*fy*ft

Cross-sectional area At

Max stress St = At*Sa St

Tubesheet yield str. Stt

fe = (ltx/do or 1)

fe

ft = (Po+Pt)/Po

ft

ft = used (0<ft<=1)

ft

Tube OD

do

Tube thickness

t

Tubes Mod.Elasticity EtT

Tubes Coef.Th.Exp.(*) at

Friction coefficient muF

=

=

=

=

=

=

=

=

=

=

=

0.1739 in2

2333 psi

33600 psi

1

1

1

0.75 in

0.083 in

28100000 psi

6.9

0.5

Test

Lmax

4665

1633

3266

4665

4432

3965

3266

4199

3732

2799

Tube allowable stress Sa = 13412 psi

Tube yield stress

Stu

Min Yield Str. (Stt,Stu)

fy = Stt/Stu

fy = used (0<fy<=1)

fy

Expanded length

ltx

TubSh mean metal tmp

T

TubSh Mod.Elast.

EsT

TubSh Coef.Th.Exp.(*) as

(*)=*10**6 in/in/F

=

=

=

=

=

=

=

=

23000 psi

23000 psi

1.46

1

2.5 in

300 F

28100000 psi

6.9

Tube to tube hole Interfacial Pressure:

Po = ((do*t-t**2)*st)/(do*ltx*muF)

Pt = (T-Tamb)*(at-as)*(EtT*EsT)/(EtT+EsT)

For joint types i, j, k:

Po = 1358 psi

Pt = 0 psi

Po + Pt <= 0.58*SigmaM

1358 psi <= 13340 psi

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 14

Printed: 24/10/2013 at 11:57:33 a.m.

UHX-9 Tubesheet Flanged Extension

G = diameter of gasket load reaction

hG = gasket moment arm

Sa = allowable stress for tubesheet extension

at ambient temperature

Sd = allowable stress for tubesheet extension

at design temperature

Ta = ambient temperature

Td = design temperature

Wo = flange design bolt load, opeating conditions

Wg = flange design bolt load, gasket seating

G = 55.0 in

hG = 1.625 in

Sa = 20000 psi

Sd

Ta

Td

Wo

Wg

=

=

=

=

=

20000 psi

70 F

300 F

317150 lbf

1356078 lbf

Minimum required thickness of the tubesheet flanged extension

hro = SQRT((1.9 * Wo * hG) / (Sd * G))

hro = 0.9435 in

hrg = SQRT((1.9 * Wg * hG) / (Sa * G))

hrg = 1.951 in

hr = MAX[hro, hrg]

hr = 1.951 in

Unperforated tubesheet segment - minimum thickness

UG-34(c)(3)

Unperf. short span

d

Controlling pressure

P

Factor C

C

Z = 3.4 - (2.4 * d) / D

=

=

=

=

1.875 in

130 psi

0.3

3.158

Unperf. long span

Allowable stress

Joint efficiency

(max 2.5)

D

S

E

Z

=

=

=

=

18.5994 in

20000 psi

1

2.5

Effect of bolt load on unperforated tubesheet segment, if any

Bolt circle

Bolt load

BC = 58.25 in

W = 317150 lbf

Segment length

Gasket moment arm

L = 182.9978 in

hg = 1.625 in

Minimum thickness of unperforated segment:

t = d * SQRT(Z*C*P/S*E + 6*W*hg/S*E*L*d**2) = 0.9284 in

Component: Rear Tubesheet

Rules for the Design of Fixed Tubesheets

ASME VIII-1 2011a UHX-13 Fig.UHX-13.1(b) Controlling Case: UHX-13.4(a)(7)

*** Tubesheet material:

Tubesheet temperature T

TubSh allowable stress S

TubSh mod.elasticity

E

Poisson's rat. tubSh

v

=

=

=

=

SA-516 K02700 Grd 70 Plate

300 F

TubSh metal tmp at rim T'= 300 F

20000 psi

*TubSh th.ex.coe. alpha = 6.9

28100000 psi *TubSh th.ex.coe. alpha' = 6.9

0.3

*(th.exp.coef * 10**6)

*** Shell material:

Design temp. shell

Shell allowable str.

Shell mod.elasticity

Poisson's ratio shell

=

=

=

=

SA-516 K02700 Grd 70 Plate

230 F

Shell metal tmp/TubS T's

20000 psi

*Shell th.ex.coe.alpha's

28450000 psi Shell mean metal tmp Tsm

0.3

*Shell th.ex.coe.alphasm

*** Tube material:

Ts

Ss

Es

vs

SA-214 K01807 Wld. tube

=

=

=

=

230 F

6.76

230 F

6.76

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 15

Printed: 24/10/2013 at 11:57:33 a.m.

Design temp. tubes

Tt

Tube allow.Str. at Tt St

Tube mod.elas. at Tt Et

Poisson's rat. tubes vt

Tube yield stress

Syt

=

=

=

=

=

300 F

13412 psi

28100000 psi

0.3

23000 psi

*** Channel material:

Design temp. channel

Channel all. stress

Channel mod.elast.

Poisson's rat.channel

=

=

=

=

SA-516 K02700 Grd 70 Plate

300 F

Channel metal tmp TS T'c = 300 F

20000 psi

*Chan.th.ex.coe.alpha'c = 6.9

28100000 psi

*(th.exp.coef * 10**6)

0.3

Tc

Sc

Ec

vc

*** Adjacent shell matl:

Adj Shell all. str. Ss,1 = -

Tubesheet thickness

Tubes mean metal tmp Ttm

Tube allow.Str. at T Stt

Tube mod.elas. at T Ett

*Tube th.ex.coe.alphatm

*(th.exp.coef * 10**6)

=

=

=

=

300 F

13412 psi

28100000 psi

6.9

*Shell th.ex.coe.alpha's1= 0.0

*Shell th.ex.coe.alpha'sm1=0.0

h = 2.625 in

Actual tubesheet thk

ha = 2.625 in

Shell side corr allow c = 0.125 in

SS TubSh corr allow

cs = 0.125 in

Tube side cor.allow.

TS TubSh corr allow

c = 0.0625 in

ct = 0.125 in

Shell diameter, Ds

Channel diameter, Dc

Shell thickness, ts

Adjacent shell thk ts,1

Channel thickness, tc

Corroded case

48.25 in

48.125 in

0.375 in

0.0 in

0.4375 in

Minimum TubSh thk, hmin

Thickness h used

Tubesheet OD

1.9961 in

2.375 in

A = 61.75 in

Uncorroded case

48.0 in

48.0 in

0.5 in

0.0 in

0.5 in

2.0576 in

2.625 in

Bolt circle diam.

C = 58.25 in

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Shell gasket diam.

Gs

Gasket reaction diam. G

Number of tubes

Nt

Pass partition groove hg

Tube outside diam.

dt

Tube pitch

p

Tube projection

tpr

Tube length L

L

Tube expanded depth ltx

Tube buckling factor

k

Outermost tube rad.

ro

Shell radius

as

Exp.joint spring rate kj

=

=

=

=

=

=

=

=

=

=

=

=

=

55.5 in

1874

0.0 in

0.75 in

1.0 in

0.125 in

354.5 in

2.5 in

1

23.375 in

24.0 in

-

Page 16

Printed: 24/10/2013 at 11:57:33 a.m.

Channel gasket diam. Gc

Gasket reaction diam. G1

Flange load

W*

Eff.tube side groove h'g

Tube thickness

tt

Center-to-center dis UL

Tube corrosion allow. c

Tube length Lt

Lt

Tube exp.depth ratio rho

Unsupported tube span l

Unsupp.length lt=k*l lt

Channel radius

ac

EJ diameter

Dj

=

=

=

=

=

=

=

=

=

=

=

=

=

55.5 in

55.5 in

1304985 lbf

0.0 in

0.083 in

1.5 in

359.75 in

0.952

30.0 in

30.0 in

27.75 in

-

Pressure cases:

Shell pressure, Ps = 130 psi

Shell vacuum pr.Psv= -

Tubes pressure, Pt = 120 psi

Tubes vacuum pr.Ptv= -

Controlling tubesheet thickness case:

Shell pressure, Ps = 130 psi

UHX-13.5.1 Step 1.

Tubes pressure, Pt = 120 psi

Determine Do, Mu, Mu* and h'g from UHX-11.5.1.

Do = 2 * ro + dt

Do

mu = (p - dt) / p

mu

d* = MAX(dt-2*tt*(Ett/E)*(Stt/S)*Rho),(dt-2*tt))

d*

Pass lane area limit

4*Do*p

Actual pass lane area, AL

AL

Effective pitch = p/SQRT(1-(4*MIN[AL,4*Do*p]/Pi*Do**2))

p*

mu* = (p* - d*) / p*

mu*

h'g = MAX[(hg-ct),(0)]

h'g

=

=

=

=

=

=

=

=

47.5 in

0.25

0.644 in

190 in2

71.25 in2

1.0207 in

0.3691

0.0 in

=

=

=

=

=

23.75 in

1.0105

1.1684

0.5328

0.7167

Calculate ao, rhos, rhoc, xs and xt

ao =

rhos

rhoc

xs =

xt =

radius of the perforated region = Do / 2

= as/ao

= ac/ao

1 - Nt*(dt/(2*ao))**2

1 - Nt*((dt-2*tt)/(2*ao))**2

ao

rhos

rhoc

xs

xt

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 17

Printed: 24/10/2013 at 11:57:33 a.m.

UHX-13.5.2 Step 2. Calculate the shell axial stiffness Ks, tube axial

stiffness Kt, and stiffness factors Ks,t and J

Shell axial stiffness, Ks = PI*ts(Ds+ts)*Es/L

Ks =

Ks* = PI*(Ds+ts)/((L-2*l1)/(Es*ts)+(2*l1/(Es,1*ts,1)) Ks* =

Tube axial stiffness, Kt = PI*tt(dt-tt)*Et/L

Kt =

Factor Ks,t = Ks/(Nt*Kt) or Ks*/(Nt*Kt)

Ks,t =

J = 1 / (1 + (Ks/Kj))

J =

6114031 lbf/in

13786 lbf/in

0.2367

1.0

Calculate shell coefficients betas, ks, lambdas and deltas

betas = (12*(1-vs**2))**0.25 / ((Ds+ts)*ts)**0.5

betas =

ks = betas*(Es*ts**3)/(6*(1-vs**2))

ks =

lambdas=(6*Ds/h**3)*ks*(1+h*betas+(h**2*betas**2)/2) lambdas =

deltas = (Ds**2/(4*Es*ts))*(1-vs/2)

deltas =

0.3691

240436

9335281

0.0000344

Calculate channel coefficients betac, kc, lambdac and deltac

betac = (12*(1-vc**2))**0.25 / ((Dc+tc)*tc)**0.5

betac =

kc = betac*(Ec*tc**3)/(6*(1-vc**2)

kc =

lambdac=(6*Dc/h**3)*kc*(1+h*betac+(h**2*betac**2)/2) lambdac =

deltac = (Dc**2/(4*Ec*tc))*(1-vc/2)

deltac =

0

0

0

0

NOTE: If the effect of plasticity used, Es or Ec will be Es* or Ec*

UHX-13.5.3 Step 3. Calculate h/p. If rho changes, recalculate d* and mu*

from UHX-11.5.1. Determine E*/E and v* relative to h/p from UHX-11.5.2

Layout: Triangular

Tubesheet thickness

From fig. UHX-11.2 or UHX-11.3 - E*/E = 0.3725

h/p = 2.625

Effective Tubsheet Mod.Elasticity E* = 10467052 psi

Parameter Xa = (24*(1-(v*)**2)*Nt*(Et*tt*(dt-tt)*

ao**2)/((E*)*L*h**3))**0.25

h = 2.625 in

v* = 0.3193

mu* = 0.3691

Xa = 4.794

UHX-13.5.4 Step 4. Calculate diameter ratio K and coefficient F.

K = A / Do

F = ((1-v*)/E*)*(lambdas+lambdac+E*Ln(K))

K = 1.300

F = 1.086

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 18

Printed: 24/10/2013 at 11:57:33 a.m.

Parameters Zd, Zv, Zw and Zm from Table UHX-13.1

Psi1(Xa)=bei(Xa)+(1-v*)/Xa*ber'(Xa)

Psi2(Xa)=ber(Xa)-(1-v*)/Xa*bei'(Xa)

Za

Zd

Zv

Zw

Zm

=

=

=

=

=

Psi1(Xa) = 0.3509

Psi2(Xa) = -4.9581

bei'(Xa)*Psi2(Xa)-ber'(Xa)*Psi1(Xa)

(ber(Xa)*Psi2(Xa)+ bei(Xa)*Psi1(Xa))/(Xa**3*Za)

(ber'(Xa)*Psi2(Xa)+ bei'(Xa)*Psi1(Xa))/(Xa**2*Za)

(ber'(Xa)*ber(Xa)+ bei'(Xa)*bei(Xa))/(Xa**2*Za)

(ber'(Xa)**2+bei'(Xa)**2)/(Xa*Za)

Za

Zd

Zv

Zw

Zm

=

=

=

=

=

17.7908

0.0139

0.0445

0.0445

0.307

Phi

Q1

Qz1

Qz2

U

=

=

=

=

=

1.4334

-0.0369

3.2352

8.7434

17.4868

Calculate Q1, Qz1, Qz2 and U

Phi = (1+v*) * F

Q1 = (rhos-1-Phi*Zv)/(1+Phi*Zm)

Qz1 = ((Zd+Q1*Zw)*Xa**4)/2

Qz2 = ((Zv+Q1*Zm)*Xa**4)/2

U = ((Zw+(rhos-1)*Zm)*Xa**4)/(1+Phi*Zm)

UHX-13.5.5 Step 5.

UHX-13.5.5(a) Calculate gamma (shown is max value for all cases)

gamma = (alphatm*(Ttm-Tamb)-alphasm*(Tsm-Tamb))*L

(= 0 used for load cases 1, 2, 3)

gamma = 0.1792 in

UHX-13.5.5(b) Calculate omegas, omegas*, omegac, omegac*

omegas = rhos*ks*betas*deltas*(1+h*betas)

omegas* = ao**2*((rhos**2-1)*(rhos-1))/4-omegas

omegac = rhoc*kc*betac*deltac*(1+h*betac)

omegac* = ao**2*(((rhoc**2+1)*(rhoc-1))/4(rhos-1)/2)-omegac

omegas = 6.0783

omegas* = -6.0469

omegac = 0.0

omegac* = 53.2049

UHX-13.5.5(c) Calculate gammab

gammab = (Gc-C)/Do

gammab = -0.0579

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Fig.UHX-13.1(b)

Page 19

Printed: 24/10/2013 at 11:57:33 a.m.

Controlling Case: UHX-13.4(a)(7)

UHX-13.5.6 Step 6. For each loading case calculate Ps', Pt', Pgamma, Pw,

Prim, and effective pressure Pe.

Ps' = (xs+2*(1-xs)*vt+(2/Kst)*(Ds/Do)**2*vs(Rhos**2-1)/(J*Kst)-((1-J)/(2*J*Kst))*

(DJ**2-Ds**2)/Do**2 ) * Ps

Ps' = 430.65 psi

Pt' = (xt+2*(1-xt)*vt+1/(J*Kst))*Pt

Pt' = 613.47 psi

Pgamma

= (Nt*Kt/(Pi*ao**2))*gamma

Pgamma = 2612.09 psi

PW

= -(U/ao**2)(gammab/(2*Pi))*W*

Prim

= -(U/ao**2)*((omegas*)(Ps)-(omegac*)(Pt))

PW = 372.77 psi

Prim = 222.3 psi

Effective pressure, Pe

Pe =

J*Kst/(1+J*Kst(Qz1+(rhos-1)Qz2))

* (Ps'-Pt'+Pgamma+PW+Prim)

Pe = 400.43 psi

UHX-13.5.7 Step 7. For each loading case calculate Q2 and Q3.

Q2 = ((omegas*)*Ps-(omegac*)*Pt)((omegas*(Ps*)-omegac*(Pc*))+

(gammab/(2*Pi))*(W*)/(1+Phi*Zm)

Q3 = Q1 + 2*Q2 / (Pe*ao**2)

Q2 = -13329.4561

Q3 = -0.155

Using Xa and Q3, determine coefficient Fm for each loading case from

either Table UHX-13.1 or Figs. UHX-13.3.-1 and UHX-13.3.-2.

Controlling x for Fm, x = 4.794

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 20

Printed: 24/10/2013 at 11:57:33 a.m.

Fm(x) = (Qv(x) + Q3 * Qm(x)) / 2

Fm = MAX|Fm(x)|

Fm(x) = -0.0775

Fm = 0.0775

For each loading case, calculate the bending stress in the tubesheet

sigma = (1.5*Fm/mu*)*(2*ao/(h-h'g))**2 * Pe

sigma = 41289 psi

|sigma| <= 2*Sy

41289 psi <= 67200 psi

UHX-13.5.8 Step 8. For each loading case, calculate the maximum shear

stress in the tubesheet across the tubesheet diameter

Area enclosed by perimeter

Perimeter of the tube layout

Shear diameter, Dia = DL or Do

|Pe| = 400.43

3.2*S*mu*h/Do = 884.21

Ligament efficiency, mu

DL = 4*AP/CP

AP

CP

DL

Do

Dia

=

=

=

=

=

1604.74 in2

154.7128 in

41.4896 in

47.5 in

47.5 in

mu = (p-dt)/p = 0.25

Controlling x for FQ, x = 4.794

FQ(x) = (Qb(x) + Q3 * Qa(x))

FQ = MAX|FQ(x)|

FQ(x) = 1.0

FQ = 1.0

Shear stress at periphery,

tau = ( 1/(4*mu))*(Dia/h)*Pe tau = 7246 psi

Max shear across diameter,

tau = (FQ/(4*mu))*(Dia/h)*Pe tau = 7246 psi

|tau| <= 0.8*S

7246 psi <= 16000 psi

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

UHX-13.5.9 Step 9.

Page 21

Printed: 24/10/2013 at 11:57:33 a.m.

Perform this step for each loading case.

UHX-13.5.9(a) Check the axial tube stress.

UHX-13.5.9(a)(1) For each loading case determine coefficient Ft,min

and Ft,max from Table UHX-13.2 and calculate the two extreme values

of sigmat,1 and sigmat,2. These values may be positive or negative

Ft(x) = [Zd(x)+Q3*Zw(x)]*(Xa**4/2)

for 0 <= x <= Xa

Ft,min = MIN[[Zd(x)+Q3*Zw(x)]*(Xa**4/2)]

Ft,max = MAX[[Zd(x)+Q3*Zw(x)]*(Xa**4/2)]

Ft,min = -0.2768

Ft,max = 1.8584

UHX-13.5.9(a)(1)(a) When Pe <> 0:

sigmat,1 = ((Ps*xs-Pt*xt)-Pe*Ft,min)/(xt-xs)

sigmat,2 = ((Ps*xs-Pt*xt)-Pe*Ft,max)/(xt-xs)

sigmat,1 = 512 psi

sigmat,2 = -4137 psi

UHX-13.5.9(a)(2) Determine sigmat,max

sigmat,max = MAX(|sigmat,1|,|sigmat,2|)

Allowable tube stress in tension

sigmat,max = 4137 psi

St = 26824 psi

UHX-13.5.9(b) Check the tube-to-tubesheet joint

UHX-13.5.9(b)(1) Calculate the tube-to-tubesheet joint load, Wt

Wt = sigmat,max*Pi*(dt-tt)*tt

Wt = 720 lbf

UHX-13.5.9(b)(2) Determine the maximum allowable load for the

tube-to-tubesheet joint design Lmax

UW-18(d) max

UW-20

max

App.A max No

App.A max

load

=

load

=

test load =

test load =

2333 lbf

2799 lbf

Lmax = 2333 lbf

UHX-13.5.9(c) Check the tubes for buckling.

UHX-13.5.9(c)(1) Calculate largest buckling length lt

Tube buckling factor

Unsupported tube span

k = 1

l = 30.0 in

lt = largest unsupported buckling length = k*l

lt = 30.0 in

UHX-13.5.9(c)(2) Calculate rt, Ft and Ct

rt = SQRT(dt**2+(dt-2*tt)**2)/4

Ft = lt/rt

Ct = SQRT(2*PI**2*(Et/Syt))

UHX-13.5.9(c)(3) Determine the factor of safety Fs

Fsc = (3.25-0.25*(Zd+Q3*Zw)*Xa**4) = 2.3251

rt = 0.2376 in

Ft = 126.242

Ct = 155.2938

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Fs = MAX((1.25, Fsc)

Page 22

Printed: 24/10/2013 at 11:57:33 a.m.

(Fs need not be > 2)

Fs = 2.0

UHX-13.5.9(c)(4) Determine the buckling stress limit Stb

For Ct <= Ft

For Ct > Ft

Stb = MIN[(1/Fs)*(PI**2*Et/(Ft**2),St]

Stb = MIN[(Syt/Fs)*(1-Ft/(2*Ct)) ,St]

Stb = Stb = 6826 psi

UHX-13.5.9(c)(5) Determine sigmat,min

sigmat,min = MIN(sigmat,1 , sigmat,2)

sigmat,min = -4137 psi

|sigmat,min| <= Stb

4137 psi <= 6826 psi

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 23

Printed: 24/10/2013 at 11:57:33 a.m.

UHX-13.5.10 Step 10. For each loading case, calculate the stresses in the

shell and /or channel integral with the tubesheet.

Calculate the axial membrane stress sigmasm, axial bending stress sigmasb

and total axial stress sigmas in the shell at its junction to the tubesheet

sigmasm = ao**2/[ts*(2*as+ts)]*[Pe+(rhos**2-1)

*(Ps-Pt)]+as**2/[ts*(2*as+ts)]*Pt

sigmasm = 12169 psi

sb1 = (6/ts**2)*ks

sb2 = betas*deltas*Ps

sb3 = 6*(1-(v*)**2)/(E*)*(ao**3/h**3)*(1+(h*betas/2))

sb4 = Pe*(Zv+Zm*Q1)+(2/ao**2)*Zm*Q2

sigmasb = sb1*(sb2+sb3*sb4)

sigmasb = 5453 psi

sigmas = |sigmasm| + |sigmasb|

sigmas = 17622 psi

sigmas <= 2*Sy

17622 psi <= 68880 psi

ASME VIII-1 2011a UHX-13 - Rules for the Design of Fixed Tubesheets

ASME Fig.UHX-13.1(b)

All Load Cases

Controlling case:

Load case:

Tubeside press, Pt

Shellside press, Ps

Axial diff.Th.Exp

120

0

0.0

0

130

0.0

120

130

0.0

***

7

0

0

0.1792

120

0

0.1792

0

130

0.1792

120

130

0.1792

TubSh Bending stress

Max TubSh Bending st

Min TubSh thk

-15407

30000

1.8812

2769

30000

0.7974

16860

30000

1.9679

29413

67200

1.7367

38520

67200

1.9874

32181

67200

1.8166

41289

67200

2.0576

TubSh Shear stress

Max TubSh Shear str

Min TubSh thk

-1074

16000

0.1284

1090

16000

0.1789

1156

16000

0.0504

7151

16000

1.1732

6156

16000

1.0099

8241

16000

1.3521

7246

16000

1.1888

Tubesheet thickness

2.625

2.625

2.625

2.625

2.625

2.625

2.625

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 24

Printed: 24/10/2013 at 11:57:33 a.m.

Component: Rear Tubesheet

ASME Fig.UHX-13.1(b)

All Load Cases

Load case:

Tubes controlling:

Tubes stress st,1

Tubes stress st,2

Max Tubes tens.str

Max Tubes comp.str

-1032

1747

13412

10921

538

-560

13412

7497

1187

-642

13412

6826

828

-5062

26824

6826

-27

-3654

26824

6826

***

1367

-5622

26824

6826

512

-4137

26824

6826

Shell controlling:

Total shell stress

Max shell stress

Max shell stress EP

29299

30000

68880

15572

30000

68880

16658

30000

68880

22251

68880

19357

68880

***

37822

68880

17622

68880

Channel controlling:

Total channel stress

Max channel stress

Max channel str. EP

EP factor - Facts(*)

EP factor - Factc(*)

1.0

1.0

1.0

1.0

1.0

1.0

(*) <= 1 used in calculations

Tube stress across the tubesheet diameter (0 <= x <= Xa)

Load case:

Ft,min

Ft,max

-2.401

9.416

-0.494

2.858

sigmat,1

Location x

-1032

2.013

538

0.096

1187

4.794

sigmat,2

Location x

1747

4.794

-560

4.794

Maximum stress

Max buckling stress

13412

10921

13412

7497

-13.837 -0.386

5.968

2.356

-0.238

1.723

-0.4

2.422

-0.277

1.858

828

0.096

-27

0.096

1367

0.096

512

0.096

-642

2.589

-5062

4.794

-3654

4.506

-5622

4.794

-4137

4.698

13412

6826

26824

6826

26824

6826

26824

6826

26824

6826

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Shell axial membrane stress, sigmasm

Load case:

|sigmasm|

Allowable stress

(JE*S) JE = 0.85

Compression:

sigmasm

Allowable stress

ASME VIII-1 2011a

1785

17000

1465

17000

3250

17000

9192

40000

10704

40000

10658

40000

12169

40000

UHX-13 - Fixed Tubesheets - All Cases

Ps

psi

Pt

psi

Gamma

in

0

130

130

0

0

130

130

120

0

120

0

120

0

120

0

0

0

0.1792

0.1792

0.1792

0.1792

Load case

1

2

3

4

5

6

7

Printed: 24/10/2013 at 11:57:33 a.m.

Units: psi

Load case

1

2

3

4

5

6

7

Page 25

P's

psi

P't

psi

0

430.7

430.7

0

0

430.7

430.7

613.5

0

613.5

0

613.5

0

613.5

Pgamma

psi

0

0

0

2612.1

2612.1

2612.1

2612.1

Pomega

psi

0

0

0

0

0

0

0

Ps*

psi

Pc*

psi

W*

lbf

0

0

0

0

0

0

0

0

0

0

0

0

0

0

311018

0

311018

1304985

1304985

1304985

1304985

Pw

psi

88.8

0

88.8

372.8

372.8

372.8

372.8

Prim

psi

197.9

24.4

222.3

0

197.9

24.4

222.3

Pe

psi

-43.3

60.2

17

395.2

340.2

455.4

400.4

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Load case

1

2

3

4

5

6

7

Q2

Q3

-6423.6

-545.9

-6969.5

-8350

-12783.6

-8895.9

-13329.5

0.4896

-0.0691

-1.4914

-0.1119

-0.1702

-0.1062

-0.155

Fm

Sigma

psi

0.2677

0.0345

0.7457

0.0559

0.0851

0.0531

0.0775

Printed: 24/10/2013 at 11:57:33 a.m.

Sigma All

psi

-15407

2769

16860

29413

38520

32181

41289

30000

30000

30000

67200

67200

67200

67200

Page 26

FQ

1.3718

1

3.7609

1

1

1

1

Tau

psi

Tau All

psi

-1074

1090

1156

7151

6156

8241

7246

16000

16000

16000

16000

16000

16000

16000

ASME VIII-1 2011a UHX-13 - Fixed Tubesheets - All Cases

Load case

1

2

3

4

5

6

7

Fs

1.25

1.8209

2

2

2

2

2

Ft,min

-2.401

-0.494

-13.837

-0.386

-0.238

-0.4

-0.277

Load case

Sigsm

psi

Sigsb

psi

1785

1465

3250

9192

10704

10658

12169

-27514

14106

-13408

13058

-8654

27164

5453

1

2

3

4

5

6

7

Ft,max

Sigt,1

psi

Sigt,2

psi

9.416

2.858

5.968

2.356

1.723

2.422

1.858

-1032

538

1187

828

-27

1367

512

1747

-560

-642

-5062

-3654

-5622

-4137

|Sigs| Sigsall

psi

psi

29299

15572

16658

22251

19357

37822

17622

30000

30000

30000

68880

68880

68880

68880

Sigcm

psi

Sigcb

psi

Sigt,All

psi

13412

13412

13412

26824

26824

26824

26824

|Sigc|

psi

-

Stb

psi

10921

7497

6826

6826

6826

6826

6826

Sigcall

psi

-

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 27

Printed: 24/10/2013 at 11:57:33 a.m.

Type of tube-to-TS joint: 'k' - Expanded with no grooves

Load case:

Wt tube-TS Load, lbf

Allowable no-test

Allowable test

Factor k

Max load K*At*Sa

1

304

1166

1400

1

2333

2

97

1166

1400

1

2333

3

206

1166

1400

1

2333

4

880

2333

2799

2

4665

5

635

2333

2799

2

4665

6

978

2333

2799

2

4665

7

720

2333

2799

2

4665

Allowable Loads per ASME Section VIII Div.1 2011a Appendix A

No Test

Type

Joint description

fr

Lmax

fr

a

Welded only a >= 1.4t

0.8

3732

1

b

Welded only t <= a < 1.4t

0.55

1283

0.7

b-1 Welded only a <= t

0

0 *

0.7

e

Welded a >= 1.4t and expanded

0.8

3732

1

f

Welded a < 1.4t exp.with 2 grooves 0.75

3499

0.95

g

Welded a < 1.4t exp.with 1 groove

0.65

3032

0.85

h

Welded a < 1.4t exp.with no grooves 0.5

2333

0.7

i

Expanded with 2 grooves

0.7

3266

0.9

j

Expanded with 1 groove

0.65

3032

0.8

k

Expanded with no grooves

0.5

2333

0.6

* = Load calculated exceeds code allowable for this joint type.

For joints types a,b,b-1,c,d,e :

Lmax = At*Sa*fr

For joints types f,g,h,

:

Lmax = At*Sa*fe*fr*fy

For joints types i,j,k

:

Lmax = At*Sa*fe*fr*fy*ft

Cross-sectional area At

Max stress St = At*Sa St

Tubesheet yield str. Stt

fe = (ltx/do or 1)

fe

ft = (Po+Pt)/Po

ft

ft = used (0<ft<=1)

ft

Tube OD

do

Tube thickness

t

Tubes Mod.Elasticity EtT

Tubes Coef.Th.Exp.(*) at

Friction coefficient muF

=

=

=

=

=

=

=

=

=

=

=

0.1739 in2

2333 psi

33600 psi

1

1

1

0.75 in

0.083 in

28100000 psi

6.9

0.5

Test

Lmax

4665

1633

3266

4665

4432

3965

3266

4199

3732

2799

Tube allowable stress Sa = 13412 psi

Tube yield stress

Stu

Min Yield Str. (Stt,Stu)

fy = Stt/Stu

fy = used (0<fy<=1)

fy

Expanded length

ltx

TubSh mean metal tmp

T

TubSh Mod.Elast.

EsT

TubSh Coef.Th.Exp.(*) as

(*)=*10**6 in/in/F

=

=

=

=

=

=

=

=

23000 psi

23000 psi

1.46

1

2.5 in

300 F

28100000 psi

6.9

Tube to tube hole Interfacial Pressure:

Po = ((do*t-t**2)*st)/(do*ltx*muF)

Pt = (T-Tamb)*(at-as)*(EtT*EsT)/(EtT+EsT)

For joint types i, j, k:

Po = 1358 psi

Pt = 0 psi

Po + Pt <= 0.58*SigmaM

1358 psi <= 13340 psi

Heat Exchanger Mechanical Design

Shell&TubeMech V8.0 (ASME 2012)

File: C:\Users\designer\Desktop\CPF PORTATIL\he-20 mech.EDR

Page 28

Printed: 24/10/2013 at 11:57:33 a.m.

UHX-9 Tubesheet Flanged Extension

G = diameter of gasket load reaction

hG = gasket moment arm

Sa = allowable stress for tubesheet extension

at ambient temperature

Sd = allowable stress for tubesheet extension

at design temperature

Ta = ambient temperature

Td = design temperature

Wo = flange design bolt load, opeating conditions

Wg = flange design bolt load, gasket seating

G = 55.0 in

hG = 1.625 in

Sa = 20000 psi

Sd

Ta

Td

Wo

Wg

=

=

=

=

=

20000 psi

70 F

300 F

311018 lbf

1304985 lbf

Minimum required thickness of the tubesheet flanged extension

hro = SQRT((1.9 * Wo * hG) / (Sd * G))

hro = 0.9343 in

hrg = SQRT((1.9 * Wg * hG) / (Sa * G))

hrg = 1.9139 in

hr = MAX[hro, hrg]

hr = 1.9139 in

Unperforated tubesheet segment - minimum thickness

UG-34(c)(3)

Unperf. short span

d

Controlling pressure

P

Factor C

C

Z = 3.4 - (2.4 * d) / D

=

=

=

=

1.875 in

130 psi

0.3

3.158

Unperf. long span

Allowable stress

Joint efficiency

(max 2.5)

D

S

E

Z

=

=

=

=

18.5994 in

20000 psi

1

2.5

Effect of bolt load on unperforated tubesheet segment, if any

Bolt circle

Bolt load

BC = 58.25 in

W = 311018 lbf

Segment length

Gasket moment arm

L = 182.9978 in

hg = 1.625 in

Minimum thickness of unperforated segment:

t = d * SQRT(Z*C*P/S*E + 6*W*hg/S*E*L*d**2) = 0.9196 in

Potrebbero piacerti anche

- Acum#2 RoladoDocumento1 paginaAcum#2 RoladoJuan PabloNessuna valutazione finora

- STHE Design (Training Material)Documento37 pagineSTHE Design (Training Material)Herman_ms2000Nessuna valutazione finora

- Tubesheet Calculation: Step 1Documento2 pagineTubesheet Calculation: Step 1Bintang LazuardiNessuna valutazione finora

- U-tube and Fixed Tubesheet Design MethodsDocumento20 pagineU-tube and Fixed Tubesheet Design MethodsEmad A.Ahmad100% (1)

- The Calculation of Fixed Tubesheet Exchangers According To ASME Section VIII Division1Documento15 pagineThe Calculation of Fixed Tubesheet Exchangers According To ASME Section VIII Division1AKSHAY BHATKAR100% (1)

- Sa 420Documento10 pagineSa 420Widya widyaNessuna valutazione finora

- PV Elite Vessel Analysis Program: Input DataDocumento30 paginePV Elite Vessel Analysis Program: Input DatachampNessuna valutazione finora

- Amine Stripper Column Crack 3501-1-T-004: PQR Test CouponDocumento2 pagineAmine Stripper Column Crack 3501-1-T-004: PQR Test Couponpstechnical_43312697100% (1)

- N11 Nozzle CalDocumento9 pagineN11 Nozzle Calגרבר פליקסNessuna valutazione finora

- External Pressure ToleranceDocumento4 pagineExternal Pressure ToleranceAKSHAY BHATKAR100% (1)

- Chibro Press Fit Piping Data SheetDocumento5 pagineChibro Press Fit Piping Data SheetBoyd JohnstonNessuna valutazione finora

- AES Type Heat ExchangerDocumento8 pagineAES Type Heat ExchangerSudhanshu67100% (1)

- Eqn Reference ASME BPVC r1sDocumento5 pagineEqn Reference ASME BPVC r1sagarcia654127Nessuna valutazione finora

- UHX - Osweiller - WhitePaper PDFDocumento20 pagineUHX - Osweiller - WhitePaper PDFMichael BasaNessuna valutazione finora

- 2019-5 TechPresentation BeachDocumento141 pagine2019-5 TechPresentation Beachaneeshta100% (1)

- Welding Neck Flanges 1Documento3 pagineWelding Neck Flanges 1bikkelbobNessuna valutazione finora

- Narrow Face Flange - Slip On Hub TypeDocumento17 pagineNarrow Face Flange - Slip On Hub TypeEng-CalculationsNessuna valutazione finora

- Codes For Vessels/Heat ExchangersDocumento23 pagineCodes For Vessels/Heat Exchangersegy pureNessuna valutazione finora

- Flange calculation as per ASME Section VIIIDocumento9 pagineFlange calculation as per ASME Section VIIIDarshan PanchalNessuna valutazione finora

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocumento1 paginaK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNessuna valutazione finora

- Stillwell Pipe ArrangementDocumento1 paginaStillwell Pipe ArrangementVishalDhiman100% (1)

- Ped Eam-0526-24-1-2006-03Documento6 paginePed Eam-0526-24-1-2006-03nathachaiNessuna valutazione finora

- B16 Case 12Documento2 pagineB16 Case 12InaamNessuna valutazione finora

- Design Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeDocumento8 pagineDesign Calculation of Nozzle Junction Based On ASME Pressure Vessel Design CodeAndres Rodriguez HerreraNessuna valutazione finora

- 강도계산프로그램Documento16 pagine강도계산프로그램심판자Nessuna valutazione finora

- 2520 z000 STD 1780 06 - B Anchor Bolt DetailDocumento2 pagine2520 z000 STD 1780 06 - B Anchor Bolt Detailabdul mujeebNessuna valutazione finora

- Pvdci 1.2 Pressure Vessel Design As Per AsmeDocumento15 paginePvdci 1.2 Pressure Vessel Design As Per AsmeAdekimi EmmanuelNessuna valutazione finora

- ASME Pressure VesselsDocumento41 pagineASME Pressure VesselsJawed Akhter100% (1)

- Asme Viii Pressure Vessels Full English 1Documento5 pagineAsme Viii Pressure Vessels Full English 1Sterling100% (1)

- Oil Gas Construction Factory L.L.CDocumento2 pagineOil Gas Construction Factory L.L.CRenny DevassyNessuna valutazione finora

- Din 6618 1Documento10 pagineDin 6618 1Rad Imam VinoNessuna valutazione finora

- BS 5500 Appendix K and DDocumento14 pagineBS 5500 Appendix K and DCRISTIAN SILVIU IANUCNessuna valutazione finora

- Analysis of a rectangular pressure vesselDocumento7 pagineAnalysis of a rectangular pressure vesselPressure VesselNessuna valutazione finora

- Stress RelievingDocumento1 paginaStress RelievingCruz Gabriel Rosetti100% (1)

- UG-84 - Changes in 2017 EditionDocumento38 pagineUG-84 - Changes in 2017 EditionDelil Ozan100% (1)

- 03 Metal Packing Support PlatesDocumento3 pagine03 Metal Packing Support PlatesypatelsNessuna valutazione finora

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocumento3 pagine"Lifting - Lug" - Lifting Lug Analysis: Program DescriptionSung Woong MoonNessuna valutazione finora

- Daftar Standard Di Elibrary RekindDocumento48 pagineDaftar Standard Di Elibrary RekindHamzah ZuhdiNessuna valutazione finora

- S275JR PDFDocumento1 paginaS275JR PDFEmrahCayboylu100% (1)

- ASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFDocumento8 pagineASMESectionVIIIDivision1 WeldNeckFlangeCalc PDFLisa MaloneNessuna valutazione finora

- VERIFICATIONDocumento3 pagineVERIFICATIONshaishavNessuna valutazione finora

- Heat TreatmentDocumento5 pagineHeat TreatmentsheikmoinNessuna valutazione finora

- ATEC Cyclone Datasheet EnglDocumento1 paginaATEC Cyclone Datasheet EnglDilnesa EjiguNessuna valutazione finora

- Checklist For Above Ground Tanks-QueenslandDocumento2 pagineChecklist For Above Ground Tanks-QueenslandmohanumaNessuna valutazione finora

- Sample Job #23: Finite Element Analysis (FEA) ReportDocumento17 pagineSample Job #23: Finite Element Analysis (FEA) Reportmanisami7036Nessuna valutazione finora

- TEMA Shell Bundle Entrance and Exit AreasDocumento3 pagineTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNessuna valutazione finora

- Pipe Weight CalculatorDocumento1 paginaPipe Weight Calculatorkenho2Nessuna valutazione finora

- ASME IX Temper Bead WeldingDocumento4 pagineASME IX Temper Bead WeldingAhmadiBinAhmadNessuna valutazione finora

- 529457Documento16 pagine529457Sundara VeerrajuNessuna valutazione finora

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Documento9 paginePipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNessuna valutazione finora

- Engineering Example CalculationDocumento78 pagineEngineering Example Calculationkae kaeNessuna valutazione finora

- Skills: Civil Engineer July 2012-PresentDocumento2 pagineSkills: Civil Engineer July 2012-Presentnirankush rathoreNessuna valutazione finora

- Tube Sheet ProceduresDocumento20 pagineTube Sheet ProceduresLcm TnlNessuna valutazione finora

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 pagineASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNessuna valutazione finora

- Asme Viii Calculation Xls PDF FreeDocumento28 pagineAsme Viii Calculation Xls PDF FreeMisbachul ChoirNessuna valutazione finora

- Asme Viii Uhx Tubesheet CalcsDocumento3 pagineAsme Viii Uhx Tubesheet CalcsjdfdfererNessuna valutazione finora

- LRFD Tension Member DesignDocumento243 pagineLRFD Tension Member DesigndonnybtampubolonNessuna valutazione finora

- Zick Analysis For Saddle SupportDocumento8 pagineZick Analysis For Saddle Supportfuransu777100% (1)

- PV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcDocumento8 paginePV Elite 2013 SP3 Licensee: ISGEC TubeSheet CalcMayank MittalNessuna valutazione finora

- IbgDocumento11 pagineIbgMilena Lemus FonsecaNessuna valutazione finora

- Dimensions of Water Storage TankDocumento1 paginaDimensions of Water Storage TankMilena Lemus FonsecaNessuna valutazione finora

- LG Refrigerator Compressor CatalogueDocumento11 pagineLG Refrigerator Compressor CatalogueMilos Lazovic73% (11)

- Engine Gas PDFDocumento76 pagineEngine Gas PDFMilena Lemus Fonseca100% (1)

- Peso PipingDocumento2 paginePeso PipingMilena Lemus Fonseca100% (1)

- Effective Electrostatic Dehydration and Desalting of Crude OilDocumento2 pagineEffective Electrostatic Dehydration and Desalting of Crude OilMilena Lemus Fonseca100% (1)

- GunBarrel Tank ExampleDocumento4 pagineGunBarrel Tank ExampleFabio EspinozaNessuna valutazione finora

- SPE Separacion Agua PDFDocumento8 pagineSPE Separacion Agua PDFJhimmy Calvache FajardoNessuna valutazione finora

- Tank Battery Systems and Production Curve GuideDocumento14 pagineTank Battery Systems and Production Curve Guidegermangsilva100% (2)

- Teddy Bear Kite Robot TrainDocumento1 paginaTeddy Bear Kite Robot TrainMilena Lemus FonsecaNessuna valutazione finora

- Effective Electrostatic Dehydration and Desalting of Crude OilDocumento2 pagineEffective Electrostatic Dehydration and Desalting of Crude OilMilena Lemus Fonseca100% (1)

- 2000 Flyer v2Documento2 pagine2000 Flyer v2Adam SamyNessuna valutazione finora

- Effective Electrostatic Dehydration and Desalting of Crude OilDocumento2 pagineEffective Electrostatic Dehydration and Desalting of Crude OilMilena Lemus Fonseca100% (1)

- LNGDocumento8 pagineLNGMilena Lemus FonsecaNessuna valutazione finora

- F 85154 PDFDocumento4 pagineF 85154 PDFMilena Lemus FonsecaNessuna valutazione finora

- Glycol Dehydration SystemsDocumento2 pagineGlycol Dehydration Systemswisnu_2202Nessuna valutazione finora

- Carga PDFDocumento4 pagineCarga PDFMilena Lemus FonsecaNessuna valutazione finora

- Absorber Tower: Standard FeaturesDocumento2 pagineAbsorber Tower: Standard FeaturesMilena Lemus FonsecaNessuna valutazione finora

- Glycol Dehydration Unit English LetterDocumento4 pagineGlycol Dehydration Unit English LetterRaulCamachoNessuna valutazione finora

- Glycol Dehydration SystemsDocumento2 pagineGlycol Dehydration Systemswisnu_2202Nessuna valutazione finora

- GD NG Rotary ScrewsDocumento8 pagineGD NG Rotary ScrewsMilena Lemus FonsecaNessuna valutazione finora

- 261ar GRDocumento13 pagine261ar GRMilena Lemus FonsecaNessuna valutazione finora

- Orifice PlatesDocumento12 pagineOrifice PlatesPhaitoon PudsriNessuna valutazione finora

- PipingDocumento2 paginePipingMilena Lemus FonsecaNessuna valutazione finora

- SSMG99BDocumento2 pagineSSMG99BMilena Lemus FonsecaNessuna valutazione finora

- BoltDocumento2 pagineBoltMilena Lemus FonsecaNessuna valutazione finora

- M Series BrochureDocumento1 paginaM Series BrochureMilena Lemus FonsecaNessuna valutazione finora

- Prueba DesarenadorDocumento16 paginePrueba DesarenadorMilena Lemus FonsecaNessuna valutazione finora

- Https WWW - Gouldspumps.com Ittgp Medialibrary Goulds Website Products 3600 InstallationOperationMaintenance 3600 en - PDF ExtDocumento110 pagineHttps WWW - Gouldspumps.com Ittgp Medialibrary Goulds Website Products 3600 InstallationOperationMaintenance 3600 en - PDF ExtMilena Lemus FonsecaNessuna valutazione finora

- Approximate Weight (LBS.) For 8 X 6 Through 12 X 5 90o LR Red. Elbows, Red. Outlet Tees and Concentric & Eccentric ReducersDocumento1 paginaApproximate Weight (LBS.) For 8 X 6 Through 12 X 5 90o LR Red. Elbows, Red. Outlet Tees and Concentric & Eccentric ReducersMilena Lemus FonsecaNessuna valutazione finora

- The Basics of General, Organic and Biological Chemistry - AttributedDocumento1.421 pagineThe Basics of General, Organic and Biological Chemistry - AttributedAlfonso J Sintjago100% (2)

- Norma Japonesa Aij-Rlb-1996Documento36 pagineNorma Japonesa Aij-Rlb-1996AnaApcarianNessuna valutazione finora

- Soal Bahasa InggrisDocumento7 pagineSoal Bahasa InggrisPelkeh Prianda25% (16)

- Heat and Temperature Unit3 - T4 - T6 PDFDocumento28 pagineHeat and Temperature Unit3 - T4 - T6 PDFhiren_mistry55Nessuna valutazione finora

- Book Review Electrochemistry: "Electrolysis". Pot-PourriDocumento2 pagineBook Review Electrochemistry: "Electrolysis". Pot-PourriShashank ChandraNessuna valutazione finora

- Relationships and Lattices in AlgebraDocumento2 pagineRelationships and Lattices in AlgebraRadhika RathoreNessuna valutazione finora

- Unit 6 WS3Documento2 pagineUnit 6 WS3Kaitlyn TranNessuna valutazione finora

- Atlas TechNotes - Complete Set Rev Nov 2011Documento50 pagineAtlas TechNotes - Complete Set Rev Nov 2011caod1712Nessuna valutazione finora

- Wiki Unified Soil Classification SystemDocumento2 pagineWiki Unified Soil Classification SystemGIRISHA001Nessuna valutazione finora

- Molykote Greases For Subsea ApplicationsDocumento1 paginaMolykote Greases For Subsea ApplicationsProject Sales CorpNessuna valutazione finora

- Skema Chemistry Paper 3Documento8 pagineSkema Chemistry Paper 3nurul atiqahNessuna valutazione finora

- Judo Bio MechanicsDocumento11 pagineJudo Bio MechanicsAttilio Sacripanti100% (6)

- Pure Substances Mixtures and SolutionsDocumento18 paginePure Substances Mixtures and SolutionsJoanna Angela LeeNessuna valutazione finora

- Love My LifeDocumento5 pagineLove My LifeLinda Veronica0% (1)

- CH 10 Circular Motion Exercises AnswersDocumento4 pagineCH 10 Circular Motion Exercises AnswersMuhammad Aslam0% (1)

- FLUIDME Quiz 02 AnswersDocumento5 pagineFLUIDME Quiz 02 AnswersSam Denielle TugaoenNessuna valutazione finora

- Notesch # 18Documento11 pagineNotesch # 18ZeeshanMahdiNessuna valutazione finora

- Pages From Cinematography-Theory and PracticeDocumento74 paginePages From Cinematography-Theory and PracticeSalazar SliterinNessuna valutazione finora

- Force & FrictionDocumento9 pagineForce & Frictionbinu_praveen100% (1)

- The Planets Comparative Superlative - 87358Documento2 pagineThe Planets Comparative Superlative - 87358Maria AdamNessuna valutazione finora

- API 510 Pressure Vessel Inspector Certification Preparation CourseDocumento4 pagineAPI 510 Pressure Vessel Inspector Certification Preparation CoursejbsantoNessuna valutazione finora

- Antimicrobial Properties of Silver NanoparticlesDocumento37 pagineAntimicrobial Properties of Silver NanoparticlesbasavarajitnalNessuna valutazione finora

- Beryllium and Beryllium Compounds: 2005 Wiley-Vch Verlag GMBH & Co. Kgaa, WeinheimDocumento28 pagineBeryllium and Beryllium Compounds: 2005 Wiley-Vch Verlag GMBH & Co. Kgaa, WeinheimjaimeNessuna valutazione finora

- Calculation of Electrical Induction Near Power LinesDocumento22 pagineCalculation of Electrical Induction Near Power LinesalpcruzNessuna valutazione finora

- 08 Energy 03 Complementary Strain Energy PDFDocumento2 pagine08 Energy 03 Complementary Strain Energy PDFjack_hero_56Nessuna valutazione finora

- Solar System and Astronomy FactsDocumento535 pagineSolar System and Astronomy FactsKavita KrishnamorthiNessuna valutazione finora

- BEYOND SYLLABUS: CURVED, COMPOSITE, UNSYMMETRICAL BEAMSDocumento11 pagineBEYOND SYLLABUS: CURVED, COMPOSITE, UNSYMMETRICAL BEAMSVignesh VickyNessuna valutazione finora

- Thermodynamics of Weak Electrolytes Including H3PO4Documento10 pagineThermodynamics of Weak Electrolytes Including H3PO4buhalnitaNessuna valutazione finora

- Principles of CT and CT TechnologyDocumento15 paginePrinciples of CT and CT TechnologyLida Velasquez SierraNessuna valutazione finora

- Assignment 1Documento3 pagineAssignment 1V V Swarat Sasa50% (2)