Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & Pipe

Caricato da

Adrian MarinTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Din 2440-78 Steel Tubes Medium Weight Suitable For Screwing: Global Marketing For Tube & Pipe

Caricato da

Adrian MarinCopyright:

Formati disponibili

Global Marketing for Tube & Pipe www.TubeSolution.

com

DI N 2440-78 STEEL TUBES MEDI UM WEI GHT SUI TABLE FOR SCREWI NG

1. Scope

This Standard applies to medium-weight tubes suitable for screwing. They are suitable for nominal pressure 2 for liquids and nominal pressure 10 for air and non-hazardous gases.

2. Other relevant Standards

DIN 2444 Zinc coatings on steel tubes; quality standard for the hot galvanizing of steel tubes for installation purposes

DIN 2999 Part 1 Whitworth pipe threads for tubes and fittings; cylindrical internal thread and conical external

DIN 17100 Steels for general structural purposes; quality specifications

DIN 50136 Testing of metallic materials; flattening test on tubes

3. Dimensions, designation

Designation of a medium-weight tube suitable for screwing, nominal width 40, seamlessly galvanized (B), in manufacturing lengths:

Table 1. Threaded tube DIN 2440 - DN 40-seamless B

Tube Screw thread

Corresponding

socket according

to DIN 2986

Weight

Distance of

screw thread

diameter

d2

from tube end

Outside

diameter

Length

Nominal

width

Connecting

nominal width

of the

fittings

according

to DIN

2950 and

DIN 2980

Whit-

worth-

pipe

threads

according

to

DIN

2999

Part1

Outside

diameter

d1

Wall

thick-

ness

s

Plain-end

tube

kg/m

socketed

tube

kg/m

Theoretical

screw

thread

diameter

d2

Threads

per

25.4mm

Usable

screw

thread

length

J

min

at

a

max.

a

max.

a

min.

min.

min.

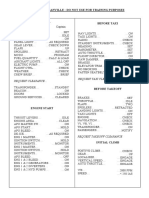

6 1/8 R 1/8 10.2 2.0 0.407 0.410 9.728 28 7.4 4.9 3.1 14 17

8 1/4 R 1/4 13.5 2.35 0.650 0.654 13.157 19 11.0 7.3 4.7 15.4 25

10 3/8 R 3/8 17.2 2.65 0.852 0.858 16.662 19 11.4 7.7 5.1 21.3 26

15 1/2 R 1/2 21.3 2.65 1.22 1.23 20.955 14 15.0 10.0 6.4 26.4 34

Global Marketing for Tube & Pipe www.TubeSolution.com

20 3/4 R 3/5 26.9 2.65 1.58 1.59 26.441 14 16.3 11.3 7.7 31.8 36

25 1 R 1 33.7 3.25 2.44 2.46 33.249 11 19.1 12.7 8.1 39.5 43

32 1 1/4 R 1 1/4 42.4 3.25 3.14 3.17 41.910 11 21.4 15.0 10.4 48.3 48

40 1 1/2 R 1 1/2 48.3 3.25 3.61 3.64 47.803 11 21.4 15.0 10.4 54.5 48

50 2 R 2 60.3 3.65 5.10 5.17 59.614 11 25.7 18.2 13.6 66.3 56

65 2 1/2 R 2 1/2 76.1 3.65 6.51 6.63 75.184 11 30.2 21.0 14.0 82 65

80 3 R 3 88.9 4.05 8.47 8.64 87.884 11 33.3 241 17.1 95 71

100 4 R4 114.3 4.5 12.1 12.4 113.030 11 39.3 28.9 21.9 122 83

125 5 R 5 139.7 4.85 16.2 16.2 138.430 11 43.6 32.1 25.1 147 92

150 6 R 6 165.1 4.85 19.2 19.8 163.830 11 43.6 32.1 25.1 174 92

1) Referred to an average length of 6m

Table 3

Nominal width

DN

d1

max.

d1

min.

6 10.6 9.8

8 14.0 13.2

10 17.5 16.7

15 21.8 21.0

20 27.3 26.5

25 34.2 33.3

32 42.9 42.0

40 48.8 47.9

50 60.8 59.7

65 76.6 75.3

80 89.5 88.0

100 115.0 113.1

Global Marketing for Tube & Pipe www.TubeSolution.com

125 140.8 138.5

150 166.5 163.9

Wall thickness

- 12.5% (-15% at individual points not longer than 2 X the outside diameter, provided that this reduction is effective only on the outer surface).

The upper limit is fixed by the permissible weight deviation.

10.6 Weight deviations

Compared with the weights specified in the table on page 1 deviations according to the following table are permissible.

Table 4

for a single tube for a consignment of not less than 10 t

10% 7.5%

10.7 Straightness

The tubes must appear straight to the eye.

10.8 Cold bending capability

Tubes suitable for screwing according to this Standard without surface treatment must be capable of being bent cold by means of a suitable commercial bending tool to a radius

of 3X tube outside diameter up to and including DIN 25, and to a radius of 3.5 X tube outside diameter in the case of tubes up to nominal width 50 (see Section 11.4).

Chemical Composition (%)

Grade Mfg. Process

C Si Mn P S Ni Cr Mo Others

St33.2 S, W rdf.DIN 17100 - - - - - - -

Tensile Test MPa or N/mm

2

Grade

Min Yield point Tensile Strength

Remarks (Similar to J IS) Similar to

KS

St33.2 - - (SGP)(SPP)

Potrebbero piacerti anche

- Din 2448Documento3 pagineDin 2448Cristian Adrian ANessuna valutazione finora

- Spec Sheet - Handler 210Documento4 pagineSpec Sheet - Handler 210Hobart Welding ProductsNessuna valutazione finora

- Din 59410Documento8 pagineDin 59410Fitra BagusNessuna valutazione finora

- Test Pack Contents SQ No. Title DescriptionDocumento14 pagineTest Pack Contents SQ No. Title DescriptionThắng Trần QuangNessuna valutazione finora

- Mig Handbook (Despark)Documento19 pagineMig Handbook (Despark)Izad Bin IdrisNessuna valutazione finora

- Fittings Din11852 Din11850Documento14 pagineFittings Din11852 Din11850dingobk1Nessuna valutazione finora

- Din en 10216-2Documento2 pagineDin en 10216-2vishal.nitham100% (1)

- Pre Production ProcedureDocumento1 paginaPre Production ProcedureNguyen Quoc TriNessuna valutazione finora

- WPS GTAW-SMAW h1Documento1 paginaWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNessuna valutazione finora

- DIN 2076 vs. ASTM A 877Documento1 paginaDIN 2076 vs. ASTM A 877tobypadfieldNessuna valutazione finora

- Din Flange Din 2627: (Dimensions in MM.)Documento12 pagineDin Flange Din 2627: (Dimensions in MM.)Wisüttisäk PeäröönNessuna valutazione finora

- VIPER XTREM + Threaded Stud ZN 8.8 HDG 8.8 M16-28 09 2022Documento8 pagineVIPER XTREM + Threaded Stud ZN 8.8 HDG 8.8 M16-28 09 2022borceNessuna valutazione finora

- Iso 15552 2004 en PDFDocumento8 pagineIso 15552 2004 en PDFashokkumarNessuna valutazione finora

- WPS - 2Documento3 pagineWPS - 2aleventNessuna valutazione finora

- Equivalents of Carbon Steel QualitiesDocumento6 pagineEquivalents of Carbon Steel QualitiesMarcos Fuller AlbanoNessuna valutazione finora

- Conical Seat Spherical Washer Is 4297Documento6 pagineConical Seat Spherical Washer Is 4297Rajasekaran Murugan0% (1)

- Quality 11Smn30: Lucefin GroupDocumento1 paginaQuality 11Smn30: Lucefin GroupPaulo ZechinNessuna valutazione finora

- WPQR3Documento3 pagineWPQR3Dimitris NikouNessuna valutazione finora

- Din 3357-4-1981Documento5 pagineDin 3357-4-1981олегNessuna valutazione finora

- Asme B18.16.6Documento1 paginaAsme B18.16.6Mario FonsecaNessuna valutazione finora

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGDocumento2 pagine16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinNessuna valutazione finora

- Din 6798 ADocumento3 pagineDin 6798 ADuong BachNessuna valutazione finora

- Parallel Pin Din 6325-2.5X12 PDFDocumento1 paginaParallel Pin Din 6325-2.5X12 PDFFer VFNessuna valutazione finora

- STAINLESS Filler Selector Guide PDFDocumento1 paginaSTAINLESS Filler Selector Guide PDFArul Edwin VijayNessuna valutazione finora

- Metric Heavy Hex Nut DimensionsDocumento3 pagineMetric Heavy Hex Nut DimensionsSenthillkumar BalasubramaniamNessuna valutazione finora

- Taha Associates CatalogueDocumento34 pagineTaha Associates CatalogueZAHIDNessuna valutazione finora

- Iso Metric 32Documento2 pagineIso Metric 32rahul caddNessuna valutazione finora

- Round Washers SN 808: July 2000Documento1 paginaRound Washers SN 808: July 2000Maurício Duarte de AndradeNessuna valutazione finora

- Wps Sp14 Reva PDFDocumento9 pagineWps Sp14 Reva PDFravi00098Nessuna valutazione finora

- DIN 3015 ClampsDocumento17 pagineDIN 3015 ClampsBalderas Rosas WilibaldoNessuna valutazione finora

- Weight Calculations Specific Weight (G/CM)Documento15 pagineWeight Calculations Specific Weight (G/CM)Ranjeet Kumar ThakurNessuna valutazione finora

- Mill Test Certificate: END OF REPORTDocumento1 paginaMill Test Certificate: END OF REPORT220479Nessuna valutazione finora

- 1DIN 6921-10.9 Hex Flange Bo.Documento2 pagine1DIN 6921-10.9 Hex Flange Bo.Sunil BaliNessuna valutazione finora

- EN 12570 - Sizing Operating ElementDocumento7 pagineEN 12570 - Sizing Operating Elementyashif aliNessuna valutazione finora

- RJR PMMTDocumento16 pagineRJR PMMTArun PrasadNessuna valutazione finora

- Tabla HDPE-Pipe PDFDocumento4 pagineTabla HDPE-Pipe PDFBerinssonScottHernandezSucsoNessuna valutazione finora

- Chinese To DinDocumento7 pagineChinese To DinDamla KaymakçıNessuna valutazione finora

- 805 Steelkote Ep ZN Hs Datasheet enDocumento3 pagine805 Steelkote Ep ZN Hs Datasheet enprasanth cp100% (1)

- Thread Standard BSPDocumento7 pagineThread Standard BSPĐạt TrầnNessuna valutazione finora

- Pins and KeysDocumento12 paginePins and KeysSam GillilandNessuna valutazione finora

- En 10029Documento5 pagineEn 10029PHAMTOAINessuna valutazione finora

- DODGE Plummer BlocksDocumento40 pagineDODGE Plummer Blocksgrupa2904100% (2)

- 1 2312 PDFDocumento4 pagine1 2312 PDFFrancisco CarrascoNessuna valutazione finora

- Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping CodeDocumento2 pagineBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Codedeua2004Nessuna valutazione finora

- Iso 7452 2013 en PDFDocumento8 pagineIso 7452 2013 en PDFfahmi aballiNessuna valutazione finora

- S/A 106 Spec Sheet A106 Pipe Specifications: ScopeDocumento7 pagineS/A 106 Spec Sheet A106 Pipe Specifications: ScopeyanurarzaqaNessuna valutazione finora

- Din 963Documento6 pagineDin 963hansgutmeierNessuna valutazione finora

- Bulloni UNI 5739-5740Documento2 pagineBulloni UNI 5739-5740gio67Nessuna valutazione finora

- Din 2616 PDFDocumento2 pagineDin 2616 PDFTahresNessuna valutazione finora

- MarcoDocumento1 paginaMarcobimboNessuna valutazione finora

- Posmac: Posco Magnesium Aluminium Alloy Coating ProductDocumento48 paginePosmac: Posco Magnesium Aluminium Alloy Coating ProductCatherine DussnNessuna valutazione finora

- Paints and Varnishes Pull-Off For Adhesion: First EditionDocumento9 paginePaints and Varnishes Pull-Off For Adhesion: First EditionmirzazubairNessuna valutazione finora

- 10 1092Documento39 pagine10 1092ThinkProgressNessuna valutazione finora

- Parker Fluid Connectors - General Technical InfoDocumento32 pagineParker Fluid Connectors - General Technical InfoJenner Volnney Quispe ChataNessuna valutazione finora

- BS en 15614 Welder Tests Template1Documento14 pagineBS en 15614 Welder Tests Template1delta lab sangliNessuna valutazione finora

- A1200 Red Thread II PipingDocumento0 pagineA1200 Red Thread II PipingjimmycabreraNessuna valutazione finora

- JIS G3452 PipeDocumento0 pagineJIS G3452 PipefaridyeniNessuna valutazione finora

- Jis G3444Documento12 pagineJis G3444yapsguanNessuna valutazione finora

- All-in-One Manual of Industrial Piping Practice and MaintenanceDa EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceValutazione: 5 su 5 stelle5/5 (1)

- SDFSDFSD GFDG F DFGDG FDG DFG DF GDFGDFGDDocumento172 pagineSDFSDFSD GFDG F DFGDG FDG DFG DF GDFGDFGDeiugyuierhgierhNessuna valutazione finora

- Phetteplace, Gary E-District Heating Guide-ASHRAE (2013)Documento374 paginePhetteplace, Gary E-District Heating Guide-ASHRAE (2013)Adrian Marin100% (1)

- Chapter 2 Ej501Documento10 pagineChapter 2 Ej501Adrian MarinNessuna valutazione finora

- Fisa Instalare VentiloconvectorDocumento35 pagineFisa Instalare VentiloconvectorAdrian MarinNessuna valutazione finora

- BR Transmitter en LoresDocumento8 pagineBR Transmitter en LoresAdrian MarinNessuna valutazione finora

- TG-KH PT100 (0) PRSH enDocumento2 pagineTG-KH PT100 (0) PRSH enAdrian MarinNessuna valutazione finora

- Aquis 6 0Documento849 pagineAquis 6 0Adrian MarinNessuna valutazione finora

- Manual For Residential 4.0Documento40 pagineManual For Residential 4.0Alain GarciaNessuna valutazione finora

- Declaration of Conformity: Equipment Name Type of Equipment Low Voltage Directive 2006/95/ECDocumento1 paginaDeclaration of Conformity: Equipment Name Type of Equipment Low Voltage Directive 2006/95/ECAdrian MarinNessuna valutazione finora

- Termis 6 0Documento952 pagineTermis 6 0Adrian MarinNessuna valutazione finora

- Alfa Laval Technical Manual 4thedDocumento176 pagineAlfa Laval Technical Manual 4thedrararaf100% (3)

- Satellite Launch SystemDocumento16 pagineSatellite Launch SystemtengyanNessuna valutazione finora

- CIAA Wildlife Hazard Management ManualDocumento47 pagineCIAA Wildlife Hazard Management ManualGrec MirceaNessuna valutazione finora

- Uc3844 PWM ControllerDocumento28 pagineUc3844 PWM ControllerTraian Serban0% (1)

- Space FramesDocumento77 pagineSpace Framesanuj seth100% (1)

- IATA Reference Manual For Audit Programs (IRM) Ed 10 - September 2019Documento123 pagineIATA Reference Manual For Audit Programs (IRM) Ed 10 - September 2019Chinar Shah100% (1)

- Singing Rock - Senior 5122022Documento4 pagineSinging Rock - Senior 5122022Pretecsi SasNessuna valutazione finora

- The Boeing 7E7Documento8 pagineThe Boeing 7E7AmandaNessuna valutazione finora

- Ano 147 Awrg 1.0 PDFDocumento40 pagineAno 147 Awrg 1.0 PDFAmmar AhmedNessuna valutazione finora

- A320 ChecklistDocumento2 pagineA320 ChecklistJuan Pablo Reina MontañezNessuna valutazione finora

- Redbird Aviation Pvt. Ltd. C-713/G, Palam Ext.,Opp. Shiksha Bharti School, Sector-7, Dwarka, ND 77 Email: Contact Us: 011-49122304,+91-9971658735,+91-9811025737Documento5 pagineRedbird Aviation Pvt. Ltd. C-713/G, Palam Ext.,Opp. Shiksha Bharti School, Sector-7, Dwarka, ND 77 Email: Contact Us: 011-49122304,+91-9971658735,+91-9811025737Crystal MurrayNessuna valutazione finora

- SR 2020 Safety Report FinalDocumento244 pagineSR 2020 Safety Report FinalEmNessuna valutazione finora

- Aurora Bearing 610 CatalogDocumento84 pagineAurora Bearing 610 CatalogDerrick Scott FullerNessuna valutazione finora

- Formula For Aerodynamic HeatingDocumento3 pagineFormula For Aerodynamic HeatingJeremy TohNessuna valutazione finora

- BroachingDocumento22 pagineBroachingSteve McsNessuna valutazione finora

- Boeing Case StudyDocumento40 pagineBoeing Case StudyTammy Soma70% (20)

- V SpeedsDocumento5 pagineV SpeedsNACILNessuna valutazione finora

- Click Here For Download: (PDF) Aircraft Design: A Conceptual Approach (Aiaa Education Series)Documento3 pagineClick Here For Download: (PDF) Aircraft Design: A Conceptual Approach (Aiaa Education Series)Nagô O Rei0% (1)

- Suspension Design Case StudyDocumento44 pagineSuspension Design Case StudyShounak BhateNessuna valutazione finora

- Fans and Blowers: Learning OutcomesDocumento17 pagineFans and Blowers: Learning OutcomesRyan CalicaNessuna valutazione finora

- Lockheed U-2 Spy PlaneDocumento16 pagineLockheed U-2 Spy PlaneJoseph Chew100% (2)

- Temporary Revision 12 053: Aircraft Maintenance ManualDocumento26 pagineTemporary Revision 12 053: Aircraft Maintenance ManualKentNessuna valutazione finora

- B737NG - 27 60 A3 01 PDFDocumento1 paginaB737NG - 27 60 A3 01 PDFMuhammed MudassirNessuna valutazione finora

- A684 PNPDocumento4 pagineA684 PNPagus2kNessuna valutazione finora

- Ch5 Finite CV AnalysisDocumento64 pagineCh5 Finite CV AnalysisAsif SunnyNessuna valutazione finora

- Sae As81934c 2019Documento18 pagineSae As81934c 2019liuyx866100% (1)

- T7 B10 FBI 302s Olsen FDR - 302s Re Michael Woodward 372Documento15 pagineT7 B10 FBI 302s Olsen FDR - 302s Re Michael Woodward 3729/11 Document ArchiveNessuna valutazione finora

- Harvald Resistance and Propulsion of Ships - Ocred PDFDocumento90 pagineHarvald Resistance and Propulsion of Ships - Ocred PDFÖmer Faruk KorkmazNessuna valutazione finora

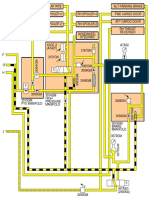

- Figure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Documento1 paginaFigure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaNessuna valutazione finora

- Aerodrome Control TowerDocumento18 pagineAerodrome Control Towertirupati100Nessuna valutazione finora

- Awnot-065-Awrg-5.2 - Airworthiness Requirements For Issue Extension and Renewal of An Air Operators Certificate (Aoc)Documento23 pagineAwnot-065-Awrg-5.2 - Airworthiness Requirements For Issue Extension and Renewal of An Air Operators Certificate (Aoc)Fahim AhmadNessuna valutazione finora