Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pick A

Caricato da

vickersDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pick A

Caricato da

vickersCopyright:

Formati disponibili

THE WITT PICKER Quick Selection Manual for Refrigerated Rooms INTRODUCTION

This manual has been written to serve as a comprehensive guide to quick-select the major equipment needed to refrigerate insulated rooms. A complete Witt Picker is comprised of Part A (this manual Bulletin No. 200-2) plus Part B (the Data Tables Bulletin No. 205). Several features have been included to improve accuracy and broaden the range of applications. All appropriate condensing units and matching unit coolers are listed for a given room size. The full range of system horsepower and unit cooler type and temperature difference can be evaluated before the system is chosen. Both Semi-hermetic and Hermetic condensing unit selections are shown. A complete set of correction factors is given so that the listed loads can be adjusted, if desired, for other ambient temperatures, insulation, etc. Product loads are given so that adjustments in product poundage and temperature reduction can be evaluated. System capacities are given so that an alternate system can easily be selected for an adjusted load without referring to a separate catalog.

Quick Start Instructions can be found in the General Selection Procedure below. Detailed Instructions can be found in the section entitled Using The Witt Picker , starting on Page 4 of this Manual.

GENERAL SELECTION PROCEDURE

Using This Manual Part A 1. ESTABLISH DESIGN CONDITIONS Room dimensions and construction, ambient temperature, product loading and equipment type. Using The Data Tables Part B 2. SELECT EQUIPMENT MODEL SERIES See Pages 3 to 5 for equipment types and model series. 3. FIND THE CORRECT QUICK SELECTION TABLE Refer to the Table of Contents for the starting page of the room temperature and condensing unit type desired. 4. LOCATE THE CORRECT ROOM SIZE Room sizes are listed in the left-hand column. 5. SELECT THE SYSTEM Appropriate condensing unit(s) and unit coolers are listed in the columns to the right of the room size. Refer to the section entitled Using The Witt Picker starting on Page 4 of this Manual for details and examples of the above procedure.

We have made every effort to insure the accuracy of the data and selections in this manual. However, it should be used as an estimation guide only due to variations in usage and construction typical of most jobs. Refer to ASHRAE load calculation procedures before making a final selection. WITT assumes no liability for selections or recommendations contained in this manual.

Copyright 1997 WITT, DIVISION OF ARDCO

THE WITT PICKER

Quick Selection Manual for Refrigerated Rooms TABLE OF CONTENTS

Part A Selection Manual

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Selection Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Using the Witt Picker Selection Table Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Room Load Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Selection Procedure Selection Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 Load Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6 System Selection Guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Load Correction Factors Glass Reach-In Door Load Additions . . . . . . . . . . . . . . . . . . . . . . . . .7 Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Floor Insulation 35 Rooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Room Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 Ambient for Coolers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 Ambient for Freezers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

USING THE WITT PICKER

SELECTION TABLE FORMAT

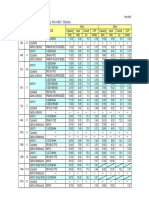

Refer to the Data Tables (Part B) Each table is divided into three major sections. The left hand section lists room details including Dimensions (W x L), Total Surface, Room Volume, Product Load in BTUH and Total Room Load in BTUH. The middle section gives condensing unit selections by model number. The right hand section is for unit cooler selections. The columns are in groups of three; each group gives a) The unit cooler size b) The system capacity with that unit cooler and c) The operating temperature difference (TD) for the system. The following model unit coolers are tabulated. 35 Coolers 30 Coolers 0 Freezers -10 Freezers -20 Freezers Model SDA, IFA, PAH, PAM, EFA Model SDE, IFE, PEM, EFE Model SDE, IFE, PEL, PEU Model SDE, IFE, PEL, PEU Model SDE, IFE, PEL, PEU AIR CHANGE LOAD ASHRAE Recommendations x 1.5 Outside Air: 95F. DB/78F. WB Room Air: 80% Relative Humidity AMBIENT TEMPERATURES Walls Ceiling Floor Condensing Unit 95F. 115F. 55F. 95F.

PRODUCT LOADS Product loads assume a 10 degree temperature reduction in every pound of product brought into the room on a given day. Product Specific Heat Coolers: Freezers: .90 BTU/lb. .45 BTU/lb.

Daily incoming product is assumed to be 2 lbs. of product per cubic foot of room volume. There has been no allowance made for product freezing loads.

ROOM LOAD SPECIFICATIONS

The data used to calculate the cooling loads in this manual is specified below. It represents a very typical set of design criteria. It is used in accordance with standard ASHRAE load calculation procedures. MISCELLANEOUS Lights: 1.0 Watt/Sq. Ft. Floor Area Unit Cooler Fans: Per Unit Cooler Selection

CONSTRUCTION

Room Height: 9 feet (Outside) Room Walls/Ceiling Floor Temp. +35 F. 4" Expanded Concrete Polystyrene On grade +30 F. 0 F. -10 F. -20 F. 4" Expanded Polystyrene 4" Urethane Foam 4" Expanded Polystyrene 6" Expanded Polystyrene

SAFETY FACTOR 10%

COMPRESSOR RUNNING TIME 35 F. Rooms: 30 F. Rooms & colder: 16 Hours/Day (Air Defrost) 18 Hours/Day (Elect. Def.)

Do not use this manual for rooms constructed with conventional stud and joist framing, using loose fill (e.g. Vermiculite) or glass fiber batt installation.

SELECTION PROCEDURE

The selection procedure outlined on Page 2 will be illustrated by the following example. The referenced Data Tables will be found in Part B. GIVEN: Supermarket Cooler 35 cooler 8x14x9 High 95 ambient at cooler & cond. unit 4 polystyrene walls & ceiling No floor insulation (on grade) No specified product load Outdoor semi-hermetic unit and 6 fin per inch low profile unit cooler.

LOAD ADJUSTMENTS Not all refrigerated rooms conform to the design data (e.g. insulation type or thickness) used to generate the Quick Selection Tables. If the room does not conform, the equipment shown in the table may not be appropriate. The tabulated load must be adjusted accordingly and the equipment selection re-evaluated. There are two different procedures which can be used to adjust the load for differing jobsite specifications.

Evaluation Heavy usage typical of back-up coolers in supermarkets. Most product is entering near storage room temperature. All given data conforms to the design standards for this manual specified on Page 4.

Load Adjustment from Experience Many seasoned estimators prefer to use their experience with similar rooms to make adjustments in our stated loads. This has been the accepted method for using quick selection booklets in the past.

Solution Using the Part B Data Tables, select a condensing unit and unit cooler model series from the equipment pictured on Pages 3 thru 5. Refer to the Table of Contents (Page 2) to find 35 Coolers listed under Semi-Hermetic Condensing Units starting on Page 6. Locate the 8x14 Cooler in the left-hand column. All rooms listed in the manual are 9 high. The 8x14 cooler in the table has a total load of 9550 BTUH and requires a 1 HP outdoor condensing unit model PWS 010H22. A Low Profile style unit cooler, Model Series SDA (6 FPI) was specified. A model SDA-105M is listed. The selected system is a Model PWS 010H22SDA 105M producing 10330 BTUH at 9.8 TD. The room load includes 1100 BTUH in product load (see 4th column). 2.0 lbs. of incoming product per cubic foot of room volume has been assumed per day (see Room Load SpecificationPage 4) . The 3rd column gives the room volume as 848 cu. ft. The daily product poundage is therefore 2.0x848=1696 lbs. being reduced 10. This is the same as 848 lbs. reduced 20 ; or 565 lbs. reduced 30 , etc.

Load Adjustment with Correction Factors Adjust the room load given in the selection table using the correction factors on Pages 7 thru 11, then select the appropriate equipment. Correction Factor Curves Most of the correction factors are given in the form of curves, since they vary in accordance with room volume. Visual interpolation between grid lines will produce sufficient accuracy.

The use of the various correction factors will be illustrated best by estimating the load for another 8x14x9 room with different construction, placed in a different environ ment. GIVEN: Restaurant Kitchen Cooler 35 cooler 8x14x9 High 100 ambient at cooler walls. 4 urethane foam walls & ceiling No floor insulation (on grade) No specified product load Outdoor semi-hermetic unit & low profile unit cooler.

Since the required product load is unknown, it is strongly recommended that this product cooling capability be stipulated when making a quotation.

Evaluation Extra heavy usage due to high temperature/ humidity infiltration and peak loads typical of kitchens. Probable loads of warm product. Use the same Heavy Usage Table as in the previous example. Again, the load is 9550 BTUH for polystyrene walls and ceiling, no floor insulation and 95 ambient temperature.

5

We must adjust the load for three non-standard factors: 1) 100 ambient at cooler walls 2) Urethane foam wall and ceiling construction 3) Extra heavy usage (from evaluation). The usage and ambient will increase the load, while the urethane room construction will reduce the load.

The system may now be selected for its BTUH capacity from those listed, since we now have a specific BTUH requirement to match. The system listed for an 8x16 room would be suitable. PWS 015H22 SDA 105M 11730 BTUH @ 11.2 TD

ADDITIONAL CORRECTION FACTORS Refer to the Table of Contents for a complete listing of factors and their page numbers. All factors are to be used in accordance with the above procedure; they can be combined as required.

Solution Determine the correction factor for each of the three deviations (from standard) listed above, then multiply the 9550 BTUH room load by each factor in turn to find the corrected room load. These steps are detailed as follows.

GLASS DOOR LOADS Refer to Curve 4C (Page 10), 100 Ambient Temperature Correction for coolers. The dashed line traces this example. Find 848 cu. ft. (by visual interpolation) on the vertical Room Volume Scale. Follow the dashed line until it intersects the curve. From that point on the curve, follow the dashed line down until it intersects the horizontal Correction Factor Scale. Read (by visual interpolation) a 1.074 factor. Refer to Curve 3B (Page 9), Extra Heavy Usage. Find 848 cu. ft. on the vertical Room Volume Scale. In the same manner as above, read a factor of 1.166 on the Correction Factor Scale. Table 1a (35 Coolers) and Table 1b (Freezers) list the BTUH addition for glass display doors. Locate the correct door size; the BTUH load per door is in the same line in the appropriate ambient temperature column. Multiply the BTUH per door times the number of doors. These figures have been corrected for compressor running time and may therefore be added directly to the Total Room Load from a Quick Selection Table. The load figures shown are for rooms 10 feet wide and over. Multiply those figures by 1.20 if the room is less than 10 feet wide. Table 1c lists the BTUH load per lamp for glass doors equipped with fluorescent lights.

Refer to Table 2 (Page 8), Insulation Correction Walls and Ceiling. Find the insulation description (which corresponds to the jobsite specification), in the left-hand column. The factor of .89 is in the column headed Coolers, opposite the 4 Urethane foam panels and sheets. Multiply the 9550 BTUH room load from the Quick Select Table by each of the three factors to get the adjusted load. Adjusted load = 9550 BTUH x 1.074 x 1.166 x .89 = 10644 BTUH

CONDENSING UNIT AMBIENT TEMPERATURE

All tables show system capacities at 95 ambient. You may correct for 90 or 100 ambient using the following factors: Room Temp. Ambient Temperature 90 100

Coolers Freezers

1.03 1.04

.97 .96

SYSTEM SELECTION GUIDANCE

The systems in the Witt Picker Data Tables are computer selected, based on the following logic: the system capacity must be at least as high as the room load, but no more than 15% oversized. If a system is just 1 BTUH less than or greater than those limits, that system will not appear as an appropriate selection. It is up to the user of this manual to decide whether or not to exceed these limits since only he is familiar with the job details. Most of the selection tables have a few rooms for which the load is stated, but no system is listed. The reason is that no system matches the load within the prescribed limits. The user can, in these cases, compare the room load with systems listed for other rooms and decide which one is best for the job.

6

10

11

Potrebbero piacerti anche

- Danfoss Facts Worth Knowing About ACDrivesDocumento208 pagineDanfoss Facts Worth Knowing About ACDrivesvickersNessuna valutazione finora

- Thermal Applications CategoryDocumento19 pagineThermal Applications CategoryvickersNessuna valutazione finora

- Danfoss Banana Ripening Application BrochureDocumento6 pagineDanfoss Banana Ripening Application BrochurevickersNessuna valutazione finora

- Frequency of Maintenance TestingDocumento5 pagineFrequency of Maintenance TestingIsmael AhmedNessuna valutazione finora

- McQuay MCW-C-H Technical Manual EngDocumento20 pagineMcQuay MCW-C-H Technical Manual EngCarlos Can PootNessuna valutazione finora

- Chillers and Heat Pumps Control-EngDocumento4 pagineChillers and Heat Pumps Control-EngvickersNessuna valutazione finora

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocumento74 pagineASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- Sanyo ScrollDocumento24 pagineSanyo Scrollworker359567Nessuna valutazione finora

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocumento10 pagine6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersNessuna valutazione finora

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Documento10 pagineReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersNessuna valutazione finora

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocumento2 pagineDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersNessuna valutazione finora

- NTC Thermistor Temperature to Resistance ChartDocumento1 paginaNTC Thermistor Temperature to Resistance ChartvickersNessuna valutazione finora

- Copeland Scroll Designation 2005Documento1 paginaCopeland Scroll Designation 2005vickersNessuna valutazione finora

- Building Sustainability AnalysisDocumento25 pagineBuilding Sustainability AnalysisvickersNessuna valutazione finora

- Chilled Beam Design GuideDocumento46 pagineChilled Beam Design GuiderjchpNessuna valutazione finora

- Cypetherm SuiteDocumento72 pagineCypetherm SuitevickersNessuna valutazione finora

- Cooling Load Temperature Difference Calculation MethodDocumento3 pagineCooling Load Temperature Difference Calculation Methodvickers50% (2)

- Comparative Table of ScrollsDocumento11 pagineComparative Table of ScrollsvickersNessuna valutazione finora

- Basics of HVACDocumento119 pagineBasics of HVACUmar FarooqNessuna valutazione finora

- CC - Rapid Load Calculator PDFDocumento1 paginaCC - Rapid Load Calculator PDFvickersNessuna valutazione finora

- CC - Quick Load CalculationsDocumento2 pagineCC - Quick Load CalculationsvickersNessuna valutazione finora

- ThermostatCatalog 570-280Documento12 pagineThermostatCatalog 570-280vickersNessuna valutazione finora

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocumento152 pagineChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersNessuna valutazione finora

- Chiller Types and ApplicationsDocumento73 pagineChiller Types and Applicationsvickers100% (3)

- INT69 KRIWAN Diagnosis SystemDocumento6 pagineINT69 KRIWAN Diagnosis Systemvickers100% (1)

- Refrigerant Charge CalculatorDocumento1 paginaRefrigerant Charge CalculatorBala Krishna GallaNessuna valutazione finora

- Multi V Water PDB (08.04.10 - ) Final PDFDocumento123 pagineMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionNessuna valutazione finora

- ZB Scroll Compressors ManualDocumento70 pagineZB Scroll Compressors ManualJavier AffifNessuna valutazione finora

- Supco TimersDocumento7 pagineSupco Timersvickers100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Safebridge 1Documento6 pagineSafebridge 1Garu VõNessuna valutazione finora

- CEMEX ReadyBlock Lightweight File016014Documento8 pagineCEMEX ReadyBlock Lightweight File016014Idrus IsmailNessuna valutazione finora

- Alpinevilla (Layouts & Costings)Documento16 pagineAlpinevilla (Layouts & Costings)rajnish kumarNessuna valutazione finora

- DSR 2012 SupplementDocumento2 pagineDSR 2012 SupplementDeeksha Bahl DiwanNessuna valutazione finora

- Consumers Guide To Gas FireplacesDocumento5 pagineConsumers Guide To Gas FireplacesSalsa_Picante_BabyNessuna valutazione finora

- Mls 61kettleholeroadboltonmaDocumento1 paginaMls 61kettleholeroadboltonmaapi-16137209Nessuna valutazione finora

- Kitchen Details by 0631 - DAGANTA PDFDocumento1 paginaKitchen Details by 0631 - DAGANTA PDFJay Carlo Daganta100% (1)

- BOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITDocumento3 pagineBOQ For Renovation of Bathrooms, Toilets & Sewage Line in A, B & C Block in Girls Hostel at MANITyamanta_rajNessuna valutazione finora

- Presented By, Pavankumar.N M.Tech 1 Sem Structural Engineering B.G.S.I.TDocumento22 paginePresented By, Pavankumar.N M.Tech 1 Sem Structural Engineering B.G.S.I.THamza MamiNessuna valutazione finora

- Classification of TimberDocumento7 pagineClassification of TimberMukhtaar Case0% (1)

- Own Notes. Timber ConstructionDocumento23 pagineOwn Notes. Timber ConstructionGraham BennettNessuna valutazione finora

- ITD-GEN-000-CIV-CHK-0005 - 0 - Building Civil ITPsDocumento16 pagineITD-GEN-000-CIV-CHK-0005 - 0 - Building Civil ITPsBerry UmpolaNessuna valutazione finora

- Loading On Typical Roof Slab: FinishDocumento25 pagineLoading On Typical Roof Slab: FinishAnonymous DCbkRoorNessuna valutazione finora

- Stone ColumnDocumento54 pagineStone ColumnFachreza AkbarNessuna valutazione finora

- Laurie Baker PDFDocumento63 pagineLaurie Baker PDFNayaab100% (1)

- Uploads Docs 2186Documento13 pagineUploads Docs 2186Sérgio GnipperNessuna valutazione finora

- Bermuda Residential Building Code 2014Documento422 pagineBermuda Residential Building Code 2014dmata90Nessuna valutazione finora

- National Highways Authority of IndiaDocumento8 pagineNational Highways Authority of IndiaNilay GandhiNessuna valutazione finora

- Pages From Div. 15-Mechanical - Full SetDocumento2 paginePages From Div. 15-Mechanical - Full SetJelak ChandranNessuna valutazione finora

- Lockable Dowels: For Temporary Movement Joints in Post-Tensioned ConcreteDocumento12 pagineLockable Dowels: For Temporary Movement Joints in Post-Tensioned ConcreteDaniel ChangNessuna valutazione finora

- Footing - f1 - f2 - Da RC StructureDocumento42 pagineFooting - f1 - f2 - Da RC StructureFrederickV.VelascoNessuna valutazione finora

- Are Cracks in Concrete Slab NormalDocumento3 pagineAre Cracks in Concrete Slab Normalmohannad eliassNessuna valutazione finora

- LSD Doubly Reinforced Simple Supported BeamDocumento10 pagineLSD Doubly Reinforced Simple Supported BeamRamilArtates100% (1)

- Cosh41 AttachmentDDocumento3 pagineCosh41 AttachmentDajmaluetNessuna valutazione finora

- Carmel Heights MIS Report 10th JanDocumento17 pagineCarmel Heights MIS Report 10th JanSasi KumarNessuna valutazione finora

- SOM - Chicago - Pearl River PDFDocumento23 pagineSOM - Chicago - Pearl River PDFAditi YadavNessuna valutazione finora

- East Meets West PHC Dharmapuri Case StudyDocumento17 pagineEast Meets West PHC Dharmapuri Case StudySAHAYA THARINI F0% (1)

- Leed Daylight BangaloreDocumento4 pagineLeed Daylight BangaloreRoma VadolaNessuna valutazione finora

- Fib Bulletin 65 ContentsDocumento7 pagineFib Bulletin 65 ContentsMarko ĆećezNessuna valutazione finora

- NCR 060816Documento2 pagineNCR 060816David Web0% (1)