Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Internal Tank Heaters

Caricato da

panos1959Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Internal Tank Heaters

Caricato da

panos1959Copyright:

Formati disponibili

Tank Heaters

Features/Benefits of Armstrong Tank Heaters

Application Flexibility

Four types of tank heaters are offered in several materials and sizes to suit your specific requirements. Several heaters are custom built, consult factory.

Space Savings

Flange Mounted Bayonet Type FBC and FBS

Flange mounted heaters are installed on various standard manhole sizes. You save internal space because only the heating element itself is inside. Steam and condensate connections are outside of the tank.

Heat Transfer Efficiency

Stiff, helically wound L fin design for an efficient and long-lasting heat transfer surface.

Vertical fin surface provides uniform heating of liquid with a minimum of coking due to hot spots.

Base Mounted Direct Type BD

Heating and Cooling Coils

Durability Over Long Life

Flange Mounted Hairpin Type FHC and FHS

Pipes and headers are of heavy construction (minimum Sch. 40 pipe for steel). Greater thickness means a stronger, more corrosion-resistant design that lasts longer.

Corrosion Resistance

Pipes, headers and connections are welded together for a tough, single material joint. Eliminating dissimilar materials precludes galvanic corrosion, thereby lengthening service life. Several heaters are custom built - consult factory.

Base Mounted Hairpin Type BHC and BHS

396

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Typical Tank Heater Arrangement

Base Mounted Hairpin Types BHC and BHS Shown

Heating and Cooling Coils

Base mounted heaters come with supports to allow for a proper distance between the tank bottom and the heating surface. This also helps to minimize the need for internal welding. Longer units are provided with mid-support members to further minimize inside welding and ensure rigid footing.

Fast, Direct Connection

Heaters are ready for connection to the steam and condensate systems as supplied. Numerous types of connections are available.

Minimum Installation Welding

Armstrong base-mounted tank heaters are installed and removed easily through manholes, eliminating the need for time-consuming welding inside the tank.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

397

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Tougher on the Job

Armstrong tank heaters are built to withstand the rigorous demands encountered in industrial installations. The heavyduty features of our units were developed in response to a need for tank heaters that could provide efficient heat transfer without sacrificing structural integrity. These features include heavy-wall pipes and headers, thick L footed fins and all welded construction. In addition, the mono-metallic construction of our units precludes galvanic corrosion, and the finned surface is rigid enough to withstand high-pressure cleaning. Experience gained over 80 years backs every Armstrong tank heater. As a steam system specialist, your Armstrong Representative can provide assistance with everything from the boiler to the condensate return system. Quality products from Armstrong, plus the practical knowledge to integrate them into your total steam system, ensure an efficient and trouble-free installation. This helically wound finned pipe is best suited for horizontal units, with the fins being in the vertical plane. This increases the natural convection currents, which increases heat transfer and continuously wipes the coil surface to maintain cleanliness.

Options to Match Your Applications

Armstrong tank heaters are available in four standard configurations: Flange Mounted HairpinTypes FHC and FHS Flange Mounted BayonetTypes FBC and FBS Base Mounted HairpinTypes BHC and BHS Base Mounted DirectType BD These four configurations offer a range of choices to suit most area coverage and thermal performance requirements. Each type includes a number of length, width and fin pitch options. All units are available in seamless carbon steel pipe construction. The hairpin and bayonet types are available in stainless steel. Liquid heated units and custom designs are also available. Critical to the heating and maintenance of temperatures for a broad variety of products, Armstrong tank heaters are widely used in breweries, chemical and food processing plants, oil refineries, paper mills, tank storage farms, and in shipping and other industries.

Efficient Heat Transfer

Finned pipe tank heaters are easier than bare pipe units to install, remove and repair. They are also more compact and provide superior efficiency in product heating. Finned pipe tank heaters provide up to 10 times as much heat transfer as an equivalent length of bare pipe, resulting in lower film or skin temperatures. This reduces coking of the product on the heat transfer surface and discoloration of heat-sensitive products. This buildup of deposits on the heater requires that more frequent cleanings be carried out to maintain maximum efficiency and original heat transfer design conditions.

Heating and Cooling Coils

398

From left to right, Base Mounted Hairpin, Flange Mounted Bayonet, Flange Mounted Hairpin and Base Mounted Direct.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Model Number Selection

MODEL NUMBER BH S 6 4 FPI 20

TYPE OF TANK HEATER

NOMINAL LENGTH

FINS PER INCH MATERIALS OF CONSTRUCTION UNIT NUMBER

Heating and Cooling Coils

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

399

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Flange Mounted Hairpin Type FHC and FHS

Overall = L + 12-1/8"

L + 8 L

Support by Others

A NPS

9/16" x 4" Long Slot

Standard Sizes

FHC Carbon Steel Units

Type A Flange Size (in) B (in) Nominal Length L(ft) 2 3 Surface Area (sq ft) 3 FPI 4 FPI 11.6 17.4 23.2 29.0 34.8 40.6 46.4 52.3 58.1 21.8 33.4 45.0 56.6 68.2 79.8 91.4 14.9 22.3 29.8 37.2 44.6 52.1 59.5 67.0 74.4 27.9 42.8 57.7 72.5 87.4 5 FPI 18.1 27.2 36.3 45.4 54.4 63.5 72.6 81.6 90.7 34.0 52.2 70.3 88.5 106.6 Weight (lb) 3 FPI 71 81 91 102 112 122 132 142 153 124 144 165 185 206 226 246 267 287 4 FPI 74 86 97 109 120 132 144 155 167 130 153 176 200 223 246 269 292 316 5 FPI 77 90 103 116 129 142 155 168 181 135 161 187 213 239 265 291 317 343 FHS-4 10 5-5/16 FHS-2 8 3-3/4

FHS Stainless Steel Units

Type A Flange Size (in) B (in) Nominal Length L(ft) 2 3 4 5 6 7 8 9 10 2 3 4 5 6 7 8 9 10 Surface Area (sq ft) 3 FPI 4 FPI 8.8 13.1 17.5 21.9 26.3 30.6 35.0 39.4 43.8 17.5 26.3 35.0 43.8 52.5 61.3 70.0 78.8 87.6 11.1 16.6 22.2 27.7 33.3 38.8 44.4 49.9 55.5 22.2 33.3 44.4 55.5 66.6 77.7 88.8 99.9 5 FPI 13.4 20.1 26.9 33.6 40.3 47.0 53.7 60.4 67.2 26.9 40.3 53.7 67.2 80.6 94.0 107.5 120.9 Weight (lb) 3 FPI 60 65 71 76 82 87 92 98 103 100 111 122 132 143 154 165 176 186 4 FPI 61 67 73 79 85 91 97 103 109 102 114 126 138 150 162 174 186 198 5 FPI 62 69 75 82 88 95 101 108 114 105 118 131 144 157 170 183 196 209

Heating and Cooling Coils

4 5 FHC-2 8 3-3/4 6 7 8 9 10 2 3 4 5 FHC-4 10 5-5/16 6 7 8 9 10

102.3 124.7 117.2 142.9

103.1 132.1 161.0 114.7 146.9 179.2

111.0 134.3

Materials of Construction Pipes: 1-1/4" NPS Sch. 80 Seamless Steel (1.66" OD x 0.191" Wall) Fins: 0.036" Thick Helically Wound Steel L Foot Return Bends: A-234 Long Radius Forged Steel Sch. 80 Mounting Flange: A-105 Forged Steel, 150 lb Raised Face Mechanical Design: 450 psig, 650F, Standard Testing Pressure 675 psi

Materials of Construction Pipes: 1-1/4" NPS Sch. 10, 304L SS (1.66" OD x 0.109" Wall) Fins: 0.020" Thick Helically Wound 304 SS L Foot Return Bends: A-403 Long Radius 304L SS Sch. 10 Mounting Flange: A-182 304L SS, 150 lb Raised Face Mechanical Design: 450 psig, 650F, Standard Testing Pressure 675 psi NOTE: Type 316L SS Construction is available.

400

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Flange Mounted Bayonet Type FBC and FBS

Overall = L + 16"

L + 6" L Vent C MPT Supply B MPT Support by Others 9/16" x 2" Long Slot Return C MPT A NPS

Standard Sizes

FBC Carbon Steel Units

Type A Flange Size (in) B (in) C (in) Nominal Surface Area (sq ft) Weight (lb) Length L(ft) 3 FPI 4 FPI 5 FPI 3 FPI 4 PFI 5 FPI 2 3 4 5 FBC-125 4 3/4 3/4 6 7 8 9 10 2 3 4 5 FBC-200 6 1 1 6 7 8 9 10 2 3 4 5 FBC-250 6 1-1/4 1 6 7 8 9 10 5.8 8.7 11.6 14.5 17.4 20.3 23.2 26.1 29.0 7.9 11.8 15.7 19.7 23.6 27.6 31.5 35.4 39.4 9.2 13.8 18.4 23.0 27.6 32.2 36.8 41.4 46.0 7.4 11.2 14.9 18.6 22.3 26.0 29.8 33.5 37.2 10.1 15.1 20.2 25.2 30.2 35.3 40.3 45.4 50.4 11.8 17.7 23.5 29.4 35.3 41.2 47.1 53.0 58.9 9.1 13.6 18.1 22.7 27.2 31.8 36.3 40.8 45.4 12.3 18.4 24.6 30.7 36.9 43.0 49.2 55.3 61.5 14.3 21.5 28.7 35.8 43.0 50.2 57.4 64.5 71.7 33 39 45 51 57 63 69 75 81 50 59 67 76 85 94 102 111 120 60 72 84 97 109 121 133 145 158 34 41 47 54 60 67 74 80 87 52 62 71 81 91 101 110 120 130 62 75 89 102 115 129 142 155 168 35 42 50 57 64 72 79 86 93 54 65 75 86 96 107 118 128 139 65 79 94 108 123 137 151 166 180 FBS-250 6 1-1/4 1 FBS-200 6 1 1 FBS-125 4 3/4 3/4

FBS Stainless Steel Units

Type A Flange B Size (in) (in) C (in) Nominal Surface Area (sq ft) Weight (lb) Length L(ft) 3 FPI 4 FPI 5 FPI 3 FPI 4 PFI 5 FPI 2 3 4 5 6 7 8 9 10 2 3 4 5 6 7 8 9 10 2 3 4 5 6 7 8 9 10 4.4 6.6 8.8 10.9 13.1 15.3 17.5 19.7 21.9 6.0 8.9 11.9 14.9 17.9 20.8 23.8 26.8 29.8 6.9 10.4 13.8 17.3 20.7 24.2 27.6 31.1 34.5 5.5 8.3 11.1 13.9 16.6 19.4 22.2 25.0 27.7 7.5 11.3 15.0 18.8 22.6 26.3 30.1 33.8 37.6 8.7 13.0 17.4 21.7 26.1 30.4 34.8 39.1 43.5 6.7 10.1 13.4 16.8 20.1 23.5 26.9 30.2 33.6 9.1 13.6 18.2 22.7 27.3 31.8 36.4 40.9 45.5 10.5 15.7 21.0 26.2 31.5 36.7 42.0 47.2 52.5 27 31 34 38 41 45 48 52 55 41 46 51 57 62 67 72 77 83 46 53 59 66 73 80 86 93 100 28 32 36 39 43 47 51 55 58 42 48 53 59 64 70 76 81 87 47 54 61 69 76 83 90 97 105 29 33 37 41

Heating and Cooling Coils

45 50 54 58 62 43 49 55 61 67 73 79 85 91 48 56 63 71 78 86 94 101 109

Materials of Construction FBC-125 Pipes: 1-1/4" NPS Sch. 40 Seamless Steel (1.66" OD x 0.140" Wall) FBC-200 Pipes: 2" NPS Sch. 40 Seamless Steel (2.375" OD x 0.154" Wall) FBC-250 Pipes: 2-1/2" NPS Sch. 40 Seamless Steel (2.875" OD x 0.203" Wall) Fins: 0.036" Thick Helically Wound Steel L Foot Inner Distributing Pipe: Sch. 80A-53F Steel End Caps: A-234 Forged Steel Sch. 40 Mounting Flange: A-105 Forged Steel, 150 lb Raised Face Mechanical Design: 450 psig, 650F, Standard Testing Pressure 675 psi NOTE: Sch. 80 Construction is available.

Materials of Construction FBS-125 Pipes: 1-1/4" NPS Sch. 10, 304L SS (1.66" OD x 0.109" Wall) FBS-200 Pipes: 2" NPS Sch. 10, 304L SS (2.375" OD x 0.109" Wall) FBS-250 Pipes: 2-1/2" NPS Sch. 10, 304L SS (2.875" OD x 0.120" Wall) Fins: 0.020" Thick Helically Wound 304 SS L Foot Inner Distributing Pipe: Sch. 10, 304L SS End Caps: A-403, 304L SS, Sch. 10 Mounting Flange: A-182, 304L SS, 150 lb Raised Face Mechanical Design: 450 psig, 650F, Standard Testing Pressure 675 psi NOTE: Type 316L SS Construction is available.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

401

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Base Mounted Hairpin Type BHC and BHS

W 1-1/2" 5-1/2" C/C 4"

1) 15 ft. and 20 ft. units have center supports. 2) Header ends are beveled for on-site butt welding.

2-1/8"

Overall + L + 13"

L 1" Slope

1" Slope

Standard Sizes

BHC Carbon Steel Units

Type Minimum Manhole Size (in) W (in) Nominal Surface Area (sq ft) Weight (lb) Length L(ft) 3 FPI 4 FPI 5 FPI 3 FPI 4 FPI 5 FPI 5 BHC-4 16 7-1/8 10 15 20 5 BHC-6 18 10-1/4 10 15 20 5 BHC-8 22 13-3/8 10 15 20 5 BHC-10 24 16-1/2 10 15 20 59 118 178 237 89 178 266 355 118 237 355 473 148 296 444 592 76 152 228 304 114 228 342 456 152 304 456 608 190 380 570 760 93 186 278 371 139 278 418 557 186 371 557 742 232 464 696 928 108 198 293 384 158 294 435 570 208 389 576 757 258 484 717 123 228 338 444 180 339 502 660 238 449 666 877 295 559 830 138 258 383 503 203 383 569 749 268 508 755 995 332 633 941 BHS-8 22 13-3/8 BHS-10 24 16-1/2 BHS-6 18 10-1/4 BHS-4 16 7-1/8

BHS Stainless Steel Units

Type Minimum Manhole Size (in) W (in) Nominal Surface Area (sq ft) Weight (lb) Length L(ft) 3 FPI 4 FPI 5 FPI 3 FPI 4 FPI 5 FPI 5 10 15 20 5 10 15 20 5 10 15 20 5 10 15 20 44 88 131 175 66 131 197 263 88 175 263 350 109 219 328 438 55 111 166 222 83 166 250 333 111 222 333 444 139 277 416 555 67 134 201 269 101 201 302 403 134 269 403 537 168 336 504 672 70 124 182 236 101 182 268 349 133 240 354 462 164 299 440 575 76 135 199 256 110 199 294 384 144 264 389 508 179 328 484 633 81 147 217 282 119 217 320 418 156 287 424 555 193 357 527 691

Heating and Cooling Coils

943 1,093 1,241

Materials of Construction Pipes: 1-1/4" NPS Sch. 40 Seamless Steel (1.66" OD x 0.140" Wall) Fins: 0.036" Thick Helically Wound Steel L Foot Headers: 2" NPS Sch. 40 Seamless Steel (2.375" OD x 0.154" Wall) Return Bends: A-234 Long Radius Forged Steel Sch. 40 Mechanical Design: 450 psig, 650F, Standard Testing Pressure 675 psi NOTE: Sch. 80 Construction is available.

Materials of Construction Pipes: 1-1/4" NPS Sch. 10, 304L SS (1.66" OD x 0.109" Wall) Fins: 0.020" Thick Helically Wound 304 SS L Foot Headers: 2" NPS Sch. 40, 304L SS (2.375" OD x 0.154" Wall) Return Bends: A-403 Long Radius 304L SS Sch. 10 Mechanical Design: 450 psig, 650F, Standard Testing Pressure 675 psi NOTE: Type 316L SS Construction is available.

402

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Base Mounted Direct Type BD

L + 6-7/8"

L

4"

7-1/2"

10"

Overall = L + 11-3/4"

1) 15 ft and 20 ft units have center supports. 2) Header ends are beveled for on-site butt welding.

Standard Sizes

BD Carbon Steel Units

Type Minimum Manhole Size (in) W (in) Nominal Surface Area (sq ft) Weight (lb) Length L(ft) 3 FPI 4 FPI 5 FPI 3 FPI 4 FPI 5 FPI 5 BD-2 14 7-1/8 10 15 20 5 BD-3 16 10-1/4 10 15 20 5 BD-4 20 13-3/8 10 15 20 5 BD-5 22 16-1/2 10 15 20 30 59 89 118 45 89 134 178 59 118 177 237 74 148 222 296 38 76 114 152 57 114 171 228 76 152 228 304 95 190 285 380 47 93 140 186 70 139 209 278 93 186 279 371 116 232 348 464 60 104 156 201 86 154 227 295 112 203 298 389 138 251 369 482 68 121 179 231 97 177 261 340 127 233 343 449 157 288 425 557 75 135 201 261 109 199 294 384 142 262 388 508 175 325 481 631

Heating and Cooling Coils

Materials of Construction Pipes: 1-1/4" NPS Sch. 40 Seamless Steel (1.66" OD x 0.140" Wall) Fins: 0.036" Thick Helically Wound Steel L Foot Headers: 2" NPS Sch. 40 Seamless Steel (2.375" OD x 0.154" Wall) Mechanical Design: 450 psig, 650F, Standard Testing Prsesure 675 psi NOTE: Sch. 80 Construction is available. These units are available only in Carbon Steel.

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

403

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Tank Heater Selection Work Sheet

Tank Information

Tank Reference Number_ ________________________________ Tank Type____________________________________________ Tank Material_ ________________________________________ Dimensions _ _________________________________________ feet Insulated? _ ___________ If yes, how thick? _ ______________ inches Open Top?_ __________________________________________ Tank Level (% full) or Fluid Volume________________________ Design Ambient Air Temperature _ ________________________ F Design Wind Velocity (if outside and not insulated)____________ mph

Steam Information

Steam Pressure ________ psig Saturated? ____________ If not, what temperature?__________ F

Fluid Information

Heating and Cooling Coils

Type of Fluid__________________________________________ Properties (not required for water)_________________________ 1. Specific Gravity _ _____ at ____________________________ F or Density _ __________ lb/cu ft at_ ______________________ F or Density _ __________ lb/US gal at ____________________ F 2. Specific Heat_________ Btu/lb/F at _ ___________________ F 3. Viscosity (at least one value required, preferably two) units_ _______________ _ __________________ at ____________________________ F _ __________________ at ____________________________ F

Heating Requirements

A. Through Load ______________________USGPM at ______ F __________ not applicable B. Heat-Up Load from ______ F to ______ F in ___________ hours _______ not applicable C. Maintenance Load to Hold ___________ F D. Total Heat Load (if known) ___________ Btu/hr

Tank Heater Requirements

1. Materials of Construction A. Carbon Steel_ ____________________________________ B. Type 304L Stainless Steel___________________________ C. Type 316L Stainless Steel___________________________ 2. Type of Unit A. Flange Mounted _ _________________(preference? Hairpin _______ Bayonet_________) B. Base Mounted ____________________(preference? Hairpin _______ Direct___________) If flange mounted, is std. flange size OK?_________ If not, specify size________________ 3. Maximum tank opening to insert heater into the tank:__________ inches.

Other Information

____________________________________________________________________________________ ____________________________________________________________________________________ ____________________________________________________________________________________

404

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Notes

Heating and Cooling Coils

Designs, materials, weights and performance ratings are approximate and subject to change without notice. Visit www.armstronginternational.com for up-to-date information.

405

North America Latin America India Europe / Middle East / Africa China Pacic Rim

armstronginternational.com

Next

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Power Plants Ratings GuideDocumento15 paginePower Plants Ratings Guidepanos1959Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Best Practice Manual-CogenerationDocumento76 pagineBest Practice Manual-Cogenerationpradeep kumarNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- EA Guide-CitizensDocumento29 pagineEA Guide-Citizenspanos1959Nessuna valutazione finora

- Methanol To Control Water Freezing ReportDocumento109 pagineMethanol To Control Water Freezing Reportpanos1959Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Cost Optimal Selection of Storage Tanks in LPG Vaporization StationDocumento6 pagineCost Optimal Selection of Storage Tanks in LPG Vaporization Stationpanos1959Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Physical Properties of MethanolDocumento4 paginePhysical Properties of Methanolpanos1959Nessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- FeasibilityStudy 2000Documento1 paginaFeasibilityStudy 2000panos1959Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- B 1 1 4 Inplant Fluid FlowDocumento5 pagineB 1 1 4 Inplant Fluid FlowBolívar AmoresNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Guy TowerDocumento103 pagineGuy Towerashraf04_ceNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Caracteristicas Del Tubo PDFDocumento3 pagineCaracteristicas Del Tubo PDFAbelino Vargas Tenjo100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 3006 SelectchartDocumento1 pagina3006 SelectchartAbby MakarimNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Vivek Vinayakumar: Work Experience SkillsDocumento1 paginaVivek Vinayakumar: Work Experience SkillsVivek VinayakumarNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Asbestos Graphite Packing RopeDocumento8 pagineAsbestos Graphite Packing RopeGnanasekar VaishniNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Documento2 pagine1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- Sanand GIDCDocumento22 pagineSanand GIDCmaulik1621976Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- VI XV Xvii Xix XX Xxi: This Page Has Been Reformatted by Knovel To Provide Easier NavigationDocumento15 pagineVI XV Xvii Xix XX Xxi: This Page Has Been Reformatted by Knovel To Provide Easier NavigationsebasfarsaNessuna valutazione finora

- Piping Thickness Measurement ReportDocumento1 paginaPiping Thickness Measurement ReportTevriyudha MardikaNessuna valutazione finora

- Technical Guidelines For Connection To District Cooling SystemDocumento30 pagineTechnical Guidelines For Connection To District Cooling Systemrizkboss8312Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Pre-Owned Equipment - Grundoburst 400G Pipe BursterDocumento1 paginaPre-Owned Equipment - Grundoburst 400G Pipe BurstercharneNessuna valutazione finora

- Method Statement of Hydraulic Pressure Test For Transmission Pipe Line-1Documento10 pagineMethod Statement of Hydraulic Pressure Test For Transmission Pipe Line-1gawtomNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Nfpa 22 IndexDocumento5 pagineNfpa 22 Indexsaladin1977Nessuna valutazione finora

- API Plans - FlowserveDocumento66 pagineAPI Plans - FlowserveJosé Alberto Herrera100% (2)

- Method Statement (MST) For Painting Work: Petronas Rapid ProjectDocumento9 pagineMethod Statement (MST) For Painting Work: Petronas Rapid ProjectAmirHakimRusliNessuna valutazione finora

- Collar Bolts: in Shell and Tube Heat ExchangersDocumento2 pagineCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Water Quality AnalyzerDocumento1 paginaWater Quality AnalyzerVictor BiacoloNessuna valutazione finora

- Rust Veto MPDocumento3 pagineRust Veto MPSubrata DasNessuna valutazione finora

- AGIP STD - Valves Specification SheetDocumento1 paginaAGIP STD - Valves Specification Sheethalim_ka100% (1)

- Company Profile - MetalmanDocumento46 pagineCompany Profile - MetalmanSahil BhatiaNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Water Spray Test To Internal InstallationDocumento5 pagineWater Spray Test To Internal InstallationWai Ling WongNessuna valutazione finora

- Hazen-William Pipe Losses CalculatorDocumento9 pagineHazen-William Pipe Losses CalculatorSing Kho Fibonacci KuanNessuna valutazione finora

- Hydro Test ProcedureDocumento17 pagineHydro Test Procedureyaser elgoharyNessuna valutazione finora

- TAC For Sprinkler SystemDocumento128 pagineTAC For Sprinkler SystemRaj Kamal80% (5)

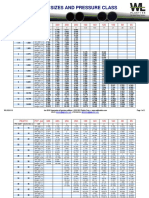

- WL102-0118 Ips Size Chart Pe4710Documento2 pagineWL102-0118 Ips Size Chart Pe4710MarcoiNessuna valutazione finora

- 10 Componentes de La Torre de PerforacionDocumento4 pagine10 Componentes de La Torre de PerforacionMauricio Flores VidaurreNessuna valutazione finora

- Saes T 911Documento67 pagineSaes T 911abdulNessuna valutazione finora

- Fire Protection Industry - UkDocumento6 pagineFire Protection Industry - UkUtsav GoswamiNessuna valutazione finora

- Steam Velocity Chart ExampleDocumento2 pagineSteam Velocity Chart ExampleAhmad Deyab100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)