Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Grout

Caricato da

Marina Gomáriz ElgerDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Grout

Caricato da

Marina Gomáriz ElgerCopyright:

Formati disponibili

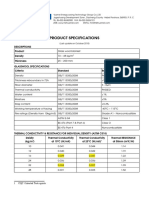

MEKASTER has commenced manufacture/assembly of a range of Grouting Systems, under Licence from world renowned HNY AG*, Switzerland.

Grouting was for a long time considered to be an art rather than a science. Much of that had to do with little knowledge of the reaction of the grout in the ground and the lack of modern 'State of the Art' equipment. With the recent developments in both, equipment and materials grouting is now more and more accepted as an efficient method for the treatment of soil and rock formations. Hence, choosing the right equipment is of the utmost importance, which Mekaster is now providing.

Grout Pumps - Series ZMP 600/700/800

A full range of Hny ZMP grout pumps covers almost every grouting requirement. These low-wear plunger type pumps handle a wide variety of grout mixes from neat cement suspensions to backfill mortar with sand of up to 8 mm particle sizes. All pumps are equipped with the automatic pressure control system (APC). With this system, the maximum pumping pressure can be preset on the hydraulic power pack. Whenever the preset pressure is reached, the pump automatically adjusts its output according to the grout take of the ground. Whenever the grout take ceases, the pump stops and maintains the pressure. The pumping rate can also be adjusted to meet the requirements of the particular ground conditions. The ZMP 700 series can be equipped with different plunger units to cover a wide range of pumping pressures and capacities.

ZMP 610V

Economic single acting pump for all applications

ZMP 625V Double Acting pump

for all applications

ZMP 710V Versatile single acting pump

for all applications

ZMP 712V

Economic single acting pump for all applications

DOUBLE ACTING GROUT PUMPS

Model Plunger Capacity Max. (W/C ratio = 1) Pressure Max. Pressure Min. Particle size max. Motor rating 50Hz ZMP mm m3/h bar bar mm kW 625V 65 2 100 3 5 5.5 85 5.5 100 2 725V 105 8.5 68 1.5 8 9 120 11 50 1

ZMP 725V Versatile high capacity double

single acting pump for all applications

SINGLE ACTING GROUT PUMPS

Model Plunger Capacity Max. (W/C ratio = 1) Pressure Max. Pressure Min. Particle size max. Motor rating ZMP mm m3/h bar bar mm kW 610V 65 1.5 100 3 5 5.5 85 3.9 100 2 710V 105 5.5 68 1.5 8 5.5 120 7.5 50 1 85 2.4 90 2.5 712V 105 3.8 58 2 8 7.5 120 4.9 45 1.5

50Hz

* Hny is a registered trademark of Hny AG, Switzerland.

High Shear Colloidal Mixer - HCM

The HCM line of highshear (colloidal) mixers is recognized worldwide for its excellent mixing performance, efficiency and wear resistance. The HCM mixers will mix water with bentonite, cement, ultra-fine cement and other similar suspensions effectively. Sands up to 8 mm particle sizes can even be added on the smaller HCM 300. The mixers can be equipped with a weigh-batching system to automatically batch and mix up to three dry ingredients and three chemical additives with water.

Model Mixing pump Capacity Max. (W/C ratio = 1) Circulation capacity Usable content Maximum particle size Motor rating 50Hz

HCM Typ m3/h l/min l mm kW

100 TMP9 2.8 360 100 3 3

300 TMP18 5 1000 260 8 5.5

300 TMP22 5 1400 260 8 9

Agitators - HRW

The HRW agitators are used as holding tanks between the HCM batch mixers and the pump. In the slowly revolving agitator, the grout suspensions are homogenized and air bubbles are removed.

Model Usable content Motor rating

HRW l kW

160 160 0.75

350 350 0.55

50Hz

Compact Grout Plants - INJECTO-COMPACT (IC)

The INJECTO-COMPACT (IC) grout plants consist of an HCM mixer, an HRW agitator and a ZMP grout pump. All components are functionally arranged on a common base with a central lifting point. The use of the INJECTO-COMPACT grout plants reduce considerably the installation time on site and minimises operating personnel. The INJECTO-COMPACT (IC) 310/325 are suitable for grouting tie-back anchors, rock bolts, soil nails, tension cables as well as for tube--manchette and rock grouting. In microtunnelling, these compact plants are used to mix and inject bentonite suspensions.

INJECTO-COMPACT Grout pump Capacity Max. (W/C ratio = 1) Pressure Max Motor rating 50Hz

IC ZMP m3/h bar kW

310 610V 1.5 100 9

325 625V 2 100 9

650 710V 5 100 11.5

650 712V 4.9 90 13.5

650 725V 5 100 15

Potrebbero piacerti anche

- Amp MBW 800amp@2006 SmallDocumento4 pagineAmp MBW 800amp@2006 Smalljanuar92021068100% (1)

- Piston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresDocumento10 paginePiston Pumps Paste-Thickened Tailings PB-PPPT-0215 LowresMartin Lara100% (1)

- MCI 2000/725 Mixing and Grouting Plant For Soil-Mixing, Bangkok, ThailandDocumento4 pagineMCI 2000/725 Mixing and Grouting Plant For Soil-Mixing, Bangkok, ThailandebsboliviaNessuna valutazione finora

- PowerStop Shock Absorber CatalogDocumento24 paginePowerStop Shock Absorber CatalogAfiyat Nur100% (1)

- Bomba Submersa FE - Petro STPDocumento6 pagineBomba Submersa FE - Petro STProbsonlagambaNessuna valutazione finora

- Eco PumpDocumento13 pagineEco PumpAntonioNessuna valutazione finora

- Sulzer Pumps For Paper IndustryDocumento4 pagineSulzer Pumps For Paper IndustryBapu612345Nessuna valutazione finora

- Mobile Systems BrochureDocumento16 pagineMobile Systems BrochureBoban StanojlovićNessuna valutazione finora

- Table Roller Mill AWMDocumento2 pagineTable Roller Mill AWMjofyNessuna valutazione finora

- Sauerbibus Sumitomo High Performance Gear Pumps Catalogue en 201007Documento28 pagineSauerbibus Sumitomo High Performance Gear Pumps Catalogue en 201007RonaldWisemanNessuna valutazione finora

- Sistemas Hidrostaticos para Maquinas ConcreterasDocumento16 pagineSistemas Hidrostaticos para Maquinas ConcreterasEdwin Uceda Alva100% (1)

- ERKE Group, Drillmec Mud Pumps CatalogDocumento12 pagineERKE Group, Drillmec Mud Pumps Catalogerkegroup100% (1)

- Oerlikon Leybold Roots Blower Vacuum Pump CatalogDocumento40 pagineOerlikon Leybold Roots Blower Vacuum Pump CatalogYasir Ali100% (1)

- Durco Mark III - Flowserve PumpDocumento4 pagineDurco Mark III - Flowserve PumpakklamNessuna valutazione finora

- Samoa Section 2 Pages25 32Documento8 pagineSamoa Section 2 Pages25 32Wiki YuanditraNessuna valutazione finora

- Myers MPBDocumento4 pagineMyers MPBMarianna MaRoNessuna valutazione finora

- KHD Comflex April 2012Documento4 pagineKHD Comflex April 2012m_verma21Nessuna valutazione finora

- Brochure Tank FarmDocumento7 pagineBrochure Tank FarmSagar DasNessuna valutazione finora

- Krebs Mill Max Centrifugal Slurry Pump We BXDocumento8 pagineKrebs Mill Max Centrifugal Slurry Pump We BXPhaniNessuna valutazione finora

- Progressing Cavity Pumps: Colfax AmericasDocumento12 pagineProgressing Cavity Pumps: Colfax AmericasKhairil AjjaNessuna valutazione finora

- Product Catalogue SomefluDocumento20 pagineProduct Catalogue SomefluIlkuNessuna valutazione finora

- Unigrout Flex M - Technical Specification - EnglishDocumento8 pagineUnigrout Flex M - Technical Specification - EnglishEmrah MertyürekNessuna valutazione finora

- Gast Compressed Air Systems enDocumento11 pagineGast Compressed Air Systems enKrzysiek PodsiadłoNessuna valutazione finora

- Unigrout Grouting Platforms: Atlas Copco Underground Rock ExcavationDocumento8 pagineUnigrout Grouting Platforms: Atlas Copco Underground Rock ExcavationVittorioNessuna valutazione finora

- 1Documento28 pagine1Enrique MurgiaNessuna valutazione finora

- Portafolio Sulzer PumpsDocumento24 paginePortafolio Sulzer PumpssagitroseNessuna valutazione finora

- Complete Range of Sintech Make PumpsDocumento8 pagineComplete Range of Sintech Make PumpssahildhingraNessuna valutazione finora

- JEREH Batch Mixing PHQ210Documento27 pagineJEREH Batch Mixing PHQ210Izma Pallfrey100% (1)

- Bombas Estacionarias SP 2800Documento2 pagineBombas Estacionarias SP 2800SchwingLatinoamerica100% (1)

- E HM 60 TD enDocumento68 pagineE HM 60 TD enRoger Quevedo MachucaNessuna valutazione finora

- Hidro TransmisijaDocumento31 pagineHidro TransmisijaMaximus MaxisNessuna valutazione finora

- Catálogo General UPA 50 HZ 2 PARTEDocumento20 pagineCatálogo General UPA 50 HZ 2 PARTENao Oi OiNessuna valutazione finora

- Emp Dry ProcessDocumento6 pagineEmp Dry ProcessragandaNessuna valutazione finora

- Fluid Metering CatalogueDocumento32 pagineFluid Metering CatalogueVikrantNessuna valutazione finora

- Shot Blasting System-SH Industrial MachineryDocumento23 pagineShot Blasting System-SH Industrial Machineryjubail13Nessuna valutazione finora

- Reciprocating Compressor Optimum Design PDFDocumento6 pagineReciprocating Compressor Optimum Design PDF최승원Nessuna valutazione finora

- Variable Speed Pump Komsta Powerpoint PresentationDocumento40 pagineVariable Speed Pump Komsta Powerpoint PresentationMohamed Semeda100% (1)

- Pump Concrete Mixture by Balaji Construction Equipment WestbengalDocumento27 paginePump Concrete Mixture by Balaji Construction Equipment WestbengalLavanya VashistNessuna valutazione finora

- Krebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsDocumento4 pagineKrebs Millmax-E Pump: The New High-Efficiency Slurry Pump Designed For Abrasive Slurry ApplicationsPhaniNessuna valutazione finora

- Gorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsDocumento8 pagineGorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsVic Van PeborghNessuna valutazione finora

- 03 Sidebar Filter Presses CatalogueDocumento12 pagine03 Sidebar Filter Presses CatalogueaptpmrezaNessuna valutazione finora

- Totaline Dual Stage Vacuum Pumps: 1.8 CFM - 7 CFMDocumento2 pagineTotaline Dual Stage Vacuum Pumps: 1.8 CFM - 7 CFMRick CarlosNessuna valutazione finora

- Advantages PCP For Offshore ApplicationDocumento4 pagineAdvantages PCP For Offshore ApplicationDwi Hermanto SetiawanNessuna valutazione finora

- Hydraulic PressDocumento24 pagineHydraulic Pressjyoti1234321100% (3)

- Hermatic LRVP CatalogueDocumento12 pagineHermatic LRVP CatalogueSunil BawaneNessuna valutazione finora

- Dealcorp MexicoDocumento6 pagineDealcorp MexicoJesus DugarteNessuna valutazione finora

- AFG Alpine Fluidised Bed Opposed Jet Mills (En)Documento10 pagineAFG Alpine Fluidised Bed Opposed Jet Mills (En)alevandrorNessuna valutazione finora

- Malmedi 50HZ 14-09-04Documento538 pagineMalmedi 50HZ 14-09-04rhusseinpos4765Nessuna valutazione finora

- Cement Plant - Energy OptimisationDocumento12 pagineCement Plant - Energy OptimisationSatya MakhijaNessuna valutazione finora

- Mobile2012 PDFDocumento12 pagineMobile2012 PDFeng13Nessuna valutazione finora

- Truck-Mounted Fire Pump SeriesDocumento8 pagineTruck-Mounted Fire Pump SeriesviceroseNessuna valutazione finora

- Motorized Ramming MachineDocumento53 pagineMotorized Ramming Machineilayaraja6100% (1)

- Flygt 5100-5150 PumpsDocumento8 pagineFlygt 5100-5150 PumpsRobsBerto ManzanedaNessuna valutazione finora

- Pumping SolutionsforDesalinationAndWaterReuse - E00551Documento16 paginePumping SolutionsforDesalinationAndWaterReuse - E00551Asad KhudriNessuna valutazione finora

- XD9 Whisper Vane Transfer Pump: VarnaDocumento4 pagineXD9 Whisper Vane Transfer Pump: Varnapippo2378793Nessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDa EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideValutazione: 4 su 5 stelle4/5 (8)

- Prezentare ComacchioDocumento27 paginePrezentare ComacchioMarina Gomáriz ElgerNessuna valutazione finora

- FEX enDocumento2 pagineFEX enMarina Gomáriz ElgerNessuna valutazione finora

- Catalogue A 2009Documento55 pagineCatalogue A 2009Marina Gomáriz ElgerNessuna valutazione finora

- Bellin Pumps CatalogueDocumento8 pagineBellin Pumps CatalogueMarina Gomáriz ElgerNessuna valutazione finora

- EarthingDocumento63 pagineEarthingLiMe GrEenNessuna valutazione finora

- Sand Treatment Package (Asabi-A-3401) 34665 Ponticelli - Al Shaheen PWTDocumento3 pagineSand Treatment Package (Asabi-A-3401) 34665 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNessuna valutazione finora

- Liquefaction Mechanism of SoilsDocumento11 pagineLiquefaction Mechanism of SoilsCSEngineerNessuna valutazione finora

- Terminal Report OJT MTTDocumento4 pagineTerminal Report OJT MTTJun MichaelNessuna valutazione finora

- En 01542 - 1999 Pull OffDocumento10 pagineEn 01542 - 1999 Pull OffPriceMarkNessuna valutazione finora

- Sample CSHP (Safety&Health D.O.13 DOLE)Documento1 paginaSample CSHP (Safety&Health D.O.13 DOLE)Jemsel D. Valdez, Sr.Nessuna valutazione finora

- Powell Hydraulic Hose Catalogue Price List 2017Documento20 paginePowell Hydraulic Hose Catalogue Price List 2017Anonymous VRspXsmNessuna valutazione finora

- (2020) Experimental Comparisons of Repairable Precast Concrete Shear Walls With ADocumento16 pagine(2020) Experimental Comparisons of Repairable Precast Concrete Shear Walls With ASofía Córdoba SáenzNessuna valutazione finora

- Solid Wall Pipe System Made With PP-MD According To DIN 14758Documento2 pagineSolid Wall Pipe System Made With PP-MD According To DIN 14758Carjan BogdanNessuna valutazione finora

- External Fire Fighting WorksDocumento28 pagineExternal Fire Fighting WorksSaurabh Kumar Sharma100% (1)

- Elastomeric Bearings RCC Bridge Over R. Subarnarekha On Purulia-Ranchi RoadDocumento3 pagineElastomeric Bearings RCC Bridge Over R. Subarnarekha On Purulia-Ranchi RoadRudranath BhattacharyaNessuna valutazione finora

- Hollow SectionsDocumento199 pagineHollow SectionsmandregomesNessuna valutazione finora

- Road CoastingDocumento145 pagineRoad CoastingBhavsar NilayNessuna valutazione finora

- URS SpecsDocumento248 pagineURS SpecsIbrahim SNessuna valutazione finora

- For Web IFPs As of July 2019v2Documento63 pagineFor Web IFPs As of July 2019v2ram roebucNessuna valutazione finora

- Clean Room Wall FinishDocumento6 pagineClean Room Wall FinishjoannakahlNessuna valutazione finora

- HSEQ-QA-CMS0016-CIV-2914 CMS Pile Material ReceivalDocumento26 pagineHSEQ-QA-CMS0016-CIV-2914 CMS Pile Material ReceivalDoni TriatmojoNessuna valutazione finora

- Maps - Useful Phrases (Updated) (2021)Documento2 pagineMaps - Useful Phrases (Updated) (2021)Vy Đặng ThảoNessuna valutazione finora

- Alluminium Composite Panel-FlexibondDocumento4 pagineAlluminium Composite Panel-Flexibondedars08Nessuna valutazione finora

- TYSONS - Food CourtDocumento20 pagineTYSONS - Food CourtManivannan J100% (1)

- Civil Engineering and Its Different SocietiesDocumento7 pagineCivil Engineering and Its Different Societieslonyx27Nessuna valutazione finora

- Technical Instruction Manual: Meva Formset MfsDocumento20 pagineTechnical Instruction Manual: Meva Formset MfspablopelaNessuna valutazione finora

- 2 Straight Line Diag.Documento1 pagina2 Straight Line Diag.Nix GabrielNessuna valutazione finora

- DNV CG 0044Documento16 pagineDNV CG 0044Cheok CH100% (1)

- Concrete Pouring During The RainDocumento3 pagineConcrete Pouring During The RainEvello MercanoNessuna valutazione finora

- Core CompetencyDocumento241 pagineCore CompetencyYeng LugtuNessuna valutazione finora

- Huamei Spec Sheets - 2018Documento1 paginaHuamei Spec Sheets - 2018Phan LongNessuna valutazione finora

- Balancing Valve (DRV) (1 4218 4x) GMFDocumento5 pagineBalancing Valve (DRV) (1 4218 4x) GMFSHINOS 3SNessuna valutazione finora

- The Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDocumento6 pagineThe Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDavid TolentinoNessuna valutazione finora

- Europacable Cable Technology UpdateDocumento13 pagineEuropacable Cable Technology UpdateA. HassanNessuna valutazione finora