Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Branch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Code

Caricato da

deua20040 valutazioniIl 0% ha trovato utile questo documento (0 voti)

88 visualizzazioni2 paginepipe

Titolo originale

pipe.docx

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentopipe

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

88 visualizzazioni2 pagineBranch (1) Calculations: Pipe Branch Reinforcement Per ASME B31.1b - 2009 Power Piping Code

Caricato da

deua2004pipe

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

8/5/2010, ReinfS1.

xls

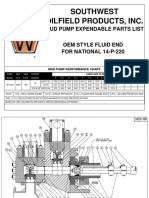

Pipe Branch Reinforcement per ASME B31.1b -2009 Power Piping Code

Branch (1) Calculations

Page 1 of 2 Client: Description: Prepared By Approval Date Rev. 0 Customer No.: Item No.: 1 2 Owner No.: Dwg. No.: 3 4 The user is responsible to verify method and results. Refer to para. 104.3.1 and Fig. 104.3.1(D) of the Code Design Temperature -320 deg. F (to -196 deg. C) Dimensional Units Design Pressure Class:300 ASME B16.5 -2009 Flanges, ASTM A182 Gr. F304L SS 18Cr-8Ni Forging , Group: 2.3 Design pressure: 600 psig = 42.2 kg/cm^2 = 41.4 bar-G = 4137 kPa Materials - Refer to ASME B31.1b - 2009, Tables A-1 thru A-9 Run Pipe: Weld joint factor, Eh = 0.85 Weld: P-8 Notes: Table A-3: (1)(9) St = 70 ksi Sy = 25 ksi Weld strength reduction factor, W h = 1.00 Branch Pipe: Weld joint factor, Eb1 = 0.85 Weld: P-8 Notes: Table A-3: (1)(9) St = 70 ksi Sy = 25 ksi Weld strength reduction factor, W b1 = 1.00 Reinforcement: Weld: P-8 Notes: Table A-3: (1)(9) St = 70 ksi Sy = 25 ksi Allowable Stresses at Design Temperature Allowances Run: SEh = 14.2 ksi = 97.9 MPa Thickness allowance (corrosion, etc.) A = 0.0000 in. Branch: SEb = 14.2 ksi = 97.9 MPa Run Dimensions Reinforcement: SEr = 16.7 ksi = 115.1 MPa Pipe size: Material Coefficient, Y Wall thk: "Y" from Table 104.1.2(A) of Code: Header, Yh = 0.4 Pipe outside diameter Doh = 12.750 in. Branch (1), Yb1 = 0.4 Pipe nominal thickness tnh = 0.375 in. Longitudinal Weld Intersection? Thk. tolerance: Millh = 12.5% or h1 = 0.000 in. Does Branch-1 intersect a longitudinal weld on the run? Branch Dimensions Angle Between Run and Branch Pipe size: Angle, alpha = 90 degrees Wall thk: Integral Reinforcement Dimensions Pipe outside diameter Dob = 8.625 in. Height of largest 60-degree right triangle supported by the branch Pipe nominal thickness: tnb = 0.322 in. and run O.D. projected surfaces and lying completely within the Thk. tolerance: Mill b = 12.5% or h2 = 0.000 in. area of reinforcement in Example B: tr i = n/a Ring or Saddle Reinforcement Dimensions Maximum height = 0.82 in. Thk. (nom.) ring, full encir. pad, or saddle: tnr = 0.375 in. Width integral reinf. area = (tr i) tan 30 wr i = n/a Width of ring or pad (= 0 if saddle is used): wr = 3.500 in. Special Reinforcement Type: Width of saddle (= 0 if ring is used): ws = 0.00 in. Full encirclement type reinforcing is NOT part of ASME B31.1. Optional special weld leg height leg = 0.000 in. Other design may be required by Engineering. Suggested usage: Thk. tolerance: Mill r = 0.0% or h3 = 0.000 in. Review when Doh / Th > 100 and / or Dob > Doh / 2. Branch Type: Suggested reinf. thk. = run thk, tnh = 0.375 in. Ring reinforced (re-pad), 90 deg. Max useful length for wr = 2 d2 - (Dob/SIN Alpha) = 7.5 in. Note: Check if diameter and thickness ratios are reasonable using criteria from ASME B31.3, para. 304.3.1(b)(1) & (2). (Dob / Doh) must not exceed 1.0 OK Branch OD is not greater than Run OD. Dob / Doh = 0.68 (Doh/Th) must not exceed 100, unless Dob <(Doh/ 2) OK Run OD/ Run Thk. < 100. See below. Doh / Th = 38.9 Is branch size less than 1/2 of run size? OK Branch OD may be any size not exceeding Run OD. Doh / 2 = 6.4 in. Required minimum wall thickness. Refer to para. 104.1.2 Eq. (3) and Table 104.1.2(A) of B31.1 Code, tm = [ P Do / (2 (SE + P Y)) ] + A --Weld will not fit on outer edge of reinf. zone. Its area not applied to A5_2.

Yes

ASTM A312 TP304L S30403 Welded Pipe SS 18Cr-8Ni (see Note (9)) ASTM A312 TP304L S30403 SMLS Pipe SS 18Cr-8Ni (see Note (9)) ASTM A312 TP304L S30403 Welded Pipe SS 18Cr-8Ni (see Note (9)) Inch NPS 12 (DN 300) Sch 40S per ASME B36.19M NPS 8 (DN 200) Sch 40S per ASME B36.19M

tri

wr tnr

wr tnr

ws tnr wr tnr

wr 8/5/2010, ReinfS1.xls

Pipe Branch Reinforcement per ASME B31.1b -2009 Power Piping Code

Branch (1) Calculations

Page 2 of 2 Minimum required run thickness, tmh = (P Doh / (2 (SEh + P Y)) ) + A tmh = 0.2649 in. Run actual measured or minimum thickness, Th = tnh(1 - Millh ) - h1 Th = 0.328 in. Run actual corroded thickness (measured or minimum thickness, less corrosion allowance), tha = Th - A tha = 0.328 in. OK Run thickness IS sufficient at design pressure. Minimum required branch thickness, tmb = (P Dob / (2 (SEb + P Yb1)) ) + A tmb = 0.1792 in. Branch actual measured or minimum thickness, Tb = tnb (1 - Millb ) - h2 Tb = 0.282 in. Branch actual corroded thickness (measured or minimum thickness, less corrosion allowance), t ba = Tb - A tba = 0.282 in. OK Branch thickness IS sufficient at design pressure Allowable Stress if Branch Intersects a Weld Allowable stress of run for reinforcement design, SE hr = SE h when branch intersects a weld on the run, or SE hr = SE h / E h when the branch does not intersect a weld on the run. Minimum required run thickness for reinforcement design, t mhr = (P Doh / (2 (SE hr + P Y )) + A tmhr = 0.2649 in. Other Dimensions Ring or saddle minimum thickness = tnr (1 - Millr ) - h3 tr = 0.375 in. Inside center-line long dimension of finished branch opening = [ Dob - 2 (Tb - A) ] / sin d1 = 8.062 in. Half width of reinforcment zone = d1 or (Tb - A) + (Th - A) + d1 / 2, whichever is greater, but not more than Doh d2 = 8.062 in. Reinf. zone height outside of run pipe, for ring or saddle = 2.5 (Th - A) or 2.5 (Tb - A) + tr , whichever is less Lr = 0.820 in. Reinf. zone height outside of run pipe, for integral reinf. = 2.5 (Th - A) Li = 0.000 in. Reinf. zone height outside of run pipe = Lr + Li L4 = 0.820 in. Reference long axis outside dimension of reinforcing ring or saddle = 2 wr + [ (Dob ) ( 2 - sin ) ] Dr = 15.625 in. Reference find the smaller of tnb or tnr (weld reference para. 127.4.8(B)) tmin = 0.322 in. Min. throat of weld at branch periphery = smaller of 6.0 mm (1/4") or 0.7 t nb, but not less than 0.7 tmin tc = 0.225 in. Minimum leg of weld at branch periphery = tc / 0.707 Weldb = 0.319 in. Minimum leg of weld at outer edge of ring or saddle = 0.5 tr / 0.707 Weldr = 0.265 in. Leg height of weld at branch periphery = greater of (tc / 0.707) or (L4 - leg) Weldbp = 0.319 in. Maximum ring width which would apply = d2 - (Dob / 2 ) / sin WRmax= 3.749 in. Reinforcement height = lesser of ( t r or L4 ) , or lesser of ( t r i or L4 ) as applicable Rh = 0.375 in. Reinforcement width = lesser of ( wr or WRmax ), or lesser of ( w r i or WRmax ) Rw = 3.500 in. Count of Welds Within Reinforcement Zone Number of complete welds, other than on pad edge, which will fit within the reinforcement zone height N wh = 2 Number of complete welds on pad edge which will fit within reinforcement zone width N ww = 0 Strength Correction Factors Factor for strength correction of branch area = 1 if SE b > SEh, or = (SEb / SEh) if SEb <= SEh Fb = 1.000 Strength correction factor for reinforcing material = 1 if SEr > SEh , or = (SEr / SEh) if SEr <= SEh Fr = 1.000 Strength correction factor for welds, Fw = lesser of Fb or Fr Fw = 1.000 Areas Pressure design area expected at end of service life = (tmhr - A)d1 A6 = 2.135 in.^2 Required reinforcement area = A6 (2 - sin ) A7 = 2.135 in.^2 Area of excess thickness in run pipe wall = (2 d2 - d1) (Th - tmhr ) A1 = 0.510 in.^2 Area of excess thickness in branch pipe wall = 2 L4 (Tb - tmb) / sin A2 = 0.168 in.^2 Total area of welds within zone = (Nwh/ 2)(Weldbp^2)+(Nww/ 2)(Weldr^2) A3 = 0.102 in.^2 Area of added reinforcement metal within the reinforcement zone = 2 x Rh x Rw A4 = 2.625 in.^2 Area provided by integral reinforcement, = Rh x Rw A4i = 0.000 in.^2 Area provided by saddle = (least of ws or WRmax) x tr x 2 A5 = 0.000 in.^2 Total contributing area (with strength correction for added metal within the reinf. zone) Ac = 3.405 in.^2 Ac = A1 + (A2)(Fb) + (A3)(Fw) + (A4 + A4i + A5)(Fr) Percent of area replaced = Ac / A7 % % Area 159%

This branch has sufficient reinforcement.

SE hr = 14.2 ksi

Potrebbero piacerti anche

- Calculation of PipeReinforcement ASMEB31 1Documento4 pagineCalculation of PipeReinforcement ASMEB31 1threedlabsNessuna valutazione finora

- Calculation of Pipe Reinforcement ASME B31 3Documento4 pagineCalculation of Pipe Reinforcement ASME B31 3ArmandoZacariasAcosta0% (1)

- Pipe Thickness & RF Pad Calculations As Per Asme b313Documento3 paginePipe Thickness & RF Pad Calculations As Per Asme b313Gaurav BhendeNessuna valutazione finora

- Pressure Design Straight Pipe (Run Pipe)Documento6 paginePressure Design Straight Pipe (Run Pipe)gembirasekaliNessuna valutazione finora

- Reinf S1Documento2 pagineReinf S1tasingenieriaNessuna valutazione finora

- Pipe Reinforcement Calculation (ASME-B31.3)Documento3 paginePipe Reinforcement Calculation (ASME-B31.3)jenshid100% (2)

- Design of Pressure ComponentsDocumento34 pagineDesign of Pressure ComponentsYFFernando100% (1)

- Reinforcement CheckDocumento2 pagineReinforcement Checkviv0102Nessuna valutazione finora

- SPREADSHEETS SERIES No. 0009S - 2Documento4 pagineSPREADSHEETS SERIES No. 0009S - 2Emma DNessuna valutazione finora

- Brance Pipe CALDocumento6 pagineBrance Pipe CALKlaikangwol AnuwarnNessuna valutazione finora

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocumento5 pagineASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNessuna valutazione finora

- Reinforcement Pad CalculationDocumento4 pagineReinforcement Pad CalculationMohammad AbdullahNessuna valutazione finora

- Hassad Project Expansion Joint Data Sheet EX-P 201: Revision: A0 DATE: 28/07/2006Documento1 paginaHassad Project Expansion Joint Data Sheet EX-P 201: Revision: A0 DATE: 28/07/2006akilasrivatsavNessuna valutazione finora

- Dummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMDocumento4 pagineDummy Leg & Trunnion Calculation Sheet: Pipe Dia. MM Pipe Nom. THK (Tnom) MMashish shrivastav50% (2)

- Nema CalculationsDocumento149 pagineNema CalculationsJ A S JASNessuna valutazione finora

- Calculation of Pipe Reinforcement ASME B31 3Documento5 pagineCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Area Reinforcement CalculatorDocumento5 pagineArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- B31.3 - Reinf Pad CalculationDocumento2 pagineB31.3 - Reinf Pad CalculationasafhoxlNessuna valutazione finora

- Blind Flange Thickness CalculationDocumento1 paginaBlind Flange Thickness Calculationmamughal123Nessuna valutazione finora

- SP Item DatasheetsDocumento21 pagineSP Item DatasheetsSELVAMANINessuna valutazione finora

- Pipe Thickness Calculation AS Per ASME 31.3Documento11 paginePipe Thickness Calculation AS Per ASME 31.3Anonymous Iev5ggSRNessuna valutazione finora

- Weldolet Branch Connection Calculation PDFDocumento3 pagineWeldolet Branch Connection Calculation PDFsaravoot_j100% (2)

- Calc Hoop StressDocumento11 pagineCalc Hoop StressApril Trevino100% (1)

- Dimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mDocumento77 pagineDimensions and Weights of Welded and Seamless Wrought Steel Pipe Asme b36.10mPablo Cesar PanessoNessuna valutazione finora

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocumento25 paginePage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNessuna valutazione finora

- ASME 31 - 8mDocumento1 paginaASME 31 - 8mMarcoAlbaNessuna valutazione finora

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDocumento5 paginePetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNessuna valutazione finora

- Excel PV 2016 Demo VersionDocumento6 pagineExcel PV 2016 Demo Versionahmadlie0% (1)

- Bends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsDocumento1 paginaBends (Elbows) (ASME B31.3-2012 Para. 304.2.1) : Design ConditionsabhisheknharanghatNessuna valutazione finora

- Spectacle Blind FlangeDocumento3 pagineSpectacle Blind Flangel kishoreNessuna valutazione finora

- Nozzle Design CalculationDocumento1 paginaNozzle Design CalculationSachin55860% (1)

- FittingsDocumento50 pagineFittingsashokNessuna valutazione finora

- SIF CalculatorDocumento4 pagineSIF CalculatorKannaphat WattanaphanNessuna valutazione finora

- Sa 420Documento10 pagineSa 420Widya widyaNessuna valutazione finora

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Documento7 paginePipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samyNessuna valutazione finora

- Branch Reinforcement Pad Requirement CalculationDocumento1 paginaBranch Reinforcement Pad Requirement Calculations.mladinNessuna valutazione finora

- Sight Glass Selection Guide PDFDocumento7 pagineSight Glass Selection Guide PDFani_datNessuna valutazione finora

- Vibration Assessment of Barred TeeDocumento1 paginaVibration Assessment of Barred Teeข้าวเม่า ทอดNessuna valutazione finora

- Reinforcement Pad CalculationDocumento5 pagineReinforcement Pad Calculationsada siva100% (1)

- Wall Thickness Calculation - ASME B31.8 2007 (Template)Documento1 paginaWall Thickness Calculation - ASME B31.8 2007 (Template)Hendra Yudistira100% (1)

- Comparison of Flange Face Finish As Per B16-5Documento1 paginaComparison of Flange Face Finish As Per B16-5Vivi OktaviantiNessuna valutazione finora

- Pipe Thickness Calculations - : ClassDocumento1 paginaPipe Thickness Calculations - : ClassOluwachidiNessuna valutazione finora

- New Storage Tanks Design GuidelinesDocumento6 pagineNew Storage Tanks Design GuidelinespaaryNessuna valutazione finora

- Cs & Las Impact Req - Asme Sec Viii Div 2Documento16 pagineCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNessuna valutazione finora

- Gasket Installation: DurlonDocumento3 pagineGasket Installation: Durlonlorenzo100% (1)

- Shree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetDocumento1 paginaShree Satyanarayan Industrial Suppliers Pvt. LTD.: Carbon Steel Pipe Hydrostatic Test Calculation SheetSalman KhanNessuna valutazione finora

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDocumento1 paginaPY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Nessuna valutazione finora

- Nozzle Reinforcement Calculation Excel SheetDocumento3 pagineNozzle Reinforcement Calculation Excel Sheetramesh punjabiNessuna valutazione finora

- Trunnion Calcualtion SheetDocumento22 pagineTrunnion Calcualtion SheetAbhijit50% (2)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Documento1 paginaPipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNessuna valutazione finora

- Check Safety Requirements For Clutch Door According To ASMEDocumento3 pagineCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533Nessuna valutazione finora

- SU Blind Plate ThicknessDocumento2 pagineSU Blind Plate Thicknessmanoj19801226100% (1)

- Reinforcement CalculationDocumento2 pagineReinforcement CalculationVekaymech100% (9)

- Calculation of PipeReinforcement ASMEB31.1Documento3 pagineCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Miter B1 ADocumento55 pagineMiter B1 AFarid TataNessuna valutazione finora

- Asme Viii CalcsDocumento20 pagineAsme Viii CalcsSriram VjNessuna valutazione finora

- Calculation of Pipe Reinforcement ASME B31.3Documento9 pagineCalculation of Pipe Reinforcement ASME B31.3yhnsharma80% (5)

- Calculation of Pipe Reinforcement ASME B31 3Documento3 pagineCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNessuna valutazione finora

- Design Calculation Sheet: H2So4 Neutralization TankDocumento43 pagineDesign Calculation Sheet: H2So4 Neutralization TankEkki Petrus BubunNessuna valutazione finora

- GRE NotesDocumento21 pagineGRE NotesMatheus Loss LizeNessuna valutazione finora

- Gradhb18 0Documento178 pagineGradhb18 0deua2004Nessuna valutazione finora

- PPPPDocumento23 paginePPPPdeua2004Nessuna valutazione finora

- 2017 GSAS FinancingGradStudyFINAL Web ReadyDocumento12 pagine2017 GSAS FinancingGradStudyFINAL Web Readydeua2004Nessuna valutazione finora

- PPPPDocumento23 paginePPPPdeua2004Nessuna valutazione finora

- Studysheet For GREDocumento15 pagineStudysheet For GREMuqarraulAhmadNessuna valutazione finora

- 'Sri Krishna Public School, Bistupur: This Question Paper Consists of 4 PagesDocumento5 pagine'Sri Krishna Public School, Bistupur: This Question Paper Consists of 4 Pagesdeua2004Nessuna valutazione finora

- Indian Forest Act 1927Documento24 pagineIndian Forest Act 1927Sidharth SudNessuna valutazione finora

- 3 Types of RocksDocumento35 pagine3 Types of RocksJulieta Bias100% (4)

- Law Collage Dhanbad PDFDocumento1 paginaLaw Collage Dhanbad PDFdeua2004Nessuna valutazione finora

- LL B I Year SyllabusDocumento42 pagineLL B I Year Syllabusdeua2004100% (1)

- Adv Arto Tsi2016Documento10 pagineAdv Arto Tsi2016deua2004Nessuna valutazione finora

- Types of RockDocumento5 pagineTypes of Rockdeua2004Nessuna valutazione finora

- Previouspaper BSSC Graduate Level Main Exam 2010 GKDocumento48 paginePreviouspaper BSSC Graduate Level Main Exam 2010 GKJay Prakash PatelNessuna valutazione finora

- DEC Salary Slip of GsDocumento1 paginaDEC Salary Slip of Gsdeua2004Nessuna valutazione finora

- Law Collage DhanbadDocumento1 paginaLaw Collage Dhanbaddeua2004Nessuna valutazione finora

- 9561 155 PVC C 534Documento1 pagina9561 155 PVC C 534deua2004100% (1)

- Digitally Signed by V.P.Johari Date: 2010.08.24 09:41:10 GMT+05:30 Reason: CAT I Location: NtpceocDocumento1 paginaDigitally Signed by V.P.Johari Date: 2010.08.24 09:41:10 GMT+05:30 Reason: CAT I Location: Ntpceocdeua2004Nessuna valutazione finora

- Conveyor Calculations Based On Is: 11592: Input SheetDocumento2 pagineConveyor Calculations Based On Is: 11592: Input Sheetdeua2004Nessuna valutazione finora

- Bangalore To Mumbai 18 March 2014 (Perhaps Not Travveled)Documento1 paginaBangalore To Mumbai 18 March 2014 (Perhaps Not Travveled)deua2004Nessuna valutazione finora

- PLS Furnish Pointwis E Reply To All OUR Comment S: FE EDDocumento1 paginaPLS Furnish Pointwis E Reply To All OUR Comment S: FE EDdeua2004Nessuna valutazione finora

- Power Cal. TSL 3.0 MtpaDocumento8 paginePower Cal. TSL 3.0 Mtpadeua2004Nessuna valutazione finora

- 9561-155-PVM-B-046-02 (Cat-1)Documento1 pagina9561-155-PVM-B-046-02 (Cat-1)deua2004Nessuna valutazione finora

- TS 1Documento17 pagineTS 1deua2004Nessuna valutazione finora

- NSE-20150422-equityonsms.com.txtDocumento32 pagineNSE-20150422-equityonsms.com.txtDhawan SandeepNessuna valutazione finora

- Comparison of Old Scope To New Scope of JSPL Package6Documento2 pagineComparison of Old Scope To New Scope of JSPL Package6deua2004Nessuna valutazione finora

- For More Inquire (: We Believe in The Strength of Teamwork and Innovative ThinkingDocumento1 paginaFor More Inquire (: We Believe in The Strength of Teamwork and Innovative Thinkingdeua2004Nessuna valutazione finora

- Sanjeet UpdatedDocumento3 pagineSanjeet Updateddeua2004Nessuna valutazione finora

- NSE-20150422-equityonsms.com.txtDocumento32 pagineNSE-20150422-equityonsms.com.txtDhawan SandeepNessuna valutazione finora

- Annexure - I Priority Circuit As Per Mom Dated 28Th May' 2010 To 31St May' 2010 DRG No. Drawing Description SL. NO Submitted ON Approval StatusDocumento1 paginaAnnexure - I Priority Circuit As Per Mom Dated 28Th May' 2010 To 31St May' 2010 DRG No. Drawing Description SL. NO Submitted ON Approval Statusdeua2004Nessuna valutazione finora

- Illustrative Worked Examples Commentary of Irc: 6-2017Documento2 pagineIllustrative Worked Examples Commentary of Irc: 6-2017jatin singlaNessuna valutazione finora

- Operating Instructions Back Pressure Regulator Series: BPR: Holter RegelarmaturenDocumento19 pagineOperating Instructions Back Pressure Regulator Series: BPR: Holter Regelarmaturenamin100% (2)

- Tjibau Cultural CentreDocumento21 pagineTjibau Cultural CentrepoojaNessuna valutazione finora

- Cep Matlab CodeDocumento5 pagineCep Matlab CodeMuhammad FurqanNessuna valutazione finora

- Dap 018 ADocumento28 pagineDap 018 AajoaomvNessuna valutazione finora

- Assignment On BTRC (Bangladesh Telecommunication Regulatory Commission) Tools and Techniques.Documento26 pagineAssignment On BTRC (Bangladesh Telecommunication Regulatory Commission) Tools and Techniques.Mosabbir Ahmed0% (1)

- Incident Report: Executive Vice PresidentDocumento1 paginaIncident Report: Executive Vice PresidentEvan MoraledaNessuna valutazione finora

- Set-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationDocumento98 pagineSet-1-Index001-ERA - ERTMS - 003204 v500 Functional Requirements SpecificationShauna MooreNessuna valutazione finora

- Report - MillingDocumento8 pagineReport - MillingMaarij Anjum50% (2)

- LX Capacity Chart Hydrogen SCFM 10-2008 PDFDocumento5 pagineLX Capacity Chart Hydrogen SCFM 10-2008 PDFZack AmerNessuna valutazione finora

- GB 2626 - 2006 Respiratory Protective Equipment Non-Powered Air-Purifying Particle RespiratorDocumento22 pagineGB 2626 - 2006 Respiratory Protective Equipment Non-Powered Air-Purifying Particle RespiratorCastañeda Valeria100% (1)

- 0811 IndiadxerDocumento6 pagine0811 IndiadxerAlexander WieseNessuna valutazione finora

- Optimization of Fuel Additive Utilisation at Boiler of Paiton Coal Fired Steam Power Plant Unit 1& 2Documento12 pagineOptimization of Fuel Additive Utilisation at Boiler of Paiton Coal Fired Steam Power Plant Unit 1& 2fajar noviantoNessuna valutazione finora

- Transformer Secondary ConductorsDocumento10 pagineTransformer Secondary ConductorsdskymaximusNessuna valutazione finora

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocumento3 pagineContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction Manualmalika_00Nessuna valutazione finora

- Oem National 14-P-220 7500psiDocumento9 pagineOem National 14-P-220 7500psiandrew0% (1)

- fmx4 PartsDocumento1 paginafmx4 PartsФедя ФедяNessuna valutazione finora

- 14 QuestionnaireDocumento14 pagine14 QuestionnaireEkta SinghNessuna valutazione finora

- Cycle CountDocumento58 pagineCycle CountPJ190275% (4)

- Chapter-2 Keyless MotorcycleDocumento27 pagineChapter-2 Keyless MotorcyclePatrick Jimenez100% (3)

- Silabus Reading VDocumento4 pagineSilabus Reading VAndi AsrifanNessuna valutazione finora

- Aadhaar Application FormDocumento4 pagineAadhaar Application Formpan cardNessuna valutazione finora

- PCBA-WP543HV HW Manual Rev1.05Documento21 paginePCBA-WP543HV HW Manual Rev1.05Surapong Pongchaiprateep100% (1)

- Reading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Documento2 pagineReading Passage 1: You Should Spend About 20 Minutes On Questions 1-12 Which Are Based On Reading Passage 1Melisa CardozoNessuna valutazione finora

- Tema Tubesheet Calculation SheetDocumento1 paginaTema Tubesheet Calculation SheetSanjeev KachharaNessuna valutazione finora

- Managing Risk: Chapter SevenDocumento39 pagineManaging Risk: Chapter SevenGrinaldo VasquezNessuna valutazione finora

- Samsung SSD 850 EVO M2 Data Sheet Rev2Documento4 pagineSamsung SSD 850 EVO M2 Data Sheet Rev2Piyush ShrivastavaNessuna valutazione finora

- Digital Market Space in BeautyDocumento48 pagineDigital Market Space in BeautyInaNessuna valutazione finora

- Manual Do Consumo de Gases DC - TruLaser - 1030 - 2011-08-09 - METRIC - VERSIONDocumento65 pagineManual Do Consumo de Gases DC - TruLaser - 1030 - 2011-08-09 - METRIC - VERSIONveraNessuna valutazione finora

- Company CFODocumento602 pagineCompany CFOgouravbhatia200189Nessuna valutazione finora

- Waste: One Woman’s Fight Against America’s Dirty SecretDa EverandWaste: One Woman’s Fight Against America’s Dirty SecretValutazione: 5 su 5 stelle5/5 (1)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDa EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionValutazione: 3 su 5 stelle3/5 (1)

- The Cyanide Canary: A True Story of InjusticeDa EverandThe Cyanide Canary: A True Story of InjusticeValutazione: 4 su 5 stelle4/5 (52)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetDa EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetValutazione: 4.5 su 5 stelle4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNessuna valutazione finora

- To Engineer Is Human: The Role of Failure in Successful DesignDa EverandTo Engineer Is Human: The Role of Failure in Successful DesignValutazione: 4 su 5 stelle4/5 (138)

- Summary of Neil Postman's Amusing Ourselves to DeathDa EverandSummary of Neil Postman's Amusing Ourselves to DeathValutazione: 4 su 5 stelle4/5 (2)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisDa EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisValutazione: 5 su 5 stelle5/5 (3)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeDa EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeValutazione: 4.5 su 5 stelle4.5/5 (59)

- Troubleshooting and Repair of Diesel EnginesDa EverandTroubleshooting and Repair of Diesel EnginesValutazione: 1.5 su 5 stelle1.5/5 (2)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsDa EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNessuna valutazione finora

- Predicting Lifetime for Concrete StructureDa EverandPredicting Lifetime for Concrete StructureNessuna valutazione finora

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDa EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansValutazione: 4.5 su 5 stelle4.5/5 (21)

- Construction Innovation and Process ImprovementDa EverandConstruction Innovation and Process ImprovementAkintola AkintoyeNessuna valutazione finora

- Structural Cross Sections: Analysis and DesignDa EverandStructural Cross Sections: Analysis and DesignValutazione: 4.5 su 5 stelle4.5/5 (19)

- Introduction to Ecology and Environmental Laws in IndiaDa EverandIntroduction to Ecology and Environmental Laws in IndiaNessuna valutazione finora

- Cable Supported Bridges: Concept and DesignDa EverandCable Supported Bridges: Concept and DesignValutazione: 5 su 5 stelle5/5 (1)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementDa EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementNessuna valutazione finora

- Up and Running with AutoCAD 2020: 2D Drafting and DesignDa EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignNessuna valutazione finora

- Designing with Geosynthetics - 6Th Edition; Vol2Da EverandDesigning with Geosynthetics - 6Th Edition; Vol2Nessuna valutazione finora

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDa EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNessuna valutazione finora

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyDa EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyValutazione: 4.5 su 5 stelle4.5/5 (5)

- The Diesel That Did It: General Motors' FT LocomotiveDa EverandThe Diesel That Did It: General Motors' FT LocomotiveNessuna valutazione finora