Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fracture of A Superplastic Ternary Brass PDF

Caricato da

hezihilikTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fracture of A Superplastic Ternary Brass PDF

Caricato da

hezihilikCopyright:

Formati disponibili

FRACTURE

OF A SUPERPLASTIC

TERNARY BRASS

S. SAGAT and D. ivl. R. TAPLIN* Fuel and IMaterials Division. CRNL. Chalk River. Ontario, Canada

Abstract-A study has been made of flow and fracture in a strain-rate sensitive ternary brass at ~8~C over the strain-rate range 10--IO-3 min- . The material is superplastic with an optimum ductility at 6OOC. Plastic flow is accompanied by the continuous development of intergranular and interphase cavities. Under these conditions failure occurs without measurable external necking. The instability of plastic Row is analyzed in terms of the development of internal bifurcations (analogous to diffuse, multiple, external necks for non-cavitating superplastic alloys) and the linking of cavities by internal necking (analogous to rapid preferential growth of one external neck). It is concluded that for precise analysis of void-linkage a dynamic model is required as opposed to the current quasi-static models. An experimental basis for this work is provided. R&urn&On a ttudiC la diformation et la rupture dun laiton ternaire sensible B Ia vitesse de diformation entre 400 et 8OOC pour des vitesses de deformation comprises entre 10-I et 10e3 min-. Le matiriau est superplastique et sa ductilitC est optimale B 6OOC. La diformation plastique est accompagnee par le dCveloppement continu de cavitts intergranulaires et interphases. Dans ces conditions, la rupture se produit sans striction externs mesurable. On analyse linstabilit0 de la d&formation en terme du d&veloppement de bifurcations inrerncs (analogues aux strictions diffuses. multiples ou externes pour les dliages superplastiques r&istants B la cavitations et de la liaison des cavites par des strictions internes (analogue B la croissance rapide pr~f~rentielle dune striction extsrne). On con&t que lanalyse p&se de la liaison des cavitCs necessite un mod&Ie dynamique. par opposition aux mod*Ies quasi-statiques habituels. On fournit une base expirimcntale pour cc travail. Zusammenfassung-FIieBen und Bruch einer dehngeschwindigkeits-empfindlichen tern&en Messinglegierung wurde untersucht bei 400 bis 8OOC iiber einen Bereich der Dehngeschwindigkeit von IO- bis IO- min- . Das Material ist superplastisch mit optimaler Duktilitlt bei 6OOC.Plastisches FlieDen ist begleitet von einer kontinuierlichen Ausbildung von Hohlrlumen zwischen Kiirnern und Phasen. Unter diesen Bedingungen tritt Bruch ohne meI3bare luDere Einschniirung auf. Die Instabilitlt des plastischen FlieDens wird nit der Entwicklung interner Zweiergabelungen (analog zu diffusen, mehrfachen externen EinschnIirungen bei nicht-hohlraumbildenden superplastischen Legierungen) und dem ZusammenschIuB von Hohlrlumen durch innere Einschntirungen (analog dem bevorzugten Wachsen einer iiuBeren EinschtGirung) erkllirt. Es u-ird gefolgert, daB fiir eine genaue Analyse des Zusammenwachsens von Hohlrlumen ein dvnamisches >fodell erforderlich ist, im Gegensatz zu den bisher angewendeten statischen Modellen. *

INTRODUCTION Fracture is the Cinderella and Flow the ugly sister. Flow has received much attention from metal scientists, to little avail, compared to the real appeal of fracture. Thus it has also been in research on superplasticity. Mechanisms of deformation have been studied ad nauseum whilst the problem of fracture has been neglected-only remembered by those with an eye for a pretty face amongst the cinders. Hot fracture is indeed a major problem and the study of fracture in superplastic alloys is relevant both for its own sake and because it provides insight into the general problem of fracture at high temperatures. It is not the first stage of fracture which seems to be the most important here but the last. Accordingly the present work-which is part of an overall project in Waterloo and Havana concerned largely with the final stage of fracture in brittle superplastic alloys of Cu [l-3] and Al [4, S]. * Department of Mechanical Engineering, University of Waterloo, Waterloo, Ontario, Canada.

Superplastic alloys which do not cavitate fail by intrinsic plastic failure, preceding which can be distinguished two geometrical instabilities of flow [6,7]. The first instability involves the formation of many diffuse necks at a strain somewhat higher than the point of maximum pulling force. It seems that a quasi-static model may be adequate to explain this behaviour. The second instability occurs much later on and involves the rapid and preferential growth of one neck accompanied by a marked increase in the flow stress. This behaviour can onIy be explained in terms of a dynamic model-and none thus far exist for the problem of bifurcation in materials, generally, let alone for strain-rate sensitive metals. In alloys which cavitate during superplastic flow the problem of failure seems to be even more complex. However. the particular aim of the present work was to try to isolate the problem of cavitation and fracture in a superplastic alloy by studying a material which cavitates extensively during superplastic flow yet exhibits no external necking prior to failure. This avoids the problem of the interaction of external instabilities (necks) with internal instabilities (cavities).

308

SAGAT

ASD

TAPLIN:

FRACTURE

OF SUPERPLASTIC

4

BRASS

uJ= 2 I WC

I

I ,

I 20 0

I

I

5 TIME

IO (hours)

15

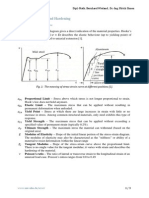

Fig. 1. Mean interphase spacing vs time at 7OOC. Linear coarsening rate 2.5 pm/ hr.

500

600 TEMPERATURE

700 (Cl)

6 IO

The research thus aims to provide a basis for further analytical work on the final stages of failure in strainrate sensitive materials. EXPERIMENTAL The material chosen was a 60/40 brass to which had been added 3% Fe. The alloy (58.5% Cu: 38.5% Zn: 3% Fe) was prepared by extrusion to give an qj phase diameter of about 10 pm throughout which was a distribution of Fe-rich particles of varying size up to 20 pm diameter but mostly 0.5 q dia. Material of three principal grain sizes (12, 31 and 54 pm) was used for the main body of the work. These were obtained by annealing at 7OoC for varying periods (Fig. 1). This plot shows that after coarsening to about 30pm grain size in 1 h the alloy exhibits a linear coarsening rate of the order of 2.5 lrn!hr over the range l-20 hr at 700C. Mechanical testing was carried out on solid cylindrical bars of 16 mm2 cross sectional area and 16 mm gauge length at a constant true strain-rate at temperatures up to 800C. A floor model Instron was modified by incorporating a variable speed motor and a linear potentiometer to give a constant true strain-rate accurate to 1.40/,[8]. High temperature tests were performed in a three-zone furnace where each zone was individually controlled by a Eurotherm proportional controller giving a hot zone which could be held to

Fig. 3. Neck-growth parameter measured samples vs test temperature.

on fractured

a constant temperature with a tolerance of + 3C over 150 mm. RESULTS

Mechanical behaviour

To determine the optimum temperature for superplastic deformation material with a grain size of 12 pm was tested at various temperatures (500--SOOC) at a constant true strain-rate of 1-= lo- min- I. The results are recorded in Fig. 2 where it is seen that a maximum linear tensile strain is obtained at about 675% However, this plot records the percentage total elongation and this may not give the optimum temperature for maximum uniform deformation. Thus a neck growth parameter (difference between transverse true strain in the neck, E, and true uniform strain, cY) has been plotted against temperature in Fig. 3. It is seen that at intermediate temperatures deformation is uniform especially at 600C where no necking was detectable at all. At 650C deformation is somewhat non-uniform and at 800C the material separates by intrinsic plastic failure. It is apparent that 6OOC is the optimum temperature for neck resistant deformation of this alloy at a strain-rate of lo-* min- and this temperature was thus chosen for most of the work.

500

700 600 TEMPERATURE

600 (Cl

100 0co1

0.010 STRAIN RATE

O.lbO

(min-1

00

Fig. 2. Total elongation vs temperature at a constant strain-rate of C = lo- min-.

Fig. 4. Total elongation vs strain rate at 6OOC.

SAGAT

AND

TAPLIN:

FRACTURE OF SUPERPLASTIC

BRASS

309

,

0.001

0.010

STRAIN RATE

0400

I.000

o-o [ , :I 0.2 j 04 TRUE

(min-1

/ 0.6 STRAIN

08

Fig. 5. Neck growth parameter of the fractured samples

vs true strain-rate. The optimum strain-rate was determined for this temperature by a series of tests at various strain-rates. Figures 4 and 5 represent plots of elongation against strain-rate and neck-growth parameter against strain rate, respectively. The deformation is uniform below a strain-rate of i = 2 x lo- mine1 and at this point also, the maximum ductility occurs. The true stresstrue strain curves obtained at different strain-rates are shown in Fig. 6. The flow stress was computed from the instantaneous force, monitored by the machine and the corresponding cross-section computed assuming uniform deformation and constant volume of the sample. The effect of temperature on the true stress/ true strain relationship is shown in Fig. 7. Deformation at room temperature is characterized by a high rate of work hardening and high level of the flow stress. (The maximum tensile strength was 478 MN/m.) Instability of flow occurred at a true strain of E = 0.29 (approximately at the point of maximum force) which is in good agreement with the limit strain E, determined graphically by the Considkre construction. Deformation at 300C is close to a steady-state flow condition and up to 6%X, deformation remained uniform so that the u+ curves were computed assuming constant volume and uniform flow of the specimen. At temperatures above 65oC, deformation

I-

0,

,

0.2 o-4

00

0.6 TRUE

0.8 STRAIN

I.0

i.2

14

Fig. 7. True stress-true strain curves tested at a constant true strain-rate of i = lo-* min- and different temperatures: (a) I-2OC. 2--3OOC. (b) l-500C. 1--600C. 3-700C. 4-8OOC.

STRESS CbLCULATED FROU FRACTURED WPLE FOR CURVE 8

01

0.0

{

02 014

0.6 TRUE

Ok STRAIN

I.0

I.2

I.4

Fig. 6. True stress-true strain curves tested at 600C. 3-i= 1-4=2x lo-tnin-, 2 -C = 10-min. 5 x IO-*min. 4-L=2 x IO-min-. j-i= 10-2min, 6-~=5~1O-~n-~,7-~=2x 10-3min-L,8-6= 5 x lo-min.

becomes increasingly non-uniform and at SOO the material fails by intrinsic plastic failure. Since these curves were computed also assuming uniform extension, they deviate from real values--particularly in the final stages of deformation. The effect of grain size (average interphase spacing) over the range 12-54pm is recorded in Fig. 8 for tests at 600C and lo- min- 1 strain-rate. Table 1 records the pertinent data from these plots. All grain sizes deformed uniformly without measurable neck formation.Theinitialflowstressincreasedmarkedlywith increasing grain size confirming the fact that deformation is controlled largely by grain/phase boundary sliding and boundary diffusion. The relationship observed is 0 = cLPwhere c = 0.43 and a = 0.7. Both parameters c and a depend on strain. The ductility decreased with increasing grain size suggesting that the mean size of cavities is important in controlling ductility and fracture. Strain-softening was apparent during a large part of deformation for the coarser grain-sizes compared with a strain hardening in the finest grain size. It seems evident that the strain hardening arises mainly from structural coarsening. In the final stages of deformation the flow stress abruptly increases, regardless of the magnitude of the interphase spacing. This final increase of the flow stress is also associated with an increase of load carrying

310

SAGAT

AND

TAPLIN:

FRACTURE OF SUPERPLASTIC

BRASS

ot

50

0.2

0.4

0.6

0.8

I,0

1.2

1.4

TRUE STRAiN

Fig. 8. Effect of grain size on u-s relation, tested at 600C and a constant true strain-rate of i = 10-2min-: ent

0.0

0.3

d6 TRUE

0.9 STRAIN

I.2

ability during the last period of deformation (Fig. 9) establishing that it must arise from a dynamic effect involving the internal discontinuities since no external necking is observedat this strain-rate. The variation of the neck growth parameter in various conditions is recorded in Table 2. Strain-rate ~rdening of the alloy at various temperatures is illustrated in Fig. IO. The data were obtained by a change-rate method [7]. The slope of the logarithmic plot of true stress vs true strain, represents the magnitude of the strain-rate sensitivity index tn. It should be noted that the apparently anomolous effect at 800C is due to the fact that at 800C the material is 100% fl phase and coarse grained. The variation of m with temperature, at a strain-rate of &= 2 x 10-2min-, is shown in Fig. 11. It is apparent that the strain-rate sensitivity index-temperature curve is similar to the elongation-tem~~ture curve shown in Fig. 2 except that the maximum strain-rate sensitivity occurs at 6CWC in accordance with the ductility as measured by uniform elongation rather than at 675C where the maximum elongation is observed. The effect of grain-size on variation of m is shown in Fig. 12. Two distinct features of these curves are worthy of comment. Firstly, at intermediate strainrates when a maximum uniform extension was achieved, the m-value decreases as the grain size is increased. Secondly, the maximum in the m - t relation is advanced to a lower level of strain-rate with increase of grain-size. The effect of strain on the m - 2 relation at 600C is shown in Fig. 13. A striking similarity between the effect of grain-size and the effect of strain indirectly suggests that coarsening of the structure takes place

Table 1

Fig. 9. Load-elongation curves tested at 600C and differstrain-rates: li = 10m3 min-, 2-G = 12 min, 3i = 1W min.

during deformation of the alloy. In addition it is observed that in the material tested at the optimum strain-rate interval of 2 = tom2 to 2 x 10e2 min-t, the value of m progressively decreases with strain due to the coarsening of the structure. Some compression tests were also carried out mainly for metallographic purposes because they allowed rapid quenching of the sample following deformation. In order to decrease the friction between the sample and the compression bars powdered graphite was used (powdered glass was unsuccessful). Despite lubrication slight barrelling occurred at reductions over 50%. The true stress/true strain curves in compression were found to be identical with those in tension up to a true strain of about 1.2. Beyond this strain in tension the flow stress increased markedly whereas in compression no marked increase was observed up to a strain of 2.4 (90% reduction). No cavitation was observed in compression whilst other structural changes were identical. Thus the marked increase in tension must be associated with the final stage of cavitation.

041t oco1

31 0.6 6.9 38 250 176 j

/

I

0010 O-100 STRAIN RATE (min)

00

Fig. IO. Logarithmic plot of true stress vs true strain-rate at different temperatures: 1-KWC, 2--SO@C, Z-6OO*C,

4-700C. 5-800C.

SAGAT AXD TAPLIN: Table 2

FRACTURE OF SCPERPLASTIC

BRASS

311

Structural ch7yrs

Optical metaIlography of material deformed at &WC and a strain-rate of 2 x 10- min- to various strains established three distinct changes: (1) The initially elongated and banded structure gradually changes to a fully equiaxed homogeneous structure which is maintained throughout the remaining deformation. Banding is virtually eliminated by E = 0.4. (2) There is strain-induced coarsening of the structure. In the head section of the specimen the grain size remains constant whereas in the gauge length the grain size increases from 12 to 45pm at a true strain of 1.5. The rate of coarsening during deformation is 30jrm/hr whereas during simpIe annealing it is 2 ,i~m/hr at &WC. (3) Deformation is accompanied by interphase and intergranular cavitation throughout the gauge length. Cavities can be detected at a strain of 0.03 and are abundant at a strain of 0.4 (Figs. 14 and 15). Studies of the surface deformation of material with an average grain size of 54pm deformed in argon at 600C and a strain-rate of 2 x lo- rnin- using fine fiducial lines revealed the following features: (1) absence of slip lines; (2) offsets at grain and phase boundaries indicating both grain and phase boundary sliding; (3) grain rotation: (4) intergranular cavitation. An extensive study of the dislocation substructures was also made by transmission electron microscopy.

001

O~OIG

STRAIN RATE

04GG

10

(minl

Fig. I?. Effect of gain size on m-2 relation 3t 6WC. 1-f: = 51 Jml. 3-x = 31 Jim, 3-z = 13 jrm.

This involved rapid quenching of specimens compressed varying amounts at 6WC at varying strainrates in the range 10--10-3 min-. Polishing of the multiphase structure presented some difficulties [SJ. A major feature of this work was the virtual absence of dislocations in the material deformed in the optimum superplastic range. This does not preclude dislocation activity. It was established that results were realistic and that dislocations had not been lost during quenching or preparation. At higher strain-rates (5 x lo- min- ) some dislocation substructures were apparent involving the formation of subgrains. Quantitative metallography established that the preferential sites for cavity nucleation were the interfaces of the coarse Fe particles (Table 3). These particles were virtually pure b.c.c, iron thus the mechanical properties of the particles themselves cannot be responsible for this as b.c.c. iron is quite soft at 6OOC compared to the r-fi brass. Thus the weak interface must be responsible. Table 3 shows that at low strains most of the cavities are associated with coarse Fe particles whereas at higher strains cavity nucleation at z fr hundaries becomes almost equally dominant. The change in number of cavities per unit area is shown in Fig. 16.

fn 0.2;

I

! 400 m 600 700 PC f

/

I 8GO

TEMPERATURE

Fig. 11. Dependence of m on temperature at true strainrate of P = 2 x lo- min-.

Fig.

13. Effect of strain on m-2 retation 3t 6oOC. t---e = 0.05w.3, 2-G = 0.7-0.8. 3-6 = i.l-1.3.

SAGAT

.&?;D

T,APLIS:

FRACTURE OF SIIPERPL.ASTIC

BRASS nwkttion

Tahte 3. Rcl~tivc number oiczvities at d&rent sites

, iitrzb.

1 ; I i 0.10 o.io

3.si i

boundrri*s s: 2: 3 i

lil

5: 9. 2

/ / !I.)3

j bounifarirs

1 x/3 i bmndacits i : j 28X 32:: ?.5Z

1 i F i

::;l:,:Lf: 57:: 351 52;

j )

@O

05

TRUE STRAIN

I.0

I.5

Fig. 14. Area ?a of cavities vs true strain at &WC and c = 2 x IO-min-. This relationship is approximately linear Gth strain. However the area1 fraction of cavities increases more rapidly with strain (Fig. 14) due to their rapid growth. At higher and lower strain-rates the extent of cavitation is reduced at 600C (Table 4). This seems to resuft from a balance between stress and sliding-both of which are necessary for cavity

nucleation f3]. .At low strain-rates the stress is low and at high strain-rates the contribution due to sfiding is reduced. These results are in accord with a recent model presented [3]. Similarly the extent of cavitation is reduced with increasing temperature (Table 5). Observations of the progress of cavitation to final fracture can be described in terms of strain-rate and temperature. Since growth of the cavities occurs concomitantly with large plastic how it is reasonable to assume that most of the growth occurs by plastic deformation rather than vacancy condensation and grainphase boundary sliding. This procss of growth is generally negiected in creep but it is certainly important there also. The present observations also

(bl

Cd)

Fig. 15. Optical micrographs showing microsfructures of material deformed. at 60WC and h = 1 x ;S- 1 min-L to various levels of true strain. Tensile axis vertical (75 x 1: la) .s u 0.4. (b) E ii 0.7. (cJ E _ Z-2, (d) E v 1.4.

SAGAT

AZD

TAPLW:

FRACTURE OF SUPERPLASTIC

BRASS

313

Table 5. Effect of temperature on the extent of

cavitation at a strain-rate of 2 x LO- at a strain E = 0.4

500C

600% 700% MO%

1350

1200 200 150

TRUE

STRAIN

Fig. 16. The number of cavities per unit area as a function of true strain at 600C and 2 x 10ez min-. the dominant influence of the strainrate sensitivity index in determining the rate of cavity interlinkage and final rupture-hence at 600C strainrate has a dominant influence on the rate of interlinkage largely irrespective of the total cavity volume present. At room temperature the material fails by normal ductile rupture, at 8OOC the material fails by intrinsic plastic rupture whilst, as noted at %O-650C an essentially brittle, neck-free fracture mode is observed along with a high tensile ductility. demonstrated DISCUSSION

It has been shown elsewhere [73 that the 0-e curves provide necessary information regarding the stability of plastic how in strain-rate sensitive materials. In alloys which do not cavitate the flow has been characterized by two instabilities. One or more diffused necks develop on the specimen gauge length and the material separates at a point. In alloys which do cavitate during high tem~rature deformation, the formation of intergranular cavities hampers the flow and causes premature failure. The true stress-true strain relations of the alloy deformed at 6OO@C will be discussed in connection with the geometrical instabilities of plastic Row. A set of b-e curves obtained at different strain-rates is shown in Fig. 6. At lower strains (e c 0.7), the curves generally exhibit strain hardening at low strain-rates and slight strain softening at high strain-rates. Similar results in a microduplex r/b brass were reported by Suery and Baudelet [9]. These authors described CH curves in terms of two processes, i.e. structural coar~ning/re~ning and continuous transfo~ation of initial fibrous structure (due to extrusion) into an

Table 4. Effect of strain-rate on the extent of cavitation at a strain E = 0.4 after testing at 6OOC

equiaxed structure. Both factors concurrentIy act during deformation, accordingly inhuence the tevel of the flow stress. The strain hardening observed at low strain rates was described [9] in terms of a prevatence of structural coarsening over the breakdown of the fibrous structure. The strain softening occurring at high strain-rates was explained on the basis of structural refinement (the grain-size was reported to decrease) and breakdown of the fibrous structure. At intermediate strain-rates both factors may cancel each other out and the stress remains approximately constant. This concept seems to be acceptable also for our alloy except for the fact that no structural refinement at high strain rates has been observed. Strain induced coarsening occurs in the whole range of strain-rates employed, however its rate decreases with increasing strain-rate due to shorter times of testing, The 0-c curves obtained in the present alloy and in binary z/p brass [l] exhibit, in the final stages of deformation, an increase of load carrying ability (Fig. 9) accompanied by a rapid increase of the flow stress (Fig. 6). This feature is interesting from a point of view that despite the fact material at this stage of deformation is quite heaviiy cavitated, the Ioad carrying ability increases. When interpreting these observations it is necessary to recaII that the ~-6 curves were computed by assuming that the volume of specimen remains constant during extension. Formation of cavities, however, increases the volume of the sample and the calculated true stress is accordingly less. The corrected CM curve cr, for the alloy deformed at 6OOC

y=l-ill

I

C

Id 2 x LO 360

0.8 TRUE STRAIN

I.2

-2

1200 820

10-L

Fig 17. u-FI curve deformed at 6OOC and g = Z x IO- min- together with the parameter y showing the onset of instability f.

311

SAGAT

AND

TAPLIN:

FRACTURE OF SUPERPLASTIC

BRASS

ated completely. When interpreting the plastic flow of the alloy in terms of parameter y. it is seen that after instability I, 7 continuously decreases below the critical value and eventually reaches a negative value. In the final stages of deformation behaviour, 7 J=l-m* abruptly increases and remains above the critical value until failure. Since y is computed from the slope (where 7 = l/cr(d+ie), m* = Ua(du/&) and G, E and 1 are true stress, true strain and true strain-rate re- of CM curve, the increase of ?-value is caused by the spectively), i.e. at true strain of en = 0.38 in Fig. 1.5, increase of the flow stress due to the dynamicallycontrolled, localized flow in the final stage of deformawhile the Considire strain l c is equal to approxition. To obtain a true y-value the 0-e curve needs mately 0.03. Experimentally, however, no formation to be corrected for the increase of local strain-rate of neck has been observed at eu and moreover, deforwhich in the case where internal non-uniformities are mation remains uniform until failure. On the other formed, would be extremely complicated. hand it is seen that the predicted onset of instability The point at which instability II occurs is detercoincides approximately with the measurable onset mined by the distribution and size of the cavities. of cavitation. It is therefore suggested that the onset Since no necking occurs, cavity growth is uniform of plastic instability in the alloy is associated more throughout the gauge length and few large cavities with formation of internal non-uniformities (caviform, as observed. The instability criterion adopted ties) rather than with external necks. To achieve for rupture is that of Brown and Embury [lo] who a picture of the cavitation behaviour during deformasuggest that a critical condition is achieved when the tion a metallographic examination of deformed cavity length is equal to the spacing. In view of the material has been carried out. A series of micrographs high density of cavitation and uniformity of size, void (Fig. 15) shows the formation, growth and interlinlinkage would then be very rapid once initiated. A kage of cavities in the final stages of deformation. simpler model involves a criterion for failure whereby As the deformation proceeds the number of cavities the cavity length equals a small multiple of the grain increases and they continuously grow. The high value size, say 1OOpm. This would also fit the experimental of the strain-rate sensitivity index minimizes the rate observations. of growth of internal necks between individual cavities in a manner analogous to the way the rate of external necks is reduced [7]. At this stage of deforCONCLUSIONS mation no preferential growth of the internal necks 1. The plastic flow of the ternary brass at 600C is apparent and deformation is quasi-uniform. When some of the necks are strained to such a degree that is characterized by strain-induced coarsening of the no more superplastic deformation in the neck region structure and formation of intergranular cavities. is possible, the deformation in such a region may be Deformation is controlled by grain/phase boundary retarded, since a higher flow stress is needed for nonsliding together with boundary diffusion. superplastic flow. This process could be repeated suc2. The process of fracture may be analyzed in an cessively a number of times accompanied by an in- analogous way to flow instability in non-cavitating crease of the flow stress. Finally the deformation can- superplastic alloys. Thus the onset of cavitation (an not be transferred to another region and instability internal, diffuse bifurcation) is analogous to the onset II occurs in such a way that one set of necks begin of external, diffuse necks (instability I). The onset of to grow preferentially followed by successive separ- cavity linkage of rapid internal necking between caviation of individual necks allowing cavity interlinkage ties is analogous to the preferential rapid growth of in a direction normal to the applied stress. During a single external neck (instability II). this process deformation is localized and the local 3. The onset of plastic instability I (marked cavistrain-rate increases significantly increasing the level tation) occurs when y = 1 - m* with nucleation at of the flow stress and load until fracture occurs. the Considere strain l , = 0.03. Nucleation sites are the Fe particles and a//? boundaries. This final process is clearly demonstrated in Figure 4. Instability II is associated with the separation 1% and d and is controlled by dynamic or overshoot effects as in neck growth of non-cavitating of internal necks followed by rapid interlinkage of superplastic alloys [7]. Figure 15(c) records condicavities in a direction normal to the applied stress. tions at a true strain of l = 1.2, where the void in This instability is not reflected in y-values since no the central region of the micrograph was formed as correction for localized increase of strain-rate has a consequence of the separation of several necks been made in this work. It can be approximately (some of them still being visible). This seems to occur explained in terms of a Brown-Embury type mode1 simultaneously in several places of the cross-section modified for strain-rate sensitive materials. An accu(in .Fig. 15(c) another void is formed on the left of rate analysis would require a dynamic model for inthe central void). The deformation proceeds by separ- ternal necking. ation of additional necks allowing interlinkage of 5. A characteristic feature of the fracture of the these large voids (Fig. 15d), until the sample is separ- alloy is the increase of load-carrying ability in the

and e = 2 x IO- min- is shown in Fig. 17 together with the parameter 7. According to the Hart criterion [6] the onset of plastic instability occurs when

SAGAT

AND

TAPLIN:

FRACTURE

OF SUPERPLASTIC

BRASS

316

final stage of deformation despite the fact that the material is very heavily cavitated at this stage of deformation. The final rupture is macroscopically planar without necking. Clearly final rupture must thus be controlIed by dynamic effects. This is also the case for necking in non-cavitating strain-rate sensitive materials. An experimental basis for such an analysis is provided. Ac~~w~edge~~ts-This work has been supported by the National Research Council of Canada. REFERENCES 1. S. Sagat, P. Blenkinsop and D. M. R. Taplin, J. Insr. Metals 100, 268 (1972).

2. G. L. Dunlop, E. Shapiro, J. Crane and D. XI. R. Taplin, &fet. Trans. 4, 2039 (1973). 3. R. G. Fleck, C. J. Beevers and D. M. R. Taplin, .tfet. Sci. 9, 49 (1975): J. .Mat. Sci. 9, 241 (1974). 4. M. W. A. Bright. D. M. R. Taplin and H. W. Kerr, JASME, J. Eng. Xfur. 12, 1 (1974). 5. Tomas Delgado. Maria-Christina Mellian and D. M. R. Taplin, Unpublished Research. Universidad de la Habana, Cuba, 1975. Superplasticity and cavitation in an industrial aluminium alloy. 6. P. 3. Wray, J. uppi. Phqs. 41, 3347 (1970): 40, 4Ol8 (1969). 7. S. Sagat and D. M. R. Taptin. iMet. Sci. IO, (1976). 8. S. Sagat, Ph.D. Thesis, University of Waterloo, 1973. 9. M. Suerv and B. Baudelet. J. Mar. Sci. 8. 363 11973). IO. L. M. Blown, and J. D. Embury, Conf. *~~et~l~o~r~~h~ of Microstructures, p, 164. Cambridge, August (1973).

Potrebbero piacerti anche

- FatigueDocumento14 pagineFatigueumair_aeNessuna valutazione finora

- JMPT 2013 Secondary Deformation of Hot Stamping SpecimensDocumento9 pagineJMPT 2013 Secondary Deformation of Hot Stamping SpecimenshezihilikNessuna valutazione finora

- Convection With Phase ChangeDocumento12 pagineConvection With Phase ChangeaminNessuna valutazione finora

- Heat Treatment With Salt Bath FurnacesDocumento12 pagineHeat Treatment With Salt Bath FurnacesVaikuntam Ramamurthy100% (1)

- False Failure in Flexural Fatigue Tests PDFDocumento11 pagineFalse Failure in Flexural Fatigue Tests PDFhezihilikNessuna valutazione finora

- Matrixcookbook PDFDocumento72 pagineMatrixcookbook PDFeetahaNessuna valutazione finora

- 117 Section 5 How To Make It in Brass PDFDocumento6 pagine117 Section 5 How To Make It in Brass PDFhezihilikNessuna valutazione finora

- Ternary PDFDocumento10 pagineTernary PDFhezihilikNessuna valutazione finora

- KizilyalliDocumento19 pagineKizilyallihezihilikNessuna valutazione finora

- Article - Screw Threads DesignDocumento7 pagineArticle - Screw Threads DesignjdfdfererNessuna valutazione finora

- Mmsm1 Handout PlasticityDocumento3 pagineMmsm1 Handout PlasticityKuldeep SinghNessuna valutazione finora

- Qm1 Hw9 ItayDocumento3 pagineQm1 Hw9 ItayhezihilikNessuna valutazione finora

- The Structural Effect of HeatingDocumento1 paginaThe Structural Effect of HeatinghezihilikNessuna valutazione finora

- Convection With Phase ChangeDocumento12 pagineConvection With Phase ChangeaminNessuna valutazione finora

- Grain Growth in Alpha-BrassDocumento3 pagineGrain Growth in Alpha-BrasshezihilikNessuna valutazione finora

- An Overview of Utilization of Slag and SludgeDocumento18 pagineAn Overview of Utilization of Slag and SludgehezihilikNessuna valutazione finora

- Internal Friction of Materials Anton PuskarDocumento342 pagineInternal Friction of Materials Anton PuskarhezihilikNessuna valutazione finora

- Thermo EquationsDocumento3 pagineThermo EquationshezihilikNessuna valutazione finora

- Chap 2Documento20 pagineChap 2hezihilik40% (5)

- 4 Kramer Good Foundry PracticesDocumento25 pagine4 Kramer Good Foundry PracticeshezihilikNessuna valutazione finora

- 4 Kramer Good Foundry PracticesDocumento25 pagine4 Kramer Good Foundry PracticeshezihilikNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Segmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFDocumento6 pagineSegmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFTarek HareedyNessuna valutazione finora

- Service Manual Goodman GPH16MDocumento63 pagineService Manual Goodman GPH16MMitchell BaileyNessuna valutazione finora

- Intro Well FoundationDocumento23 pagineIntro Well FoundationgoutammandNessuna valutazione finora

- Procurement 2023Documento11 pagineProcurement 2023Roi Andrei GalangNessuna valutazione finora

- Detail Ground TankDocumento1 paginaDetail Ground TankRully SaputraNessuna valutazione finora

- (TM) Nissan Manual de Taller Nissan Versa 2007Documento4 pagine(TM) Nissan Manual de Taller Nissan Versa 2007Jheral Manzanedo cruzNessuna valutazione finora

- Fastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatDocumento2 pagineFastenings For The Rehabilitation of Historical Structures-Abstract Standard FormatRay RamiloNessuna valutazione finora

- A9-1&2 SL03,04-Street Lighting Feeder Pillar Detail-A9-1Documento1 paginaA9-1&2 SL03,04-Street Lighting Feeder Pillar Detail-A9-1amirul aizadNessuna valutazione finora

- Architecture March 2017Documento19 pagineArchitecture March 2017ArtdataNessuna valutazione finora

- Bondor BondorPanel Insulated Walling Technical DataDocumento2 pagineBondor BondorPanel Insulated Walling Technical DataSvan Dxi ArulNessuna valutazione finora

- Design and Construction of BreakwatersDocumento24 pagineDesign and Construction of Breakwatersshakirhamid6687100% (2)

- Stress and Strain - Axial Loading2Documento33 pagineStress and Strain - Axial Loading2Clackfuik12Nessuna valutazione finora

- Aramco Hot Tap Welding Procedure Rev 1Documento3 pagineAramco Hot Tap Welding Procedure Rev 1BWQNessuna valutazione finora

- Saep 309Documento22 pagineSaep 309brecht1980Nessuna valutazione finora

- Scrutiny Report of Building PlanDocumento7 pagineScrutiny Report of Building PlanSubirBhowmikNessuna valutazione finora

- 04 Marl Chemical Park PDFDocumento36 pagine04 Marl Chemical Park PDFAnusha Rajagopalan100% (1)

- Fabrication EnquiryDocumento180 pagineFabrication Enquiryvinod23456100% (1)

- Ecoply Bracing - EP1 Specification (Apr-09)Documento1 paginaEcoply Bracing - EP1 Specification (Apr-09)郭骥Nessuna valutazione finora

- Construction Progress ReportDocumento11 pagineConstruction Progress ReportAnthny Alfrt GsprNessuna valutazione finora

- Real Estate and Destination Development in TourismDocumento331 pagineReal Estate and Destination Development in Tourismfarah fadillahNessuna valutazione finora

- 002JTGT B02-01-2008-EnDocumento75 pagine002JTGT B02-01-2008-Enziming liNessuna valutazione finora

- TOYOTA Yaris 1.33 VVT-i 1NR-FE: Timing Chain: Removal/installationDocumento17 pagineTOYOTA Yaris 1.33 VVT-i 1NR-FE: Timing Chain: Removal/installationMapaqui Mapaqui100% (1)

- Majlis Peranan Dan FungsiDocumento1 paginaMajlis Peranan Dan FungsiKNS CSBNessuna valutazione finora

- Assignment-10 CE39 NOC20Documento7 pagineAssignment-10 CE39 NOC20jayadeep ksNessuna valutazione finora

- Cathodic ProtectionDocumento52 pagineCathodic Protectionredback666100% (2)

- Revit-MEP-HVAC-HYDRONIC PIPINGDocumento206 pagineRevit-MEP-HVAC-HYDRONIC PIPINGRagul0042100% (1)

- B. Chatveera, P. LertwattanarukDocumento8 pagineB. Chatveera, P. LertwattanarukArmigce PintoNessuna valutazione finora

- Lennox LGH Product SpecsDocumento60 pagineLennox LGH Product SpecsjrodNessuna valutazione finora

- Ideal Aquaview - Report2Documento22 pagineIdeal Aquaview - Report2ANKAN RAKSHITNessuna valutazione finora

- AM2755 - Testing, Commissioning and Handover Template Rev T0Documento40 pagineAM2755 - Testing, Commissioning and Handover Template Rev T0Mohammed MuzakkirNessuna valutazione finora