Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vacuum Tray Dryers

Caricato da

Ahlada Group of CompaniesCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Vacuum Tray Dryers

Caricato da

Ahlada Group of CompaniesCopyright:

Formati disponibili

Vacuum Tray Dryers

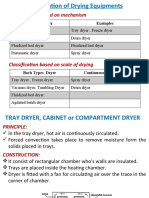

Vacuum Tray dryer is the most commonly used batch dryer. They are

box-shaped and loaded and unloaded via a door (two doors on the

larger models). Inside are several heating plates mounted one above

the other on which the product is placed in trays. The bottoms of

both heating plates and trays should be as smooth as possible to

permit optimal heat transfer between plates and product. The

Function : medium flowing through the heating plates is water, steam or

Used mainly for drying of high grade, temperature thermal oil. The distance between the heating plates is determined

and oxygen sensitive products. Highly suitable for primarily by the surface loading and the foaming of the product. To

drying hygroscopic substances, which are dried void retrograde condensation the cabinet walls are indirectly

to very low residual moisture, content level. preheated by the heating plates. Next, the product is introduced and

Frequently vacuum drying cabinets are the sole heated at atmospheric pressure. Only after all individual product

possibility for drying lumpy, glutinous products or trays reach the same temperature the cabinet is evacuated and

products of low pomposity. Capacity: Standard drying can start. The preheating phase is very important in order that

models range from 4 trays to 48 trays. the drying curve and the foaming of the product is identical

Salient Features: throughout the cabinet. During the main drying phase the vacuum is

in the range of 40 to 80 mbar abs and in the final drying phase

Bodies may be of cylindrical or rectangular cross

vacuums of only few mbar abs are reached. Heating temperatures

section. Both shelves and body are heated (the

body to prevent internal condensation) with are normally in the range between 800C and 1100°C. Depending on

controlled circulation of hot water, steam or dia product and surface load, drying takes from a few hours to 1 to 2

thermic fluid. Vacuum is drawn through large days. For some products the vacuum and temperature profiles are

diameter ducts to minimize pressure drops and automatically controlled in order to prevent a pass over of the critical

produce minimum working pressures. Both product temperature.

rotary and static dryers can be supplied with the

The dimensioning of the vacuum system is an important factor in the

following optional ancillaries.

design of drying cabinet systems. If for example vigorous foaming of

the product is desired, evacuation to the operational vacuum level

must take place very quickly. Vapors produced during drying are

• Heater system for either pressurized hot

taken out direct, or via a steam jet compressor to a surface

water or diathermic fluid.

condenser in which the vapors condensate. The non-condensable

• Cyclones and sleeve filters for powder

vapors are extracted by the vacuum system. On completion of the

recovery (for rotary dryers)

drying, the product can be cooled by circulating of cold water

• Solvent recovery system with condenser

through the heating plates.

and receiver, vacuum pump and ancillaries,

characteristics and dimensions depending

on the drying processes.

Potrebbero piacerti anche

- Pharmaceutical DryersDocumento2 paginePharmaceutical Dryersf_azarNessuna valutazione finora

- Drying EquipmentDocumento9 pagineDrying EquipmentHIT- MANNessuna valutazione finora

- Solution For Contin Uous Dryi NG: SeparationDocumento16 pagineSolution For Contin Uous Dryi NG: SeparationJohan ConradieNessuna valutazione finora

- Dryers and Drying ProcessesDocumento65 pagineDryers and Drying ProcessesEyra AngelesNessuna valutazione finora

- 1 Autoclave: Can Be Sterilized in An AutoclaveDocumento4 pagine1 Autoclave: Can Be Sterilized in An Autoclaveabdelrhman aboodaNessuna valutazione finora

- DRYINGDocumento71 pagineDRYINGARJYA ROY100% (1)

- Spray DryingDocumento30 pagineSpray Dryingpriyanka minjNessuna valutazione finora

- Intro Exp 2Documento2 pagineIntro Exp 2Nur amirahNessuna valutazione finora

- Intro Exp 2Documento2 pagineIntro Exp 2Nur amirahNessuna valutazione finora

- Drying PDFDocumento48 pagineDrying PDFuzzal ahmedNessuna valutazione finora

- Drying in Mass TransferDocumento57 pagineDrying in Mass TransferMohammad JunaidNessuna valutazione finora

- Drying 2020Documento26 pagineDrying 2020Samir PatelNessuna valutazione finora

- Drying Drying Is A Mass Transfer Process Consisting of The Removal of WaterDocumento21 pagineDrying Drying Is A Mass Transfer Process Consisting of The Removal of WaterConquer ConquerNessuna valutazione finora

- Activity No. 8: DryersDocumento19 pagineActivity No. 8: DryersCherry ObiasNessuna valutazione finora

- Lab en Autoclave Tuttnauer 05 11 17 - 0Documento12 pagineLab en Autoclave Tuttnauer 05 11 17 - 0rachmonaaNessuna valutazione finora

- DRYERSDocumento39 pagineDRYERSaswinhacker28Nessuna valutazione finora

- How Choose Vacuum DryerDocumento4 pagineHow Choose Vacuum DryerGomatheeswariNessuna valutazione finora

- Dryer and Drying SystemDocumento53 pagineDryer and Drying Systemeric labordoNessuna valutazione finora

- Classification Based On Mechanism: Types of Dryer ExamplesDocumento19 pagineClassification Based On Mechanism: Types of Dryer ExamplesTeenaNessuna valutazione finora

- FT 409 - (19 Arid 4816)Documento32 pagineFT 409 - (19 Arid 4816)Hani TatlaNessuna valutazione finora

- GROUP 2 MIPPV Dryers and Drying ProcessDocumento23 pagineGROUP 2 MIPPV Dryers and Drying ProcessmarkdanielgolisaoNessuna valutazione finora

- Mass TransferDocumento16 pagineMass TransferYash PardhiNessuna valutazione finora

- Process Thermodynamic Steam Trap PDFDocumento9 pagineProcess Thermodynamic Steam Trap PDFhirenkumar patelNessuna valutazione finora

- Drum Dryer enDocumento8 pagineDrum Dryer enTiara Kurnia KhoerunnisaNessuna valutazione finora

- CompAir Desiccant DryersDocumento10 pagineCompAir Desiccant DryersAhtisham KhanNessuna valutazione finora

- 1.5 DryingDocumento23 pagine1.5 DryingDerese BishawNessuna valutazione finora

- Vacuum Dryer: Aim: To Find Time of Constant Rate Period and Constant Fall Period Using ADocumento6 pagineVacuum Dryer: Aim: To Find Time of Constant Rate Period and Constant Fall Period Using Aanjan_srihari0% (1)

- Industrial Plant Drying of SolidsDocumento12 pagineIndustrial Plant Drying of SolidskennnNessuna valutazione finora

- Types of DryersDocumento14 pagineTypes of DryersChintan ModiNessuna valutazione finora

- Lecture Notes On DryingdsgaaaaaaaaaaDocumento15 pagineLecture Notes On DryingdsgaaaaaaaaaaSaumith DahagamNessuna valutazione finora

- Spray DryerDocumento30 pagineSpray Dryerrajesh kumar100% (1)

- Product Brochures PDF 1503921864Documento7 pagineProduct Brochures PDF 1503921864Jignesh PanchalNessuna valutazione finora

- Medical Sterilization Methods - LemoDocumento52 pagineMedical Sterilization Methods - LemoPedro GomesNessuna valutazione finora

- Different Type Air DryerDocumento9 pagineDifferent Type Air DryermishtinilNessuna valutazione finora

- Mass Taransfer Operation - 2: Topic: Types of DryerDocumento14 pagineMass Taransfer Operation - 2: Topic: Types of DryerChintan ModiNessuna valutazione finora

- Dryer DesignDocumento18 pagineDryer DesignCamille Guya50% (2)

- DehumidificationDocumento31 pagineDehumidificationmohammed hussienNessuna valutazione finora

- MTO Module 5Documento128 pagineMTO Module 5Oğuzhan KocaoğluNessuna valutazione finora

- Drying EquipmentsDocumento18 pagineDrying EquipmentsCeazar Justine FuluganNessuna valutazione finora

- Aspects of Lead Acid Battery Technology 5 Dry Charging of Formed Negative PlatesDocumento12 pagineAspects of Lead Acid Battery Technology 5 Dry Charging of Formed Negative PlatestjkiddNessuna valutazione finora

- Continuous Direct Dryers: Drying EquipmentDocumento60 pagineContinuous Direct Dryers: Drying EquipmentNur AmaninaNessuna valutazione finora

- Spin Flash Dryer General Description: The Wet Product Is Introduced in The Form at Which It Leaves The PrecedingDocumento1 paginaSpin Flash Dryer General Description: The Wet Product Is Introduced in The Form at Which It Leaves The PrecedingDeepakNessuna valutazione finora

- Fuzzy Control of Fabrics Drying On An Induction Heated RotatingDocumento41 pagineFuzzy Control of Fabrics Drying On An Induction Heated RotatingIng Emisael AlarcónNessuna valutazione finora

- SERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsDocumento8 pagineSERIES 40/40D AND C250/260: Yarway Process Thermodynamic Steam TrapsEngr Mohammad FarhanNessuna valutazione finora

- Desiccant Wheel Dehumidification 2Documento19 pagineDesiccant Wheel Dehumidification 2ovidiu73Nessuna valutazione finora

- Types of Industrial Dryers and Their Selection PDFDocumento20 pagineTypes of Industrial Dryers and Their Selection PDFHari KishoreNessuna valutazione finora

- Chapter 11Documento13 pagineChapter 11zekariyas kuneNessuna valutazione finora

- Rotary Drum Dryer ManualDocumento14 pagineRotary Drum Dryer ManualShoaib PathanNessuna valutazione finora

- 4.1.2 Pan Dryer: Nptel - Chemical Engineering - Chemical Engineering Design - IIDocumento1 pagina4.1.2 Pan Dryer: Nptel - Chemical Engineering - Chemical Engineering Design - IIPooja ThaparNessuna valutazione finora

- Catálogo de Secadores de AireDocumento12 pagineCatálogo de Secadores de AiredavidnpsNessuna valutazione finora

- DRYERS AND DRYING PROCESS Group 2Documento9 pagineDRYERS AND DRYING PROCESS Group 2markdanielgolisaoNessuna valutazione finora

- Dryers and Drying ProcessesDocumento24 pagineDryers and Drying ProcessesKristine Joy MataroNessuna valutazione finora

- Heat and Mass TransferDocumento90 pagineHeat and Mass TransferAnonymous 0zrCNQNessuna valutazione finora

- Dryers and Drying ProcessDocumento33 pagineDryers and Drying ProcessddNessuna valutazione finora

- Agitated Thin-Film EvaporatorsDocumento4 pagineAgitated Thin-Film Evaporatorsزهرة النرجس100% (4)

- Dryers and Drying ProcessDocumento72 pagineDryers and Drying ProcessDiether RigorNessuna valutazione finora

- Lecture 24 (Pneumatic and Fluidized Bed Dryer)Documento18 pagineLecture 24 (Pneumatic and Fluidized Bed Dryer)MALIK ZARYABBABARNessuna valutazione finora

- Drying 2Documento13 pagineDrying 2Ayesha RalliyaNessuna valutazione finora

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDa EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNessuna valutazione finora

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDa EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingValutazione: 5 su 5 stelle5/5 (3)

- Ribbon BlenderDocumento1 paginaRibbon BlenderAhlada Group of CompaniesNessuna valutazione finora

- Pressure Nutsche FilterDocumento1 paginaPressure Nutsche FilterAhlada Group of Companies100% (1)

- Rotocone Vacuum DryersDocumento1 paginaRotocone Vacuum DryersAhlada Group of CompaniesNessuna valutazione finora

- Pass Through'sDocumento1 paginaPass Through'sAhlada Group of CompaniesNessuna valutazione finora

- Laminar Air FlowDocumento1 paginaLaminar Air FlowAhlada Group of CompaniesNessuna valutazione finora

- Double Cone BlenderDocumento1 paginaDouble Cone BlenderAhlada Group of CompaniesNessuna valutazione finora

- Dispensing and Sampling BoothDocumento1 paginaDispensing and Sampling BoothAhlada Group of CompaniesNessuna valutazione finora

- Cleanroom Furniture 01Documento1 paginaCleanroom Furniture 01Ahlada Group of CompaniesNessuna valutazione finora

- Cleanroom Furniture 02Documento1 paginaCleanroom Furniture 02Ahlada Group of CompaniesNessuna valutazione finora

- Cleanroom ClassificationsDocumento1 paginaCleanroom ClassificationsAhlada Group of CompaniesNessuna valutazione finora

- Air ShowerDocumento1 paginaAir ShowerAhlada Group of CompaniesNessuna valutazione finora

- Ahlada Group of CompaniesDocumento1 paginaAhlada Group of CompaniesAhlada Group of CompaniesNessuna valutazione finora

- Aphanizomenon Flos-Aquae - WikipediaDocumento4 pagineAphanizomenon Flos-Aquae - WikipediaLucas Rueles da CunhaNessuna valutazione finora

- Design TrainingDocumento20 pagineDesign Trainingbenjito7Nessuna valutazione finora

- Experimental Investigation On Black Cotton Soil Treated With Terrabind Chemical and Glass PowderDocumento12 pagineExperimental Investigation On Black Cotton Soil Treated With Terrabind Chemical and Glass PowderIJRASETPublicationsNessuna valutazione finora

- A New Technique of Processing For Waste-Expanded Polystyrene Foams As AggregatesDocumento7 pagineA New Technique of Processing For Waste-Expanded Polystyrene Foams As Aggregatestimtoihochoi1Nessuna valutazione finora

- PseudoephedrineDocumento2 paginePseudoephedrineSiti Marwasofa100% (3)

- CATALOG Blind and Solid RivetsDocumento58 pagineCATALOG Blind and Solid Rivetsjhos douglasNessuna valutazione finora

- Genetic Linkage & Mapping (Article) - Khan AcademyDocumento22 pagineGenetic Linkage & Mapping (Article) - Khan Academy嘉雯吳Nessuna valutazione finora

- Kaplan and Pelton QuestionsDocumento13 pagineKaplan and Pelton Questionstixy2013Nessuna valutazione finora

- Absorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinDocumento24 pagineAbsorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinMadel Tutor ChaturvediNessuna valutazione finora

- Assignment Chemistry Sk025 (Ain Bashirah - b3t9) - 2Documento23 pagineAssignment Chemistry Sk025 (Ain Bashirah - b3t9) - 223005852Nessuna valutazione finora

- CW Cat enDocumento44 pagineCW Cat enStefanArtemonMocanuNessuna valutazione finora

- Backwards Heat Equation InfoDocumento1 paginaBackwards Heat Equation InfoMelissa Marie HernandezNessuna valutazione finora

- Apollo Valves 20 104 03 Instruction Installation ManualDocumento2 pagineApollo Valves 20 104 03 Instruction Installation ManualRobinson JimenezNessuna valutazione finora

- Effects of Clinker Grinding Aids On Flow of Cement Based MaterialsDocumento11 pagineEffects of Clinker Grinding Aids On Flow of Cement Based MaterialsJaga JayNessuna valutazione finora

- Demand Controlled VentilationDocumento58 pagineDemand Controlled VentilationthenshanNessuna valutazione finora

- ME09 801 Refrigeration & Air ConditioningDocumento79 pagineME09 801 Refrigeration & Air ConditioningVenkiteshNessuna valutazione finora

- COD Anaysis and ReductionDocumento13 pagineCOD Anaysis and ReductionelaNessuna valutazione finora

- Problem On IC-Engine Testing-1Documento7 pagineProblem On IC-Engine Testing-1SouravSaw100% (1)

- Concrete Reinforcement and Glass Fibre Reinforced PolymerDocumento9 pagineConcrete Reinforcement and Glass Fibre Reinforced PolymerchanakaNessuna valutazione finora

- Ensival MoretDocumento6 pagineEnsival MoretPatricia J ÁngelesNessuna valutazione finora

- Anti TermiteDocumento5 pagineAnti TermiteDamitha Anjana WeerakoonNessuna valutazione finora

- Conversion Table: Distance PressureDocumento2 pagineConversion Table: Distance Pressurerizkboss8312Nessuna valutazione finora

- Dioxido de Titanio R-2196+ - TDSDocumento1 paginaDioxido de Titanio R-2196+ - TDSBenito JuárezNessuna valutazione finora

- Practical Process Plant Layout and Piping DesignDocumento136 paginePractical Process Plant Layout and Piping Designgonvic7411Nessuna valutazione finora

- G178 - MSDSDocumento16 pagineG178 - MSDSjeanada phillipsNessuna valutazione finora

- AFR - Turbine PDFDocumento20 pagineAFR - Turbine PDFChetanPrajapatiNessuna valutazione finora

- Biological Oxygen Demand (Bod)Documento4 pagineBiological Oxygen Demand (Bod)vishnuNessuna valutazione finora

- Rohm and Haas Ion Exchange Laboratory GuideDocumento32 pagineRohm and Haas Ion Exchange Laboratory GuideAlfonso Dominguez GonzalezNessuna valutazione finora

- PLATE & SHELL Heat Exchangers: A Shell & Tube AlternativeDocumento4 paginePLATE & SHELL Heat Exchangers: A Shell & Tube AlternativearianaseriNessuna valutazione finora

- Lab Safety Scavenger HuntDocumento2 pagineLab Safety Scavenger Huntdaniela ayalaNessuna valutazione finora