Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Steel Manufacturing Process

Caricato da

Winny Shiru MachiraDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Steel Manufacturing Process

Caricato da

Winny Shiru MachiraCopyright:

Formati disponibili

Running Head: STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES

Steel Manufacturing Process Steel Portal Frames Name Institution

STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES Steel manufacturing process Steel is a term used to describe any carbon alloy and is one of the most important and

useful product in the world. Its manufacturing process is composed of a complex number of steps that turns it from ore into the final product which is steel. Over the years, different methods of steel manufacturing have been developed. There are the methods that involve the use of converters and other methods that involve the use of open hearth furnaces (Bugayev et al, 2001). Iron making is the first step in the manufacturing process. During this step, the raw inputs which consist of iron ore, coke as well as lime are melted inside a blast furnace. The resultant product is referred to as hot metal or molten iron and contains some impurities and carbon which makes it a brittle substance. This brittle substance is also known as pig iron and it requires further refining to ensure that it is free from all impurities. The additional refining is done in a refining furnace where the excess carbon is burned off to a point where only the required elements are left (Bugayev et al, 2001). When the refining process is complete, the process of primary steel making is started. In this process the metal is converted into high quality steel. The methods for performing this process are different as some use the EAF method while others use the BOS method. In the BOS method, hot metal is fed to the furnace in order to remove some elements that are undesired which include sulphur, Phosphorous as well as Silicon. These impurities are removed in form of gases or slag and the end product is molten steel that is in liquid form (Stubbles, n.d). In the EAF method, the steel scrap is melted by using the heat that is generated by graphite electrodes and the result is crude steel which can be fed into the casting cycle. The electricity that these electrodes produce forms an arc that is then used in melting the scrap. As

STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES the scrap is being melted, other fera-alloys are added to it to achieve the desired element composition. The molten steel is also cast into vertical cats for the purpose of rolling after the heating in the primary mill and in the finishing mill are all completed (Stubbles, n.d).

Secondary steel making is the step that follows primary steel making. In this process, the molten steel that is produced by either the EAF or the BOS is treated. This is done in order to adjust the composition of steel in the molten steel. The adjustment is done by either removing some elements or manipulating both the temperature and production environments. There are various steel making processes that can be used depending on the types of steels that are required. Processes like stirring, De-gassing, ladle furnace as well as ladle injection can be applied depending on the chemical compositions that are required for the steel (World Bank Group, 1998). Continuous casting: This step involved the casting of molten steel into cooled moulds that cause the steel shells to become solids. The steel shells are then removed by the use of guided rolls and are fully cooled and then solidified in a simultaneous process. The strands are then cut into the lengths and shapes that are desired and then transported to the hot rolling mills which produce the final steel products (Green & Batchelor, n.d). Hot rolling: The hot rolling process involved the final shaping of the semi finished steel and converting them to the final products that are sold to the steel industry. The steel is heated in a furnace till they get to 1200o C. it is taken to the roughing stand, which is the first part of the rolling mill, where a collection of steel rolls squeeze the hot steel that is passing through. These steel rolls squeeze the hot iron due to the pressure that is applied to them. During the squeezing the steel is formed into the required shape and then passed through the stand for a couple of

STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES

times .In each passing, the shape and dimension of the steel is gradually adjusted till it gets to the point where it is a finished product (Green & Batchelor, n.d). After passing through the roughing stand, the steel is passed through the finishing stand where the steel is passed through continuously and rolled around in every angle. As it passes through the finishing stand, the process of cooling the steel is also given a lot of attention; the cooling is done either by using cold water sprays or by the use of large fans that performed the cooling process in a moderate manner. On completing the hot rolling, further action can be done on the steel to fit the customer requirements or to fir the manufacturers standards. For instance, processes like fabricating, profiling or coating can be done to the steel depending on the eventual use of the end product (Green & Batchelor, n.d). Steel Portal frames Steel portal frames are common in single storied houses where the buildings are constructed using steel frames for creating the structural forms. They are mainly constructed using hot rolled sections that are used in supporting the buildings roof and side claddings. This support is done by the use of cold formed purlins as well as sheet rails. By using these portal frames, buildings get to economically sound structural solutions for their buildings (Emmitt & Gorse, 2010). In addition to their economic viability, steel portal frames have been found to increase the amount of clear room in buildings and allow for maximum adaptability inside the buildings. It is also possible to extend them at later dates without affecting the structural integrity of the buildings and it makes them effective in constructing buildings that have future expansion prospects. Portal frames made of steel have been found to enhance the strength of buildings. By

STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES using steel as the main structural component in the buildings, the strength of the building is assured because they shield buildings from structural fallings that could occur as a result of natural or human disasters (Emmitt and Gorse, 2010). Li & Li (2007) categorizes the steel frames into four categories: Pure frames,

concentrically braced frames, eccentrically braced frames as well as frame tubes. These different categories have been widely applied in various construction projects and are applied based on the design requirements of different buildings. Pure frames have good ductility but fail to possess enough sway and are not effective in multi-storey buildings. As a result, the concentrically braced frames have become more popular in the multi storey structures because they have been enhanced and have lesser stiffness as compared to the pure frames. The eccentrically braced frames are another major improvement on the concentrically braced frames because they have enjoyed major improvements in load capacity and are effective in protecting the building against earthquakes. Frame tube frames are the most recent improvement on the steel frame portals and have been effective in the construction of high rise buildings. The frame tubes are created by the use of steel beams and columns and this makes the frame tubes effective in dealing with sway stiffness and load capacity (Li & Li, 2007). According to Emmitt & Gorse (2010) steel portal frames can be categorized into either medium or long span steel frames. Both of these categories have both their rafters and posts connected and this connection is haunched at the knee level. This is done to ensure that the frames have a stiffer connection and to also ensure that bending is reduced in the frames. Steel portal frames can either be pinned or permanently fixed to the foundations of buildings. While

STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES fixing the frames to the roofs of buildings, purlins are attached to the rafters to ensure that there is wall cladding and insulation in the building. Due to the benefits that the steel portal frames offers, their usage in the construction industry is likely to increase. The improvements that have been made on the frames from the pure frames to the frame tubes have ensured that they can now be safety applied to high rise buildings and offer structural stability to these buildings (Emmitt & Gorse, 2010).

STEEL MANUFACTURING PROCESS STEEL PORTAL FRAMES

References Bugayev, K.,. Konovalov, Y ., Bychkov, Y. & E. Tretyakov, E. 2001 . Iron and Steel Production. The Minerva Group: Hong Kong. Emmitt, S. & Gorse, C. 2010. Barry's Advanced Construction of Buildings. John Wiley & Sons: West Sussex. Green, J & Batchelor,J. n.d. THE MANUFACTURE OF STEEL. BHP NZ Steel. Retrieved from: http://nzic.org.nz/ChemProcesses/metals/8A.pdf Li, J & Li, G. 2007. Advanced Analysis and Design of Steel Frames. John Wiley & Sons: West Sussex. Stubbles, J. n.d. The Basic Oxygen Steelmaking (BOS) Process. Steel Works. Retrieved from: http://www.steel.org/en/Making%20Steel/How%20Its%20Made/Processes/Processes%20 Info/The%20Basic%20Oxygen%20Steelmaking%20Process.aspx World Bank Group, 1998. Iron and Steel Manufacturing. Retrieved from: http://www.ifc.org/wps/wcm/connect/7786e08048855c2a8b44db6a6515bb18/ironsteel_P PAH.pdf?MOD=AJPERES

Potrebbero piacerti anche

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesDa EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNessuna valutazione finora

- Materials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CDocumento25 pagineMaterials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CNidhi MehtaNessuna valutazione finora

- Steel Thermal Expansion Coefficient ConcreteDocumento4 pagineSteel Thermal Expansion Coefficient Concretejohny BavitoNessuna valutazione finora

- Steel PDFDocumento82 pagineSteel PDFGloremay Ann AlemanNessuna valutazione finora

- Steel Thermal Expansion Coefficient ConcreteDocumento4 pagineSteel Thermal Expansion Coefficient ConcreteAllenNessuna valutazione finora

- 209106029-Shierly Anggraeni-Cognition Practice ReportDocumento6 pagine209106029-Shierly Anggraeni-Cognition Practice ReportShierly AnggraeniNessuna valutazione finora

- L3-Structural SteelDocumento58 pagineL3-Structural SteelTjia Tjie100% (1)

- Light Gauge Steel FramingDocumento14 pagineLight Gauge Steel Framingremon100% (4)

- BEC6Documento6 pagineBEC6angelolagfNessuna valutazione finora

- Structural Steel Design Course OverviewDocumento20 pagineStructural Steel Design Course OverviewImani LughoNessuna valutazione finora

- IbsDocumento26 pagineIbsAshadi HamdanNessuna valutazione finora

- Steel StructureDocumento6 pagineSteel StructureONG VNessuna valutazione finora

- Steel Making - Nptel PDFDocumento214 pagineSteel Making - Nptel PDFanurag3069100% (3)

- Design of Cold Formed Steel StructuresDocumento94 pagineDesign of Cold Formed Steel StructuresGia Cát LạngNessuna valutazione finora

- Steel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionDocumento6 pagineSteel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionSAMANTHA SARAH PURBANessuna valutazione finora

- Avani and RitijaDocumento17 pagineAvani and RitijaDevyaniAgrawalNessuna valutazione finora

- CMT - Module 7 (STEEL)Documento7 pagineCMT - Module 7 (STEEL)John Fred Marzan CativoNessuna valutazione finora

- Construction Engineering and Building Information Modelling: Dr. Nasir JavedDocumento73 pagineConstruction Engineering and Building Information Modelling: Dr. Nasir JavedBilal JamilNessuna valutazione finora

- Construction of Cold Formed Steel StructuresDocumento6 pagineConstruction of Cold Formed Steel Structureseksi_hasanNessuna valutazione finora

- Steel Manufacturing ProcessDocumento1 paginaSteel Manufacturing ProcessdalyemNessuna valutazione finora

- Cold Formed SteelDocumento5 pagineCold Formed SteelYeeYern LimNessuna valutazione finora

- Steel Making FundamentalsDocumento42 pagineSteel Making FundamentalsHimadhar Sadu100% (1)

- (IJETA-V11I1P1) :gaurav Singh Raghav, Mohsin Khan AgwanDocumento10 pagine(IJETA-V11I1P1) :gaurav Singh Raghav, Mohsin Khan AgwanIJETA - EighthSenseGroupNessuna valutazione finora

- METALWORKINGDocumento3 pagineMETALWORKINGIrene FranchinNessuna valutazione finora

- Design of Cold Formed Steel StructuresDocumento94 pagineDesign of Cold Formed Steel Structuresrobersasmita80% (5)

- Hand Out CMTDocumento6 pagineHand Out CMTAlden TeodoroNessuna valutazione finora

- Review Article: Review On Cold-Formed Steel ConnectionsDocumento12 pagineReview Article: Review On Cold-Formed Steel ConnectionsRakeshNessuna valutazione finora

- Bldgtec1 Act Fno2Documento3 pagineBldgtec1 Act Fno2fabre.mikaellaNessuna valutazione finora

- A Guide To The Language of SteelDocumento7 pagineA Guide To The Language of SteelIwona AnkaNessuna valutazione finora

- Chapter One - Introduction To Steel StructuresDocumento8 pagineChapter One - Introduction To Steel StructuresJohn Philip Molina NuñezNessuna valutazione finora

- About Cold Formed SteelDocumento2 pagineAbout Cold Formed SteelGonzilaNessuna valutazione finora

- Manufacturing of SteelDocumento3 pagineManufacturing of SteelfaeradaNessuna valutazione finora

- STRUCTURAL STEEL SECTIONS GUIDEDocumento9 pagineSTRUCTURAL STEEL SECTIONS GUIDEKavish Singh100% (2)

- Development of Chinese Light Steel Construction Residential BuildingsDocumento5 pagineDevelopment of Chinese Light Steel Construction Residential BuildingsUday PratapNessuna valutazione finora

- Steel Trusses PDFDocumento73 pagineSteel Trusses PDFmayuresh barbarwar100% (1)

- CE 362 - Topic 1 - Student'sDocumento76 pagineCE 362 - Topic 1 - Student'sJohn Joseph SuanNessuna valutazione finora

- Introduction On Principles of Steel DesignDocumento9 pagineIntroduction On Principles of Steel DesignMaria Therese PrietoNessuna valutazione finora

- Steel FrameDocumento13 pagineSteel FrameJensen ChoyNessuna valutazione finora

- Structural Steel Shapes and StandardsDocumento5 pagineStructural Steel Shapes and Standardsnazlie1707Nessuna valutazione finora

- Steel FrameDocumento5 pagineSteel FrameDanielle Ann Joyce ValenciaNessuna valutazione finora

- Automatic ingot feeder streamlines aluminum castingDocumento5 pagineAutomatic ingot feeder streamlines aluminum castingPooja BanNessuna valutazione finora

- Manufacturing Process of C PurlinsDocumento17 pagineManufacturing Process of C PurlinsJOHNEDERSON PABLONessuna valutazione finora

- Hot Rolled SteelDocumento2 pagineHot Rolled SteelabhishekNessuna valutazione finora

- Cokeless Iron Making Procedures Are Currently Being Studied And, in Some Places, ImplementedDocumento9 pagineCokeless Iron Making Procedures Are Currently Being Studied And, in Some Places, ImplementedVinothKumarVinothNessuna valutazione finora

- Metal CastingDocumento28 pagineMetal CastingAngel ChanteyNessuna valutazione finora

- 4.1 Metal FormingDocumento7 pagine4.1 Metal FormingVinothKumarVinothNessuna valutazione finora

- RSW-BT-YONGDocumento10 pagineRSW-BT-YONGfraniancis0922Nessuna valutazione finora

- ReinforcementDocumento6 pagineReinforcementakinyemioaNessuna valutazione finora

- Key Words: Primary Steelmaking, Ladle Metallurgy, Ingot Casting, Continuous Casting ConceptDocumento4 pagineKey Words: Primary Steelmaking, Ladle Metallurgy, Ingot Casting, Continuous Casting ConceptAbhijeet BhagavatulaNessuna valutazione finora

- Cold Form Steel PDFDocumento70 pagineCold Form Steel PDFJohnnatan ViniciusNessuna valutazione finora

- Steel Materials WikipediaDocumento12 pagineSteel Materials WikipediaSam AlaxNessuna valutazione finora

- Design of Steel StructuresDocumento6 pagineDesign of Steel StructuresNanthini JagadeesanNessuna valutazione finora

- Report by Faten HanyDocumento4 pagineReport by Faten HanyNader HemayaNessuna valutazione finora

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingDa EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingValutazione: 1 su 5 stelle1/5 (1)

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDa EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNessuna valutazione finora

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsDa EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsValutazione: 5 su 5 stelle5/5 (1)

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelDa EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelValutazione: 5 su 5 stelle5/5 (4)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyDa EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNessuna valutazione finora

- Lesson-07-Management Information SystemsDocumento4 pagineLesson-07-Management Information SystemsWinny Shiru MachiraNessuna valutazione finora

- Lesson 4 Review of Network Access (Contd.) .: Web BrowsersDocumento5 pagineLesson 4 Review of Network Access (Contd.) .: Web BrowsersWinny Shiru MachiraNessuna valutazione finora

- Lecture 24Documento6 pagineLecture 24Winny Shiru MachiraNessuna valutazione finora

- Lesson 36: Conjoint AnalysisDocumento6 pagineLesson 36: Conjoint AnalysisWinny Shiru MachiraNessuna valutazione finora

- Lecture 19Documento5 pagineLecture 19Winny Shiru MachiraNessuna valutazione finora

- Lesson 38: Cluster Analysis: Cluster Analysis What It Is and What It's NotDocumento5 pagineLesson 38: Cluster Analysis: Cluster Analysis What It Is and What It's NotWinny Shiru MachiraNessuna valutazione finora

- Lecture 22Documento6 pagineLecture 22Winny Shiru MachiraNessuna valutazione finora

- MArketing Research Notes Chapter4Documento1 paginaMArketing Research Notes Chapter4manojpatel51100% (1)

- MArketing Research Notes Chapter2Documento9 pagineMArketing Research Notes Chapter2manojpatel51Nessuna valutazione finora

- Lesson 23: Tests of Hypotheses - Small SamplesDocumento5 pagineLesson 23: Tests of Hypotheses - Small SamplesWinny Shiru MachiraNessuna valutazione finora

- Lesson 34: Principal Component Analysis: 1. Cross-TabulationDocumento4 pagineLesson 34: Principal Component Analysis: 1. Cross-TabulationWinny Shiru MachiraNessuna valutazione finora

- Lecture 27Documento4 pagineLecture 27Winny Shiru MachiraNessuna valutazione finora

- Lecture 33Documento5 pagineLecture 33Winny Shiru MachiraNessuna valutazione finora

- Lecture 39Documento15 pagineLecture 39Winny Shiru MachiraNessuna valutazione finora

- What Is A Computer Network?Documento20 pagineWhat Is A Computer Network?ssprudhviNessuna valutazione finora

- Notes on Computer Networks and ProtocolsDocumento93 pagineNotes on Computer Networks and ProtocolsinamullahbNessuna valutazione finora

- Human Res. Management - M. Com - IDocumento151 pagineHuman Res. Management - M. Com - IShailesh Mehta100% (2)

- Organization's ImageDocumento13 pagineOrganization's Imagesweetlittlegirl_92Nessuna valutazione finora

- E Hrmguide PDFDocumento33 pagineE Hrmguide PDFsonuNessuna valutazione finora

- Individual Income Tax Law of The People's Republic of China (2011 Amendment)Documento12 pagineIndividual Income Tax Law of The People's Republic of China (2011 Amendment)Winny Shiru MachiraNessuna valutazione finora

- Fs-1030mfp Fs-1... 5mfp Og EngDocumento442 pagineFs-1030mfp Fs-1... 5mfp Og EngVali FlorinNessuna valutazione finora

- Lesson 18 Description of Network Design: Windows Peer-to-Peer Networking ArchitectureDocumento4 pagineLesson 18 Description of Network Design: Windows Peer-to-Peer Networking ArchitectureWinny Shiru MachiraNessuna valutazione finora

- Operation Guide Command CenterDocumento32 pagineOperation Guide Command CenterAnthony CiprianiNessuna valutazione finora

- Mentoring Prog Operations ManualDocumento14 pagineMentoring Prog Operations ManualWinny Shiru MachiraNessuna valutazione finora

- Mol Biol Evol 1997 Suzuki 800 6Documento7 pagineMol Biol Evol 1997 Suzuki 800 6Winny Shiru MachiraNessuna valutazione finora

- Lecture 30Documento3 pagineLecture 30Winny Shiru MachiraNessuna valutazione finora

- Support For Growth Orinted Women in KenyaILO-KENYA - 12.01.2005Documento73 pagineSupport For Growth Orinted Women in KenyaILO-KENYA - 12.01.2005Winny Shiru MachiraNessuna valutazione finora

- Who Offset 36Documento27 pagineWho Offset 36alexgo5_7186Nessuna valutazione finora

- Computer Hardware: Chapter PreviewDocumento38 pagineComputer Hardware: Chapter PreviewajayakomnaNessuna valutazione finora

- Cisco Networking EssentialsDocumento36 pagineCisco Networking Essentialsapi-19655487100% (4)

- Rehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadDocumento2 pagineRehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadAljie CañeteNessuna valutazione finora

- The Market Scape 01: Goals For "Integrated" Streets For DelhiDocumento3 pagineThe Market Scape 01: Goals For "Integrated" Streets For DelhiVamsi Krishna ReddyNessuna valutazione finora

- Variable Hangers and Supports - 2018 - Rev.3.1Documento19 pagineVariable Hangers and Supports - 2018 - Rev.3.1Nassim Ben AbdeddayemNessuna valutazione finora

- Lg933 Wheel Loader Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdDocumento147 pagineLg933 Wheel Loader Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdЭрнест БекировNessuna valutazione finora

- Work Stress Column DesignDocumento7 pagineWork Stress Column DesignAkhtar BahramNessuna valutazione finora

- Research Portals for Construction Project ManagementDocumento9 pagineResearch Portals for Construction Project ManagementrajnishatpecNessuna valutazione finora

- Daily RFI Schedule 20210302Documento1 paginaDaily RFI Schedule 20210302samwel kariukiNessuna valutazione finora

- AnnexureDocumento16 pagineAnnexureAmirNessuna valutazione finora

- Geotech pressure calcsDocumento5 pagineGeotech pressure calcsHarris LeeNessuna valutazione finora

- Ts LCRBY FiltersDocumento2 pagineTs LCRBY FiltersRazvanNessuna valutazione finora

- Re 25715 - 2022-05Documento8 pagineRe 25715 - 2022-05HeiderHuertaNessuna valutazione finora

- Performance Based Specifications For RoadwaysDocumento12 paginePerformance Based Specifications For RoadwaysMohammad TarawnehNessuna valutazione finora

- Imphal EasaaDocumento1 paginaImphal EasaaKosygin LeishangthemNessuna valutazione finora

- Design of Rigid Pavement CC Road With M25Documento5 pagineDesign of Rigid Pavement CC Road With M25pravincs_007Nessuna valutazione finora

- T-ZED Homes, Whitefield, BengaluruDocumento5 pagineT-ZED Homes, Whitefield, BengaluruHello ShraaNessuna valutazione finora

- Solar Project Construction: Nextera Energy Resources (Neer)Documento20 pagineSolar Project Construction: Nextera Energy Resources (Neer)absriva00Nessuna valutazione finora

- Structural Drawings: Sl/Adb/St-CsDocumento35 pagineStructural Drawings: Sl/Adb/St-Csharold romuald Lele FotsoNessuna valutazione finora

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDocumento10 pagineSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedNessuna valutazione finora

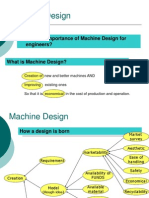

- Machine Design - Introduction PDFDocumento13 pagineMachine Design - Introduction PDFDida KhalingNessuna valutazione finora

- M 171 Specs for Curing Concrete SheetsDocumento1 paginaM 171 Specs for Curing Concrete SheetsFranz Richard Sardinas MallcoNessuna valutazione finora

- Noise Control Buildings-Seminar ReportDocumento29 pagineNoise Control Buildings-Seminar ReportVîkÅš VìČký69% (13)

- Plaxis: Computational Geotechnics Course (2D Plaxis Course)Documento2 paginePlaxis: Computational Geotechnics Course (2D Plaxis Course)Fajar Adi NugrohoNessuna valutazione finora

- Friction Stir Welding ENHANCEMENT SEMINAR Friction Stir WeldingDocumento66 pagineFriction Stir Welding ENHANCEMENT SEMINAR Friction Stir Weldingrobertalha100% (1)

- Bar STDDocumento8 pagineBar STDtushk20100% (1)

- 45-144 - A505 - Elevator Details (Version)Documento1 pagina45-144 - A505 - Elevator Details (Version)Parth DaxiniNessuna valutazione finora

- Designation System of Screws and BoltsDocumento3 pagineDesignation System of Screws and BoltsGiri DharanNessuna valutazione finora

- PMC IpdDocumento19 paginePMC IpdAbhik BhattacharjeeNessuna valutazione finora

- Soft Sealing Gate Valve PN25Documento2 pagineSoft Sealing Gate Valve PN25Emran HaniniNessuna valutazione finora

- No Fines Conc SpecsDocumento3 pagineNo Fines Conc Specsway2saleemNessuna valutazione finora

- Maintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyDocumento1 paginaMaintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyAneesh ConstantineNessuna valutazione finora