Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Management Info System NCP 28

Caricato da

Shelly DelhiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Management Info System NCP 28

Caricato da

Shelly DelhiCopyright:

Formati disponibili

Course No.: NCP 28 Course title: Management Information System Assignment No.

: Seven

ASSIGNMENT ON

Management Information System

By Dattatray Kashinath Shelake Student Registration No. 28-01-11-4727-292

NATIONAL INSTITUTE OF CONSTRUCTION MANAGEMENT AND RESEARCH Pune (2008)

For construction of Hydel-Power project in which we have to construct main Dam, weir, Electric Power station and tunnel. For that we have to organize all the

recourses, manpower and Material and also keeping consumption record. For proper material requirement demand by which we can avoid the delay of procurement of material at site. Material Management is very important for timely completion of the projects. A delay in providing the materials for construction will naturally put the project behind schedule from which it may never recover or the cost of bringing it backs on schedule may be very high. Such shortages disrupt the work how and apart from the lowering morale, need additional organizational efforts to generate the flow again. Men and machines remain idle while they await the arrival of the materials. These delays are not simply a matter of few weeks or days. They have a cascading effect on the entire project performance. Because the construction is delayed. The billing gets held up and affects the cash flow. Added to it, the additional overheads that will be required to carryon the project to its final completion and the liquidated damages that a contractor may have to pay for exceeding the time, limit or the loss in production and revenue for the owners. Material Management covers a wide scope. It includes procuring materials.. Their transportation, storage, issuing material to various sites for use in construction, maintaining records and data for effective control and to provide useful guide for further. Through it is distinct from other activities, it is closely related to planning, design and estimating, construction accounting, etc.

Inventory Control:- This can be considered as the most important function of materials management. It is mainly concerned with laying the policies regarding how much

guarantee of material should be held is stock so that the aim of the material management viz. ensuring continuity of the construction with the minimum investment is materials is fulfilled. Necessity of Inventory Control:- The aim of the materials management has been stated to be making available the right type of Material in right quantity, at the right price, at the right time and at the right place. The objective is that the construction work is not held up for want of material but the total investment on the materials minimum. If we examine the aims and objectives very carefully the dilemma faced by the stock inventory control so also crucial role in the materials management is obvious. As the inventory /stock represents idle locking up of the capital, one would desire that there should preferably be inventory/stock. The materials should be so procured that are directly consumed in the construction on the user or construction staff would insist on a safe stocks absorb changes in the construction schedule. The real solution to the problem would be to examine both the sides of problem in greater detail and arrive of an optimum solution.

Economic order quality (EOQ) :Total Cost

Ordering Cost

Inventory carrying cost

Frequency of ordering The curve AMB indicates the graph of inventory carry cost for various frequencies of ordering please note that low ordering turn means in inventory and hence inventory carrying cost. It also means few orders and hence less ordering cost. OMG shows the graph of ordering costs corresponding to various frequencies. If we add the two costs we got a graph PQR, which indicates the total invent cost corresponding to various frequencies, Q is the least c and hence the intercept QS shows the most desirable frequency of ordering for which the total inventory cost is minimum. The quantity of order corresponding to the frequency is known as Economic order quantity (EOQ). We can also plot the graph with quantity per order plotted along x-axis and costs along y-axis (What will be the no here that two graphs in such a case ? ). Both the costs when totaled will get the total cost. The intercept on x axis corresponding to the lowest point on the total cost will now give economic order quantity (EOQ). This is also known as economic order quantity (EOQ). This is also known as Economic lot size.

Graphical Representation of the EOQ model. The working of the above inventory model can be graphically as shown in the following figure. It is assumed that inventory cycle starts with the material of the lot size Q in the stocks.

The intercept OP on y-axis indicates the economic lot size Q received 0-1, 1-2, 2-3, 34, etc. indicates the cycle period (e.g. year ). With OP=Q as the starting quantity, the stocks are depleted uniformly indicated by the lint PT). AE 1 the quantity of hand is zero when the next economic lot size ( 1 Pi) is ordered. The cycle then continues x, x1, x2, is the dotted line indicating average

inventory.(i.e. ox = 1 xi = Q/2)

Site storage and reporting :When certain materials have to be held in stock before they are used, it is necessary to store them properly to guard against determination pilferage etc. in a construction organization storage needs to be carefully considered depending or factors

like number of construction works. Their nature magnitude and locations. Nature of material decides type of the storage open, closed etc. The scope of materials management externals over other areas like search for new materials of construction, identify new sources, controlling the consumption by minimizing wastage introducing a proper recording and reporting system disposal of scrap. Carrying out value analysis where the construction is mechanized. Materials management is also concerned with purchase of equipment, fuels, spares, etc.

Efficient and effective material management is expected achieve the following aims. (i) Probable needs of the materials requirement can forecast within reasonable limits of accuracy. (ii) Adequate quantity of the materials of the specified quantity (specification ) is

received on the work site at the appropriate time. In fact the motto of good materials management is to make available right quality of materials in the right quantity of the right price of the right time. iii) with the help of construction work schedule (like bar charts networks etc. )

procurement schedules are prepared for materials taking into consideration the time required for placing orders, inspection testing deliveries etc. this help in maintaining stocks of materials to the minimum level but at the same time. It avoids any hold up of construction work for want of materials. iv) By maintaining proper records and analyzing them it is possible to generals useful data, which will serve as guide in future.

v) By studying market conditions and with the constant touch with development in the field of materials, it is possible to (i) force cast fluctuations availability or otherwise, price change etc. and false appropriate timely action (ii) identify new substitute materials (iii) improve upon the procurement procedure.

Integrated approach to materials management :Materials management by itself no doubt comprises various functions mentioned in the previous paragraph but at the same time is closely related with other departments. For example, it is related to tendering and planning departments in so far as the requirement of materials in considered. It is concerned with construction department for the day-to-day demand of materials, its specification etc. Accounts department is of course very closely related to the materials managements. There must be an integrated approach for a successful materials management. The objectives of different functional heads may be different and sometimes objectives of one function may conflict with the other. An illustration will clarify this. The purchasing department is interested is buying as large a quantity as possible to avail of the discount offered by the supplier for purchasing large quantities. This however results is the shortage of large quantities of materials which would mean, loading up of capital loss of material due to deterioration pilferage, expenditure on watch and word etc. In order to achieve the overall goal of the materials managements there has to be an integrated approach. This concept is based on the principle of co-ordination. All the departments concerned must attend full co-operation and work in co-operation and work in co-ordination to achieves the desired goal.

Properties of management Reporting System :Many MRSs specialize in producing periodic reports from operational level of transactional data. These reports are used for a wide variety of purposes like planning, monitoring and control activities. The following examples illustrate how MRS is used is organizations today. Every evening, the first thing the Technical Director of a company likes to see is

the total output and safe done for the previous day. The Accounts Manager wants to see the amounts outstanding against the

customers as of today. Types of Reports :- An MRS can produce a hard or soft copy of the output. Hard copies are the most common form of output. Reports produced by such systems usually fall into one of the three categories. i) Scheduled Reports :- Sometimes called periodic reports, these are the reports which are issued at defined time provides for instance, daily production report monthly cash inflows etc. These reports can be used for planning and control purpose. ii) Exception Reports :- These are issued when something unusual happens that

requires the managements attention for instance an expense overrun a delay in payment would result in exceptional reports such reports are used few controlling purposes. These reports may trigger can action also e.g. sending reminders for payments. iii) Demands Reports :- These are generated when an authorized person requests

for them for example an executive asking for the status of pending orders or for inventory in hand.

System Development :Stages of system development are as follow 1. Recognition of Need What is the Problem? 2. Feasibility study need, worth 3. Analysis how 4. Design plan 5. Implementation - Execute. 6. Post implementation and maintance.

Types of systems :- There are variety of systems where system analysis would be required, which can be classified as follows. Data processing system :- The data already exists put need processing to achieve certain results the focus is on computing eg, daily progress Report material consumption report etc. Transaction processing system :- Processing of transaction using some stored data and business rules. The focus is on the transaction execution e.g. calculation of over budgets earn values, overload of resource early and late dates etc. Functional systems :- the production, sales purchase and finance systems, where several transactions and stored data is used to produce certain information. The focus is on the operations. Management eg. Stocks status in materials departments quality status in quality department, material issue to various projects, receipt, invoices, and bills maintained by accounts department for various projects.

Integrated Systems :- More than one system is processed together to produce an updated status and business results, where the systems are networked and interfaced. The focus is on process management across the business function eg. P3 for enterprise. Enterprise Management :- It is a set of systems functioning in the respective areas playing a local service role, as well as providing service inputs to other systems in the organization. The focus is on decision support for strategic management to achieve enterprise goals and mission eg. ERP (Integration of all functional systems for an enterprise) Data Flow Diagrams :DFD :- The first step is to draw data flow diagram in system analysis and design. DFD is also known as bubble chart that has the purpose of classifying system requirements and identifying major transformations that will become programs in system design. DFD describes what data flow (logical ) rather that how they are processed. Therefore DFD does not depend on hardware and software or data structure and file organization Four basic DFD symbols A square defines a source ( orginatev ) Or destination of system data. An arrow defines data flow data in motion it is a pipe line through which information flow. A circle or bubble some people use an oval bubble) represents a process that transforms incoming data flows into out going data flows. An open rectangle is a data store data of rest, or a temporary reposition of data

10

= Source or destination of data

= Data Flow

Or Or = Process that transforms data flow

Or

= Data Store

File structure A file of data contains the attributes of a large number of items or entities A personal record file would contain data about a large number of employees in the organization. The data about one teacher form one record in the file. The file containing data of about 50,000 teachers would contains 50000 records one for each teacher. These records may be grouped into groups of 5, 10 or more records each for the purpose of convenience. A group of records is called a Block each record contains various attributes of the teacher. File Media : Files of data for computer based information system can be maintained on any of the acceptable input/ output media. The commonly used file media are Punched cards Magnetic tapes Magnetic disks

11

Models of file organizations 1. Pile file 2. Sequential file 3. Indexed sequential file 4. Indexed file (inverted file) 5. Direct file 6. Multiring file Structure of data base: The records of entities and the relationship among entities in the data base are organized into a structure called schema the schema of the entire data base may be designed and maintained by the data base administrator Models of data structure: Data base system can be categorized according to the models of data structure they use in building the conceptual structure or schema of the data base. One of the three approaches is used in most data base system viz Hierarchical model Network model Relational Model

Bibliography : 1) Management Information System. (NCP-28)

12

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- PGPM31 M57Documento29 paginePGPM31 M57Shelly DelhiNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Food AdulterationDocumento33 pagineFood AdulterationShivam Garg100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Effect of Sio2 On StrengthDocumento1 paginaEffect of Sio2 On StrengthShelly DelhiNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Construction of Concrete Roads and Overlays - Do's and Don'Ts Brochure FinalDocumento7 pagineConstruction of Concrete Roads and Overlays - Do's and Don'Ts Brochure FinalShelly Delhi0% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- NCP 21Documento30 pagineNCP 21Shelly Delhi100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- NCP 23 - PGPPMDocumento22 pagineNCP 23 - PGPPMShelly Delhi100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Generic QMS Template - Nov 2012Documento62 pagineGeneric QMS Template - Nov 2012Farai KutadzausheNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- NCP 29Documento21 pagineNCP 29Shelly DelhiNessuna valutazione finora

- TQM The Construction IndustryDocumento27 pagineTQM The Construction Industryducsonkt16Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Vitamin B6Documento20 pagineVitamin B6Shelly Delhi100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- NCP 21Documento30 pagineNCP 21Shelly Delhi100% (1)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Long Paper - RDocumento63 pagineLong Paper - RShelly Delhi100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- NCP 29Documento21 pagineNCP 29Shelly DelhiNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Long Paper - RDocumento63 pagineLong Paper - RShelly Delhi100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- LKP Spade - Torrent Pharma - 7octDocumento3 pagineLKP Spade - Torrent Pharma - 7octpremNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- bài tập tổng hợp 1Documento10 paginebài tập tổng hợp 1Hoàng Bảo TrâmNessuna valutazione finora

- SCM Jattaoi Rice MillDocumento2 pagineSCM Jattaoi Rice MillAhmedNessuna valutazione finora

- Tuition Fee InvoiceDocumento1 paginaTuition Fee InvoiceE-Ern NgNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- CH12Documento4 pagineCH12Kurt Del RosarioNessuna valutazione finora

- Spectra NDocumento5 pagineSpectra NRichelle Mea B. PeñaNessuna valutazione finora

- Messier's Reign at Vivendi UniversalDocumento14 pagineMessier's Reign at Vivendi Universalsandycse2005Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Financial Markets and Institutions: 13 EditionDocumento35 pagineFinancial Markets and Institutions: 13 EditionTherese Grace PostreroNessuna valutazione finora

- Family OfficeDocumento1 paginaFamily OfficeTurcan Ciprian Sebastian100% (1)

- Esdc Lab1058Documento2 pagineEsdc Lab1058Kavinda BandaraNessuna valutazione finora

- MGT 263 Assignment 1Documento8 pagineMGT 263 Assignment 1Aysha Muhammad ShahzadNessuna valutazione finora

- Cash Flows and Accrual Accounting in Predicting Future Cash FlowsDocumento210 pagineCash Flows and Accrual Accounting in Predicting Future Cash FlowsNicolai AquinoNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Awais Ahmed Awan BBA 6B 1711267 HRM Project On NestleDocumento11 pagineAwais Ahmed Awan BBA 6B 1711267 HRM Project On NestleQadirNessuna valutazione finora

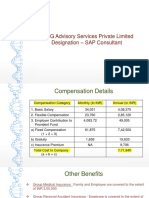

- KPMG Advisory Services Private Limited Designation - SAP ConsultantDocumento8 pagineKPMG Advisory Services Private Limited Designation - SAP ConsultantDhanad AmberkarNessuna valutazione finora

- New York Placement ListDocumento4 pagineNew York Placement ListDan Primack100% (1)

- Organizational Behavior 15th Ed: Foundations of Organizational StructureDocumento22 pagineOrganizational Behavior 15th Ed: Foundations of Organizational StructureJerome MogaNessuna valutazione finora

- Reformulation of Financial StatementsDocumento30 pagineReformulation of Financial StatementsKatty MothaNessuna valutazione finora

- HOWA QA-HW-12 Supplier Quality Manual Rev.8 (English) - SignedDocumento25 pagineHOWA QA-HW-12 Supplier Quality Manual Rev.8 (English) - Signedl.hernandezNessuna valutazione finora

- Groz ToolsDocumento71 pagineGroz ToolsAnil BatraNessuna valutazione finora

- Exercises OnDocumento5 pagineExercises OnPrasanth GummaNessuna valutazione finora

- Session 01 - Introduction To MarketingDocumento44 pagineSession 01 - Introduction To MarketingNipun HarshaNessuna valutazione finora

- Top 99 Wholesale Sources PDFDocumento27 pagineTop 99 Wholesale Sources PDFAnonymous 8DYrvTUNessuna valutazione finora

- Income From Business and Profession HandoutDocumento29 pagineIncome From Business and Profession HandoutAnantha Krishna BhatNessuna valutazione finora

- RMC No. 44-2022 Annex A (Manner of Filing of AITR)Documento2 pagineRMC No. 44-2022 Annex A (Manner of Filing of AITR)wendy lynn amanteNessuna valutazione finora

- Chapter 4 SDocumento17 pagineChapter 4 SLê Đăng Cát NhậtNessuna valutazione finora

- Chapter 1Documento4 pagineChapter 1sadsadsa100% (1)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Cfas Pas 34 & 10 and Pfrs 1Documento11 pagineCfas Pas 34 & 10 and Pfrs 1Tunas CareyNessuna valutazione finora

- For Sample MCQ ISCADocumento19 pagineFor Sample MCQ ISCAsaraNessuna valutazione finora

- Components of Inventory CostDocumento33 pagineComponents of Inventory CostJohn PangNessuna valutazione finora

- Curriculum Vitae: Name: Ahmed Hallala Algerian Residence: Jijel - AlgeriaDocumento6 pagineCurriculum Vitae: Name: Ahmed Hallala Algerian Residence: Jijel - AlgeriaXulfi KhanNessuna valutazione finora