Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Principles of Scientific Management

Caricato da

Mae JudelynTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Principles of Scientific Management

Caricato da

Mae JudelynCopyright:

Formati disponibili

1. Performance Standards F.W. Taylor found out that there were no scientific performance standards.

Taylor introduced Time and Motion Studies to fix performance standards. He fixed performance standards for time, cost, and quality of work, which lead to uniformity of work. 2. Differential Piece Rate System Under differential piece rate system, a standard output was first fixed. Then two wage rates were fixed as follows :Low wage rate was fixed for those workers who did not produce the standard output. Higher wage rate was fixed for those workers who produced the standard output or who produced more than the standard output. 3. Functional Foremanship Taylor started "Functional Foremanship". Here, 8 foremen (lower level manager or supervisor) are required to supervise the workers. This is because one foremen cannot be an expert in all the functions. Taylor's functional foremanship consists of two groups of supervisors :At the Planning Level or Office Level. Time and Cost Clerk : This boss prepares the standard time for completing the work and cost of doing that work. each Route Clerk : This boss makes the exact route (way) through which product has to travel from a raw-ma4terial to a finished product. Discipline Clerk : This boss looks after the discipline and absenteeism problems in the organisation. Instruction Card Clerk : The boss gives instructions about how to do a particular work. At the Doing Level or Factory Level. and for Gang Boss : He is responsible for setting up the machines and tools direct supervision of workers. Speed Boss : He is responsible for maintaining a proper speed of work. Repair Boss : He is responsible for the repairs and maintenance of machines.

Inspector Boss : He is responsible for maintaining the quality of production. 4. Mental Revolution Taylor introduced the concept of "Mental Revolution". He said that the management and workers should have a positive attitude towards each other. This will result in close cooperation between them. This will increase productivity and profits. 5. Time Study Time study means to record the time taken for doing each part of a job. Time study helps the management to know exactly how much time it will take to do a particular job. This helps the management to fix the amount of work to be done by each worker in one hour or in one day. Taylor advised all managers to do time study. This will prevent the workers from passing time, working slowly and doing less work. Time study helps to increase the productivity of the organisation. 6. Fatigue and Motion Study Frank and Lillian Gilbreth (Husband and Wife) introduced fatigue and motion studies. Fatigue and motion studies find out and remove unnecessary and wasteful movements while doing the job. 7. Gantt Charts Henry Gantt invented the Gantt chart. This chart shows the planned work and the completed work at each stage of production. It also shows the time taken to do the work. Gantt chart is the basis for following two concepts :The Critical Path Method (CPM), and The Program Evaluation Review Technique (PERT).

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 8 Effective Web Design Principles You Should KnowDocumento34 pagine8 Effective Web Design Principles You Should KnowMae Judelyn100% (1)

- CFJV00198BDocumento360 pagineCFJV00198BCheongNessuna valutazione finora

- Bell Desk-2Documento96 pagineBell Desk-2Arrow PrasadNessuna valutazione finora

- Complex Numbers AlgebraDocumento5 pagineComplex Numbers AlgebraMae JudelynNessuna valutazione finora

- HISTORY (Founding of Battalion of Loyal VolunteersDocumento21 pagineHISTORY (Founding of Battalion of Loyal VolunteersMae JudelynNessuna valutazione finora

- Edited-Manual For Students - Giov Version - Sept. 11 2011Documento120 pagineEdited-Manual For Students - Giov Version - Sept. 11 2011Mae JudelynNessuna valutazione finora

- 45 Things Girls Want But Won't AskDocumento3 pagine45 Things Girls Want But Won't AskMae JudelynNessuna valutazione finora

- Mainframe Vol-II Version 1.2Documento246 pagineMainframe Vol-II Version 1.2Nikunj Agarwal100% (1)

- Avaya Call History InterfaceDocumento76 pagineAvaya Call History InterfaceGarrido_Nessuna valutazione finora

- Synthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Documento9 pagineSynthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Ved PrakashNessuna valutazione finora

- Green Line TransformerDocumento4 pagineGreen Line TransformerwakasNessuna valutazione finora

- Microbial Enhanced Oil Recovery (Meor)Documento7 pagineMicrobial Enhanced Oil Recovery (Meor)Yomel Ramzi100% (1)

- Water System PQDocumento46 pagineWater System PQasit_mNessuna valutazione finora

- RT120 ManualDocumento161 pagineRT120 ManualPawełNessuna valutazione finora

- Owners Manuel SupplementDocumento6 pagineOwners Manuel SupplementJohn HansenNessuna valutazione finora

- V1 V2 Cal PRCDocumento5 pagineV1 V2 Cal PRCCyril J PadiyathNessuna valutazione finora

- EFR32BG1 Blue Gecko BluetoothDocumento102 pagineEFR32BG1 Blue Gecko BluetoothLullaby summerNessuna valutazione finora

- Activation and Deactivation of CatalystsDocumento16 pagineActivation and Deactivation of Catalystsshan0214Nessuna valutazione finora

- Seminar Report 2Documento25 pagineSeminar Report 2DrMahendra Kumar Gokhroo0% (1)

- Ism Practical FileDocumento62 pagineIsm Practical FilePriya AgrawalNessuna valutazione finora

- Analysis of Metal Matrix Composite (MMC) Applied Armor System Analysis of Metal Matrix Composite (MMC) Applied Armor SystemDocumento8 pagineAnalysis of Metal Matrix Composite (MMC) Applied Armor System Analysis of Metal Matrix Composite (MMC) Applied Armor SystemDerianSyahNessuna valutazione finora

- BEC198 (Finals)Documento180 pagineBEC198 (Finals)Lorenz BerroyaNessuna valutazione finora

- Design Procedures For Dynamically Loaded Foundations Choice of Parameters For Equivalent Lumped SystemsDocumento11 pagineDesign Procedures For Dynamically Loaded Foundations Choice of Parameters For Equivalent Lumped SystemsAnonymous osfiXqUkNessuna valutazione finora

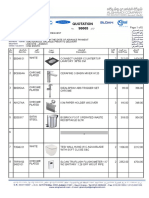

- Quotation 98665Documento5 pagineQuotation 98665Reda IsmailNessuna valutazione finora

- Viewnet Diy PricelistDocumento2 pagineViewnet Diy PricelistKhay SaadNessuna valutazione finora

- Data Flow Diagrams PDFDocumento9 pagineData Flow Diagrams PDFYasmine2410Nessuna valutazione finora

- Review of C++ Programming: Sheng-Fang HuangDocumento49 pagineReview of C++ Programming: Sheng-Fang HuangIfat NixNessuna valutazione finora

- Apple A9Documento10 pagineApple A9Savithri NandadasaNessuna valutazione finora

- 2015 Audi q5 sq5 71153 PDFDocumento302 pagine2015 Audi q5 sq5 71153 PDFPraveen100% (1)

- 8-0-SP1 Designer BPM Process Development HelpDocumento260 pagine8-0-SP1 Designer BPM Process Development HelpEric CaceresNessuna valutazione finora

- En Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARDocumento4 pagineEn Privacy The Best Reseller SMM Panel, Cheap SEO and PR - MRPOPULARZhenyuan LiNessuna valutazione finora

- Cold Rolled Steel Sheet-JFE PDFDocumento32 pagineCold Rolled Steel Sheet-JFE PDFEduardo Javier Granados SanchezNessuna valutazione finora

- Cloud Computing - Feb-Mar 2017Documento40 pagineCloud Computing - Feb-Mar 2017Abhishek SinghNessuna valutazione finora

- Udyam Registration Certificate UDYAM-MH-26-0097771Documento3 pagineUdyam Registration Certificate UDYAM-MH-26-0097771Suresh D ChemateNessuna valutazione finora

- MC9S12XD128 ProcessadorDocumento1.350 pagineMC9S12XD128 ProcessadorMarcelo OemNessuna valutazione finora