Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Section 13 Heat Rate

Caricato da

sandi1111Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Section 13 Heat Rate

Caricato da

sandi1111Copyright:

Formati disponibili

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13.

SECTION-13

STATION HEAT RATE OF COAL/LIGNITE BASED THERMAL POWER STATIONS 13.1

INDEX

The heat rate of a conventional fossil-fueled power plant is a measure of how efficiently it converts the chemical energy contained in the fuel into electrical energy. This conversion is accomplished in four major steps. First, the chemical energy in the fuel is converted into thermal energy, then the thermal energy is converted into kinetic energy, then the kinetic energy is converted in mechanical energy, and finally the mechanical energy is converted to electrical energy. In each of these sub-processes, some energy is lost to the environment. Some of the fuel is not burnt completely, some of the thermal energy is lost out of the stack and rejected to the cooling water, some of the kinetic and mechanical energy produces heat instead of electricity, and lastly some of the electricity that is produced is used by these sub-processes. The heat rate of a power plant is the amount of chemical energy that must be supplied to produce one unit of electrical energy. If a power plant converted 100% of the chemical energy in the fuel into electricity, the plant would have a heat rate of 860 kcal/kWh. Alternatively, the required input divided by the actual output, is the reciprocal of the efficiency. Chemical energy is usually measured in kilocalories (kcal) (or sometimes kilojoules, kJ) and electrical energy is usually measured in kilowatt-hours (kWh), the unit of heat rate is normally kcal/kWh (or kJ/kWh). The Station Heat Rate (SHR) is an important index for assessing the efficiency of a thermal power station. It should be the endeavor of any station to operate the unit as near their design Heat Rate as possible. Station heat rate improvement also helps in reducing pollution from Thermal Power Stations. Key points for improving Heat Rate: Heat rate improvements are possible at any plant, and at many plants the improvement can easily be in the range of 1-2 percentage points. Heat rate improvement programme could be started, concentrating on one or two areas, (i.e. condenser performance and/or burner balancing) or by concentrating on one or two activities (i.e. monitoring primary process indicators, testing, etc.) Heat rate improvement must have the full support of the plant management.

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 2

Improvements do not just happen, there must be a concerted effort made just to maintain current status, and even more effort expended to make improvements. Each plant should have a detailed plan listing specific activities that are to be carried out to make improvements, and the plant must be reviewed periodically to ensure that the plan is being carried out. Heat rate improvement is a continuing process. It must become part of the normal work activities, it must be considered along with, and at par with, reliability, safety, environmental concern, etc., when operating the unit, scheduling maintenance, and all other routine activities. The responsibility of heat rate improvement cannot be assigned to one individual or organization but requires the active involvement of the all plant staff.

A performa has been devised in CEA to monitor various parameters of efficiency of Thermal Power Stations in the country. Data related to Station Heat Rate parameters was received from 56 Thermal Power Stations during 2006-07, which have been compiled, analyzed and compared with their design SHR. The analysis of station heat rate so carried out has been highlighted in the Annexure 13.1. The analysis of station heat rate parameters has been carried out in different categories such as: range of SHR deviation (0-5%), (5-10%), (10-20%) and more than 20%. The stations under 0-10% variation category are considered as good performing stations and stations having greater than 10% variation are considered as poorly operating ones. All the stations analysed are using coal as primary fuel and oil as secondary fuel for flame stabilization/starting purposes except Neyveli, Kutch and Surat Lignite which are lignite based Thermal Power Stations. The analysis has been carried out on the Station basis. The following assumptions have been made for the analysis of station Heat Rate: a) Analysis of only those power stations has been carried out where data of at least 9 months operation was available. Design Station Heat Rate has been evaluated based on design data of turbine heat rate and boiler efficiency as submitted by TPSs and compared with their Operating Station Heat Rate. The data related to various parameters of station heat rate such as generation, fuel consumption, calorific values of fuels, etc. has been

b)

c)

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 3

taken from TPS authorities / SEBs / Generating Companies/ Utilities on monthly basis. d) Weighted average of Coal Gross Calorific Value (GCV) and Oil GCV has been computed yearly for calculating heat rate for the year.

THIS ANALYSIS IS BASED ON THE PERFORMANCE DATA AS AVAILAIBLE TO CEA. THE STATIONS WHICH ARE NOT FIGURING AVAILIBLE IN THIS LIST HAVE EITHER NOT SUBMITTED DATA OR SUBMITTED INCOMPLETE DATA. 13.2 METHODS: There are two methods for heat rate evaluation of Thermal Power Stations, i.e., Indirect Method and Direct Method.

13.2.1 INDIRECT METHOD: Indirect method of Heat Rate Measurement is an instantaneous method which is used for short duration and not possible throughout the year. It is a very complex method and basically a loss based method of measurement of Heat Rate. This method is generally adopted during the Energy Audit Studies. 13.2.2 DIRECT METHOD: Direct Method of Heat Rate Assessment is suitable for long duration in which averaging gives almost actual Heat Rate because Coal consumption measurement is fairly accurate if taken over a month/Year. Therefore, this method is employed at almost all stations as per the standard practice. The methodology adopted by CEA for assessment of station heat rate is based on Direct Method and the same is given in brief as follows: Step 1 All design data such as Turbine Heat Rate, Boiler Efficiency and basic history of Thermal Power Station has been collected from Station authorities and Unit Heat Rate (UHR) is evaluated with respect to unit capacities at 100% PLF. Step 2 Monthly operating data such as gross generation, total coal consumption, coal average G.C.V, Specific Oil Consumption and Oil GCV have been

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 4

collected from Thermal Power Station authorities based on which Operating Station Heat Rate for each month is calculated. Further, weighted Sp. Coal Consumption, weighted Sp. Oil Consumption, weighted GCV of coal and weighted GCV of oil are computed yearly for calculating yearly SHR. Step3 Operating SHR thus calculated is then compared with respect to design Station Heat Rate and percentage deviation is found to give an idea of performance of the station as a whole as per Step 2. 13.3 SALIENT FEATURES OF THE GROSS STATION HEAT RATE DATA ANALYSIS: The Operating Heat Rate of Thermal Power Stations during 2006-07, their deviation from the design values and their improvement / deterioration over the preceding year 2005-06 is given in the Annexure 13.1. The main highlights of the outcomes for the year 2006-07 and a comparative analysis with respect to the preceding year are given below: (a) ALL INDIA STATION HEAT RATE

Year

No. of Stations analyzed

Capacity

( MW)

Weighted Average Design SHR (kcal/kWh)

Weighted average Operating SHR (kcal/kWh)

% Operating SHR Deviation

with respect to Design

SHR

% improvement (+) / deterioration (-) in Operating Station Heat Rate over preceding year

2005-06 2006-07

57 56

35480 38611

2398 2398

2747 2861

14.57 19.31

(-) 1.47

(wrt 2004-05)

(-) 3.35

The above analysis indicates that there has been an overall deterioration of 3.35% in operating SHR during the year 2006-07 over the preceding year.

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 5

(b)

REGION WISE STATION HEAT RATE Year Weighted Average Design SHR (kcal/kWh) Weighted average Operating SHR (kcal/kWh)

% Operating SHR Deviation with respect to Design SHR (kcal/kWh) Northern 2005-2006 2418 2793 15.51 2006-2007 2418 2938 21.49 Western 2005-2006 2360 2737 16.02 2006-2007 2369* 2833 19.61 Southern 2005-2006 2404 2667 10.06 2006-2007 2400* 2679 11.62 Eastern 2005-2006 2413 3072 18.58 2006-2007 2429* 3109 28.00 * No. of Stations considered for 2005-06 and 2006-07 are different The above analysis indicates there was no improvement in Operating SHR of any region during the year 2006-07 over the preceding year 2005-06. Further, the Southern Region achieved the lowest Operating SHR of 2679 kcal/kWh among all other regions during 2006-07 and all four regions registered deterioration in their Operating SHR. The number of power stations, whose Operating SHR deviation w.r.t. design heat rate falls in the range of 0-5%, 5-10%, 10-20% & more than 20% are given in the following table for the year 2006-07. S. N. 1. 2. 3. 4. 5. (d) Particulars Total Stations analyzed No. of Stations in the range of SHR deviation (0-5%) No. of stations in the range of SHR deviation (5-10%) No. of stations in the range of SHR deviation (10-20%) No. of stations with SHR deviation of more than 20% 2006-07 56 6 10 15 25

Region

(c)

(e)

Thermal Power Stations at Dahanu, Trombay, Ib Valley, Vijayawada and Rayal Seema have been assessed as the best stations for the year 2006-07 with SHR deviations of 2.05%, 2.83%, 3.06%, 3.33%, 3.60% respectively with respect to their Design SHR. In all about 25 stations out of analyzed 56 stations during 2006-07 which are operating at very poor SHR with variation exceeding need closer monitoring. There is a need to have an Energy Efficiency Monitoring Cell at all stations for improving their efficiency through regular vigilance on energy/heat lost from various equipment / processes.

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 6

ANNEXEURE-13.1

ANALYSIS OF OPERATING STATION HEAT RATE OF THERMAL POWER STATIONS DURING 2006-07 Sl. No. Name of Station Installed Capacity (MW) Design Heat Rate (kcal/kWh) 2005-06 Operating Heat Rate (Kcal/kWh) Operating Heat Rate (Kcal/kWh) 2006-07 % Deviation with respect to Design Heat Rate % improvement (+) / deterioration (-) in Operating Heat Rate over the preceding year (-)2.55 9.87 5.30 (-)1.24 (-)7.56 (-)1.35 (-)6.35 1.58 0.84 (-)8.85 (-)10.45 18.50 (-)5.2 (-)1.33

1 2 3 4 5 6 7 8 9 10 11 12

I.P. RAJGHAT PANIPAT FARIDABAD BHATINDA LEHRA MOHABAT ROPAR KOTA SURATGARH OBRA PANKI PARICHHA NORTHERN REGION BHUSAWAL

247.5 135.0 1360.0 165.0 440.0 420.0 1260.0 1045.0 1250.0 1550.0 210.0 640.0 8722.5 482.5

13

NORTHERN REGION 2623.0 3774.0 2580.3 3560.0 2322.2 2934.0 2810.5 4212.0 2510.2 2908.0 2237.9 2407.0 2277.4 2541.0 2418.4 2620.0 2260.1 2490.0 2700.9 3073.0 2381.5 3186.0 2376.3 4298.0 2418.2 2793.0 WESTERN REGION 2406.0 2635.0

3870.1 3208.7 2778.5 4264.2 3127.9 2439.5 2702.4 2578.6 2469.0 3345.0 3519.1 3503.0 2937.9 2669.9

47.55 24.35 19.65 51.73 24.61 9.01 18.66 6.63 9.24 23.85 47.77 47.41 21.49 10.97

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 7

Sl. No.

Name of Station

Installed Capacity (MW)

Design Heat Rate (kcal/kWh)

2005-06 Operating Heat Rate (Kcal/kWh)

Operating Heat Rate (Kcal/kWh)

2006-07 % Deviation with respect to Design Heat Rate 14.14 2.05 15.45 25.85 15.15 21.38 11.34 2.83 72.16 8.90 29.11 6.46 21.31 18.56 33.14 36.38 33.60 12.15 20.23 19.61

14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

CHANDARPUR DAHANU KHAPERKHEDA KORADI NASIK PARAS PARLI TROMBAY GANDHI NAGAR KUTCH LIGNITE SIKKA SURAT LIGNITE TORRENT UKAI AMAR KANTAK SATPURA II BIRSINGHPUR KORBA (EAST) KORBA (WEST) WESTERN REGION

2340.0 500.0 840.0 1100.0 910.0 62.5 690.0 500.0 870.0 215.0 240.0 250.0 400.0 850.0 290.0 1142.5 840.0 240.0 840.0 13602.5

2277.9 2226.0 2254.5 2402.1 2347.8 2686.1 2424.3 2413.8 2336.0 2872.7 2388.7 2399.0 2502.4 2360.5 2930.7 2437.4 2292.9 2368.6 2312.4 2369.1

2611.0 2298.0 2600.0 2981.0 2651.0 3198.0 2665.0 2387.0 2568.0 3368.0 2926.0 2742.0 NA $ 2746.0 3918.0 3288.0 2829.0 2946.0 2653.0 2737.0

2600.0 2271.7 2602.7 3023.0 2703.5 3260.4 2699.2 2482.1 3034.4 3128.5 3084.0 2554.0 3035.6 2798.5 3901.8 3324.2 3063.3 2656.4 2780.2 2833.8

% improvement (+) / deterioration (-) in Operating Heat Rate over the preceding year 0.42 1.15 (-)0.10 (-)1.41 (-)1.98 (-)1.95 (-)1.28 (-)3.98 (-)18.16 7.11 (-)5.40 6.86 NA $ (-)1.91 0.41 (-)1.10 (-)8.28 9.83 (-)4.79 (-)3.5

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 8

Sl. No.

Name of Station

Installed Capacity (MW)

Design Heat Rate (kcal/kWh)

2005-06 Operating Heat Rate (Kcal/kWh)

Operating Heat Rate (Kcal/kWh)

2006-07 % Deviation with respect to Design Heat Rate

% improvement (+) / deterioration (-) in Operating Heat Rate over the preceding year (-)2.17 (-)2.33 (-)0.18 1.00 1.77 0.56 0.98 2.00 (-)0.48 (-)0.59 0.31 NA $ (-)0.25 (-)0.5 (-)0.51 NA $ NA $ (-)9.09

33 34 35 36 37 38 39 40 41 42 43 44 45

KOTHAGUNDEM K'GUDEM(New), RAYALSEEMA VIJAYWADA ENNORE METTUR NEYVELI-Expansion NEYVELI NEYVELI -II NORTH CHENNAI TUTICORIN RAICHUR TORANGALLU SOUTHERN REGION JOJOBERA IB Valley BAKRESWAR BANDEL

720.0 500.0 420.0 1260.0 450.0 840.0 420.0 600.0 1470.0 630.0 1050.0 1470.0 260.0 10090.0 427.5 420.0 630.0 530.0

46 47 48 49

SOUTHERN REGION 2460.9 2660.0 2234.1 2312.0 2250.2 2327.0 2301.4 2402.0 2506.9 3309.0 2386.0 2537.0 2434.4 2770.0 2739.3 3992.0 2589.6 2878.0 2348.1 2440.0 2343.9 2502.0 2288.0 NA $ 2219.6 2382.0 2400.4 2667.0 EASTERN REGION 2338.0 2562.0 2350.4 NA $ 2250.3 NA $ 2509.6 3005.0

2717.7 2365.9 2331.3 2378.0 3250.4 2522.8 2742.9 3912.1 2891.7 2454.4 2494.2 2585.3 2388.0 2679.2 2575.0 2422.4 3057.3 3278.1

10.43 5.90 3.60 3.33 29.66 5.73 12.67 42.81 11.67 4.53 6.41 12.99 7.59 11.62 13.05 3.06 35.86 30.62

Performance Review of Thermal Power Stations 2006-07 Section-13 PAGE NO 13. 9

Sl. No.

Name of Station

Installed Capacity (MW)

Design Heat Rate (kcal/kWh)

2005-06 Operating Heat Rate (Kcal/kWh)

Operating Heat Rate (Kcal/kWh)

2006-07 % Deviation with respect to Design Heat Rate 6.67 33.02 18.27 58.36 49.41 38.99 33.24 28.00 19.31

50 51 52 53 54 55 56

BUDGE BUDGE DPL KOLAGHAT SANTALDIH BOKARO 'B' CHANDRAPURA DURGAPUR (DVC) EASTERN REGION ALL INDIA

500.0 390.0 1260.0 480.0 427.5 781.0 350.0 6196.0 38611.0

2314.1 2699.4 2643.8 2298.1 2338.0 2349.2 2395.6 2429.2 2398.0

2460.0 3320.0 NA $ 3418.0 3363.0 3292.0 NA $ 3071.9 2768.4

2468.4 3590.8 3126.7 3639.1 3493.3 3265.1 3191.9 3109.0 2861.1

% improvement (+) / deterioration (-) in Operating Heat Rate over the preceding year (-)0.34 (-)8.16 NA $ (-)6.47 (-)3.88 0.82 NA $ (-)1.20 (-)3.35

N.A. $ data not available in the year 2005-06

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hardware Catalog 98HDocumento43 pagineHardware Catalog 98Hsandi1111Nessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

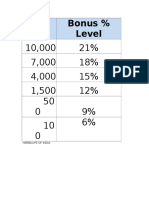

- Bonus of HerbalifeDocumento1 paginaBonus of Herbalifesandi1111Nessuna valutazione finora

- Tank Calibration: The Institute of PetroleumDocumento9 pagineTank Calibration: The Institute of Petroleumsandi1111Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Bonus ScheduleDocumento1 paginaBonus Schedulesandi1111Nessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- PrdsDocumento0 paginePrdssandi1111Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- HERBALIFE Bonus - ScheduleDocumento1 paginaHERBALIFE Bonus - Schedulesandi1111Nessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Technical Support Executive CV TemplateDocumento2 pagineTechnical Support Executive CV Templatesandi1111100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Intraday Using BreakoutDocumento6 pagineIntraday Using Breakoutmanoharreddy_g100% (1)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Control Valve SelectionDocumento10 pagineControl Valve SelectioninstruchampNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Chapter12 RefractoryDocumento10 pagineChapter12 Refractorysandi1111Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Burnham Wetback Vs DrybackDocumento2 pagineBurnham Wetback Vs Drybacksandi1111Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Resume of Candidate # 025Documento2 pagineResume of Candidate # 025sandi1111Nessuna valutazione finora

- Control Valve SelectionDocumento10 pagineControl Valve SelectioninstruchampNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- CV Template Web DeveloperDocumento2 pagineCV Template Web DeveloperNaveen PrinceNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Control Valve SelectionDocumento10 pagineControl Valve SelectioninstruchampNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 5th Mech ListDocumento1 pagina5th Mech Listsandi1111Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- PHP Developer CV TemplateDocumento2 paginePHP Developer CV Templatesat0979Nessuna valutazione finora

- PAN AO Codes Non International Taxation Other Than Mumbai - Ver6.2 - 18062013Documento894 paginePAN AO Codes Non International Taxation Other Than Mumbai - Ver6.2 - 18062013sandi1111100% (1)

- Intraday Using BreakoutDocumento6 pagineIntraday Using Breakoutmanoharreddy_g100% (1)

- 32 1 Boe Exam Viva NotificationDocumento1 pagina32 1 Boe Exam Viva Notificationsandi1111Nessuna valutazione finora

- Mission: LAN AdministratorDocumento4 pagineMission: LAN Administratorsandi1111Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Resume of Candidate # 002 For Browse More TCY Network Engineer's Resume, Please VisitDocumento3 pagineResume of Candidate # 002 For Browse More TCY Network Engineer's Resume, Please VisitElbson EspirituNessuna valutazione finora

- 1.information Security CV TemplateDocumento2 pagine1.information Security CV TemplatePrabath DanansuriyaNessuna valutazione finora

- 001Documento4 pagine001Venkata Nagi ReddyNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- CCNP Network Engineer Resume Free Word DownloadDocumento9 pagineCCNP Network Engineer Resume Free Word DownloadbilllNessuna valutazione finora

- BOILER12Documento4 pagineBOILER12sandi1111Nessuna valutazione finora

- PC Inauguraion Invitation - FinalDocumento1 paginaPC Inauguraion Invitation - Finalsandi1111Nessuna valutazione finora

- Questions On BoilerDocumento4 pagineQuestions On BoilerTochi Krishna AbhishekNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- 3-Element Drum LVL ControlDocumento6 pagine3-Element Drum LVL ControlNAYEEM100% (1)

- Hydroelectric Power Tutorial Question Updated AnswerDocumento5 pagineHydroelectric Power Tutorial Question Updated AnswerAdreana AmirahNessuna valutazione finora

- SEMESTERTEST IfDocumento9 pagineSEMESTERTEST IfAngin kulonNessuna valutazione finora

- Surge Compressor StallDocumento1 paginaSurge Compressor StallvinayNessuna valutazione finora

- P & P EnglishDocumento26 pagineP & P EnglishmissaouiNessuna valutazione finora

- Hfo To Mdo Change Over ProcedureDocumento3 pagineHfo To Mdo Change Over ProcedureJanell Prince50% (2)

- Field Instrument List: Plant S1A / Compressor Unit Gb-601Documento8 pagineField Instrument List: Plant S1A / Compressor Unit Gb-601Bou LemNessuna valutazione finora

- 220 KV Bus Fault Level: Case Study of Dr. NTTPS 220 KV SwitchyardDocumento7 pagine220 KV Bus Fault Level: Case Study of Dr. NTTPS 220 KV SwitchyardRukma Goud ShakkariNessuna valutazione finora

- EFRC Scope of Standards and Guidelines For Reciprocating Compressor Systems 20190408Documento90 pagineEFRC Scope of Standards and Guidelines For Reciprocating Compressor Systems 20190408subrataNessuna valutazione finora

- Series Das Dirt & Air Separ Ator: InformationDocumento2 pagineSeries Das Dirt & Air Separ Ator: InformationVikrant GargNessuna valutazione finora

- Solution File Name: F:/solutia1Documento3 pagineSolution File Name: F:/solutia1Florian Marian MarțanNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Problema 7.2-7.3-7.4Documento6 pagineProblema 7.2-7.3-7.4JOHAN SEBASTIAN FRANCO RAMIREZNessuna valutazione finora

- Gencell G5Rx: Utility Backup Power SolutionDocumento4 pagineGencell G5Rx: Utility Backup Power Solutionrriveram1299Nessuna valutazione finora

- Micro Hydro Moving MountainsDocumento36 pagineMicro Hydro Moving MountainssolarbobkyNessuna valutazione finora

- Local News Article TleDocumento1 paginaLocal News Article TleImari RejanoNessuna valutazione finora

- Calydracomfort PiDocumento16 pagineCalydracomfort PiionNessuna valutazione finora

- Oil and Gas Separation ProcessDocumento13 pagineOil and Gas Separation ProcessRome John Francisco100% (2)

- WHRB FittingDocumento2 pagineWHRB FittingMohan BabuNessuna valutazione finora

- XX55燃料电池Documento2 pagineXX55燃料电池狐狸Nessuna valutazione finora

- Tank Farm Design GuidelinesDocumento2 pagineTank Farm Design GuidelinesSouparna DuttaNessuna valutazione finora

- PDB MV5 STD 380VDocumento453 paginePDB MV5 STD 380V9 9 9Nessuna valutazione finora

- Vragen VACBI A330-200 ATA 29Documento3 pagineVragen VACBI A330-200 ATA 29Arkadiy Chernov100% (1)

- Aalborg Engineering Sg8 EngDocumento4 pagineAalborg Engineering Sg8 EngHenrique de OliveiraNessuna valutazione finora

- Chapter 1 Vapor Power Cycles - CompleteDocumento97 pagineChapter 1 Vapor Power Cycles - CompleteAdnan NimachwalaNessuna valutazione finora

- Daily Commissioning Report (3 Days) : 1. N2 Purging & Gas Leak TestDocumento1 paginaDaily Commissioning Report (3 Days) : 1. N2 Purging & Gas Leak TestMokhtar BeghielNessuna valutazione finora

- Centrifugal Pumps and CompressorsDocumento22 pagineCentrifugal Pumps and CompressorsNishant Vinod Patil .Nessuna valutazione finora

- Steam Turbine EtcDocumento56 pagineSteam Turbine EtcFakh RojiNessuna valutazione finora

- Power System 1 - Power System EEE3233Documento33 paginePower System 1 - Power System EEE3233hafiz azman0% (2)

- GAS TURBINE (50 Hz/60 HZ) : Industrial-Strength, Field-Proven ReliabilityDocumento2 pagineGAS TURBINE (50 Hz/60 HZ) : Industrial-Strength, Field-Proven ReliabilityMarutisinh RajNessuna valutazione finora

- Flash and Condensate Savings CalculatorDocumento2 pagineFlash and Condensate Savings CalculatorHiranthaNessuna valutazione finora

- Chapter 7 - Work Study (Time and Motion Study)Documento8 pagineChapter 7 - Work Study (Time and Motion Study)Pankaj KanatheNessuna valutazione finora