Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hoisting and Rigging - Lift Planning and Control For Ordinary Lifts

Caricato da

cyno21Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Hoisting and Rigging - Lift Planning and Control For Ordinary Lifts

Caricato da

cyno21Copyright:

Formati disponibili

Plan #

Hoisting and Rigging: Lift Planning and Control for Ordinary Lifts

Plan Preparer(s)

Signature Printed name

Department or Group

Date

Approvals

Signature Printed name Date

Authorized Personnel

Authorized employee

Signature

Date

Authorizing supervisor

Signature

Date

Note

This form includes basic lift planning and control elements for ordinary lifts. For additional lift plan examples, or to compare an ordinary lift planning to planning considerations for critical or production lifts see DOE-STD-1090-2007.

39217.29 (updated 39934.29)

SLAC-I-730-0A21J-022-R001

1 of 5

Plan #

Performing the Lift: Checklist

See also: Hoisting and Rigging: Lift Planning and Control Guidelines 1 Keep a copy of this plan at the work site and follow the plan Assign a designated leader Ensure all personnel involved in the lift understand the plan Provide the task-qualified supervision specified in the planning process Vacate all non-essential personnel from the building or adjacent area Ensure a signaler is assigned, if required Identify the crane operator Follow specific instructions/procedures for attachment of the rigging gear to the load. Use proper rigging techniques. Examples include padding sharp corners, orientation of chocker hitches for rolls, orientation of hooks, no binding of hoist rings, etc. Test and balance the load. Slowly raise the crane to take the slack out of the rigging without actually lifting the item. Allow the rigging gear to settle into place, checking for twists and binding. Make sure that padding has remained in place and all slings are protected from sharp edges. Begin to raise the item to verify balance and check the braking system by watching that the load does not sink. If load is not balanced, lower the load and adjust. Repeat as necessary until the load is evenly balanced. Follow Conduct of Operator requirements2 Stop the job when any potentially unsafe conditions is recognized

Hoisting and Rigging: Lift Planning and Control Guidelines (SLAC-I-730-0A21T-008), http://www-group.slac.stanford.edu/esh/eshmanual/references/hoistingGuideLiftPlan.pdf DOE-STD-1090-2007 7.5, 8.5, 9.5, 10.5, 16.5

39217.29 (updated 39934.29)

SLAC-I-730-0A21J-022-R001

2 of 5

Plan #

Characterize the Load(s)

This plan covers Single load only Variety of similar loads: enter dimensions and weight of largest load covered by the plan *Weight determination (choose one) Marked on load Weighed Estimated Length __________________ Width __________________ Height __________________ Diameter __________________ Load weight* __________________

Other _____________________________(describe) Drawing number ___________________

Weight calculated by _________________________ (attach calculations)

Name

Characterize the Task (Include directions for lifting, rotation, flipping, speeds, and travel)

Evaluate the Hazards (Define specific controls)

Plan the Rigging

On a sketch or photo (see page 4 for sketch grid), show how the item will be rigged and the type of gear to be used: 1. Show location of shackles, hoist rings, spreader beams, slings, etc 2. Show attachment points (how rigging gear will be attached to load) 3. Show where padding of sharp edges are necessary 4. Provide the weight of heavy equipment such as a lifter or spreader beam 5. Show proper orientation of eyebolts 6. Indicate the center of gravity (horizontal and vertical)

39217.29 (updated 39934.29)

SLAC-I-730-0A21J-022-R001

3 of 5

Plan #

Characterize Attachment Points

Note: Attach photos to illustrate, as necessary. Manufacturer-provided lift point Sling in choker hitch Sling in basket hitch Sling in vertical hitch

Threaded hole (eyebolt or hoist ring) Hole diameter ___________ Material type

___________

Other _________________________________________________________________ Note: Confirm attachment points or hitch methods with the load owner if in doubt. The lift points or attachment methods described in this lift plan can withstand the forces created by the rigging gear.

__________________________

Load owner

______________________

Signature

__________________

Date

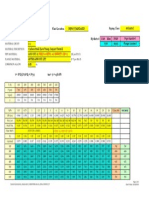

Define Rigging Gear Requirements

1. 2. 3. 4. 5. List each piece of rigging gear shown on the rigging sketch or photo in the table below (such as: load hook, shackles, slings, eye bolts). If a component weighs more than 10 pounds, include the weight in the weight column. Label the sketch or photo using the corresponding letter for the gear. Draw sling angles and the resulting load reduction factors for slings and eyebolts. Calculate the force on each piece of rigging gear. Show that angles are accounted for in determining forces. Determine the required rigging gear capacity and size. Indicate if this is an exact specification or a minimum. Weight Force on rigging gear Capacity / rating / working load limit Size specification

Type

A B C D E F G H I

39217.29 (updated 39934.29)

SLAC-I-730-0A21J-022-R001

4 of 5

Plan #

Rigging Sketch or Photo of Rigged Item

Include all information required to determine that the load is properly rigged and that appropriate rigging gear is selected. Include, as applicable, sling angles, eye bolt orientation, padding points, center of gravity, type of sling hitch, and any other pertinent information.

39217.29 (updated 39934.29)

SLAC-I-730-0A21J-022-R001

5 of 5

Potrebbero piacerti anche

- Onshore Critical Lift Plan FormDocumento2 pagineOnshore Critical Lift Plan FormSyaiful Akhmad100% (1)

- Lifting Procedure ComplianceDocumento12 pagineLifting Procedure ComplianceHamid Ali100% (1)

- Planned Critical Lift Crane PermitDocumento5 paginePlanned Critical Lift Crane PermitsurnaikNessuna valutazione finora

- Appointed Person: Planning and Regulatory RequirementsDocumento6 pagineAppointed Person: Planning and Regulatory RequirementssamNessuna valutazione finora

- LIFTING AND MOBILE EQUIPMENT AWARENESSDocumento100 pagineLIFTING AND MOBILE EQUIPMENT AWARENESSPhilip AdewunmiNessuna valutazione finora

- Maj Concslb 043 0Documento3 pagineMaj Concslb 043 0Mohammed JassimNessuna valutazione finora

- Tips Critical Crane LiftDocumento5 pagineTips Critical Crane LiftSteve John PolandNessuna valutazione finora

- Method Statement For Cranage & LiftingDocumento6 pagineMethod Statement For Cranage & Liftingadeniyi abiolaNessuna valutazione finora

- Lifting Equipment InspectionDocumento113 pagineLifting Equipment Inspectionmac1677Nessuna valutazione finora

- Auxiliary Boiler Critical Lifts Rev 5Documento11 pagineAuxiliary Boiler Critical Lifts Rev 5Ahmed A MoniemNessuna valutazione finora

- Crane and Forklift Safety GuidelinesDocumento4 pagineCrane and Forklift Safety Guidelinesferry ferdiansyah pradanaNessuna valutazione finora

- Lifting Plan Site InspectionDocumento4 pagineLifting Plan Site Inspectionkhaled redaNessuna valutazione finora

- Strong Dual Hawk Tandem Rev H 2008Documento70 pagineStrong Dual Hawk Tandem Rev H 2008FaderNessuna valutazione finora

- Crane Loading ProcedureDocumento6 pagineCrane Loading ProcedureBala MNessuna valutazione finora

- Cranes Hoisting and RiggingDocumento25 pagineCranes Hoisting and Riggingkanakarao1Nessuna valutazione finora

- Alison Generator: Critical Lift PlanDocumento1 paginaAlison Generator: Critical Lift Plansurakanti pratap reddyNessuna valutazione finora

- G18-2-LP-003 DG - Lifting PlanDocumento25 pagineG18-2-LP-003 DG - Lifting PlanMohammed JassimNessuna valutazione finora

- Lifting Plan DetailsDocumento2 pagineLifting Plan DetailssivaavissriNessuna valutazione finora

- Lifting Plan of SpoolDocumento1 paginaLifting Plan of SpoolhazopengineerNessuna valutazione finora

- Critical Lift PlanDocumento2 pagineCritical Lift PlanPatrick ChambersNessuna valutazione finora

- Crane Safety: Factors Reducing Lifting Capacity Below Rated ValuesDocumento1 paginaCrane Safety: Factors Reducing Lifting Capacity Below Rated ValuesvishnuNessuna valutazione finora

- LIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Documento16 pagineLIFTING PLAN FOR Foundation and Miscelanious Items Using Telehandler - AUHJ460Balram Kumar PandeyNessuna valutazione finora

- Multiple Crane LiftingDocumento11 pagineMultiple Crane LiftingAbdul Majid ZulkarnainNessuna valutazione finora

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Documento3 pagineStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNessuna valutazione finora

- 3-Pre-Lift Checklist Rev A 06302015Documento2 pagine3-Pre-Lift Checklist Rev A 06302015Zubair Ahmed Khaskheli100% (1)

- Routine Lift Plan for 5.5 Ton LoadDocumento1 paginaRoutine Lift Plan for 5.5 Ton LoadPanruti S SathiyavendhanNessuna valutazione finora

- Hoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesDocumento5 pagineHoisting and Rigging Plan: Location: Date of Lift: Load Description: Lift Director Ordinary: Critical: Multiple CranesAfdalNessuna valutazione finora

- Tandem lifting plan WHR boilerDocumento7 pagineTandem lifting plan WHR boilertfpl hseNessuna valutazione finora

- Lifting Plan AgcDocumento8 pagineLifting Plan Agcragesh p rNessuna valutazione finora

- The Crosby Sling CalculatorDocumento3 pagineThe Crosby Sling CalculatorRash AcidNessuna valutazione finora

- D - D Ratio and The Effect On Sling Capacity - Unirope LTD PDFDocumento3 pagineD - D Ratio and The Effect On Sling Capacity - Unirope LTD PDFalphadingNessuna valutazione finora

- Generic lifting plan titleDocumento3 pagineGeneric lifting plan titlemuhammad umarNessuna valutazione finora

- Anything: RiggingDocumento20 pagineAnything: Riggingallyssa monica duNessuna valutazione finora

- TÜV Rheinland Arabia Services CalendarDocumento1 paginaTÜV Rheinland Arabia Services Calendarshoaib2scribedNessuna valutazione finora

- Critical & General LiftingDocumento9 pagineCritical & General LiftingVikash Kumar RayNessuna valutazione finora

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDocumento80 paginePPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiNessuna valutazione finora

- 01.05.2021 Method Statement For Electrical & InstrumentationDocumento6 pagine01.05.2021 Method Statement For Electrical & InstrumentationPangky Abasolo100% (1)

- Rigging Gear Store Management RegisterDocumento6 pagineRigging Gear Store Management RegisterKhawaja Arslan Ahmed0% (1)

- Referensi Rigging PlanDocumento4 pagineReferensi Rigging PlanLaurentius CalvinNessuna valutazione finora

- Lifting ProcedureDocumento25 pagineLifting ProcedureAkmal Yassin100% (1)

- Structure Rehabilitation and Repair PDFDocumento31 pagineStructure Rehabilitation and Repair PDFJerry Lee Moran MerkNessuna valutazione finora

- General lifting layout and checklistDocumento2 pagineGeneral lifting layout and checklistMohd Firdaus KamaruddinNessuna valutazione finora

- Complex Lift Plan and ChecklistDocumento3 pagineComplex Lift Plan and Checklistsudeesh kumar100% (1)

- Rigging Safety ProcedureDocumento82 pagineRigging Safety Procedurebehnam197100% (1)

- Safe crane lifting planDocumento25 pagineSafe crane lifting planFred Alma100% (1)

- Westlund Industrial Safety Manual: Health and Safety: OverviewDocumento201 pagineWestlund Industrial Safety Manual: Health and Safety: OverviewShams TabrezNessuna valutazione finora

- Rigger Apprenticeship CurriculumDocumento34 pagineRigger Apprenticeship Curriculummd nasimNessuna valutazione finora

- Unloading Gas Turbine Generator PlanDocumento9 pagineUnloading Gas Turbine Generator Planamritrj444Nessuna valutazione finora

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Documento3 pagineRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNessuna valutazione finora

- Lifting Supervision EssentialsDocumento28 pagineLifting Supervision EssentialsYahya YusufzayNessuna valutazione finora

- Installation Method StatementDocumento6 pagineInstallation Method StatementgururajNessuna valutazione finora

- Rigging Loft RegisterDocumento2 pagineRigging Loft RegisterMohamed FathyNessuna valutazione finora

- Samuel Francis Lifting Engineer ResumeDocumento5 pagineSamuel Francis Lifting Engineer Resumeanthony jamesNessuna valutazione finora

- 015-Lifting Plan Method & Risk AssessmentDocumento3 pagine015-Lifting Plan Method & Risk AssessmentMAB AliNessuna valutazione finora

- ORF Crane Lift Plan 508Documento5 pagineORF Crane Lift Plan 508japv_pasNessuna valutazione finora

- H R Lift Plan Procedure SSRL LPP 000 r1Documento7 pagineH R Lift Plan Procedure SSRL LPP 000 r1Nenad RuzicNessuna valutazione finora

- Contractor Lift Plan Sep 1509Documento9 pagineContractor Lift Plan Sep 1509Saju JosephNessuna valutazione finora

- Hoisting Guide Lift PlanDocumento3 pagineHoisting Guide Lift PlanPera HarlizonNessuna valutazione finora

- MCM Lifting Operation ChecklistDocumento8 pagineMCM Lifting Operation ChecklistHein SiNessuna valutazione finora

- Mechanical Inspection Checklist for Handing Over Room AreasDocumento12 pagineMechanical Inspection Checklist for Handing Over Room Areascyno21Nessuna valutazione finora

- Liquid Filling ApplicationsDocumento24 pagineLiquid Filling Applicationscyno21100% (2)

- Pier Volume CalculatorDocumento1 paginaPier Volume Calculatorcyno21Nessuna valutazione finora

- MSDS For Polymer Ion BatteryDocumento0 pagineMSDS For Polymer Ion Batterycyno21Nessuna valutazione finora

- Direct CostDocumento1 paginaDirect Costcyno21Nessuna valutazione finora

- Irish Building Regulations (B) FireDocumento172 pagineIrish Building Regulations (B) FirethespecifierNessuna valutazione finora

- RainSky E ReferenceDocumento2 pagineRainSky E Referencecyno21Nessuna valutazione finora

- MSDS For Polymer Ion BatteryDocumento0 pagineMSDS For Polymer Ion Batterycyno21Nessuna valutazione finora

- Grohe Water Enjoyment Vol.2Documento119 pagineGrohe Water Enjoyment Vol.2cyno21Nessuna valutazione finora

- How To Make MicroSIMDocumento0 pagineHow To Make MicroSIMcyno21Nessuna valutazione finora

- SR - No. Description Rate/Rs. PerDocumento3 pagineSR - No. Description Rate/Rs. Percyno21Nessuna valutazione finora

- 4S08 Project ControlsDocumento14 pagine4S08 Project Controlssaleem_b89% (9)

- Symbols and WordingsDocumento1 paginaSymbols and Wordingscyno21Nessuna valutazione finora

- Lift & Tail CalcsDocumento3 pagineLift & Tail Calcsnazeer_mohdNessuna valutazione finora

- Perlite Roof Deck and Insulating ConcreteDocumento3 paginePerlite Roof Deck and Insulating Concretecyno21Nessuna valutazione finora

- Concrete Cast Record FormDocumento1 paginaConcrete Cast Record Formcyno21Nessuna valutazione finora

- ITI LiftCount CalculatorDocumento1 paginaITI LiftCount CalculatorJefferson PachecoNessuna valutazione finora

- Piping Class P-T RatingDocumento1 paginaPiping Class P-T Ratingcyno21Nessuna valutazione finora

- Project Execution ProcedureDocumento4 pagineProject Execution Procedurecyno2167% (3)

- Piping Class DatasheetDocumento5 paginePiping Class Datasheetcyno21100% (2)

- Pipe (Sus, Duplex & C.S) Fabrication Shop Pipe (Sus, Duplex & C.S) Fabrication ShopDocumento1 paginaPipe (Sus, Duplex & C.S) Fabrication Shop Pipe (Sus, Duplex & C.S) Fabrication Shopcyno21Nessuna valutazione finora

- Branch Conn Table 11Documento1 paginaBranch Conn Table 11cyno21Nessuna valutazione finora

- Vendor Master FileDocumento1 paginaVendor Master Filecyno21Nessuna valutazione finora

- Lift Classification Flow ChartDocumento1 paginaLift Classification Flow Chartcyno21100% (1)

- Project Execution ProcedureDocumento4 pagineProject Execution Procedurecyno2167% (3)

- Safety ProcedureDocumento9 pagineSafety ProcedurezoewongshNessuna valutazione finora

- Hourly Labor Cost WorksheetDocumento3 pagineHourly Labor Cost Worksheetcyno21Nessuna valutazione finora

- Datasheet of Air-Conditioning SystemDocumento1 paginaDatasheet of Air-Conditioning Systemcyno21Nessuna valutazione finora

- Site PhotoDocumento1 paginaSite Photocyno21Nessuna valutazione finora

- Quetions and Answers First TermDocumento4 pagineQuetions and Answers First TermXaik Ziya Ash NeeNessuna valutazione finora

- Dr. Swole's Upper Lower Program (High Volume)Documento4 pagineDr. Swole's Upper Lower Program (High Volume)Anderson MatosNessuna valutazione finora

- CWUP ProgramDocumento21 pagineCWUP ProgramSamehAlyNessuna valutazione finora

- CH 01Documento24 pagineCH 01Mike RodeloNessuna valutazione finora

- Properties of Matter LessonDocumento5 pagineProperties of Matter LessonMarkusNessuna valutazione finora

- Structural Efficiency: Dakota White, Kyle Perry CEA A-Day P.MDocumento6 pagineStructural Efficiency: Dakota White, Kyle Perry CEA A-Day P.MChris FindlayNessuna valutazione finora

- wph13 June 2023 IAL Edexcel Examiner ReportDocumento59 paginewph13 June 2023 IAL Edexcel Examiner ReportAliza ImtiazNessuna valutazione finora

- Length, Mass and Time: T OokDocumento16 pagineLength, Mass and Time: T OoksreeNessuna valutazione finora

- WBL5001 E98031Documento16 pagineWBL5001 E98031Tony Gregory100% (1)

- Principle of Moments EDEXCELDocumento12 paginePrinciple of Moments EDEXCELHuyenThanhNguyenNessuna valutazione finora

- G 8 Physics 2020-2021 TERM1 Exam - Answer KeyDocumento16 pagineG 8 Physics 2020-2021 TERM1 Exam - Answer KeyEsraa AhmedNessuna valutazione finora

- Fundamentals Fluid MechanicsDocumento24 pagineFundamentals Fluid MechanicsPraveenKumarNessuna valutazione finora

- Competency Based TypeDocumento3 pagineCompetency Based Typediy with rishikaNessuna valutazione finora

- 10 - Predetermined Time Systems PDFDocumento42 pagine10 - Predetermined Time Systems PDFRoberto De La PazNessuna valutazione finora

- Universal Governor AppartusDocumento21 pagineUniversal Governor Appartusramniwas123Nessuna valutazione finora

- Fentanyl LK SX Fluid CRI Kgs-Lbs 10-19-11 LockedDocumento2 pagineFentanyl LK SX Fluid CRI Kgs-Lbs 10-19-11 LockedDamian galiñanesNessuna valutazione finora

- RP Male Physique Template 3x Week Full BodyDocumento3 pagineRP Male Physique Template 3x Week Full Bodyashrafartist86Nessuna valutazione finora

- IB Physics HL Topic I: Measurement and UncertaintyDocumento7 pagineIB Physics HL Topic I: Measurement and UncertaintyAhmad OmarNessuna valutazione finora

- Frank Shy KeepDocumento20 pagineFrank Shy Keepbogs8065100% (3)

- Ramachandran S., Mechanics of Fluids, 2016Documento600 pagineRamachandran S., Mechanics of Fluids, 2016Safa Eng90Nessuna valutazione finora

- LM 2 in Fluid MechanicsDocumento7 pagineLM 2 in Fluid MechanicsPicsec MartinezNessuna valutazione finora

- API RP 2A - Recommended Practice For Planning, Designing, and Constructing Fixed Offshore Platforms-Working Stress DesignDocumento4 pagineAPI RP 2A - Recommended Practice For Planning, Designing, and Constructing Fixed Offshore Platforms-Working Stress DesignkometmayorNessuna valutazione finora

- Managing EPC ContractsDocumento8 pagineManaging EPC ContractsKurniawanNessuna valutazione finora

- Lab 01 - Fluid PropertiesDocumento5 pagineLab 01 - Fluid PropertiesAswaja313Nessuna valutazione finora

- Masterlist of ChildrenDocumento8 pagineMasterlist of ChildrenJoena BalicaoNessuna valutazione finora

- 2-General Physics 1-Uncertainties in MeasurementDocumento22 pagine2-General Physics 1-Uncertainties in MeasurementLiza Macalinao MangalimanNessuna valutazione finora

- Resultant of Parallel ForcesDocumento11 pagineResultant of Parallel Forcesderpiboy100% (2)

- WorkoutDocumento3 pagineWorkoutCael McCaskillNessuna valutazione finora

- General Physics 1: Western Leyte CollegeDocumento15 pagineGeneral Physics 1: Western Leyte CollegeDaniela Grace Mata100% (1)

- Operating Instructions Industrial Scales: Kern IfsDocumento25 pagineOperating Instructions Industrial Scales: Kern IfsReuben JamesNessuna valutazione finora