Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Vent and Flare Systems Design and Operation

Caricato da

Kmt_Ae0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

57 visualizzazioni1 paginaVent and Flare System

Titolo originale

Vent and Flare Systems

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoVent and Flare System

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

57 visualizzazioni1 paginaVent and Flare Systems Design and Operation

Caricato da

Kmt_AeVent and Flare System

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

e nggcyclo pe dia.

co m

http://www.enggcyclo pedia.co m/vent-flare-systems/

Vent and Flare Systems

Buoyancy seals and velocity seals- Buoyancy seal typically uses the dif f erence in densities of the purge gas and ambient air to keep the air f rom entering f lare system. Velocity seal is a cone-shaped obstruction placed inside the f lare tip so as to obstruct the inf iltrating air f rom hugging the inner wall. T he purge gas f low coming through the cone is a f ocused stream which sweeps away the inf iltrating air along with it. Continuous purge gas flow requirement in flare networks One of the ways to avoid air ingress into the f lare stack, vent KO drum, f lare network and subsequent catastrophic consequences, is to continuously purge a small f low rate of hydrocarbon gases. T his continuous hydrocarbon gas purge f low in the f lare network helps to build up some positive backpressure at the vent knock out drum. Emissivity coefficient for flare tip Emissivity coef f icient f or a f lare tip is the f raction of heat generated at the f lare tip that is radiated to surroundings. Not all the heat that is generated by burning hydrocarbon gases at the tip of a f lare is radiated. Major f raction of the heat generated by a f lare is carried to the surroundings in the f orm of hot gases by convection and the f raction of this heat is simply radiated to surroundings. Flare radiation plots / isopleths Radiation plots are representative of the incident radiated heat f rom f lare reaching at dif f erent locations in the surroundings. Radiation plots typically consist of isopleths. Isopleths are curves on a map of the f lare surroundings which connect geographical points receiving the same intensity of heat radiated f rom the f lare. Flare tip burn back Burn back of the f lare tip is caused by low exit velocities of the gas at f lare tip. T he f lare tip and f lare stack diameter are designed handling f or the maximum possible f low in the f lare network. However, the normal gas f low in the f lare stack is much lower than the design f low rate, resulting in low exit gas velocities at the f lare tip. Low gas velocities mean that the gas begins to burn much closer to the f lare tip than desired, thus causing burn back of the f lare tip. Liquid Seals on Flare/Vent Stack liquid seal at the f lare stack base is essentially a cylindrical volume of liquid into which the gas inlet to f lare stack is dipped. T his volume allows the f low of f lared gas f rom inlet pipe to the stack in f orm of bubbles rising through the liquid. Liquid seal volume does not permit any air f low entering the gas inlet pipe, thus preventing air ingress into the f lare network.

Potrebbero piacerti anche

- Pipe Stess Static and Dynamic AnalysisDocumento5 paginePipe Stess Static and Dynamic AnalysisKmt_AeNessuna valutazione finora

- World Class ShutdownDocumento6 pagineWorld Class ShutdownKmt_AeNessuna valutazione finora

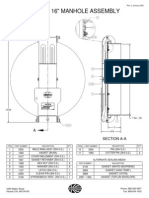

- Ld3310 16" Manhole Assembly: Rev. 0, January 2003Documento1 paginaLd3310 16" Manhole Assembly: Rev. 0, January 2003Kmt_AeNessuna valutazione finora

- Corrosion Control in E&PDocumento7 pagineCorrosion Control in E&PKmt_AeNessuna valutazione finora

- API 580 and 581risk Based InspectionDocumento5 pagineAPI 580 and 581risk Based InspectionKmt_Ae100% (1)

- Catalog 2001Documento10 pagineCatalog 2001Kmt_AeNessuna valutazione finora

- Aerosol Adhesives LitDocumento18 pagineAerosol Adhesives LitKmt_AeNessuna valutazione finora

- Corrosion Control in Refining IndustryDocumento8 pagineCorrosion Control in Refining IndustryKmt_Ae0% (1)

- Pressure ReliefDocumento207 paginePressure ReliefAH100% (1)

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocumento5 pagineAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeNessuna valutazione finora

- Heat Exchanger Fouling Mitigation TechnologyDocumento5 pagineHeat Exchanger Fouling Mitigation TechnologyKmt_AeNessuna valutazione finora

- ASME VIII Pressure Vessel MasterclassDocumento6 pagineASME VIII Pressure Vessel MasterclassKmt_AeNessuna valutazione finora

- Acoustic and Flow Induced VibrationDocumento5 pagineAcoustic and Flow Induced VibrationKmt_AeNessuna valutazione finora

- API 579 Fitness For ServiceDocumento5 pagineAPI 579 Fitness For ServiceKmt_Ae100% (1)

- API 579 Fitness For ServiceDocumento5 pagineAPI 579 Fitness For ServiceKmt_Ae100% (1)

- z4 Coupe Roadster DatasheetDocumento8 paginez4 Coupe Roadster DatasheetStephenNessuna valutazione finora

- API 653 - Storage Tank Inspector Certification Examination Preparatory CourseDocumento5 pagineAPI 653 - Storage Tank Inspector Certification Examination Preparatory CourseKmt_AeNessuna valutazione finora

- API 571 Damage Mechanism Affecting Fixed Refining EquipmentsDocumento4 pagineAPI 571 Damage Mechanism Affecting Fixed Refining EquipmentsKmt_AeNessuna valutazione finora

- FC Catalogue PDFDocumento36 pagineFC Catalogue PDFIndra FandyNessuna valutazione finora

- API 510 Inspector CourseDocumento6 pagineAPI 510 Inspector CourseKmt_AeNessuna valutazione finora

- Tema & HtriDocumento5 pagineTema & HtriKmt_AeNessuna valutazione finora

- API 570 Piping InspectorDocumento6 pagineAPI 570 Piping InspectorBuddharaju KiranNessuna valutazione finora

- Heat Exchanger Fouling Mitigation TechnologyDocumento5 pagineHeat Exchanger Fouling Mitigation TechnologyKmt_AeNessuna valutazione finora

- z4 Coupe Roadster CatalogueDocumento19 paginez4 Coupe Roadster CatalogueKmt_AeNessuna valutazione finora

- Aboveground Storage Tank Design Masterclass (M'Sia) - LynnDocumento5 pagineAboveground Storage Tank Design Masterclass (M'Sia) - LynnKmt_AeNessuna valutazione finora

- x5 DatasheetDocumento7 paginex5 DatasheetKmt_AeNessuna valutazione finora

- Advanced Pressure Vessels and Other Pressure EquipmentsDocumento6 pagineAdvanced Pressure Vessels and Other Pressure EquipmentsKmt_AeNessuna valutazione finora

- x5 CatalogueDocumento18 paginex5 CatalogueKmt_AeNessuna valutazione finora

- z4 Coupe Roadster CatalogueDocumento19 paginez4 Coupe Roadster CatalogueKmt_AeNessuna valutazione finora

- x3 DatasheetDocumento7 paginex3 DatasheetKmt_AeNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Crude Oil Assay Database - Crude Oil Data Properties and Definitions - KnovelDocumento6 pagineCrude Oil Assay Database - Crude Oil Data Properties and Definitions - KnovelValeanu ErmilNessuna valutazione finora

- Cimiracemates A-D, Phenylpropanoid Esters From The Rhizomes of Cimicifuga RacemosaDocumento5 pagineCimiracemates A-D, Phenylpropanoid Esters From The Rhizomes of Cimicifuga RacemosaLarisa CatautaNessuna valutazione finora

- Mollis Range Catalogue 1577960812Documento6 pagineMollis Range Catalogue 1577960812Ug1Nessuna valutazione finora

- AC Transformer LectureDocumento4 pagineAC Transformer LectureDE VERA, KENNETH GABRIEL D.Nessuna valutazione finora

- Model-A Physics (3) 2 PDFDocumento16 pagineModel-A Physics (3) 2 PDFk bhuvanNessuna valutazione finora

- Starting With Zero: Create Your Own Topographic Map ProjectDocumento4 pagineStarting With Zero: Create Your Own Topographic Map ProjectVinujah SukumaranNessuna valutazione finora

- M1 January 2012 Question PaperDocumento28 pagineM1 January 2012 Question PapergerikaalhuNessuna valutazione finora

- Resazurin Cell Viability Assay - Orzel (Full)Documento5 pagineResazurin Cell Viability Assay - Orzel (Full)ShawnNessuna valutazione finora

- Advanced materials processing techniques for automotive, aerospace and energy applicationsDocumento3 pagineAdvanced materials processing techniques for automotive, aerospace and energy applicationsvinothksNessuna valutazione finora

- Position and momentum: Calculating average velocity in quantum mechanicsDocumento7 paginePosition and momentum: Calculating average velocity in quantum mechanicsIbrar ahmadNessuna valutazione finora

- IScience 6-Teachers ManualDocumento98 pagineIScience 6-Teachers ManualAngelica TalaveraNessuna valutazione finora

- TH-L32C10R2: Model NoDocumento121 pagineTH-L32C10R2: Model Nozerson13Nessuna valutazione finora

- BASF Specialty Monomers 1Documento16 pagineBASF Specialty Monomers 1Victor LopezNessuna valutazione finora

- Essential organic compounds and their common namesDocumento16 pagineEssential organic compounds and their common namesCheryl ChaudhariNessuna valutazione finora

- Thermal Control of High Power Applications On Cubesats: October 2018Documento16 pagineThermal Control of High Power Applications On Cubesats: October 2018Josue Manuel Pareja ContrerasNessuna valutazione finora

- Efficient H2S Scavenger Glyoxal Outperforms TriazineDocumento8 pagineEfficient H2S Scavenger Glyoxal Outperforms TriazineMo OsNessuna valutazione finora

- Adiabatic Operation of A Tubular Reactor For Cracking of Acetone (Prob. 4.3)Documento10 pagineAdiabatic Operation of A Tubular Reactor For Cracking of Acetone (Prob. 4.3)ahmed ubeedNessuna valutazione finora

- Elastomers: Dr. Dmitri KopeliovichDocumento10 pagineElastomers: Dr. Dmitri KopeliovichBara Giat PrakarsaNessuna valutazione finora

- Mineral Physics ModuleDocumento17 pagineMineral Physics ModuleDanielle CardiñoNessuna valutazione finora

- ESAS-Lindeburg Terms (Dreamforce)Documento14 pagineESAS-Lindeburg Terms (Dreamforce)e5865domingoascotbaguioNessuna valutazione finora

- Effects of Blue Light On Plants: Technically SpeakingDocumento1 paginaEffects of Blue Light On Plants: Technically SpeakingmadhavaNessuna valutazione finora

- Homework 3 data analysis and interpretationDocumento111 pagineHomework 3 data analysis and interpretationFebriNessuna valutazione finora

- PET Depolymerization: A Novel Process For Plastic Waste Chemical RecyclingDocumento15 paginePET Depolymerization: A Novel Process For Plastic Waste Chemical RecyclingFabianNessuna valutazione finora

- Local Treatment of Electron Correlation-Svein SaeboDocumento24 pagineLocal Treatment of Electron Correlation-Svein SaeboAndré RojasNessuna valutazione finora

- Exercise: PlaceDocumento1 paginaExercise: PlaceaslamNessuna valutazione finora

- Em PDFDocumento88 pagineEm PDFFranck Duprey MvogoNessuna valutazione finora

- Trixene Bi 7960 - TDS - enDocumento2 pagineTrixene Bi 7960 - TDS - enEthling PortilloNessuna valutazione finora

- Better Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production KDocumento10 pagineBetter Aluminium Mirrors by Integrating Plasma Pretreatment, Sputtering, and Plasma Polymerization For Large-Scale Car Headlight Production Kani putkaradzeNessuna valutazione finora

- Chapter 1: The Quantum Theory of The Submicroscopic WorldDocumento28 pagineChapter 1: The Quantum Theory of The Submicroscopic WorldHun Qiu LimNessuna valutazione finora