Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

S1r9a9m9 Water Car

Caricato da

Angy AngyDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

S1r9a9m9 Water Car

Caricato da

Angy AngyCopyright:

Formati disponibili

Page 1 Convert vehicle 1978 Chevy Camaro with stock 350 engine, automatic trans.

Stock 4-barrel carb, and stock fuel pump. The gas tank has been changed to a metal water tank and the fill cap is vented to release heat and pressure. The exhaust was replaced with new 2-inch pipe that is ducted into the water tank. The water tank has baffles inside it which also muffles the exhaust noise. The stock exhaust manifolds were used, but they will rust on the inside, custom stainless steel pipes would be best but cost was the reason they were not used. All the stock ignition system is used, no changes were made. A second battery was placed on the opposite side under the hood. The inverter was placed on the fender well on the passenger side. A fresh air duct was placed to the grill section and covers around the inverter to keep it cool, a relay was hooked up to turn the inverter on and off with the ignition switch and fused with a 20 amp in line fuse on the wire. This relay only turns the inverter on and off. The inverter is connected to the batteries with a positive wire and a ground wire. The inverter is (not) grounded to the car at any point.. A wire is plugged into the inverter and connected to the spark plug ignition box. Eight (8) wires are connected to the spark plug ignition box and connected to the spark plugs, the positive wire connects to the head of the spark plug the same way as the old wire would but the ground wire has a washer type

Page 2 Connecter that the plug is tightened down on. This is the only place the 110 volt system is grounded to the vehicle. The eight (8) plug wires on the stock distributor are connected to the spark plug ignition box in the same firing order as they were on the engine. The spark plug ignition box is fairly simple. The wires going into the box connects to two (2) plastic blocks with metal strips on them. One positive and one ground, one on top of the other. Eight (8) 110-volt relays are used one for each spark plug. The relays only click on and off when the plug wires fire to the relay. Both positive and ground wires go through the relays. The relays are separated about an inch apart. The relays grounds the firing from the distributor plug wire to activate the relay. The power from the inverter can not be grounded to the car or engine it will result in a electrical shock. The inverter cant be grounded to the car either, it blows the main fuse. The only place it grounds is at the base of the spark plugs. The delay in the spark time is slowed down from the time the coil on the distributor fires and the relays fire the plugs. I dont know the exact power to the plugs. The inverter has 2-110 volt outlets AC. The power to the inverter is 12 volts DC, only one outlet is used on the inverter. The alternator is the stock 95 amp that charges both batteries. There is a spark knock sound when the engine is first started cold. But another post here suggested that a preheated on the fuel system. I think just before the carb to warm the water to around 120 degrees (F). maybe a

Page 3 System like a tank less hot water heater with a sensor to cut it off once the engine warms up to Running temperature. I am also thinking about flushing the cooling system and using the water From the tank to cool the engine. Parts list : Metal water tank with baffles to replace the gas tank. Inverter 750 watts or higher. DO NOT GROUND TO CAR. 110 volt wire is 14-2 size as used in homes. Extra spark plug wire ends to insulate the 14-2 wires. 14-2 wire to connect the inverter to the new spark relay box. The relay box looks a lot like a breaker box does on the inside and both positive and ground have to break connection when the relay clicks on and off. Relays can be found in appliance stores. I do not know what appliance they were used on and they had no part numbers on them. Dont ground the spark box to the car or engine. Use two auto or marine batteries with high cranking amps. New exhaust system piped into the new water fuel tank. Bigger ports in the carb for more fuel flow. I tried a mist flow above the carb but there was no way to regulate the flow of extra water into the engine. 16g wire to connect the on/off switch for the inverter to the cars electrical system. The inverter must remain on while the engine is being started. Misc. insulator pads to go under the inverter and spark box. I used the packing material from around a glass jar

Page 4 my wife received in the mail. Reset the timing to were the engine runs best. Mine runs at 35 degrees retarded. I did use a timing light to see where the timing was set at. The spark plug gap was set at 65 and now it is set at 80. There are some draw backs to this. A slight decrease in power. Rust in the exhaust system. Probably a few more not sure yet. (No) the headlights do not dim down when driving at night. My wife purchased the vehicle fore me to restore from a friend of ours. She turned 71 and decided to sell it. When I started restoring it I started cleaning up in my shop thats when the wire fell into the can of water. I changed the vehicle over to water then finished restoring it. It is valued a $16,000.00 by our insurance company. I didnt build this to sell or get a patent on it or make big bucks from the information. I did it because I could and did. You can crunch the numbers all day long, but each car will have a little deference setting. In working on the Chevy 350 engine with a carb and no computer controls. Well this is all. The only thing I can add is just try it.

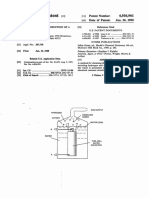

This is s1r9a9m9 diagram

Potrebbero piacerti anche

- The Single Cure: Human Life Extension to 300+ YearsDa EverandThe Single Cure: Human Life Extension to 300+ YearsNessuna valutazione finora

- S1r9a9m9 Water CarDocumento7 pagineS1r9a9m9 Water Carapi-372572650% (2)

- Charles Nelson Pogue - US Patent - 1759354Documento18 pagineCharles Nelson Pogue - US Patent - 1759354PM100% (1)

- Motionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreDocumento6 pagineMotionless Free Energy: Because It Opposes Itself, It Can Never Be More Than 100% Efficient. We AreRolling76Nessuna valutazione finora

- Manual Book HHO GENERATOR Fuel EfficientDocumento56 pagineManual Book HHO GENERATOR Fuel EfficientLuis Enrique Jarquin AramburoNessuna valutazione finora

- The Smith Generator BlueprintsDocumento36 pagineThe Smith Generator BlueprintsZoran AleksicNessuna valutazione finora

- Timing 101Documento5 pagineTiming 101Juan MonNessuna valutazione finora

- Hydraulic Ram Pump How-ToDocumento4 pagineHydraulic Ram Pump How-ToIsrael J. PattisonNessuna valutazione finora

- HHO Fine TuneDocumento92 pagineHHO Fine TuneOscar BernalNessuna valutazione finora

- Tkramer Part2-Electrolysis NHO2Documento17 pagineTkramer Part2-Electrolysis NHO2danevideNessuna valutazione finora

- The TransformerDocumento21 pagineThe TransformerAshok KumarNessuna valutazione finora

- Do-It-Yourself Yeast-Generated CO2 SystemDocumento3 pagineDo-It-Yourself Yeast-Generated CO2 SystemPuscau SorinNessuna valutazione finora

- Magnetron Water Powered Lawnmower Engine PlansDocumento2 pagineMagnetron Water Powered Lawnmower Engine Plansshawnleegabriel100% (3)

- Firmware Download For Off Grid InverterDocumento3 pagineFirmware Download For Off Grid InverterLadislav BreckaNessuna valutazione finora

- Dony WatssDocumento49 pagineDony WatssvbugaianNessuna valutazione finora

- Build A Barbecue Smoker For 9Documento13 pagineBuild A Barbecue Smoker For 9Anonymous e2GKJupNessuna valutazione finora

- A Practical Guide For HOHDocumento164 pagineA Practical Guide For HOHDan AngheleaNessuna valutazione finora

- Alekz SystemDocumento10 pagineAlekz SystemAlicia Amazias100% (1)

- Understanding How Atomizing Waste Oil Burners WorkDocumento4 pagineUnderstanding How Atomizing Waste Oil Burners WorkAnonymous NUn6MESxNessuna valutazione finora

- John Kanzius Water Fuel PatentDocumento62 pagineJohn Kanzius Water Fuel PatentkatzrayNessuna valutazione finora

- Car That Runs On Tap Water - Plasma Spark - Oct 2005 - Hydrogen Fuel - Free Energy - Stanley MeyerDocumento139 pagineCar That Runs On Tap Water - Plasma Spark - Oct 2005 - Hydrogen Fuel - Free Energy - Stanley MeyerGheorghe SilviuNessuna valutazione finora

- Valve Job and Timing The E38 Vanos Engine M62tuDocumento9 pagineValve Job and Timing The E38 Vanos Engine M62tuDOMINO66Nessuna valutazione finora

- Tensor DL DS ManualDocumento162 pagineTensor DL DS ManualJoao RobertoNessuna valutazione finora

- Hybrid Tech Eat On Fuel CellDocumento13 pagineHybrid Tech Eat On Fuel CellhhojonNessuna valutazione finora

- AgriculturalResearchBulletin v019 b210Documento37 pagineAgriculturalResearchBulletin v019 b210Adrien PEAUDNessuna valutazione finora

- Running An Automobile On Hydrogen Using Water, by DrunvaloDocumento6 pagineRunning An Automobile On Hydrogen Using Water, by DrunvaloColin MaharajNessuna valutazione finora

- Bedini Bonus1Documento18 pagineBedini Bonus1gibberish-euNessuna valutazione finora

- Robert Adams Motor Generates 8x More PowerDocumento268 pagineRobert Adams Motor Generates 8x More PowerTun DuttaNessuna valutazione finora

- Induction heating circuit built by Daniel from Melnik, CzechDocumento6 pagineInduction heating circuit built by Daniel from Melnik, Czechnangkarak8201Nessuna valutazione finora

- Power Generation by Foot Step Method - Rack and PinionDocumento13 paginePower Generation by Foot Step Method - Rack and Pinionprem53100% (2)

- Biodiesel BookDocumento17 pagineBiodiesel Bookapi-3802837Nessuna valutazione finora

- Charles Pogue Carb. PDFDocumento27 pagineCharles Pogue Carb. PDFTomislav JovanovicNessuna valutazione finora

- Book 2-B Water For GasDocumento115 pagineBook 2-B Water For GasRussell RungeNessuna valutazione finora

- Gas Bottle Wood BurnerDocumento13 pagineGas Bottle Wood BurnerGringgo KweeNessuna valutazione finora

- Handbook - Mcdonnell Miller Service GuideDocumento40 pagineHandbook - Mcdonnell Miller Service Guidemnt6176100% (2)

- Carl Cella Water CarDocumento8 pagineCarl Cella Water CarRuddyMartiniNessuna valutazione finora

- Dasifier The Up-Downdraft Gasifier For Metal Melting 2001 PDFDocumento3 pagineDasifier The Up-Downdraft Gasifier For Metal Melting 2001 PDFguytr2Nessuna valutazione finora

- World Changing Water Secrets 03122015wmDocumento14 pagineWorld Changing Water Secrets 03122015wmBillMundyNessuna valutazione finora

- Free EnergyDocumento34 pagineFree Energyquan123456789Nessuna valutazione finora

- Friction heat space heater patentDocumento6 pagineFriction heat space heater patentBastien Gall de SilléNessuna valutazione finora

- Build A 3-Band Shortwave Converter For Your CarDocumento2 pagineBuild A 3-Band Shortwave Converter For Your CarbobbyunlockNessuna valutazione finora

- 3 Ijeeerfeb20173Documento10 pagine3 Ijeeerfeb20173TJPRC PublicationsNessuna valutazione finora

- Furnace Boosting DesignDocumento8 pagineFurnace Boosting Designasitchawla100% (1)

- Lead Acid Battery Desulfator GuideDocumento5 pagineLead Acid Battery Desulfator GuidetopazeusNessuna valutazione finora

- Revenoor CatalogDocumento17 pagineRevenoor Catalogripkim100% (1)

- (Free Energy) Kunel PatentDocumento9 pagine(Free Energy) Kunel PatentIra Weinstein100% (1)

- The Making of The Källe-GasifierDocumento15 pagineThe Making of The Källe-GasifierMarky Maypo100% (1)

- Charles Garrett and Archie Blue Electrolysers Ran Cars on WaterDocumento11 pagineCharles Garrett and Archie Blue Electrolysers Ran Cars on WaterAleksa Nataša RančićNessuna valutazione finora

- The Resonance Energy Device Explained: PrefaceDocumento39 pagineThe Resonance Energy Device Explained: PrefaceR. K GuptaNessuna valutazione finora

- Making A Self-Powered GeneratorDocumento11 pagineMaking A Self-Powered GeneratorAwwad IyadNessuna valutazione finora

- Us 4936961Documento8 pagineUs 4936961PratikNessuna valutazione finora

- Covid Economics: Vetted and Real-Time PapersDocumento82 pagineCovid Economics: Vetted and Real-Time PapersbehnazNessuna valutazione finora

- A Practical Guide To Free Energy' Devices: Replication of Stanley Meyer's Demonstration ElectrolyserDocumento0 pagineA Practical Guide To Free Energy' Devices: Replication of Stanley Meyer's Demonstration ElectrolyserTom TeraNessuna valutazione finora

- DIY HHO Torch Water Torch For Only 4Documento11 pagineDIY HHO Torch Water Torch For Only 4martin ongNessuna valutazione finora

- Free Energy - Fact or Fiction - Animations by MAllen7424Documento35 pagineFree Energy - Fact or Fiction - Animations by MAllen7424baywatch80Nessuna valutazione finora

- Ram Pump PDFDocumento9 pagineRam Pump PDFoliververonamanuelNessuna valutazione finora

- HV GeneratorDocumento6 pagineHV GeneratorNatasaBugaianNessuna valutazione finora

- Boost Your Bike's Starting Power with a Battery and Starter Circuit CheckDocumento3 pagineBoost Your Bike's Starting Power with a Battery and Starter Circuit CheckKaine WrightNessuna valutazione finora

- Ignition Solutions For Small Engines and Garden Pulling TractorsDocumento40 pagineIgnition Solutions For Small Engines and Garden Pulling Tractorsws25329438833% (3)

- Geet Fuel ProcessorDocumento64 pagineGeet Fuel ProcessorYuveAero100% (3)

- Geet PlansDocumento5 pagineGeet PlansbyenterNessuna valutazione finora

- Masoneria Simbolistica Si SimboluriDocumento1 paginaMasoneria Simbolistica Si SimboluriAngy AngyNessuna valutazione finora

- Arminianism vs. CalvinismDocumento40 pagineArminianism vs. CalvinismJesus LivesNessuna valutazione finora

- Chisinau website content from February 2011Documento290 pagineChisinau website content from February 2011griveigiombei100% (19)

- Antrenament in Crestinism 1 Si 2 PDFDocumento257 pagineAntrenament in Crestinism 1 Si 2 PDFNicolasNessuna valutazione finora

- V5X Electric Control IntroductionDocumento67 pagineV5X Electric Control Introductionনির্জন পথিকNessuna valutazione finora

- Electric Drives - EPM 451 - Module1modifiedDocumento68 pagineElectric Drives - EPM 451 - Module1modifiedasmrsamir5Nessuna valutazione finora

- Ews 1021Documento24 pagineEws 1021MilanNessuna valutazione finora

- Difference Between Micromaster 411, 420, 430 & 440Documento2 pagineDifference Between Micromaster 411, 420, 430 & 440Ayman ElotaifyNessuna valutazione finora

- 4 Induction Motor VFD CDocumento6 pagine4 Induction Motor VFD Cliju101Nessuna valutazione finora

- Electric Machines and Power ElectronicsDocumento58 pagineElectric Machines and Power ElectronicsMuhammad Faraz100% (1)

- Is Iec 61683 1999Documento21 pagineIs Iec 61683 1999vijay_rainaNessuna valutazione finora

- Camry Hybrid ReportDocumento30 pagineCamry Hybrid Reportmihai_1957Nessuna valutazione finora

- Energy Efficiency Program For Power Availability in Research InstitutionsDocumento13 pagineEnergy Efficiency Program For Power Availability in Research InstitutionsSAMPSON BENDORNessuna valutazione finora

- PRO LCD C Series InverterDocumento4 paginePRO LCD C Series InverterJuan SanchezNessuna valutazione finora

- Simulation and Comparison of SPWM and SVPWM Techniques for InvertersDocumento6 pagineSimulation and Comparison of SPWM and SVPWM Techniques for InvertersIkram RidhoNessuna valutazione finora

- Omrom Inv PDFDocumento12 pagineOmrom Inv PDFmamaligosu1Nessuna valutazione finora

- Embedded BLCDDocumento24 pagineEmbedded BLCDDhananjay PatilNessuna valutazione finora

- Bien-Tan SiemensDocumento452 pagineBien-Tan SiemensTài liệu Công ty TNHH Nam Trung100% (1)

- Brake Motor Manual E - MM0202EDocumento27 pagineBrake Motor Manual E - MM0202EThinh Nguyen100% (1)

- MGE Galaxy EPS 8000: Three Phase UPSDocumento4 pagineMGE Galaxy EPS 8000: Three Phase UPSAnibalNessuna valutazione finora

- Frequency Drive - ZapMetaDocumento4 pagineFrequency Drive - ZapMetaJemerald MagtanongNessuna valutazione finora

- Modeling of Three-Winding Transformers PDFDocumento20 pagineModeling of Three-Winding Transformers PDFGhislainNessuna valutazione finora

- Unsw Spree 040719 SmaDocumento78 pagineUnsw Spree 040719 Smasurag1982Nessuna valutazione finora

- Ingedrive lv400 Fy06iptt01 ADocumento2 pagineIngedrive lv400 Fy06iptt01 AafsalNessuna valutazione finora

- Modelling and Control of Multi-Terminal MVDC Distribution NetworkDocumento13 pagineModelling and Control of Multi-Terminal MVDC Distribution NetworkVedaste NdayishimiyeNessuna valutazione finora

- BeneView T8 Service ManualDocumento192 pagineBeneView T8 Service ManualbmjuberNessuna valutazione finora

- Sunpower Residential Ac Module: Sunpower E-Series: E20-327 - E19-320Documento2 pagineSunpower Residential Ac Module: Sunpower E-Series: E20-327 - E19-320Saad BenyahiaNessuna valutazione finora

- 12V To 120V Inverter: Home Circuits Power SupplyDocumento4 pagine12V To 120V Inverter: Home Circuits Power SupplyKrishna ChaitanyaNessuna valutazione finora

- Power Quality Improvement Using DVRDocumento6 paginePower Quality Improvement Using DVRNirav RanaNessuna valutazione finora

- Seilzug DR 3 - 10 - ENDocumento36 pagineSeilzug DR 3 - 10 - ENAmazonas ManutençãoNessuna valutazione finora

- DatasheetDocumento80 pagineDatasheetMohammad AmerNessuna valutazione finora

- Silver State South POD 070111Documento97 pagineSilver State South POD 070111SaveTheDesertNessuna valutazione finora

- Calculation of VIL - .Documento9 pagineCalculation of VIL - .bipin1025Nessuna valutazione finora

- Applying Sensorless Vector ControlDocumento6 pagineApplying Sensorless Vector Controlluis palaciosNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDa EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentValutazione: 4.5 su 5 stelle4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDa EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNessuna valutazione finora

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyDa EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNessuna valutazione finora

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Renewable Energy: A Very Short IntroductionDa EverandRenewable Energy: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDa EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successValutazione: 4.5 su 5 stelle4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionDa EverandBuild Your Own Electric Vehicle, Third EditionValutazione: 4.5 su 5 stelle4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeDa EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeValutazione: 4 su 5 stelle4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureDa EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureValutazione: 3.5 su 5 stelle3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachDa EverandImplementing an Integrated Management System (IMS): The strategic approachValutazione: 5 su 5 stelle5/5 (2)

- Handbook on Battery Energy Storage SystemDa EverandHandbook on Battery Energy Storage SystemValutazione: 4.5 su 5 stelle4.5/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksDa EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNessuna valutazione finora

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- The Rare Metals War: the dark side of clean energy and digital technologiesDa EverandThe Rare Metals War: the dark side of clean energy and digital technologiesValutazione: 5 su 5 stelle5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemDa EverandISO 50001: A strategic guide to establishing an energy management systemNessuna valutazione finora

- The Way Home: Tales from a life without technologyDa EverandThe Way Home: Tales from a life without technologyValutazione: 4 su 5 stelle4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesDa EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertValutazione: 3 su 5 stelle3/5 (2)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyDa EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyValutazione: 5 su 5 stelle5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDa EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)