Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FOCSWATER.C Water Cooled Chiller - R134a

Caricato da

ntt_121987Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FOCSWATER.C Water Cooled Chiller - R134a

Caricato da

ntt_121987Copyright:

Formati disponibili

Flooded Water Cooled Screw Chiller

FOCSWATER.C Series 460-1690kW (130-500Tons)

Water cooled screw chiller

FOCSWATER.C

UNIT FEATURERS

Maximum Reliability

Design, manufacturing, testing comply with the several regulations such as AHRI, EN, UNI, JIS and Chinese standard GB/T18430.1. The built-in 3 stages oil separator and external efficient second separator ensure the constant presence of oil inside. Besides, unique device is designed by CLIMAVENETA dedicated to guaranty oil return. The unit has been charged with R134a and oil before shipped out from factory, and tested and inspected strictly according to UNI9218 standard. Only after water and electrical power being connected on site, the unit can be put into production for providing chilled water.

Optimized and Efficient Parts Compressors

Semi-hermetic screw compressors specifically designed for R134a & flooded evaporation application, featuring in high efficiency and energy saving. Precisely manufacturing technology and least moving component result in reliable performance and simple maintenance. T h e c o m p r e s s o r, w i t h i t s o w n c a p a c i t y r e g u l a t i n g electromagnetic v a l v e a n d s l i d e v a l v e t o g e t h e r w i t h Climaveneta's micro-computer controlling system, can adjust load output automatically according to the requirement of processing, realize 10~100% stepless of precision variable adjustment and reduce power consumption.

The electronic valve is adopted to grant the ideal operation of the evaporator in all conditions. The complete flooding of tubes is granted with a sophisticated detection of the refrigerant level in the heat exchangers. The fast processing of the acquired data allow a quick, fluctuation-free regulation, and therefore a highly accurate adjustment to the swings of load and ambient conditions. Economizer has been adopted to improve unit efficiency.

Dedicated Flooded Evaporator/ Condenser

Multiple applications

Gaseous Flooded evaporator/condenser refrigerant with integral rippled tube are modified to enhance the initiation of nucleate boiling sites and surface area, improving turbulent flow, resulting in increasingly overall heat transfer coefficient and high unit efficiency. The evaporator is characterized by low pressure drops on both the gas side and the water side. Liquid refrigerant The level of refrigerant inside the flooded evaporator is guaranteed by dedicate sensor level and modulating electronic valve. Single circuit design even for multiple compressor improves unit part load efficiency. Chilled water inside tube make maintanence work convinient and simple.

Standard chilled water applied for HVAC system; By adopting brine or glycol solution, the outlet temperature of evaporator can be in the range of -8~12oC, either for ice storage application or for industrial process purpose; Heat recovery function is optional.

Safety of electrical devices

Inner structure of electrical cabinet, electrical components and circuit layout are designed according to EN60204-1/IEC204-1 standard. Controlling power is separated from main power by transformer so as to protect from impact and interfere of electrical current. The power section uses a bar-type distribution system and interlock-door mains isolator for safety and reliability. Each load of compressor is equipped with its own overload protector, fuse and contactor. Electric elements are with features of excellent insulation, dust-proof and humidity proof, and suitable for various inferior environments. Electrical system of the unit is in compliance with EMC code.

Water cooled screw chiller

FOCSWATER.C

Convenient application and maintenance

Fully computer controlling, menu displaying, self-checking of unit, running, load adjusting and safety protection are all completed by computer control system. Daily operation is only to switch on starter. Multiple refrigerating systems are available for standby equipment. The unit is available of functions such as fault protection, memorizing and alarming. All faults are clearly displayed. Each return circuit has inspection valve with "pump down" function which is convenient for repairing.

Latest Control System

Protecting and alarming functions of unit Self-test when power on to avoid running with problem. Three lever password protection to prevent from mal-operation of persons without authorization. Overload, overheat and overvoltage protection and alarming of compressor; high discharge temperature protection and alarming of compressor. Water antifreeze protection, antifouling protection and alarming of evaporator; Protection and alarming of over high and low chilled water and cooling water temperature; protection and alarming of low water flow; Protection and alarming of low and high pressure of refrigeration system, and alarming of refrigerant leakage. Fault processing function Automatically functioning protection of acousto-optic alarming, load reducing of compressor, stopping of compressor and stopping of unit according to each fault grade. Automatically identifying fault and instructing fault category. Automatically recording fault with record capacity as much as 200 faults. Black box function which automatically record on-site state and all data of fatal fault for providing analyzing data.

Group Control Device

Friendly interface Fully computer-controlled with no necessity of person duty; Objective user operational panel with multiple windows clearly displaying parameters of different categories; Graphical symbol inputting and displaying with convenient operation; Convenient adjusting and setting of data input through menu and fast key combination. Control functions of the unit The unit adopts W3000 intelligent microcomputer control system with setting, adjusting and controlling functions, such as: stepless regulation of cooling capacity; inlet/outlet chilled water temperature regulation; Starting, unloading and stopping functions of compressor; starting delay function of compressor; time limiting function of each hour start of the compressor; operation timing function of compressor; and running time balance function of compressor.

A group composed of various hydronic units permits better management for the lowest running cost. Coordinating the units for optimized operating times assumes fundamental importance and provides significant advantages in terms of reliability (e.g. the compressors) while also permitting energy savings and delivering water flows constantly at the right temperature without fluctuation. Resources are always used according to the user's requirements without needless compressor cycles or power absorption peaks. The unit pumps are intelligently managed. The number of hours of operation is balanced for more efficient maintenance. Resource priority assignment gives precedence to the unit with greater efficiency: such as chillers with free-cooling function. The stand-by mode grants response to possible peaks in load. The elevated characteristics offered by the serial interface keypad are the highest currently available in the market.

Gr2000

Gr3000

Water cooled screw chiller

FOCSWATER.C

FWS3000 Field Web Server

Device for supervising Climaveneta units. Supervision takes place via a direct link with the computer or via LAN: hence this option can also be managed through internet resources thanks to the built-in webserver and the availability of suitably defined graphical pages. Thus the resulting supervision does not entail installing any additional software on the computer and, moreover, employs the most common types of browser; this means any networked computer can be used.

Electronic control features

Microprocessor

Mufti-language menu Phase sequency relay Cumulative fault alarm Alarms log function Black-Box function for alarm events Programming of daily/weekly program Evaporator inlet/outlet water temperature display Compressor/circuit failure display General unit alarms display Quick Mind when stopped Pump-down when stopped Starting compressors sequency control Management of the compressors working hours Remote keyboard W3000 Par. OPT

Microprocessor

Local/Remote supervision through browser and FWS Communication protocol Metasys Johnson Controls communication gateway Modbus communication protocol Bacnet communication protocol Interface connection to Lon Works network Siemens communication gateway Remote on/off with external volt-free contact Double set-point by external contact Set-point regulation from external signal (4-20 mA) Continuous regulation of the compressors Relay manage pump Reduced load functioning from external contact Connection to sequencier

W3000 OPT OPT OPT OPT OPT OPT OPT OPT OPT OPT OPT OPT

Standard OPT Available on request Par. Available modifying a value of the configuration parameters

Water cooled screw chiller

FOCSWATER.C

General Technical Data

FOCSWATER.C Cooling capacity Power input Evaporator water flow Evaporator water pressure drop Condenser water flow Condenser water pressure drop Microprocessor Number of compressors Refrigerating circuit Capacity regulating Refrigerant charge Oil charge Unit Weight Operating weight Dimension Length Width Height Remarks: Chilled water (in/out) 12/7 Condenser water (in/out) 30/35 mm mm mm 2900 1170 1930 2930 1170 1990 2930 1205 2000 2980 1290 2200 4430 1280 2240 4430 1280 2260 4430 1280 2260 4565 1300 2400 4640 1300 2400 4680 1300 2400 kg kg kg kg 97 35 2930 3080 n n 1 1 1 1 126 35 3090 3280 1 1 143 35 3360 3580 1 1 172 38 3690 3980 KW KW m /h KPa m /h KPa

3 3

1301C 459.9 82.5 79.2 48 93.1 55

1651C 591.8 103.9 101.9 51 119.4 55

2001C 691.2 121.0 119.0 50 139.4 56

2501C 837.0 149.3 144.1 50 169.3 55

3002C 1062.1 186.9 182.8 52 214.4 54 W3000 2 2 222 70 6020 6500

3502C 1217.7 214.0 209.6 51 245.7 56 2 2 252 70 6490 7070

4002C 1382.4 242.1 238.0 50 278.9 53 2 2 286 70 6660 7300

4202C 4502C 1470.3 1521.6 252.2 253.1 48 295.7 51 2 2 309 73 7050 7760 268.1 262.0 52 307.2 55 2 2 309 76 7110 7820

5002C 1689.5 298.7 290.1 53 341.3 55 2 2 343 76 7230 8000

25-100% stepless

12.5-100% stepless

Electrical Data

Maximum values FOCSWATER.C n 1301C 1651C 2001C 2501C 3002C 3502C 4002C 4202C 4502C 5002C F.L.I. F.L.A. L.R.A. S.A. 1 1 1 1 2 2 2 2 2 2 Compressor(each) F.L.I (kW) 122 155 175 216 138 155 175 175/196 196 216 F.L.A (A) 197 247 286 351 223 247 286 286/318 318 351 L.R.A (A) 404 465 586 805 436 465 586 586/650 650 805 F.L.I (kW) 122 155 175 216 275 310 350 371 391 432 Total unit F.L.A (A) 197 247 286 351 446 494 572 604 636 702 S.A (A) 404 465 586 805 659 712 872 936 968 1156

Power input Current absorption Locked rotor current for single compressor Starting current

Electrical source: 380-3ph-50Hz Voltage tolerance: 10% Maximum voltage unbalance: 3% Safety values to be considered when cabling the unit for power supply and line-protections

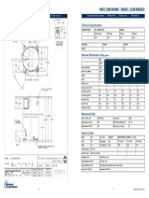

Dimension Drawing

Water cooled screw chiller

FOCSWATER1301C2501C

FOCSWATER3002C5002C

5

Lifting points Power inlet Main isolator

Evaporator water inlet Condensers water inlet Evaporator water outlet Condensers water outlet Remarks:Please contact Climaveneta office for detail drawings.

Recommended Operating and Service Clearances

Weight H(mm) 1930 1990 2000 2200 P ./W.(Kg) 2930 3090 3360 3690 A(mm) 4" 4" 5" 6" A(mm) 4" 4" 5" 6" Water Connection Size FOCSWATER.C 3002C 3502C 4002C 4202C 4502C 5002C Dimension A(mm) 4430 4430 4430 4565 4640 4680 B(mm) 1280 1280 1280 1300 1300 1300 H(mm) 2240 2260 2260 2400 2400 2400 Weight P ./W.(Kg) 6020 6490 6660 7050 7110 7230 Water Connection Size A(mm) 6" 6" 6" 8" 8" 8" A(mm) 6" 6" 6" 8" 8" 8"

FOCSWATER.C

Dimension

1301C 1651C 2001C 2501C

A(mm) 2900 2930 2930 2980

B(mm) 1170 1170 1205 1290

FOCSWATER.C

Water cooled screw chiller

FOCSWATER.C

Field Wiring Diagram

Dynamic part

Control section

RS485/RJ45

W3000 Motherboard

Remote set point/ secondary set point Optional modules

Pump control Remote (summer/winter)

Determined by the number according to the compressor

Climaveneta Italy: 36061 BASSANO DEL GRAPPA (VICENZA) ITALIA - VIA SARSON 57/c TEL. +39 / 0424 509 500 (r.a.) - TELEFAX +39 / 0424 509 509 E-mail:info@climaveneta.com http://www.climaveneta.com Climaveneta China: No,88 Baiyun Road Xinghuo Developing Zone ,Shanghai,China Post Code:201419 TEL: +86-21-57505566 FAX: +86-21-57505797 E-mail:info@climaveneta.com.cn http://www.climaveneta.com.cn Climaveneta Hongkong: Room 2003,CCT Telecom Building, 11 Wo Shing Street,Fotan,Shatin,N.T.,Hongkong TEL: +85-2-26871755 FAX: +85-2-26873078 E-mail:info@climaveneta.com.cn http://www.climaveneta.asia Climaveneta Vietnam: 381A1 Cong Hoa Street Ward 13 Tan Binh District, HCM City, Vietnam TEL: +84-8-38497529 FAX: +84-8-38124190 E-mail:info@climaveneta.com.cn http://www.climaveneta.asia

All specification and data are subject to change without notice

B215 CCU/01-03-2011CN-SH

Potrebbero piacerti anche

- AHU Owners ManualDocumento84 pagineAHU Owners ManualTom MurphyNessuna valutazione finora

- 30XA Product Data PDFDocumento36 pagine30XA Product Data PDFanoopkumar1231150100% (2)

- 30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersDocumento8 pagine30HXC - 50 H: Water-Cooled Screw Compressor Liquid ChillersHải TrầnNessuna valutazione finora

- NA592 - Powerciat LX R134aDocumento57 pagineNA592 - Powerciat LX R134apaldopalNessuna valutazione finora

- PCU0610A - Chiller (Small)Documento16 paginePCU0610A - Chiller (Small)jeromeduytscheNessuna valutazione finora

- Tecs HF 0251 1954 200910 GB PDFDocumento43 pagineTecs HF 0251 1954 200910 GB PDFLeuce LaviniuNessuna valutazione finora

- 19 TVR6G ID+OD 50Hz Product CatalgoueDocumento98 pagine19 TVR6G ID+OD 50Hz Product CatalgoueKareem Abo Seif100% (1)

- FWW DaDocumento24 pagineFWW DaYazan Tamimi0% (1)

- (ED) DMS502B51 (BACnet Gateway) EngDocumento14 pagine(ED) DMS502B51 (BACnet Gateway) EngTuongnhu DinhNessuna valutazione finora

- CPU Structure and Function: Arithmetic Logic Unit Control Unit Control Registers DatapathDocumento47 pagineCPU Structure and Function: Arithmetic Logic Unit Control Unit Control Registers DatapathSuhaila NajibNessuna valutazione finora

- GS3BA Series High Efficiency Air Conditioner: Technical SpecificationsDocumento4 pagineGS3BA Series High Efficiency Air Conditioner: Technical Specificationstrien15Nessuna valutazione finora

- Cat WSCWDC 6Documento108 pagineCat WSCWDC 6Emerson PenaforteNessuna valutazione finora

- CLCP Euro - Commercial May 09: Quick Selection ProcedureDocumento2 pagineCLCP Euro - Commercial May 09: Quick Selection ProcedurehfrankieNessuna valutazione finora

- Manual Controlli MVB56Documento2 pagineManual Controlli MVB56dwNessuna valutazione finora

- Rcu2e Ag2 & Rhu2e Ag2 PDFDocumento192 pagineRcu2e Ag2 & Rhu2e Ag2 PDFKostas AstrinisNessuna valutazione finora

- Weiss ITC Manual 13 Web Engl 201307Documento123 pagineWeiss ITC Manual 13 Web Engl 201307Ciprian BalcanNessuna valutazione finora

- MS Samsung Ar9000 Inverter AirconditioningDocumento2 pagineMS Samsung Ar9000 Inverter AirconditioningMacSparesNessuna valutazione finora

- Liebert PCW Ts en Emea 273555Documento67 pagineLiebert PCW Ts en Emea 273555Hồ Viết DuyNessuna valutazione finora

- 160 80-PW3Documento5 pagine160 80-PW3juan991Nessuna valutazione finora

- CG Svu01b E4 - 0304 PDFDocumento32 pagineCG Svu01b E4 - 0304 PDFCristian JianuNessuna valutazione finora

- M52 Controller - Simplicity by DesignDocumento6 pagineM52 Controller - Simplicity by Designluis pardo solano100% (1)

- York Heat-Pump enDocumento29 pagineYork Heat-Pump enFalak KhanNessuna valutazione finora

- C-PAC Gas R22Documento22 pagineC-PAC Gas R22Leed ENNessuna valutazione finora

- Daikin Packaged Unit UAYQ-C Series Engineering DataDocumento58 pagineDaikin Packaged Unit UAYQ-C Series Engineering DataMichaelNessuna valutazione finora

- Dunham Bush - IntroductionDocumento3 pagineDunham Bush - Introductionchris110Nessuna valutazione finora

- VCV WesperDocumento12 pagineVCV Wesperciperu55Nessuna valutazione finora

- 6BSB000930Documento4 pagine6BSB000930OnofreNessuna valutazione finora

- York Yoea36fs36adhDocumento20 pagineYork Yoea36fs36adhjean_carlos_abreu_rNessuna valutazione finora

- CIF-15 Data Converter Service ManualDocumento30 pagineCIF-15 Data Converter Service ManualBernardo GermanNessuna valutazione finora

- Servicemanual AC 46-56-86Documento24 pagineServicemanual AC 46-56-86ggg100% (1)

- SANHUA DPF-T/S SERIES - Electronic Expansion ValveDocumento3 pagineSANHUA DPF-T/S SERIES - Electronic Expansion ValveSANHUA EMEANessuna valutazione finora

- Challenger 3000 Parts ManualDocumento52 pagineChallenger 3000 Parts ManualCristhian Aguilar100% (1)

- H23A383DBEADocumento1 paginaH23A383DBEABruno Monteiro0% (1)

- RTP 3 25 TR For Rooftoppackage 1Documento52 pagineRTP 3 25 TR For Rooftoppackage 1GeorgeNessuna valutazione finora

- BrochureA53Folds XPower 2 Hi-Wall 112012Documento2 pagineBrochureA53Folds XPower 2 Hi-Wall 112012Elaisa KasanNessuna valutazione finora

- Technical YLCSDocumento34 pagineTechnical YLCSnairam2003Nessuna valutazione finora

- AERCO Boiler Benchmark 3.0Documento129 pagineAERCO Boiler Benchmark 3.0hfdadl100% (1)

- High Efficiency High AmbientGeneral Sales BrochureDocumento30 pagineHigh Efficiency High AmbientGeneral Sales BrochureJosue Alvarez GomezNessuna valutazione finora

- Split System Air Conditioners: Inverter SeriesDocumento428 pagineSplit System Air Conditioners: Inverter SeriesstevenloNessuna valutazione finora

- CLS CLH BassaDocumento342 pagineCLS CLH Bassaapi-3769211100% (1)

- ItysDocumento32 pagineItysciohaniNessuna valutazione finora

- Ed5lfs2 ST22V1Documento24 pagineEd5lfs2 ST22V1Matheus BorgesNessuna valutazione finora

- SU BrochureDocumento4 pagineSU BrochureOreolNessuna valutazione finora

- R32 Heat Pump User Manual (6kw, 10kw)Documento29 pagineR32 Heat Pump User Manual (6kw, 10kw)Cata Moncea100% (1)

- Rtxa 209 - 212 Iom E30im001-Gb - 1098Documento32 pagineRtxa 209 - 212 Iom E30im001-Gb - 1098DianaNessuna valutazione finora

- Water Heater SelectionDocumento57 pagineWater Heater SelectionEric0% (1)

- CSRAT-Y Air Cooled Chiller - R134aDocumento36 pagineCSRAT-Y Air Cooled Chiller - R134aLeed ENNessuna valutazione finora

- Trane Rooftop PDFDocumento76 pagineTrane Rooftop PDFriz333Nessuna valutazione finora

- 30GT226 - Product Data Supplement 2Documento12 pagine30GT226 - Product Data Supplement 2Hani SaidNessuna valutazione finora

- Boosterpaq Grundfos Cr-Booster Systems 60 HZDocumento40 pagineBoosterpaq Grundfos Cr-Booster Systems 60 HZNShebertNessuna valutazione finora

- CH-DIN - P $fpENG031998Documento12 pagineCH-DIN - P $fpENG031998Γεώργιος Παπαδόπουλος100% (1)

- Tcgbutopia G8Documento216 pagineTcgbutopia G8faffsNessuna valutazione finora

- L010129H44 Om 02 2016 33awDocumento92 pagineL010129H44 Om 02 2016 33awVicNessuna valutazione finora

- Product Guide - HCD600Documento2 pagineProduct Guide - HCD600Anonymous R9Lpd68FTA0% (1)

- Catalogue Air Cooled Chiller Uaa-St3m (R134) PDFDocumento9 pagineCatalogue Air Cooled Chiller Uaa-St3m (R134) PDFNanda AulianaNessuna valutazione finora

- 30XA France CatalogDocumento24 pagine30XA France CatalogKannan KrishnamoorthyNessuna valutazione finora

- FOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01Documento15 pagineFOCSWATER.C Water Cooled Chiller - R134a - 2012!01!01ntt_121987Nessuna valutazione finora

- Turbocore ChillersDocumento4 pagineTurbocore Chillerss341232Nessuna valutazione finora

- Multi Stack Chiller Srw150c Mv6 v1.0Documento9 pagineMulti Stack Chiller Srw150c Mv6 v1.0Nico RobinNessuna valutazione finora

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Documento2 pagineCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987Nessuna valutazione finora

- No. Model Selling Price USD: Bình Tank Hiệu Zilmet - Ý - 10 BarsDocumento1 paginaNo. Model Selling Price USD: Bình Tank Hiệu Zilmet - Ý - 10 Barsntt_121987Nessuna valutazione finora

- 0702 Sound and Vibration ControlDocumento7 pagine0702 Sound and Vibration Controlntt_121987Nessuna valutazione finora

- 1Documento3 pagine1ntt_121987Nessuna valutazione finora

- Commercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1Documento2 pagineCommercial Unit Cooler:Cubic Type: F35HC 174 N 6 N. Units: 1ntt_121987Nessuna valutazione finora

- FVG FVPG FD R22Documento154 pagineFVG FVPG FD R22thanhlong2005Nessuna valutazione finora

- Thu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNDocumento2 pagineThu Gui Khach Hang - Doi Tesdfn Viet Kim Thanh Daikin VNntt_121987Nessuna valutazione finora

- Perforated GrilleDocumento5 paginePerforated Grillentt_121987Nessuna valutazione finora

- Stair Pressurization - 23 5 2015Documento8 pagineStair Pressurization - 23 5 2015ntt_121987Nessuna valutazione finora

- 3.MECH Duct11Documento2 pagine3.MECH Duct11ntt_121987Nessuna valutazione finora

- MechanicalDocumento56 pagineMechanicalntt_121987Nessuna valutazione finora

- 2 Fire DamperDocumento28 pagine2 Fire Damperntt_121987Nessuna valutazione finora

- Pressure Relief DamperDocumento1 paginaPressure Relief Damperntt_121987Nessuna valutazione finora

- Motorised DamperDocumento3 pagineMotorised Damperntt_121987Nessuna valutazione finora

- Non Return DamperDocumento3 pagineNon Return Damperntt_121987Nessuna valutazione finora

- Linear Bar Grille - FullDocumento7 pagineLinear Bar Grille - Fullntt_121987Nessuna valutazione finora

- Volume Control DamperDocumento8 pagineVolume Control Damperntt_121987Nessuna valutazione finora

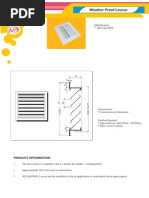

- Weather Proof Louvre MDocumento6 pagineWeather Proof Louvre Mntt_121987Nessuna valutazione finora

- Double DeflectorDocumento7 pagineDouble Deflectorntt_121987Nessuna valutazione finora

- Weather Proof LouvreDocumento6 pagineWeather Proof Louvrentt_121987Nessuna valutazione finora

- Air Light TrofferDocumento2 pagineAir Light Trofferntt_121987Nessuna valutazione finora

- Supply Air DiffuserDocumento6 pagineSupply Air Diffuserntt_121987Nessuna valutazione finora

- Lourve: Product InformationDocumento8 pagineLourve: Product Informationntt_121987Nessuna valutazione finora

- Egg Crate: Product InformationDocumento5 pagineEgg Crate: Product Informationntt_121987Nessuna valutazione finora

- Single DeflectorDocumento7 pagineSingle Deflectorntt_121987Nessuna valutazione finora

- Plenum BoxDocumento2 paginePlenum Boxntt_121987Nessuna valutazione finora

- Round DiffuserDocumento2 pagineRound Diffuserntt_121987Nessuna valutazione finora

- State Point & Process ReportDocumento1 paginaState Point & Process Reportntt_121987Nessuna valutazione finora

- Jet DiffuserDocumento5 pagineJet Diffuserntt_121987Nessuna valutazione finora

- MMZG 533Documento8 pagineMMZG 533Prakash Kumar SenNessuna valutazione finora

- Six Levels of Linguistic AnalysisDocumento12 pagineSix Levels of Linguistic AnalysisRoshio Tsuyu Tejido67% (3)

- Oracle Fusion Middleware Developer GuideDocumento1.422 pagineOracle Fusion Middleware Developer GuideahsunNessuna valutazione finora

- Weld Simulator PDFDocumento4 pagineWeld Simulator PDFAmilin HatiaraNessuna valutazione finora

- Philosophy of Charlie Kaufman PDFDocumento319 paginePhilosophy of Charlie Kaufman PDFCherey Peña RojasNessuna valutazione finora

- How To Get Google Maps API Key For Android. Issues and Errors SolvedDocumento11 pagineHow To Get Google Maps API Key For Android. Issues and Errors SolvedFrancisco FeitosaNessuna valutazione finora

- MulticollinearityDocumento25 pagineMulticollinearityDushyant MudgalNessuna valutazione finora

- Amateur Photographer - May 28, 2016Documento84 pagineAmateur Photographer - May 28, 2016Lee100% (1)

- Sl500 User Manual NewDocumento40 pagineSl500 User Manual NewAmrutha SudhakaranNessuna valutazione finora

- Animals Grow Hessa Science: Students Will Need To Be Familiar With The Vocabulary WordsDocumento4 pagineAnimals Grow Hessa Science: Students Will Need To Be Familiar With The Vocabulary WordsHessa MohammedNessuna valutazione finora

- IELTS Speaking Study Planner For September-December - 2023Documento2 pagineIELTS Speaking Study Planner For September-December - 2023Althea Zhenya Antonio Claud100% (1)

- Contemporary PluralismDocumento8 pagineContemporary PluralismTerence BlakeNessuna valutazione finora

- Research Las 1Documento4 pagineResearch Las 1Lorianne ArcuenoNessuna valutazione finora

- How To Get Blackboard Working On Your PCDocumento19 pagineHow To Get Blackboard Working On Your PCJatin PathakNessuna valutazione finora

- GLSL Specification 1.40.08.fullDocumento111 pagineGLSL Specification 1.40.08.fullmushakkNessuna valutazione finora

- Practice CompletaDocumento3 paginePractice CompletaEmanuel G.Nessuna valutazione finora

- Cursive Writing LP MembersDocumento7 pagineCursive Writing LP MembersAng gnalikaD KomentoNessuna valutazione finora

- Strategi Pengembangan Dan Analisis Swot Pada Pt. Garuda Indonesia TBKDocumento12 pagineStrategi Pengembangan Dan Analisis Swot Pada Pt. Garuda Indonesia TBKtedzmedicalNessuna valutazione finora

- Cover Letter For Content Writer With No ExperienceDocumento6 pagineCover Letter For Content Writer With No Experiencebcrqhr1n100% (2)

- Leadership Course OutlineDocumento3 pagineLeadership Course OutlineKashif Mahmood100% (2)

- Ghis Manual (New)Documento18 pagineGhis Manual (New)rookie100% (1)

- Sample FormatDocumento18 pagineSample FormatgetnetNessuna valutazione finora

- Test Math 6th Unit 8Documento4 pagineTest Math 6th Unit 8lourdesNessuna valutazione finora

- Choosing A SolverDocumento12 pagineChoosing A SolversnthejNessuna valutazione finora

- Flame Resistant Conveyor Belts To EN 14973 and EN 12882Documento6 pagineFlame Resistant Conveyor Belts To EN 14973 and EN 12882luis martinezNessuna valutazione finora

- Introduction To Advertising: Tutorial 3Documento29 pagineIntroduction To Advertising: Tutorial 3Hung LeNessuna valutazione finora

- Ids X64 700-398-02DDocumento96 pagineIds X64 700-398-02DEric Twizeyimana KalisaNessuna valutazione finora

- Fundamentals of ProbabilityDocumento58 pagineFundamentals of Probabilityhien05Nessuna valutazione finora

- ECEN 314: Matlab Project 1 Fourier Series Synthesizer: Due April 8th, 2013Documento3 pagineECEN 314: Matlab Project 1 Fourier Series Synthesizer: Due April 8th, 2013Dante HavershamNessuna valutazione finora

- Literature Review Situasional LeadershipDocumento7 pagineLiterature Review Situasional LeadershipNor Fairus Mp0% (1)